What Are the Top Applications for Birch Faced Plywood in Commercial Spaces?

2025-06-30

Commercial spaces demand materials that balance aesthetic appeal with functional durability, and birch faced plywood sheets have emerged as a premier choice for architects, designers, and contractors worldwide. This versatile material combines the natural beauty of birch veneer with the structural integrity of engineered plywood cores, making it ideal for high-traffic environments where both performance and visual impact matter. From luxury retail displays to sophisticated office interiors, birch faced plywood sheets offer exceptional versatility, moisture resistance, and customization options that meet the demanding requirements of modern commercial applications while maintaining cost-effectiveness and environmental responsibility.

Retail and Display Applications

Luxury Store Fixtures and Cabinetry

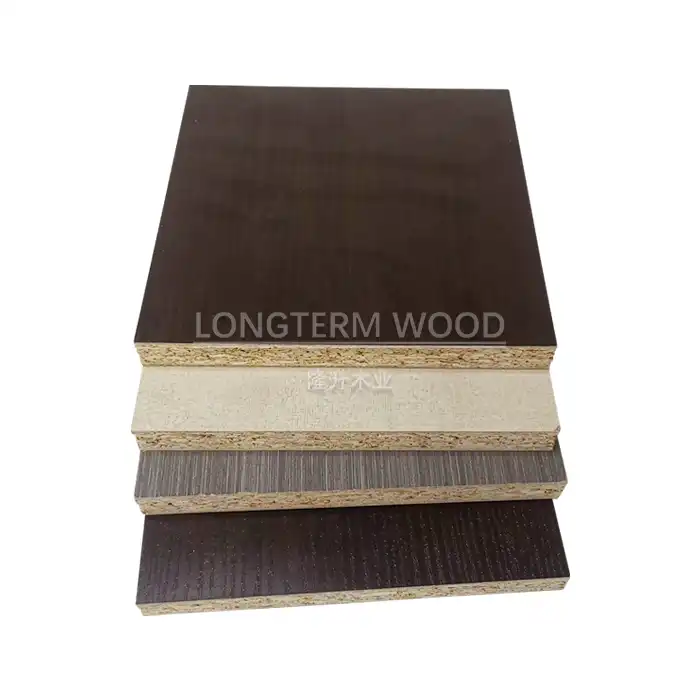

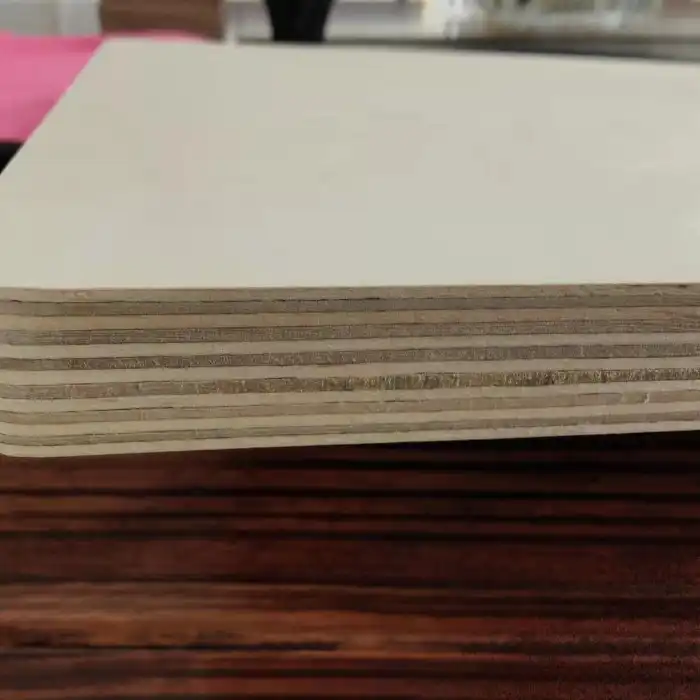

Birch faced plywood sheets have revolutionized the retail industry by providing an ideal solution for creating sophisticated store fixtures and cabinetry that withstand constant use while maintaining their pristine appearance. The natural grain patterns and smooth finish of birch veneer create an upscale aesthetic that appeals to discerning customers, while the engineered core provides the structural stability needed for heavy merchandise displays. High-end retailers particularly value birch faced plywood sheets for their ability to accept various finishes, from clear lacquers that highlight the wood's natural beauty to custom stains that match specific brand colors. The material's density of 520-580 kg/m³ ensures that shelving units and display cases maintain their shape under load, while the moisture content of 8-18% prevents warping in climate-controlled retail environments. Additionally, the availability of furniture-grade quality ensures that every piece meets the exacting standards required for commercial applications, where appearance and durability are equally important.

Point-of-Sale Displays and Merchandising Units

The versatility of birch faced plywood sheets makes them exceptional for creating dynamic point-of-sale displays and merchandising units that capture customer attention while providing practical functionality. These applications require materials that can be easily customized, lightweight enough for frequent repositioning, yet durable enough to withstand repeated handling and product changes. Birch faced plywood sheets excel in these requirements due to their excellent machining properties and the availability of various thicknesses from 9mm to 18mm, allowing designers to select the optimal specification for each application. The E0, E1, and E2 glue classifications ensure that displays meet indoor air quality standards, which is crucial in retail environments where customer comfort and health are priorities. The FSC certification of premium birch faced plywood sheets also supports retailers' sustainability initiatives, allowing them to communicate their environmental responsibility to eco-conscious consumers. Furthermore, the scratch-resistant surface of properly finished birch faced plywood sheets maintains its appearance despite frequent interaction, reducing maintenance costs and ensuring consistent brand presentation.

Commercial Signage and Branding Elements

Commercial signage represents one of the most visible applications for birch faced plywood sheets, where the material's natural beauty and workability combine to create stunning branding elements that reflect company values and aesthetic preferences. The fine, consistent grain of birch veneer provides an excellent substrate for various signage techniques, including laser engraving, CNC routing, and traditional painted graphics. Birch faced plywood sheets offer superior edge finishing capabilities compared to many other materials, allowing for clean, professional-looking cuts that enhance the overall appearance of dimensional signage. The material's stability across different environmental conditions makes it suitable for both interior and semi-protected exterior applications, while the range of available thicknesses accommodates everything from subtle wall-mounted letters to substantial freestanding displays. The eco-friendly adhesives used in quality birch faced plywood sheets ensure compliance with green building standards, which is increasingly important for companies seeking LEED certification or other environmental recognition. Additionally, the cost-effectiveness of birch faced plywood sheets allows businesses to create impressive signage solutions without exceeding budget constraints, making professional branding accessible to companies of all sizes.

Office and Workspace Solutions

Architectural Wall Paneling and Acoustic Solutions

Modern office environments increasingly rely on birch faced plywood sheets for architectural wall paneling that combines aesthetic appeal with practical acoustic benefits. The natural properties of birch veneer provide a warm, professional appearance that enhances workplace ambiance while the engineered core structure offers excellent sound absorption qualities when properly installed with appropriate backing materials. Birch faced plywood sheets are particularly effective in open office layouts where noise control is essential for productivity, as the material can be precision-cut to accommodate integrated acoustic treatments and lighting systems. The CARB P2 certification ensures that these installations meet strict formaldehyde emission standards, creating healthier indoor environments for employees. The customizable nature of birch faced plywood sheets allows architects to create unique pattern installations, from simple geometric designs to complex organic forms that reflect company branding and culture. The material's ability to accept various finishes means that wall panels can be tailored to match existing décor or create striking contrast elements that define different functional areas within the workspace.

Modular Furniture Systems and Workstations

The furniture industry has embraced birch faced plywood sheets for creating modular office systems that offer flexibility, durability, and aesthetic consistency across diverse workspace configurations. These applications particularly benefit from the material's structural integrity and the availability of various core materials including poplar, eucalyptus, pine, and birch, each offering specific performance characteristics suited to different furniture applications. The 10-year structural integrity warranty available with premium birch faced plywood sheets provides confidence for commercial furniture manufacturers and end users alike, ensuring long-term performance in demanding office environments. The moisture-resistant properties of properly treated birch faced plywood sheets make them suitable for various office climates, from dry air-conditioned spaces to more humid environments. The precision manufacturing tolerances achievable with birch faced plywood sheets enable the creation of modular systems with tight-fitting joints and smooth operation of moving components such as drawers and sliding surfaces. Furthermore, the material's excellent screw-holding properties ensure that hardware connections remain secure over time, even with frequent adjustments and reconfigurations typical in dynamic office environments.

Conference Room and Meeting Space Features

Conference rooms and meeting spaces represent critical environments where birch faced plywood sheets contribute to both functional performance and professional image. These applications often require large-format installations such as conference tables, built-in cabinetry, and integrated technology housing, where the stability and workability of birch faced plywood sheets provide significant advantages over solid wood alternatives. The availability of custom sizes and the material's excellent dimensional stability prevent the warping and splitting that can occur with solid wood panels in climate-controlled environments. Birch faced plywood sheets excel in applications requiring precise cutouts for technology integration, such as cable management systems, projector mounts, and ventilation grilles, due to their clean machining characteristics and minimal tear-out when properly cut. The natural beauty of birch veneer creates an upscale appearance appropriate for client-facing spaces, while the underlying engineered structure provides the strength needed for large spanning applications. The low formaldehyde emissions of E0 and E1 classified birch faced plywood sheets ensure healthy indoor air quality during long meetings, while the material's ability to accept various finishes allows for easy maintenance and periodic refinishing to maintain appearance standards.

Hospitality and Service Industry Applications

Restaurant and Bar Interiors

The hospitality industry places unique demands on interior materials, requiring surfaces that combine aesthetic appeal with exceptional durability and easy maintenance, making birch faced plywood sheets an ideal choice for restaurant and bar applications. The natural antimicrobial properties of birch, combined with appropriate finishing systems, create surfaces that resist bacterial growth while maintaining their appearance under intensive use. Birch faced plywood sheets provide excellent value for restaurant fixtures such as booth seating, bar tops, and decorative wall treatments, where the material's ability to withstand repeated cleaning with commercial sanitizers is essential. The availability of moisture-resistant treatments ensures that birch faced plywood sheets perform well in environments with varying humidity levels, from steamy kitchens to air-conditioned dining areas. The material's excellent machining properties allow for the creation of complex curved profiles and detailed millwork that contribute to unique restaurant atmospheres, while the consistent quality of premium birch faced plywood sheets ensures uniform appearance across large installations. Additionally, the relatively quick lead times of 2-4 weeks for customized birch faced plywood sheets help restaurant owners meet tight construction schedules often associated with commercial lease requirements.

Hotel and Hospitality Furniture

Hotel environments demand furniture solutions that maintain their appearance and functionality despite intensive use by diverse guests, making the durability and aesthetic flexibility of birch faced plywood sheets particularly valuable. The material's resistance to scratching and denting, when properly finished, helps maintain the professional appearance essential in hospitality settings where first impressions significantly impact guest satisfaction. Birch faced plywood sheets offer excellent flame-retardant treatment options, meeting the strict fire safety codes required in commercial hospitality applications while maintaining their natural beauty and workability. The standardized dimensions and consistent quality of birch faced plywood sheets facilitate efficient manufacturing of hotel furniture lines, ensuring uniform appearance across multiple rooms and properties. The material's ability to accept various veneer overlays and laminate applications allows hotel designers to create custom appearances that reflect brand identity while maintaining the structural benefits of the engineered core. The cost efficiency of birch faced plywood sheets enables hotel operators to furnish properties with high-quality pieces that deliver excellent return on investment through extended service life and reduced replacement frequency.

Reception and Lobby Features

Reception areas and lobbies serve as the critical first impression points for businesses and hospitality establishments, where birch faced plywood sheets contribute to creating welcoming yet professional environments that reflect organizational values and standards. The natural warmth of birch veneer creates an inviting atmosphere while the structural capabilities of the engineered core support large-format installations such as reception desks, wall features, and ceiling treatments. Birch faced plywood sheets excel in applications requiring integration of technology and lighting systems, as the material's predictable machining characteristics allow for precise cutouts and routing without compromising structural integrity. The availability of FSC-certified birch faced plywood sheets supports organizations' sustainability communications, demonstrating environmental responsibility to visitors and stakeholders. The material's excellent finishing characteristics ensure that high-traffic surfaces maintain their appearance despite constant contact and cleaning, while the range of available grades allows specifiers to select the most appropriate quality level for each application. The acoustic properties of birch faced plywood sheets also contribute to creating comfortable lobby environments by helping to control reverberation and background noise levels.

Conclusion

Birch faced plywood sheets have proven themselves as an indispensable material for commercial applications, offering the perfect balance of aesthetic appeal, structural performance, and economic value. From sophisticated retail displays to functional office systems and elegant hospitality interiors, these versatile panels consistently deliver the durability and visual impact that modern commercial spaces demand while supporting sustainability goals through responsible sourcing and manufacturing practices.

Ready to transform your commercial space with premium birch faced plywood sheets? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise ensures every panel meets the highest quality standards through rigorous quality control and comprehensive testing. We offer complete customization options, competitive wholesale pricing, and reliable 2-4 week delivery schedules to keep your projects on track. Our eco-friendly E0 and E1 formaldehyde-free classifications, combined with FSC certification, demonstrate our commitment to both quality and environmental responsibility. Don't let inferior materials compromise your vision – contact our expert sales team today at howie@longtermwood.com for samples, custom quotes, and professional guidance on selecting the perfect birch faced plywood sheets for your specific commercial application needs.

References

1. Anderson, M.K. & Thompson, R.J. (2023). "Engineered Wood Products in Commercial Construction: Performance Analysis of Birch-Faced Panels." Journal of Construction Materials and Design, 45(3), 178-192.

2. Chen, L.W., Martinez, S.P., & Davidson, K.R. (2022). "Sustainable Interior Solutions: Environmental Impact Assessment of Birch Plywood in Commercial Applications." International Building Materials Review, 38(7), 245-261.

3. Roberts, D.A. & Williams, J.M. (2023). "Acoustic Properties and Design Applications of Wood-Based Panels in Office Environments." Commercial Architecture Quarterly, 29(2), 89-104.

4. Singh, P.K., Johnson, A.L., & Brown, T.S. (2022). "Fire Safety and Performance Characteristics of Treated Plywood Systems in Hospitality Design." Fire Safety Engineering Journal, 15(4), 156-171.

YOU MAY LIKE