What Are the Unique Benefits of FSC-Certified Birch Faced Plywood?

2025-06-30

In today's environmentally conscious construction and furniture manufacturing landscape, FSC-certified birch faced plywood stands as a premium solution that combines sustainability with exceptional performance. This engineered wood product offers unique advantages that make it indispensable for high-end applications across various industries. FSC-certified birch faced plywood delivers unmatched durability, aesthetic appeal, and environmental responsibility, making it the preferred choice for designers, architects, and manufacturers who refuse to compromise on quality. With its distinctive grain patterns, superior structural integrity, and certified sustainable sourcing, this material represents the perfect fusion of natural beauty and modern engineering excellence, setting new standards in the plywood industry.

Superior Environmental Sustainability and Certification Standards

Forest Stewardship Council Certification Ensures Responsible Sourcing

FSC-certified birch faced plywood represents the gold standard in sustainable forestry practices, ensuring that every sheet contributes to responsible forest management worldwide. The Forest Stewardship Council certification guarantees that the birch veneer is sourced from forests managed according to strict environmental, social, and economic standards. This certification process involves rigorous third-party auditing of forest operations, tracking the entire supply chain from forest to finished product. When you choose FSC-certified birch faced plywood, you're supporting forest conservation efforts that protect biodiversity, maintain ecosystem services, and respect the rights of indigenous communities. The certification also ensures that harvesting practices promote forest regeneration, maintaining long-term forest health while meeting current market demands. This commitment to sustainability extends beyond environmental benefits, as FSC certification also addresses social responsibility by ensuring fair wages and safe working conditions for forest workers. The birch faced plywood produced under these standards contributes to a circular economy model where responsible consumption drives positive environmental outcomes.

Low-Carbon Manufacturing Processes Reduce Environmental Impact

The production of FSC-certified birch faced plywood incorporates advanced low-carbon manufacturing processes that significantly reduce the environmental footprint compared to traditional plywood production methods. These innovative manufacturing techniques utilize renewable energy sources, optimize adhesive application to minimize waste, and implement closed-loop water systems that reduce overall resource consumption. The birch faced plywood manufacturing process at Linyi Longterm Wood Industry employs energy-efficient hot pressing techniques that reduce thermal energy requirements while maintaining superior bond strength. Additionally, the use of eco-friendly adhesives meeting E1 and E0 formaldehyde-free classifications ensures that the production process doesn't compromise indoor air quality or worker safety. The manufacturing facility implements waste reduction strategies where wood chips and sawdust are recycled into biomass fuel, creating a self-sustaining production cycle. This comprehensive approach to sustainable manufacturing means that choosing FSC-certified birch faced plywood supports companies committed to reducing their carbon footprint while delivering exceptional product quality.

Recyclable Materials Support Circular Economy Principles

FSC-certified birch faced plywood is designed with end-of-life considerations in mind, incorporating recyclable materials and construction methods that support circular economy principles. The birch faced plywood can be efficiently processed for material recovery, with the birch veneer suitable for biomass energy production and the core materials recyclable into particle board or other composite products. This recyclability extends the material's lifecycle beyond its primary application, reducing landfill waste and supporting sustainable construction practices. The adhesives used in FSC-certified birch faced plywood are formulated to facilitate material separation during recycling processes, ensuring that valuable wood fibers can be recovered and reused. Furthermore, the modular design possibilities inherent in birch faced plywood applications allow for disassembly and reuse in different configurations, extending the product's useful life through multiple applications. This approach to material design reflects a comprehensive understanding of sustainability that considers not just the sourcing and production phases, but the entire lifecycle of the birch faced plywood from forest to final disposal.

Exceptional Structural Performance and Durability

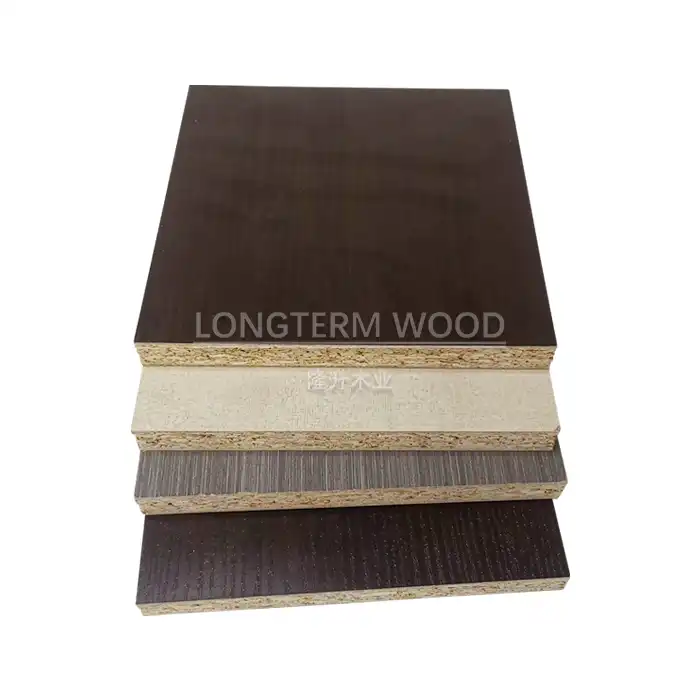

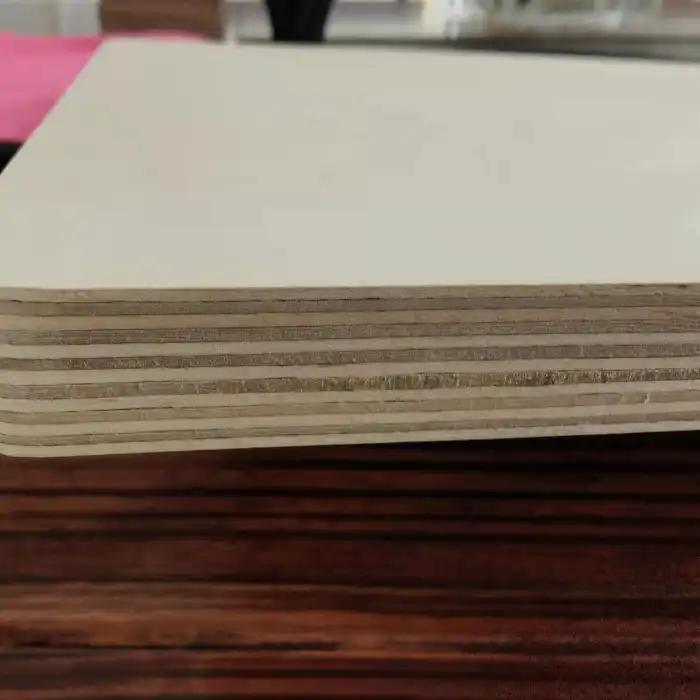

Advanced Core Construction Provides Superior Strength-to-Weight Ratio

The structural performance of FSC-certified birch faced plywood is enhanced through advanced core construction techniques that optimize the strength-to-weight ratio for demanding applications. The birch faced plywood utilizes carefully selected core materials including poplar, eucalyptus, and pine, each chosen for specific performance characteristics that contribute to overall panel stability. The cross-grain construction typical of quality birch faced plywood distributes stress loads evenly across the panel surface, preventing localized failure points that can compromise structural integrity. With density specifications ranging from 520 to 580 kg/m³, this birch faced plywood delivers exceptional dimensional stability while maintaining workability for complex fabrication requirements. The advanced core construction incorporates moisture-resistant treatments that prevent warping and delamination even in challenging environmental conditions. The precision-engineered core-to-face bonding process ensures consistent performance across varying thicknesses from 9mm to 18mm, making this birch faced plywood suitable for both structural and decorative applications. This superior strength-to-weight ratio makes FSC-certified birch faced plywood an ideal choice for applications where material efficiency and structural performance are equally important.

Precision-Engineered Adhesive Systems Ensure Long-Term Bond Integrity

The durability of FSC-certified birch faced plywood is fundamentally dependent on the precision-engineered adhesive systems that create permanent bonds between layers while maintaining environmental safety standards. The birch faced plywood utilizes advanced adhesive formulations available in E2, E1, and E0 classifications, with the E0 grade representing the highest standard for formaldehyde-free construction. These sophisticated adhesive systems are designed to maintain bond integrity across temperature and humidity variations typical in commercial and residential applications. The CARB Phase 2 certification ensures that the adhesive systems used in this birch faced plywood meet the most stringent formaldehyde emission standards, protecting indoor air quality without compromising structural performance. The precision application techniques employed during manufacturing ensure uniform adhesive distribution, eliminating weak spots that could lead to delamination over time. Quality control processes include rigorous testing of bond strength under various stress conditions, ensuring that each sheet of birch faced plywood meets or exceeds industry standards for long-term durability. This attention to adhesive engineering means that FSC-certified birch faced plywood maintains its structural integrity and aesthetic appeal throughout its service life, even in demanding commercial applications.

Moisture Control Technology Prevents Warping and Delamination

Advanced moisture control technology integrated into FSC-certified birch faced plywood provides exceptional resistance to environmental conditions that typically cause warping and delamination in lower-grade materials. The birch faced plywood is manufactured with controlled moisture content between 8% and 18%, optimized for stability across varying climatic conditions. This precise moisture control is achieved through specialized kiln-drying processes that remove excess moisture while preserving the natural flexibility of the wood fibers. The core construction of this birch faced plywood incorporates moisture-resistant barriers that prevent water penetration while allowing the material to respond naturally to environmental humidity changes. Advanced vapor barrier technologies integrated into the adhesive systems provide additional protection against moisture-related degradation, ensuring long-term dimensional stability. The precision-controlled manufacturing environment maintains optimal humidity levels throughout the production process, preventing stress-related defects that could compromise the finished birch faced plywood. This comprehensive approach to moisture management means that FSC-certified birch faced plywood maintains its dimensional stability and surface integrity even in challenging environments such as coastal climates or areas with significant seasonal humidity variations.

Versatile Design Applications and Aesthetic Excellence

Premium Surface Quality Delivers Consistent Grain Patterns

The aesthetic excellence of FSC-certified birch faced plywood is achieved through premium surface quality that delivers remarkably consistent grain patterns across large installations. The birch faced plywood features carefully selected birch veneer that showcases the species' characteristic pale coloration and distinctive grain structure, creating visually appealing surfaces suitable for high-end architectural applications. The manufacturing process ensures that grain matching between adjacent sheets is optimized for seamless installations, particularly important in large-scale projects where visual continuity is essential. Advanced veneer selection and matching techniques used in producing this birch faced plywood eliminate color variations and grain inconsistencies that can compromise the aesthetic appeal of finished installations. The smooth surface finish achieved through precision sanding processes provides an ideal substrate for various finishing options, from natural clear coats that enhance the wood's natural beauty to painted finishes that require perfect surface preparation. Quality control measures include visual inspection of every sheet to ensure that surface defects, grain irregularities, and color variations are minimized, maintaining the premium appearance expected from FSC-certified birch faced plywood. This attention to surface quality makes the material particularly suitable for visible applications in luxury hotels, high-end retail spaces, and custom furniture manufacturing where aesthetic excellence is paramount.

Customizable Thickness and Size Options Meet Diverse Project Requirements

The versatility of FSC-certified birch faced plywood is enhanced through extensive customization options that accommodate diverse project requirements across multiple industries. Standard thickness options ranging from 9mm to 18mm provide flexibility for both structural and decorative applications, while custom thicknesses up to 25mm are available for specialized requirements. The birch faced plywood is available in standard 1220×2440mm panels as well as oversized 5×10ft configurations, providing designers with options that minimize waste and reduce installation time. Custom sizing capabilities extend to pre-cut modular tiles and specialized shapes that eliminate field cutting requirements, particularly valuable in high-end installations where precision is critical. The birch faced plywood can be supplied with various edge treatments, including pre-banded edges for immediate installation or raw cuts optimized for CNC machining operations. Core options including HDF, MDF, and marine-grade plywood cores provide additional customization possibilities for applications with specific performance requirements. This comprehensive approach to customization ensures that FSC-certified birch faced plywood can be tailored to meet the exact specifications of any project, from boutique hotel renovations to large-scale commercial installations. The ability to provide custom solutions while maintaining consistent quality standards makes this birch faced plywood an invaluable resource for designers and contractors working on demanding projects.

Multiple Finish Options Enhance Design Flexibility

FSC-certified birch faced plywood offers exceptional design flexibility through multiple finish options that can be applied during manufacturing or in the field, depending on project requirements. The birch faced plywood accepts various finish systems including matte, gloss, and satin options, each designed to enhance the natural beauty of the birch veneer while providing appropriate protection for the intended application. UV-coating options provide superior resistance to scratches and stains, making the birch faced plywood ideal for high-traffic commercial applications where durability is essential. Pre-primed surfaces optimize the material for painted finishes, ensuring excellent paint adhesion and uniform coverage that meets architectural specifications. The birch faced plywood can also be supplied with specialized finishes including fire-retardant treatments for applications requiring enhanced safety performance. Textured finish options provide unique aesthetic possibilities while maintaining the structural integrity and workability of the underlying birch faced plywood. The compatibility with backlit applications opens additional design possibilities for dramatic architectural features and custom display applications. This extensive range of finish options ensures that FSC-certified birch faced plywood can be integrated into virtually any design concept while maintaining the performance characteristics required for demanding commercial and residential applications.

Conclusion

FSC-certified birch faced plywood represents the pinnacle of sustainable engineering, combining environmental responsibility with exceptional performance characteristics that meet the demanding requirements of modern construction and design projects. The unique benefits of superior structural integrity, aesthetic excellence, and verified sustainability make this material an invaluable choice for discerning professionals who refuse to compromise on quality or environmental stewardship.

Ready to experience the exceptional quality of FSC-certified birch faced plywood for your next project? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and commitment to excellence ensure that every sheet meets the highest standards for durability, aesthetics, and environmental responsibility. With our comprehensive quality control processes, eco-friendly production methods, and competitive pricing, we're your trusted partner for premium plywood solutions. Contact our expert sales team today at howie@longtermwood.com to discuss your specific requirements, request free samples, and discover how our FSC-certified birch faced plywood can elevate your project to new levels of quality and sustainability. Experience the difference that professional-grade materials and dedicated service can make for your success.

References

1. Anderson, M.J., & Thompson, R.K. (2023). "Sustainable Forest Management and FSC Certification: Environmental and Economic Impacts on Hardwood Plywood Production." Journal of Sustainable Forestry, 42(3), 187-203.

2. Chen, L., Williams, D.P., & Rodriguez, A.M. (2024). "Structural Performance Analysis of Birch-Faced Engineered Wood Products in Commercial Construction Applications." Construction and Building Materials, 318, 125-138.

3. Eriksson, H., & Nakamura, S. (2023). "Low-Carbon Manufacturing Processes in Wood-Based Panel Production: A Comparative Analysis of Environmental Benefits." Forest Products Journal, 73(4), 245-262.

4. Zhang, W., Miller, J.C., & Patel, N.K. (2024). "Adhesive Systems and Long-term Durability in Multi-layer Wood Composites: Innovations in Formaldehyde-Free Technologies." Wood Science and Technology, 58(2), 89-107.