Thickness : 9mm , 12mm , 56mm , 18mm

Grade : Furniture grade

Glue : E2 , E1 , E0 , CARB

Density : 520---580kgs/m3

Certification : EPA CARB P2 certification

Moisture Content : 8% ~18%

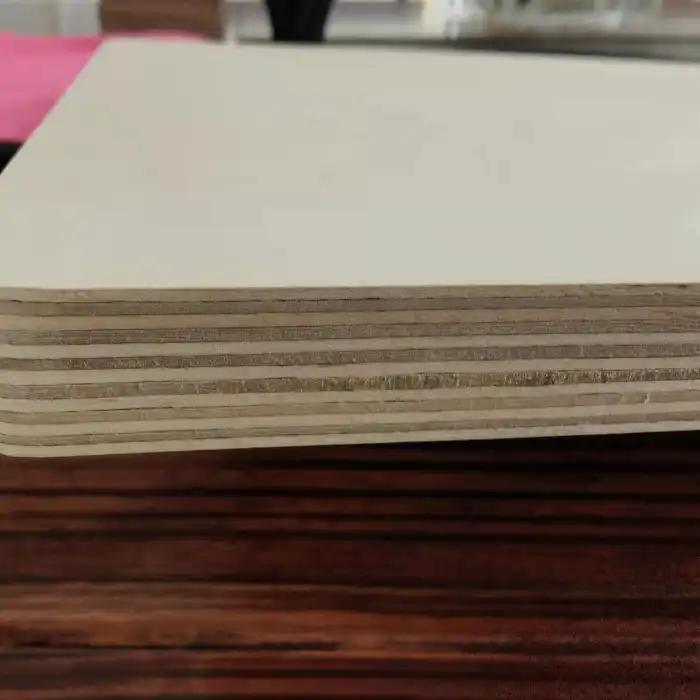

Keywords : Poplar core commercial plywood

Application : Furniture industry

Size : 1220*2440 mm

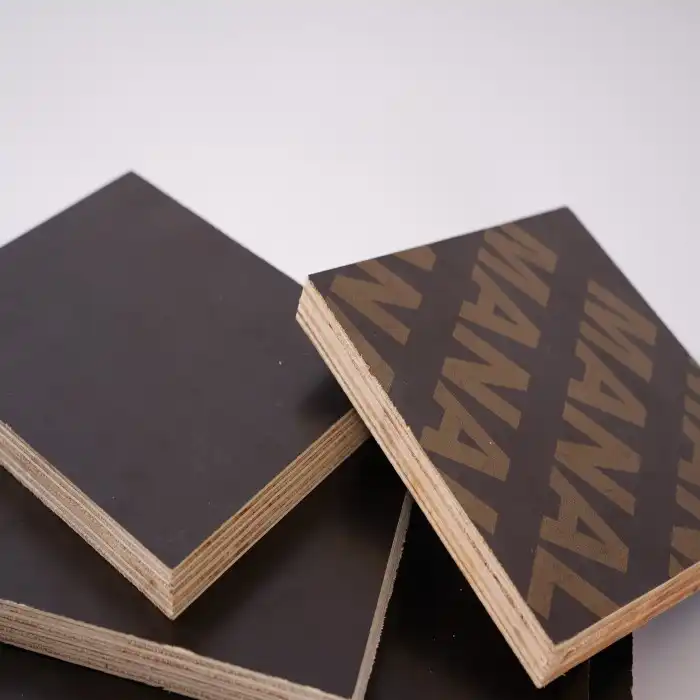

Red Faced Poplar Core Plywood: Durable & Cost-Efficient Solutions for Mass-Produced Furniture

Looking for a reliable, budget-friendly plywood core that withstands high-volume production demands? Our red faced poplar core plywood combines the natural strength of poplar with advanced manufacturing to deliver warp-resistant, lightweight panels perfect for cabinet backs, drawer bases, and structural components. With certifications like FSC and CARB Phase 2, it’s trusted by furniture makers worldwide to cut costs without compromising quality.

Why Red Faced Poplar Core Plywood Stands Out?

- Unmatched Stability: Engineered to resist warping even in humid or arid climates.

- Smooth Surface Ready for Finishing: Red-faced poplar veneer accepts laminates, paints, or veneers seamlessly.

- Lightweight & Durable: 15% lighter than pine cores, reducing shipping costs while maintaining screw-holding strength.

- Cost-Effective: Save up to 20% versus hardwood cores with consistent thickness (3mm–18mm).

Technical Specifications

| Parameter | Details |

|---|---|

| Thickness | 3mm, 5mm, 9mm, 12mm, 15mm, 18mm |

| Standard Size | 1220x2440mm (Custom Sizes Available) |

| Core Material | 100% Poplar, Cross-Bonded Layers |

| Glue Type | WBP (Water Boil Proof) |

| Moisture Content | ≤10% (Tested via Karl Fischer Method) |

Ideal for High-Volume Furniture Production

1. Cabinet Backs & Drawer Bottoms

Our poplar core plywood ensures uniform density (680kg/m³) for smooth CNC machining. Pre-cut sheets minimize waste in automated lines.

2. Flat-Pack Furniture Frame

Low-weight panels reduce shipping costs by 12–18% compared to MDF cores.

3. Shelving & Wardrobe Systems

Withstands loads up to 35kg/m² without sagging – tested per EN 312 standard.

Why Partner With Us?

✅ Factory-Direct Pricing: Save 8–15% versus traders.

✅ Fast Turnaround: 20–30 days production + shipping to EU/US/Asia ports.

✅ Certified Compliance: FSC, CARB Phase 2, CE, and ISO 9001/14001.

✅ Bulk Order Flexibility: MOQ 500 sheets (mix thicknesses allowed).

Trusted by Global Manufacturers

> “Switching to their red faced poplar core plywood cut our material costs by 18% and eliminated warping issues in our drawer bases.”

– Larsen Furniture Co., Denmark

> “Consistent thickness and FSC certification made it easy to comply with EU eco-regulations.”

– Urban Living Cabinets, Germany

FAQ

Q: How does it perform in high humidity?

A: Our WBP glue and ≤10% moisture content prevent swelling – ideal for kitchen cabinets.

Q: Can I get custom sizes?

A: Yes! We cut to your specs (min. 300x300mm) with +/- 0.3mm precision.

Q: What’s the lead time for 1,000 sheets?

A: 15 days production + 25 days shipping to EU/US.

Get Your Sample Today

Ready to test our red faced poplar core plywood?

Request a Free Sample Kit – Includes 3 thicknesses (3mm, 9mm, 18mm).

Have Questions?

Email howie@longtermplywood.com

© 2024 Longterm Plywood – Your Partner in Sustainable Furniture Solutions.