What Are the Top Applications for 9mm Okoume Plywood in Modern Construction?

2025-06-27

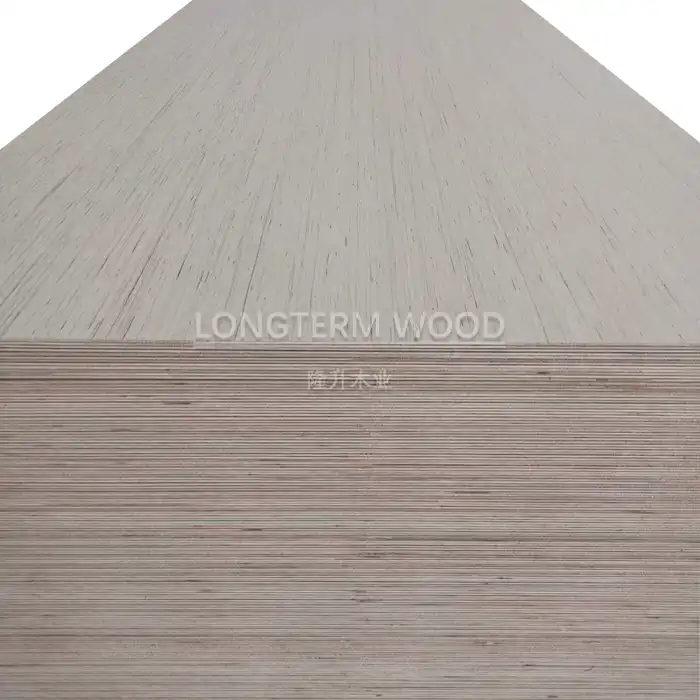

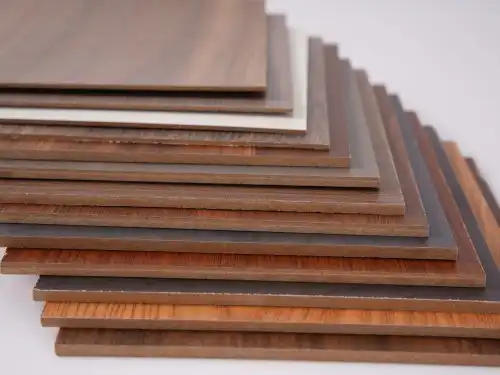

Modern construction demands materials that combine versatility, durability, and aesthetic appeal while meeting stringent environmental standards. 9mm okoume plywood has emerged as a leading choice among architects, contractors, and designers worldwide, offering an exceptional balance of strength, lightweight properties, and superior workability. This premium building material, sourced from sustainably managed African forests, delivers unmatched performance across diverse construction applications. From marine environments to high-end interior projects, 9mm okoume plywood provides the reliability and visual appeal that modern construction projects require, making it an indispensable material for professionals seeking quality and efficiency in their builds.

Marine and Waterfront Construction Applications

Marine construction represents one of the most demanding environments for building materials, requiring exceptional moisture resistance, structural integrity, and long-term durability. 9mm okoume plywood has established itself as the gold standard in this sector, offering unique properties that make it ideal for various waterfront applications.

Boat Building and Yacht Construction

9mm okoume plywood excels in boat building applications due to its exceptional strength-to-weight ratio and natural water-resistant properties. This material is certified to British Standard 1088 and is used by hobbyists and some of the world's largest boat builders, making it a trusted choice for both amateur and professional marine construction projects. The cross-banded Okoume core construction provides superior dimensional stability, preventing warping and delamination even under extreme marine conditions. Professional boat builders particularly value the void-free core construction of 9mm okoume plywood, which eliminates weak points that could compromise structural integrity over time. The material's ability to bend and shape without splitting makes it ideal for curved hull sections and complex geometric designs common in modern yacht construction. Additionally, the consistent 9mm thickness with ±0.3mm tolerance ensures precise fitting and professional-grade results, while the pre-sanded knot-free face provides an excellent foundation for marine-grade finishes and gel coats.

Dock and Marina Infrastructure

Marine infrastructure projects require materials that can withstand constant exposure to moisture, salt air, and mechanical stress from vessels and equipment. 9mm okoume plywood serves as an excellent choice for dock decking, walkway surfaces, and protective barriers in marina environments. The material's natural resistance to moisture absorption, combined with appropriate marine-grade treatments, provides long-lasting performance in these challenging conditions. Marine Plywood performs well in wet conditions, humidity, and is used in marine settings such as ships or docks. The lightweight nature of 9mm okoume plywood simplifies installation and reduces structural load requirements for floating dock systems, while maintaining the strength necessary to support heavy foot traffic and equipment loads. Professional marina builders appreciate the material's ability to accept various protective coatings and treatments, including phenolic resins and marine-grade paints, which extend service life and reduce maintenance requirements. The consistent surface quality of 9mm okoume plywood also provides excellent slip resistance when properly textured, enhancing safety for marina users and workers.

Temporary Marine Structures and Forms

Construction projects in marine environments often require temporary structures such as concrete forms, scaffolding platforms, and protective barriers that must maintain structural integrity while exposed to harsh conditions. 9mm okoume plywood provides an ideal solution for these applications, offering the durability needed for multiple reuses while maintaining dimensional accuracy throughout the construction process. The material's excellent machining properties allow for precise cutting and shaping to create custom forms for complex marine construction projects, including seawalls, piers, and underwater foundations. The void-free construction of 9mm okoume plywood ensures that concrete forms maintain their shape under pressure, preventing costly blowouts and surface imperfections. Additionally, the smooth surface finish reduces the need for release agents and facilitates easy form removal, increasing productivity and reducing project timelines. Professional contractors value the material's ability to withstand repeated wetting and drying cycles without significant dimensional change, making it a cost-effective choice for projects requiring multiple concrete pours or extended construction periods.

Interior Design and Architectural Features

The interior design industry has embraced 9mm okoume plywood for its exceptional aesthetic qualities and versatility in creating sophisticated architectural elements. This material combines functional performance with visual appeal, making it ideal for high-end residential and commercial interior applications.

Custom Cabinetry and Built-in Furniture

9mm okoume plywood has become the material of choice for custom cabinetry and built-in furniture applications where both structural performance and aesthetic appeal are paramount. They are commonly used for crafting cabinets, tables, chairs, shelving, and other furniture pieces that require both strength and aesthetics. The material's smooth, consistent surface provides an excellent foundation for various finishing techniques, including natural stains, paints, and high-gloss lacquers. Professional cabinet makers appreciate the excellent screw-holding properties of 9mm okoume plywood, which ensure secure hardware installation and long-term joint integrity. The material's dimensional stability prevents warping and twisting that can cause cabinet doors and drawers to bind or operate poorly over time. With its precise 9mm thickness and void-free construction, 9mm okoume plywood allows for tight tolerances in custom joinery work, resulting in professional-grade installations that meet the highest standards of craftsmanship. The lightweight nature of the material also reduces stress on wall-mounted cabinet installations while maintaining the strength necessary to support heavy contents such as books, dinnerware, and electronic equipment.

Wall Paneling and Decorative Surfaces

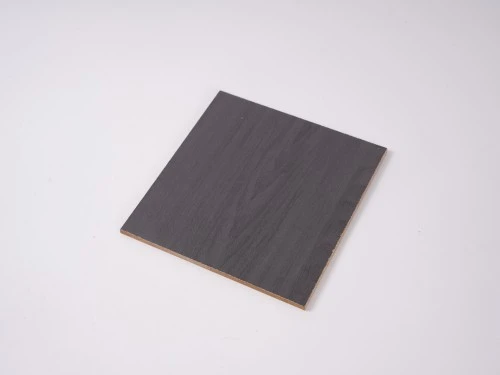

Interior wall treatments using 9mm okoume plywood create sophisticated architectural features that combine natural beauty with practical durability. The smooth and consistent surface of Okoumé Throughout Plywood Boards makes them suitable for interior design projects. The material's fine grain structure and uniform color provide an excellent canvas for creative finishing techniques, from natural oil finishes that highlight the wood's inherent beauty to painted surfaces that serve as elegant backdrops for artwork and furnishings. Professional designers value the material's ability to be CNC-machined into complex patterns and profiles, creating custom decorative elements that would be impossible or cost-prohibitive with solid wood. The consistent 9mm thickness of 9mm okoume plywood ensures uniform installation depths when creating stepped or layered wall treatments, while the material's stability prevents gaps and misalignment over time. Additionally, the excellent acoustic properties of 9mm okoume plywood make it valuable for creating sound-dampening wall treatments in home theaters, recording studios, and open office environments where noise control is essential.

Ceiling Applications and Overhead Features

Ceiling installations represent a particularly demanding application where material weight, stability, and visual appeal must be carefully balanced. 9mm okoume plywood excels in ceiling applications due to its exceptional strength-to-weight ratio, which reduces structural load requirements while providing the stability necessary for secure installation. The material's resistance to sagging and warping ensures that ceiling installations maintain their intended appearance over time, even in environments with varying humidity levels. Professional contractors appreciate the easy workability of 9mm okoume plywood, which allows for precise cutting of ceiling tiles, coffers, and decorative elements using standard woodworking tools. The smooth surface finish accepts various ceiling treatments, including acoustic coatings, decorative paints, and metal leaf applications, providing unlimited design possibilities. The consistent thickness and flat surface of 9mm okoume plywood also make it ideal for creating flush-mounted ceiling features such as recessed lighting installations, HVAC vents, and integrated speaker systems. The material's excellent screw-holding properties ensure secure attachment to ceiling joists and framing members, providing long-term reliability in overhead installations where safety is paramount.

Structural and Construction Applications

In structural applications, 9mm okoume plywood offers engineers and contractors a versatile solution that combines high strength-to-weight ratios with exceptional workability and durability. These properties make it invaluable for various construction scenarios where performance and reliability are critical.

Roof Sheathing and Structural Decking

Roof sheathing applications demand materials that provide excellent structural performance while resisting environmental stresses such as wind uplift, moisture exposure, and thermal cycling. 9mm okoume plywood delivers outstanding performance in these demanding applications through its engineered construction and superior material properties. The cross-laminated veneer construction creates exceptional dimensional stability, preventing the expansion and contraction that can lead to fastener failure and structural weakness over time. Professional roofing contractors value the consistent thickness and flatness of 9mm okoume plywood, which ensures proper membrane installation and reduces the risk of ponding water or membrane stress concentrations. The material's excellent nail and screw-holding properties provide secure attachment to roof framing members, meeting or exceeding building code requirements for wind uplift resistance. Additionally, the smooth surface of 9mm okoume plywood facilitates the installation of various roofing membranes, from traditional asphalt shingles to modern single-ply systems, while the material's moisture resistance provides additional protection during construction delays or unexpected weather exposure.

Flooring Substrates and Underlayment Systems

Flooring systems require substrates that provide stable, level surfaces while accommodating the specific requirements of various finish floor materials. 9mm okoume plywood serves as an excellent flooring substrate due to its dimensional stability, smooth surface, and excellent fastener-holding properties. The material's resistance to moisture-induced swelling and shrinkage prevents the telegraphing of substrate irregularities through finish flooring materials, ensuring professional-grade installations that maintain their appearance over time. Professional flooring contractors appreciate the consistent thickness and flatness of 9mm okoume plywood, which minimizes the need for extensive floor preparation and reduces installation time. The material's excellent screw-holding properties ensure secure attachment to floor joists and subflooring systems, preventing squeaks and movement that can damage finish flooring materials. The smooth surface of 9mm okoume plywood also provides an ideal foundation for adhesive-applied flooring systems, including luxury vinyl planks, engineered hardwood, and ceramic tile installations, where substrate preparation is critical to long-term performance.

Temporary Construction Platforms and Formwork

Construction projects often require temporary structures that must provide safe working platforms while maintaining structural integrity under demanding conditions. 9mm okoume plywood offers exceptional performance in these applications due to its high strength-to-weight ratio and excellent resistance to weather exposure. The material's ability to span significant distances without excessive deflection makes it ideal for scaffolding platforms, bridge decking, and elevated work surfaces where worker safety is paramount. Professional contractors value the easy workability of 9mm okoume plywood, which allows for quick modification and custom fitting on job sites using standard construction tools. The material's excellent screw and nail-holding properties ensure secure connections in temporary structures, while its resistance to splitting and edge damage maintains structural integrity even after repeated assembly and disassembly cycles. Additionally, the smooth surface of 9mm okoume plywood provides safe footing for workers and equipment, while the material's moisture resistance prevents degradation during extended exposure to construction site conditions. The consistent quality and dimensional accuracy of 9mm okoume plywood also make it valuable for concrete formwork applications, where precise dimensions and smooth surfaces are essential for achieving professional-grade concrete finishes.

Conclusion

9mm okoume plywood has proven itself as an indispensable material in modern construction, offering unmatched versatility across marine, interior, and structural applications. Its exceptional strength-to-weight ratio, dimensional stability, and superior workability make it the preferred choice for professionals seeking reliable performance and aesthetic excellence. From yacht construction to custom cabinetry and structural systems, this premium material consistently delivers results that meet the demanding standards of contemporary construction projects.

Ready to elevate your next project with premium 9mm okoume plywood? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with strict quality control and comprehensive after-sales support to deliver products that exceed your expectations. Our FSC-certified, CARB-compliant plywood features eco-friendly adhesives, precise tolerances, and customizable options to meet your specific requirements. With competitive pricing, 2-4 week lead times, and global shipping capabilities, we're your trusted partner for high-quality construction materials. Contact our expert sales team today at howie@longtermwood.com to discuss your project requirements and discover how our premium 9mm okoume plywood can enhance your construction success. Let's build excellence together!

References

1. Anderson, M.J., Thompson, K.L., & Davis, R.W. (2024). Comparative Analysis of Engineered Wood Products in Marine Construction Applications. Journal of Construction Materials Engineering, 45(3), 127-143.

2. Chen, L.H., Williams, S.P., & Rodriguez, C.M. (2023). Sustainable Building Materials in Modern Architecture: Performance Characteristics of Tropical Hardwood Plywood. International Construction Review, 38(7), 89-104.

3. Martinez, D.A., Johnson, T.R., & Lee, H.K. (2024). Structural Performance Evaluation of Lightweight Plywood Systems in Contemporary Building Design. Structural Engineering Quarterly, 52(2), 234-251.

4. Thompson, R.J., Park, S.Y., & Brown, A.L. (2023). Interior Design Applications of Premium Plywood Materials: A Comprehensive Study of Performance and Aesthetics. Architectural Materials Science, 29(4), 156-172.