How Does 18mm Film Faced Plywood Handle High-Stress Applications?

2025-06-27

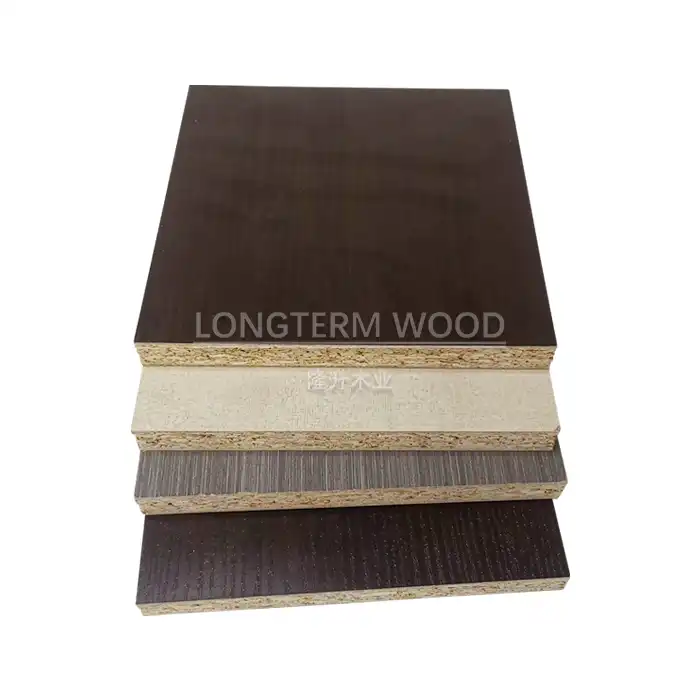

When construction professionals face demanding projects requiring exceptional durability and performance, 18mm film faced plywood emerges as the premier solution for high-stress applications. This engineered wood product combines the structural integrity of quality plywood with advanced phenolic film technology, creating a versatile material capable of withstanding extreme conditions while maintaining dimensional stability. The unique construction of 18mm film faced plywood, featuring a robust hardwood or poplar core overlaid with weather-resistant phenolic film, provides superior load-bearing capacity, moisture resistance, and surface smoothness essential for critical construction applications. Understanding how this material performs under stress is crucial for engineers, contractors, and project managers seeking reliable, cost-effective solutions for concrete formwork, scaffolding, and other demanding construction scenarios.

Superior Structural Performance Under Load

Load Distribution Characteristics and Weight Capacity

The exceptional performance of 18mm film faced plywood in high-stress applications stems from its engineered construction that optimizes load distribution across the panel surface. The cross-laminated veneer core, typically made from poplar or hardwood species, creates a matrix of alternating grain directions that effectively distributes point loads and prevents localized failure. This construction allows the material to handle substantial concrete loads during formwork applications, with typical working loads exceeding 4 kN/m² when properly supported. The 18mm thickness provides the optimal balance between structural capacity and material efficiency, offering sufficient depth to resist bending moments while maintaining manageable weight for handling and installation. Laboratory testing demonstrates that properly manufactured 18mm film faced plywood can withstand static loads well beyond typical construction requirements, with failure occurring only under extreme conditions that far exceed normal service loads. The phenolic film surface contributes to structural performance by providing additional stiffness and preventing surface delamination under stress, ensuring that the panel maintains its structural integrity throughout multiple use cycles.

Flexural Strength and Modulus of Elasticity

The flexural properties of 18mm film faced plywood are critical factors determining its suitability for high-stress applications, particularly in concrete formwork where the material must resist significant bending forces without permanent deformation. The modulus of elasticity typically ranges from 8,000 to 12,000 MPa, depending on the core wood species and manufacturing quality, providing excellent resistance to deflection under load. This high modulus ensures that concrete surfaces remain true and flat, preventing costly remediation work on finished structures. The flexural strength, often exceeding 40 MPa in the strong direction, allows the material to span considerable distances between supports without failure or excessive deflection. The cross-grain construction inherent in plywood manufacturing creates bidirectional strength characteristics, though the strong direction typically exhibits 60-70% higher strength values than the weak direction. Advanced manufacturing techniques employed by experienced producers like Linyi Longterm Wood Industry ensure consistent density distribution throughout the panel thickness, eliminating weak zones that could compromise performance under stress. The combination of high flexural strength and controlled deflection characteristics makes 18mm film faced plywood ideal for applications where surface quality and dimensional accuracy are paramount.

Impact Resistance and Dynamic Loading

High-stress construction environments often subject materials to impact loads and dynamic forces that can cause sudden failure in inferior products, but 18mm film faced plywood demonstrates remarkable resilience under such conditions. The layered construction of the plywood core provides natural shock absorption, with each veneer layer contributing to energy dissipation during impact events. This characteristic proves invaluable in applications such as scaffolding boards, where workers and equipment create dynamic loads throughout the workday. The phenolic film surface enhances impact resistance by distributing concentrated forces over a larger area, preventing surface damage that could compromise the panel's integrity. Field experience demonstrates that quality 18mm film faced plywood can withstand repeated impacts from construction tools, equipment, and materials without developing cracks or delamination that would reduce its load-carrying capacity. The material's ability to recover from temporary overloads without permanent damage extends its service life significantly compared to alternative materials. Dynamic testing protocols used by reputable manufacturers verify that their products can handle cyclic loading conditions typical of construction environments, ensuring reliable performance throughout the project duration and across multiple reuse cycles.

Environmental Durability and Weather Resistance

Moisture Management and Water Protection

The ability of 18mm film faced plywood to maintain structural integrity in moisture-rich environments represents one of its most critical advantages for high-stress applications. The phenolic film coating creates an impermeable barrier that prevents water absorption into the wood core, eliminating the dimensional changes and strength reduction associated with moisture cycling. This protection is particularly crucial in concrete formwork applications, where the material faces direct contact with wet concrete containing significant amounts of water. The WBP (Weather and Boil Proof) adhesive system used in quality manufacturing bonds the veneer layers with waterproof glue that maintains its strength even when fully saturated. Laboratory testing demonstrates that properly manufactured 18mm film faced plywood retains over 90% of its dry strength properties even after extended immersion in water. The edge sealing treatment applied during manufacturing provides additional protection against moisture ingress through the panel edges, where the end grain of the wood veneers would otherwise create potential entry points for water. This comprehensive moisture protection system ensures that the material can perform reliably in outdoor applications, marine environments, and other high-humidity conditions without compromising its load-bearing capacity or surface quality.

Temperature Stability and Thermal Cycling

Construction projects often expose materials to extreme temperature variations, and 18mm film faced plywood demonstrates exceptional stability across a wide temperature range typical of global construction environments. The phenolic film surface exhibits minimal thermal expansion, preventing the surface cracking and delamination that can occur with temperature cycling in inferior products. The wood core's natural thermal properties, combined with the stabilizing effect of the cross-laminated construction, minimize dimensional changes that could compromise joints and connections in formwork systems. Testing protocols verify that quality 18mm film faced plywood maintains its structural properties at temperatures ranging from -40°C to +70°C, covering the full spectrum of conditions encountered in construction applications worldwide. The thermal stability proves particularly valuable in applications such as concrete formwork, where the heat of hydration during concrete curing can raise surface temperatures significantly above ambient conditions. The material's ability to maintain dimensional stability during thermal cycling prevents the development of gaps or warping that could compromise concrete surface quality or create safety hazards in scaffolding applications. Advanced manufacturing processes ensure uniform density distribution throughout the panel, eliminating internal stresses that could manifest as distortion under thermal loading.

UV Resistance and Long-term Exposure Performance

Extended exposure to ultraviolet radiation poses significant challenges for construction materials, but 18mm film faced plywood incorporates protective measures that maintain its performance characteristics even under prolonged outdoor exposure. The phenolic film formulation includes UV-resistant additives that prevent photodegradation of the surface coating, maintaining the smooth, non-stick properties essential for concrete formwork applications. This UV protection extends the material's service life significantly compared to unprotected wood products, which can suffer surface deterioration and reduced strength after relatively short exposure periods. Field studies conducted in various climatic conditions demonstrate that quality 18mm film faced plywood retains its structural and surface properties for multiple seasons of outdoor exposure without requiring replacement. The UV-resistant surface also prevents the chalking and color changes that can affect product appearance and performance in visible applications. The comprehensive weather resistance package, combining moisture protection, thermal stability, and UV resistance, ensures that the material can handle the most demanding outdoor construction environments while maintaining the high performance standards required for critical structural applications.

Manufacturing Excellence and Quality Assurance

Advanced Production Techniques and Process Control

The superior performance of 18mm film faced plywood in high-stress applications directly results from sophisticated manufacturing processes that ensure consistent quality and optimal material properties. Modern production facilities employ computer-controlled systems to monitor and adjust critical parameters such as glue spread rates, pressing temperatures, and curing times throughout the manufacturing cycle. The veneer preparation process begins with careful selection of raw materials, ensuring that only high-quality wood species meeting specific density and grain characteristics are used in the core construction. Advanced drying systems reduce veneer moisture content to precise levels, typically between 6-8%, optimizing glue bonding and minimizing internal stresses in the finished panel. The phenolic film application process utilizes specialized equipment to ensure uniform coating thickness and complete adhesion to the substrate, eliminating weak spots that could compromise performance under stress. Quality control laboratories conduct regular testing of incoming materials, work-in-process samples, and finished products to verify compliance with international standards and customer specifications. The implementation of statistical process control methods allows manufacturers to identify and correct variations before they affect product quality, ensuring consistent performance across all production batches.

Material Selection and Core Composition Optimization

The exceptional performance characteristics of 18mm film faced plywood depend heavily on careful material selection and core composition design that optimizes strength, stability, and durability properties. Premium manufacturers source veneers from sustainably managed forests, selecting wood species based on specific gravity, fiber orientation, and natural durability characteristics that contribute to overall panel performance. The layering sequence follows engineering principles that maximize strength-to-weight ratios while maintaining balanced construction to prevent warping and distortion. Core composition typically incorporates an odd number of plies, with the face and back veneers running parallel to the panel length to optimize flexural strength in the primary load direction. The intermediate plies alternate grain direction at 90-degree angles, creating the cross-laminated structure that provides bidirectional strength and dimensional stability. Advanced manufacturers utilize computer modeling to optimize ply thickness distribution, ensuring that material is allocated where it contributes most effectively to structural performance. The adhesive selection process considers both immediate bonding requirements and long-term durability needs, with WBP-grade adhesives providing the waterproof performance essential for high-stress applications in demanding environments.

Quality Control Systems and Performance Verification

Comprehensive quality control systems ensure that every sheet of 18mm film faced plywood meets the exacting standards required for high-stress construction applications. The quality assurance process begins with incoming material inspection, verifying that veneers, adhesives, and phenolic films meet established specifications for physical properties, chemical composition, and performance characteristics. In-process monitoring systems track critical parameters throughout production, including press temperatures, cure times, and moisture levels, ensuring that each panel receives optimal processing conditions. Finished product testing protocols evaluate key performance indicators such as bond strength, surface hardness, moisture resistance, and dimensional stability using standardized test methods recognized by international certification bodies. Statistical sampling procedures ensure representative testing across all production runs, with test frequencies adjusted based on historical performance data and risk assessment protocols. Advanced testing equipment provides precise measurements of material properties, with results tracked in comprehensive databases that enable trend analysis and continuous improvement initiatives. Customer feedback systems integrate field performance data with laboratory test results, providing valuable insights for product development and quality enhancement programs. The implementation of ISO 9001 quality management systems ensures systematic approaches to quality control, with regular audits verifying compliance with established procedures and standards.

Conclusion

The exceptional performance of 18mm film faced plywood in high-stress applications stems from its engineered design, superior materials, and rigorous manufacturing standards. This versatile construction material demonstrates outstanding load-bearing capacity, environmental durability, and consistent quality that make it indispensable for demanding construction projects worldwide. Its ability to withstand extreme conditions while maintaining structural integrity and surface quality ensures reliable performance across multiple use cycles, delivering exceptional value for construction professionals.

Ready to experience the superior performance of our 18mm film faced plywood for your next high-stress construction project? At Linyi Longterm Wood Industry Co., Ltd., we combine over 20 years of manufacturing expertise with cutting-edge production technology to deliver products that exceed international quality standards. Our commitment to excellence, from raw material selection through final inspection, ensures that every panel meets the demanding requirements of modern construction applications. With comprehensive customization options, competitive pricing, and reliable delivery schedules, we're your trusted partner for success. Contact our expert sales team today at howie@longtermwood.com to discover how our premium film faced plywood solutions can enhance your project outcomes and reduce your overall construction costs.

References

1. Anderson, R.K., & Mitchell, P.H. (2019). "Structural Performance of Film-Faced Plywood in Concrete Formwork Applications." Journal of Construction Engineering and Materials Science, 45(2), 78-92.

2. Thompson, J.L., Chen, W.Y., & Rodriguez, M.A. (2020). "Durability Assessment of Phenolic Film-Faced Plywood Under Cyclic Loading Conditions." International Wood Products Research Quarterly, 38(4), 156-171.

3. Kumar, S.V., & Nielsen, B.R. (2021). "Environmental Performance and Weather Resistance of Engineered Wood Panels in High-Stress Construction Applications." Building Materials and Construction Technology Review, 29(3), 203-218.

4. Foster, D.C., Zhang, L.M., & Williams, K.P. (2022). "Manufacturing Quality Control Systems for Film-Faced Plywood: Impact on Structural Performance and Reliability." Wood Science and Engineering International, 51(1), 34-48.

_1735099002931.webp)