Thickness : 9mm , 12mm , 56mm , 18mm

Grade : Furniture grade

Glue : E2 , E1 , E0 , CARB

Density : 520---580kgs/m3

Certification : EPA CARB P2 certification

Moisture Content : 8% ~18%

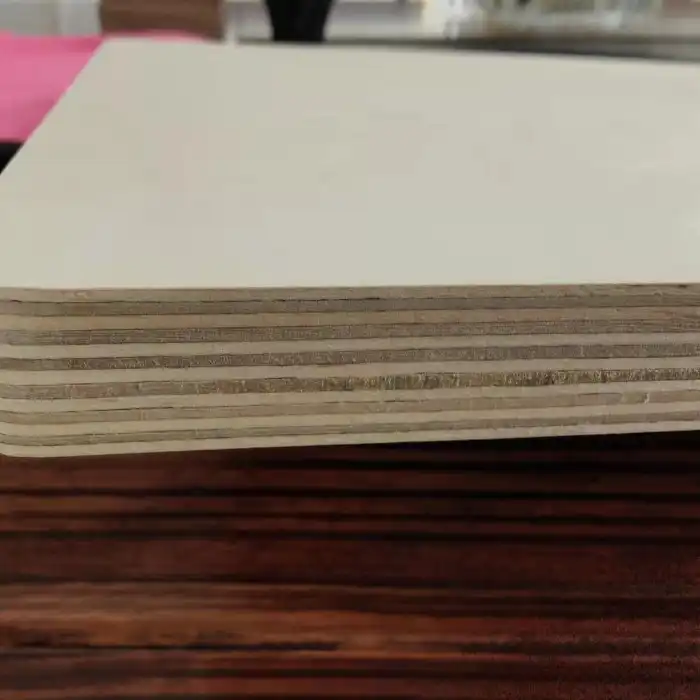

Keywords : Poplar core commercial plywood

Application : Furniture industry

Size : 1220*2440 mm

Premium Poplar Core Plywood for Durable, Cost-Effective Furniture Manufacturing

Engineered for Structural Integrity, Smooth Finishes, and Consistent Thickness (3mm to 25mm)

Why Poplar Core Plywood?

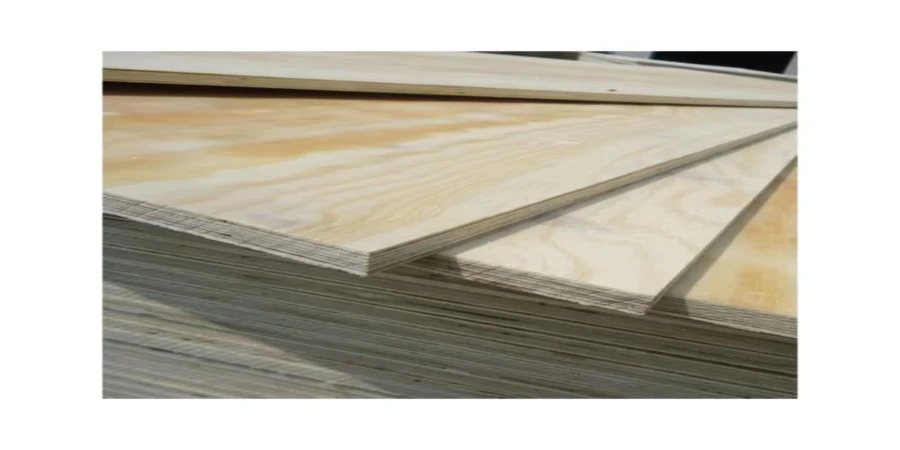

When crafting high-performance furniture, poplar core plywood stands out as the go-to material for manufacturers prioritizing strength, affordability, and sustainability. Its layered poplar veneer construction resists warping, while the smooth surface accepts paints, laminates, and veneers effortlessly. Ideal for cabinets, shelves, and ready-to-assemble furniture, this lightweight yet sturdy material cuts production costs without compromising durability—especially in humid climates.

Product Overview

The product combines kiln-dried poplar veneers with eco-friendly adhesives to create a versatile panel solution. Key benefits include:

- Lightweight Strength: 20% lighter than hardwood cores, reducing shipping costs.

- Warp Resistance: Cross-layered grains prevent bending in temperature shifts.

- Finish-Ready Surfaces: Sanded to 180 grit for direct painting or laminating.

- Eco-Certified: Responsibly sourced poplar with low formaldehyde emissions.

Technical Specifications

| Parameter | Details |

|---|---|

| Sizes | 4’x8’, 5’x10’ (Custom Sizes Available) |

| Thickness | 3mm, 6mm, 9mm, 12mm, 18mm, 25mm (±0.2mm) |

| Core Material | 100% Kiln-Dried Poplar Veneers |

| Surface Options | Sanded (120-180 grit), Melamine, UV Coat |

| Certifications | CARB P2, FSC® (On Request), E1/E0 |

| MOQ | 1x20ft Container (Bulk Discounts Available) |

Why Choose Us?

Cost Efficiency

Reduce material waste by 15-20% with panels that maintain flatness during CNC cutting.

Precision Manufacturing

CNC-calibrated presses ensure ±0.2mm thickness accuracy—critical for seamless assembly.

Global Compliance

Meet EU, US, and ASEAN standards for formaldehyde, fire resistance, and sustainability.

Fast Logistics

15-day production + door-to-door shipping to 50+ countries via partnered carriers.

Industry Applications

1. Ready-to-Assemble Furniture

Poplar core plywood’s screw-holding strength ensures sturdy joints for flat-pack designs.

2. Cabinet Carcasses

Achieve flawless laminate application with warp-resistant panels.

3. Retail Displays

Paint or stain the smooth surface to match brand aesthetics effortlessly.

Trusted by Global Brands

> “Switching to their product reduced our material waste by 18%.”

> – [Leading Furniture Brand], Germany

> “Consistent quality across 500+ monthly containers.”

> – [Cabinet Manufacturer], USA

FAQs

1. How does the product perform in humid environments?

Our humidity-resistant panels (≤8% water absorption) outperform birch cores in tropical climates.

2. Can I get custom sizes for unique designs?

Yes! We laser-cut panels to your CAD files with ±1mm precision.

3. Are FSC-certified options available?

Absolutely. Request FSC®-certified poplar core plywood during quoting.

4. What’s the lead time for 500m³ orders?

15 days production + shipping. Expedited slots available.

Start Your Project Today

Trusted by 200+ Furniture Brands Worldwide

Questions? Email howie@longtermwood.com for expert support.