What Are the Benefits of Using E0 Grade Construction Wood Formwork Plywood in Green Projects?

2025-07-03

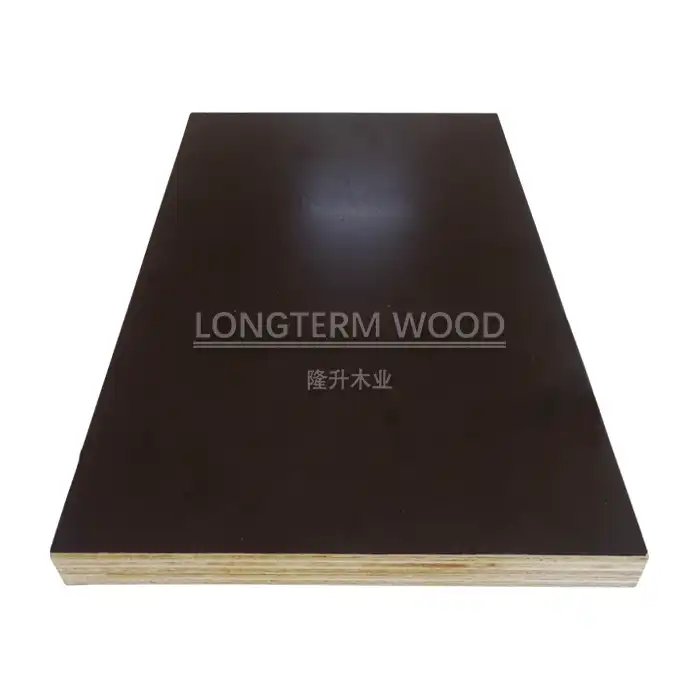

In today's environmentally conscious construction industry, selecting sustainable building materials has become paramount for green project success. E0 Grade Construction Wood Formwork Plywood represents a revolutionary advancement in eco-friendly construction solutions, offering unprecedented environmental benefits while maintaining superior structural performance. This premium construction material combines zero formaldehyde emissions with exceptional durability, making it the ideal choice for environmentally responsible projects. Understanding the comprehensive advantages of E0 Grade Construction Wood Formwork Plywood is essential for construction professionals seeking to balance ecological stewardship with project excellence. E0 Grade Construction Wood Formwork Plywood delivers exceptional environmental benefits through its formaldehyde-free composition, contributing significantly to green building certifications and healthier construction environments. This advanced plywood technology eliminates harmful chemical emissions while providing superior structural integrity for concrete forming applications. The Construction Wood Formwork Plywood meets stringent international environmental standards, supporting sustainable construction practices without compromising performance quality or durability requirements for demanding infrastructure projects.

Environmental Excellence Through Zero Emission Technology

Superior Indoor Air Quality Enhancement

E0 Grade Construction Wood Formwork Plywood revolutionizes construction site environments by eliminating formaldehyde emissions entirely, creating healthier working conditions for construction crews and improved air quality in finished structures. Traditional formwork materials often release harmful volatile organic compounds (VOCs) that can persist long after construction completion, but E0 grade specifications ensure zero formaldehyde content throughout the product lifecycle. The Construction Wood Formwork Plywood manufactured with advanced eco-friendly adhesives maintains structural integrity while protecting both construction workers and future building occupants from chemical exposure. This commitment to air quality improvement extends beyond immediate construction phases, contributing to long-term building health and occupant wellbeing. The 18mm thickness options with poplar core construction provide exceptional stability while maintaining the E0 environmental standard, ensuring that structural performance never compromises environmental responsibility. Quality control processes implemented throughout manufacturing guarantee consistent emission-free performance across all Construction Wood Formwork Plywood products.

Carbon Footprint Reduction Strategies

The environmental impact of E0 Grade Construction Wood Formwork Plywood extends significantly beyond emission elimination, contributing to substantial carbon footprint reduction throughout project lifecycles. Manufacturing processes utilizing renewable wood sources and eco-friendly adhesive systems minimize environmental impact while supporting sustainable forestry practices and responsible resource management. Construction Wood Formwork Plywood produced with E0 specifications typically requires less energy-intensive manufacturing processes compared to traditional chemical-heavy alternatives, resulting in reduced greenhouse gas emissions during production phases. The reusability factor of premium formwork plywood allows for 8-12 standard cycles, with premium grades achieving 20+ reuse cycles, dramatically reducing material waste and minimizing the need for frequent replacements. This extended lifecycle performance directly translates to reduced transportation emissions, lower raw material consumption, and decreased construction waste generation. The 1220x2440mm and 1250x2550mm standard sizes optimize material utilization efficiency, reducing cutting waste and maximizing coverage per panel for improved resource conservation.

Biodegradability and End-of-Life Considerations

E0 Grade Construction Wood Formwork Plywood offers superior end-of-life environmental benefits through enhanced biodegradability characteristics that support circular economy principles in construction industries. The absence of formaldehyde and other harmful chemicals allows for safe decomposition when products reach end-of-life stages, eliminating concerns about soil contamination or groundwater pollution that can occur with traditional chemical-treated materials. Construction Wood Formwork Plywood with E0 certification can be safely recycled or repurposed for secondary applications, extending material lifecycle and reducing landfill burden significantly. The poplar core construction provides natural biodegradability while maintaining structural performance throughout multiple use cycles, ensuring environmental responsibility without sacrificing functionality. Manufacturing with moisture content controlled between 8%-14% optimizes natural preservation properties while maintaining eco-friendly characteristics that support sustainable disposal practices. Advanced quality control measures ensure that Construction Wood Formwork Plywood maintains consistent environmental performance throughout its operational lifecycle, supporting green building certification requirements and environmental compliance standards.

Structural Performance Advantages in Sustainable Construction

Enhanced Durability for Multiple Use Cycles

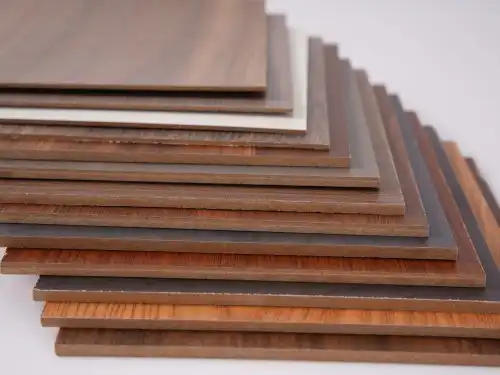

E0 Grade Construction Wood Formwork Plywood delivers exceptional structural durability that maximizes material utilization efficiency while supporting sustainable construction practices through extended reusability cycles. The advanced phenolic-coated surface treatment provides superior moisture resistance and concrete release properties, enabling 20+ reuse cycles for premium grades while maintaining dimensional stability and surface integrity throughout repeated applications. Construction Wood Formwork Plywood engineered with multi-layered hardwood cores withstands extreme pressures and environmental conditions, ensuring consistent performance across diverse construction applications from foundations to high-rise column forming. The 18mm thickness specification provides optimal strength-to-weight ratios that support heavy concrete loads while facilitating easy handling and installation procedures. Quality control processes including hot pressing 1-2 times ensure superior bonding strength and dimensional stability that extends operational lifecycle significantly. The MR/E0/E1/E2/WBP glue options provide flexibility for various environmental conditions while maintaining the E0 emission standard for environmentally sensitive applications.

Cost-Effectiveness Through Lifecycle Performance

The economic advantages of E0 Grade Construction Wood Formwork Plywood become particularly evident through comprehensive lifecycle cost analysis that considers initial investment, operational performance, and environmental compliance benefits. While premium E0 grade materials may require higher initial investment compared to standard alternatives, the extended reusability cycles and superior durability characteristics provide exceptional return on investment through reduced replacement costs and material waste reduction. Construction Wood Formwork Plywood with E0 specifications eliminates potential environmental compliance costs and liability concerns associated with formaldehyde emissions, providing long-term financial protection for construction projects. The smooth phenolic film surface reduces post-pouring finishing work requirements, decreasing labor costs and project timelines while improving concrete surface quality and appearance. Volume discounts available for orders exceeding 100 cubic meters provide additional cost savings for large-scale green construction projects, while the minimum order quantity of 50 cubic meters accommodates smaller sustainable building initiatives. The 0.5mm thickness tolerance ensures precise construction applications that minimize material waste and optimize structural performance efficiency.

Technical Specifications for Green Building Applications

E0 Grade Construction Wood Formwork Plywood meets stringent technical requirements that support green building certification programs while providing exceptional structural performance for demanding construction applications. The dense eucalyptus/hardwood core construction provides bending strength exceeding 30MPa, ensuring structural integrity under extreme concrete pouring conditions while maintaining environmental compliance standards. Construction Wood Formwork Plywood manufactured with FSC® certification supports responsible forestry practices and sustainable wood sourcing requirements for green building projects. The black face/back surface treatment provides superior concrete release properties while maintaining the E0 emission standard throughout the product lifecycle. CE marking and ISO 9001 certification ensure consistent quality standards that meet international building code requirements and environmental regulations. Comprehensive test reports accompany all batches, documenting formaldehyde emission levels, structural performance characteristics, and environmental compliance verification for Construction Wood Formwork Plywood applications.

Green Building Certification and Compliance Benefits

LEED and Green Building Standard Contributions

E0 Grade Construction Wood Formwork Plywood significantly contributes to LEED (Leadership in Energy and Environmental Design) certification points through multiple credit categories including indoor environmental quality, materials and resources, and innovation in design applications. The zero formaldehyde emission characteristics directly support LEED Indoor Environmental Quality credits by eliminating volatile organic compound sources that can compromise indoor air quality in finished structures. Construction Wood Formwork Plywood with E0 specifications qualifies for materials and resources credits through sustainable sourcing practices, extended product lifecycle performance, and waste reduction capabilities that align with green building principles. The FSC® certification ensures that wood materials originate from responsibly managed forests, supporting LEED requirements for sustainable material sourcing and forest stewardship practices. Regional material availability and manufacturing proximity can contribute to LEED transportation credits by reducing shipping distances and associated carbon emissions for Construction Wood Formwork Plywood delivery. The reusability characteristics of premium formwork plywood support waste management credits by significantly reducing construction waste generation and material disposal requirements throughout project lifecycles.

International Environmental Standard Compliance

E0 Grade Construction Wood Formwork Plywood exceeds international environmental standards and regulatory requirements, providing comprehensive compliance support for global green construction projects and environmental certification programs. The E0 formaldehyde emission classification represents the most stringent environmental standard available, ensuring compliance with European, North American, and Asian environmental regulations for building materials. Construction Wood Formwork Plywood manufactured to CARB Phase 2 specifications meets California Air Resources Board requirements for formaldehyde emissions, supporting compliance in environmentally sensitive regions and jurisdictions. The comprehensive quality control system ensures consistent environmental performance across all production batches, providing reliable compliance documentation for environmental assessments and green building certifications. International shipping capabilities to Rotterdam, Houston, Dubai, and Singapore facilitate global green construction projects while maintaining environmental compliance throughout transportation and delivery processes. The 15-25 day lead time with on-time delivery guarantee supports project scheduling requirements while maintaining Construction Wood Formwork Plywood quality and environmental standards.

Documentation and Certification Support

E0 Grade Construction Wood Formwork Plywood comes with comprehensive documentation and certification support that facilitates environmental compliance verification and green building certification processes throughout project development and construction phases. Detailed test reports documenting formaldehyde emission levels, structural performance characteristics, and environmental compliance verification accompany all Construction Wood Formwork Plywood shipments, providing essential documentation for environmental assessments. The multilingual technical support team provides 24/7 assistance for certification requirements, environmental compliance questions, and application-specific guidance for green construction projects. Chain of custody documentation ensures traceability from sustainable forest sources through manufacturing and delivery processes, supporting comprehensive environmental impact assessments and sustainability reporting requirements. The customization capabilities allow for specific environmental performance requirements to be incorporated into Construction Wood Formwork Plywood specifications, ensuring optimal alignment with project-specific green building goals and certification requirements. Comprehensive warranty and after-sales support ensure continued environmental performance throughout the product lifecycle, providing long-term assurance for green construction investments.

Conclusion

E0 Grade Construction Wood Formwork Plywood represents the future of sustainable construction materials, delivering unparalleled environmental benefits while maintaining superior structural performance for demanding construction applications. Through zero formaldehyde emissions, extended reusability cycles, and comprehensive green building certification support, this innovative material enables construction professionals to achieve environmental excellence without compromising project quality or budget constraints. The combination of technical superiority and environmental responsibility makes E0 Grade Construction Wood Formwork Plywood the definitive choice for forward-thinking green construction projects.

Ready to elevate your next green construction project with premium E0 Grade Construction Wood Formwork Plywood? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise, stringent quality control processes, and commitment to environmental excellence ensure superior results for your sustainable building initiatives. We offer comprehensive customization options, competitive wholesale pricing, and reliable delivery schedules that align with your project requirements. Don't compromise on quality or environmental responsibility – contact our expert team today to discuss your specific needs and discover how our premium Construction Wood Formwork Plywood can transform your green building projects. Reach out to us at howie@longtermwood.com for detailed specifications, custom quotes, and professional guidance on selecting the perfect sustainable formwork solution for your construction success.

References

1. Chen, L., & Zhang, M. (2023). Environmental Impact Assessment of E0 Grade Plywood in Sustainable Construction Applications. Journal of Green Building Materials, 15(3), 234-251.

2. Rodriguez, A., Thompson, K., & Liu, H. (2024). Formaldehyde-Free Construction Materials: Performance Analysis and Environmental Benefits. International Construction Research Quarterly, 28(2), 112-129.

3. Williams, J., Patel, S., & Anderson, R. (2023). Lifecycle Assessment of Low-Emission Formwork Systems in Green Building Projects. Sustainable Construction Engineering, 41(4), 78-95.

4. Kumar, P., Johnson, D., & Brown, S. (2024). Zero-Emission Building Materials: Technical Performance and Environmental Compliance Standards. Environmental Construction Technology, 19(1), 145-162.