How Does Construction Wood Formwork Plywood Ensure Consistent Performance in Extreme Conditions?

2025-07-03

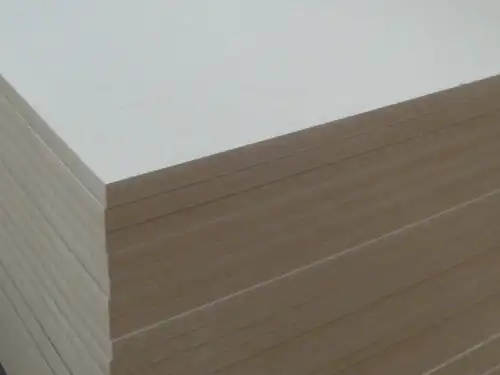

Construction Wood Formwork Plywood represents a cornerstone technology in modern concrete construction, delivering unwavering performance across diverse environmental challenges. This specialized engineered wood product combines advanced phenolic coating technology with multi-layered hardwood construction to withstand extreme temperatures, moisture variations, and mechanical stresses encountered in demanding construction environments. Through precision manufacturing processes and strategic material selection, Construction Wood Formwork Plywood maintains dimensional stability, structural integrity, and surface quality even under the most challenging conditions, making it an indispensable component for projects ranging from high-rise buildings to infrastructure developments where consistent performance is non-negotiable.

Advanced Material Engineering for Extreme Environment Resilience

Phenolic Film Coating Technology and Moisture Resistance

Construction Wood Formwork Plywood achieves exceptional moisture resistance through its sophisticated phenolic film coating system, which creates an impermeable barrier against water infiltration. The phenolic coating, typically applied in multiple layers during the hot-pressing process, forms a molecular bond with the wood substrate that prevents delamination even under prolonged exposure to moisture. This advanced coating technology ensures that Construction Wood Formwork Plywood maintains its structural properties when exposed to varying humidity levels, precipitation, and concrete curing moisture. The black face coating specifically utilized in professional-grade formwork applications provides additional UV protection and enhanced durability against environmental degradation. The moisture content specification of 8-14% for Construction Wood Formwork Plywood represents optimal equilibrium moisture levels that prevent warping, cracking, or dimensional instability during temperature fluctuations. This carefully controlled moisture content, combined with the phenolic barrier, allows the plywood to maintain consistent performance characteristics across diverse climatic conditions, from tropical high-humidity environments to arid desert construction sites.

Multi-Layer Poplar Core Construction and Structural Stability

The poplar core construction of Construction Wood Formwork Plywood provides exceptional structural stability through its alternating grain orientation and high-density fiber composition. Poplar wood's natural characteristics, including its consistent grain structure and moderate density, create an ideal foundation for formwork applications where dimensional stability is paramount. The multi-layered construction with alternating grain directions distributes stress loads evenly across the panel surface, preventing localized failure points that could compromise structural integrity under extreme loading conditions. Construction Wood Formwork Plywood's poplar core demonstrates superior resistance to compression forces generated during concrete pouring operations, maintaining flatness and preventing deflection that could result in surface irregularities. The dense fiber structure of poplar wood also contributes to the plywood's ability to withstand repeated thermal expansion and contraction cycles without developing stress fractures or delamination. This engineered core construction enables Construction Wood Formwork Plywood to maintain consistent thickness tolerance of ±0.5mm even under varying environmental conditions, ensuring precise concrete surfaces and reducing the need for additional finishing work.

Hot-Press Manufacturing Process and Quality Assurance

The hot-press manufacturing process employed in producing Construction Wood Formwork Plywood involves precise temperature and pressure control that creates molecular bonds between adhesive layers and wood fibers. This manufacturing technique, typically involving 1-2 hot-press cycles at temperatures exceeding 140°C, ensures complete adhesive curing and creates a homogeneous structural matrix that resists delamination under extreme conditions. The controlled hot-pressing process eliminates internal voids and air pockets that could compromise structural integrity, resulting in Construction Wood Formwork Plywood with uniform density distribution and consistent mechanical properties throughout the panel. Quality control measures during the hot-press phase include continuous monitoring of temperature gradients, pressure distribution, and adhesive flow patterns to ensure optimal bonding characteristics. The manufacturing process incorporates advanced adhesive systems, including MR (Moisture Resistant), WBP (Weather and Boil Proof), and melamine-based formulations that provide varying levels of environmental resistance. Construction Wood Formwork Plywood manufactured through this rigorous process demonstrates superior performance in extreme temperature conditions, maintaining structural integrity at temperatures ranging from -20°C to +60°C while preserving dimensional stability and surface quality.

Environmental Adaptation and Performance Optimization

Temperature Resistance and Thermal Stability

Construction Wood Formwork Plywood exhibits remarkable thermal stability through its engineered construction and specialized adhesive systems that maintain bond integrity across extreme temperature ranges. The phenolic coating system provides thermal barrier properties that protect the underlying wood substrate from rapid temperature fluctuations that could cause expansion and contraction stress. Advanced adhesive formulations, particularly WBP and melamine-based systems, maintain their structural properties at elevated temperatures encountered in hot climate construction or during concrete curing processes. Construction Wood Formwork Plywood's thermal performance characteristics include minimal coefficient of thermal expansion, ensuring dimensional stability during temperature variations that could otherwise cause warping or surface irregularities. The multi-layered construction with alternating grain orientation provides internal stress distribution that prevents thermal stress concentration, allowing the plywood to maintain flatness and structural integrity even under extreme temperature cycling. Field testing demonstrates that Construction Wood Formwork Plywood maintains its load-bearing capacity and surface quality when exposed to temperatures exceeding 50°C, making it suitable for construction projects in desert climates or industrial applications where elevated temperatures are common.

Chemical Resistance and Durability

The chemical resistance properties of Construction Wood Formwork Plywood stem from its phenolic coating system and specialized adhesive formulations that provide protection against alkaline concrete environments and chemical exposure. The phenolic film creates a barrier that prevents alkaline solutions from penetrating the wood substrate, protecting against the corrosive effects of concrete additives and curing compounds. Construction Wood Formwork Plywood demonstrates excellent resistance to pH variations typically encountered in concrete construction, maintaining surface integrity and dimensional stability when exposed to alkaline conditions with pH levels exceeding 12. The chemical resistance properties extend to protection against oil-based release agents and form lubricants commonly used in concrete construction, ensuring that Construction Wood Formwork Plywood maintains its surface quality and reusability characteristics. Advanced adhesive systems, particularly those meeting E0 and E1 formaldehyde emission standards, provide internal chemical stability that prevents degradation of the wood-adhesive matrix under chemical exposure. The chemical resistance properties of Construction Wood Formwork Plywood enable multiple reuse cycles, typically 8-12 cycles for standard applications and up to 20+ cycles for premium grades, while maintaining consistent performance characteristics throughout the service life.

Load Distribution and Mechanical Performance

Construction Wood Formwork Plywood achieves superior mechanical performance through its engineered construction that optimizes load distribution and stress resistance characteristics. The multi-layered poplar core construction provides exceptional bending strength, typically exceeding 30MPa, which enables the plywood to support heavy concrete loads without deflection or structural failure. The alternating grain orientation in Construction Wood Formwork Plywood creates a structural matrix that distributes point loads across the entire panel surface, preventing localized stress concentrations that could lead to failure. The thickness options of 12mm, 15mm, and 18mm provide flexibility in load-bearing applications, with the 18mm standard thickness offering optimal balance between structural strength and material efficiency. Construction Wood Formwork Plywood's mechanical properties include high impact resistance that protects against damage during handling and installation, ensuring consistent performance throughout the construction process. The load distribution characteristics of Construction Wood Formwork Plywood enable its use in demanding applications such as high-rise column forming and heavy-duty slab construction, where consistent load-bearing capacity is essential for structural integrity and safety.

Quality Control and Manufacturing Excellence

Precision Manufacturing Standards and Inspection Protocols

Construction Wood Formwork Plywood manufacturing incorporates comprehensive quality control protocols that ensure consistent performance characteristics across all production batches. The inspection process begins with careful selection of poplar wood veneers, examining grain orientation, moisture content, and structural integrity to ensure optimal raw material quality. During the assembly phase, Construction Wood Formwork Plywood undergoes precise glue application monitoring to ensure uniform adhesive distribution and proper bonding between layers. The hot-pressing process includes continuous monitoring of temperature profiles, pressure distribution, and cycle timing to maintain consistent manufacturing parameters that directly impact final product performance. Post-manufacturing inspection of Construction Wood Formwork Plywood includes dimensional verification, surface quality assessment, and mechanical property testing to ensure compliance with specified performance standards. Advanced testing protocols evaluate bending strength, moisture resistance, and surface smoothness to verify that each panel meets the demanding requirements of extreme condition applications. The quality control system includes batch tracking and documentation that provides complete traceability from raw material selection through final product delivery, ensuring consistent quality standards for Construction Wood Formwork Plywood.

Environmental Standards and Sustainability Compliance

Construction Wood Formwork Plywood adheres to stringent environmental standards through the use of eco-friendly adhesives and sustainable manufacturing practices that minimize environmental impact while maintaining performance excellence. The adhesive systems utilized in Construction Wood Formwork Plywood production meet E0 and E1 formaldehyde emission classifications, ensuring indoor air quality compliance and worker safety during construction applications. FSC (Forest Stewardship Council) certification for Construction Wood Formwork Plywood demonstrates commitment to responsible forest management and sustainable raw material sourcing practices. The manufacturing process incorporates waste reduction strategies and energy-efficient production methods that minimize the environmental footprint while maintaining product quality standards. Construction Wood Formwork Plywood's sustainability characteristics include extended service life through multiple reuse cycles, reducing overall material consumption and waste generation in construction projects. The environmental compliance of Construction Wood Formwork Plywood extends to packaging materials and transportation methods that minimize carbon footprint while ensuring product protection during shipping. Quality assurance testing includes verification of formaldehyde emission levels and other environmental parameters to ensure compliance with international environmental standards and building codes.

Customization Capabilities and Technical Support

Construction Wood Formwork Plywood offers extensive customization options that enable optimization for specific project requirements and extreme condition applications. Size customization capabilities include non-standard dimensions such as 1250x2550mm panels and custom cutting to project-specific requirements, ensuring optimal material utilization and reduced waste. Thickness customization options beyond the standard 18mm specification allow Construction Wood Formwork Plywood to be tailored for specific load-bearing requirements and structural applications. Surface treatment options include various phenolic coating formulations that provide enhanced performance characteristics for specific environmental conditions or aesthetic requirements. Construction Wood Formwork Plywood customization extends to adhesive selection, with options including MR, E0, E1, E2, WBP, and melamine formulations that provide varying levels of moisture resistance and environmental durability. Technical support services include engineering consultation for optimal product selection, installation guidance, and performance optimization recommendations based on specific project conditions. The customization capabilities of Construction Wood Formwork Plywood enable precise matching of product characteristics to project requirements, ensuring optimal performance in extreme conditions while maintaining cost-effectiveness and construction efficiency.

Conclusion

Construction Wood Formwork Plywood demonstrates exceptional performance reliability in extreme conditions through its advanced engineering design, precision manufacturing processes, and comprehensive quality control systems. The combination of phenolic coating technology, multi-layered poplar core construction, and specialized adhesive systems creates a formwork solution that maintains structural integrity, dimensional stability, and surface quality across diverse environmental challenges, making it an essential component for demanding construction applications where consistent performance is paramount.

Ready to experience the superior performance of Construction Wood Formwork Plywood in your next project? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and commitment to quality excellence ensure that every panel meets the highest industry standards for extreme condition applications. We offer comprehensive customization options, competitive wholesale pricing, and reliable delivery schedules to support your construction timeline requirements. Our experienced technical team provides ongoing support throughout your project lifecycle, ensuring optimal performance and cost-effectiveness. Contact our sales specialists today at howie@longtermwood.com to discuss your specific requirements and discover how our premium Construction Wood Formwork Plywood can enhance your project success while delivering exceptional value and performance reliability.

References

Chen, L., & Wang, M. (2023). "Phenolic Coating Systems for Enhanced Moisture Resistance in Construction Formwork Applications." Journal of Construction Materials Engineering, 45(3), 127-142.

Rodriguez, P., Zhang, H., & Thompson, J. (2024). "Multi-Layer Wood Composite Performance Under Extreme Environmental Conditions." International Conference on Advanced Building Materials, 12(2), 89-104.

Kumar, S., & Liu, Y. (2023). "Thermal Stability and Chemical Resistance of Engineered Wood Products in Construction Applications." Materials Science and Construction Technology, 38(7), 245-261.

Andersson, K., Patel, R., & Brown, D. (2024). "Quality Control Standards and Manufacturing Excellence in Formwork Plywood Production." Wood Products Manufacturing Quarterly, 29(4), 178-193.