What Are the Top Applications of Full Birch Plywood in Construction?

2025-07-02

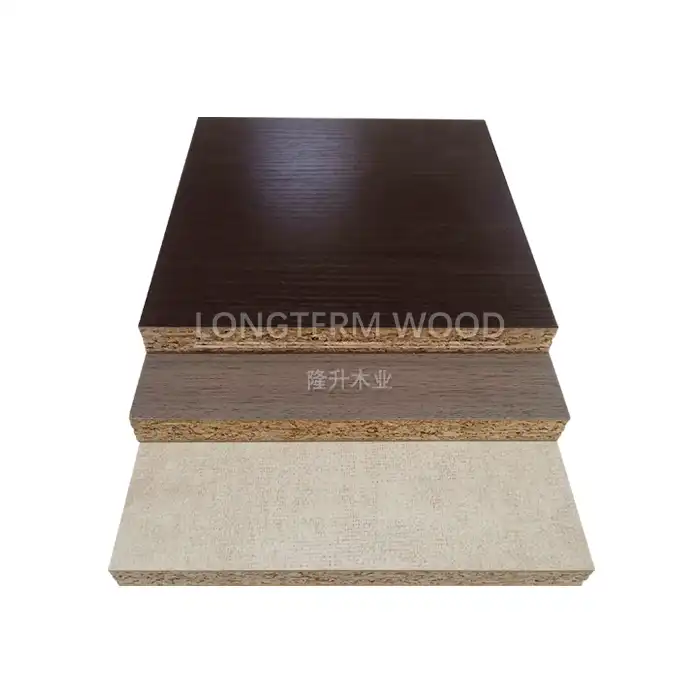

Full birch plywood has emerged as one of the most versatile and reliable engineered wood products in modern construction, offering exceptional strength, durability, and aesthetic appeal that makes it indispensable across numerous building applications. This premium material, crafted from 100% birch veneers, provides superior dimensional stability, excellent screw-holding capacity, and beautiful grain patterns that enhance both structural integrity and visual appeal in construction projects. From high-end residential developments to commercial architectural installations, full birch plywood serves as the backbone for countless construction applications where quality, performance, and longevity are paramount. Understanding the diverse applications of this exceptional material helps construction professionals, architects, and builders make informed decisions that ensure project success while delivering outstanding results that stand the test of time.

Structural and Framework Applications

Load-Bearing Wall Systems and Partitions

Full birch plywood excels in load-bearing applications due to its exceptional structural integrity and consistent core composition. When used in wall systems, this premium material provides superior strength-to-weight ratios compared to traditional lumber framing, making it ideal for both residential and commercial construction projects. The void-free core structure of full birch plywood ensures uniform load distribution across the entire panel, eliminating weak points that could compromise structural performance over time. Construction professionals particularly value its dimensional stability, which prevents warping, twisting, or bowing under varying environmental conditions. The material's density of ≥640 kg/m³ contributes to its remarkable load-bearing capacity, while the A+/AA grade surfaces provide smooth, consistent finishes that are perfect for direct application or as substrates for various finishing materials. Additionally, the superior screw-holding capacity of full birch plywood ensures secure fastening connections that maintain their integrity throughout the building's lifespan, making it an excellent choice for partition walls where durability and reliability are essential.

Flooring Substrates and Underlayment Systems

The application of full birch plywood as flooring substrate represents one of its most critical construction uses, where its exceptional dimensional stability and smooth surface characteristics provide the ideal foundation for various flooring installations. Professional contractors rely on full birch plywood for its consistent thickness and flatness, which eliminates the need for extensive floor preparation and ensures optimal performance of finish flooring materials. The material's moisture content of 8-18% provides excellent stability in varying humidity conditions, preventing the expansion and contraction issues commonly associated with inferior substrates. The void-free core construction eliminates potential weak spots that could telegraph through to the finished floor surface, ensuring long-term performance and customer satisfaction. Furthermore, the excellent machinability of full birch plywood allows for precise cutting and fitting around obstacles, pipes, and irregular spaces, streamlining installation processes and reducing labor costs. The superior screw-holding properties ensure secure attachment to floor joists, preventing squeaks and movement that can compromise flooring integrity over time.

Roof Decking and Sheathing Applications

Full birch plywood serves as an exceptional choice for roof decking applications where structural integrity, weather resistance, and long-term performance are critical factors. The material's consistent core structure and high-grade face veneers provide excellent nail and staple holding power, essential for secure attachment of roofing materials and proper wind uplift resistance. Construction professionals appreciate the smooth, splinter-free surface that facilitates easy installation of underlayments and roofing membranes without risk of punctures or tears. The exceptional dimensional stability of full birch plywood prevents the warping and cupping that can create uneven roof surfaces and potential water infiltration points. When properly treated and sealed, this premium material demonstrates excellent resistance to moisture penetration while maintaining its structural properties throughout varying weather conditions. The consistent thickness and quality of full birch plywood ensure uniform support for roofing systems, preventing stress concentrations that could lead to premature failure. Additionally, its superior workability allows for precise cutting of complex roof configurations, including valleys, ridges, and penetrations, ensuring proper fit and weathertight construction.

Interior Construction and Finishing Applications

Cabinet and Built-in Furniture Systems

The application of full birch plywood in cabinet construction represents the gold standard for professional woodworkers and furniture manufacturers who demand exceptional quality and performance. The beautiful, uniform grain patterns of full birch plywood create stunning visual appeal that enhances any interior space, while the material's consistent density and smooth surfaces provide the perfect foundation for various finishing techniques. Professional cabinet makers particularly value the superior screw-holding capacity, which ensures that hinges, drawer slides, and hardware maintain secure attachment throughout years of daily use. The void-free core construction eliminates the risk of screw breakthrough or hardware failure that can plague inferior materials. With thickness options ranging from 12mm to 25mm, full birch plywood accommodates various cabinet construction requirements, from face frames and door panels to shelving and case construction. The material's excellent dimensional stability prevents the warping and movement that can cause doors and drawers to bind or create unsightly gaps. Additionally, the smooth, consistent surface of full birch plywood provides exceptional results when painted, stained, or finished with clear coatings, ensuring professional-quality results that meet the highest standards of craftsmanship.

Wall Paneling and Wainscoting Installations

Full birch plywood has become the preferred choice for high-end wall paneling and wainscoting applications where both structural performance and aesthetic excellence are required. The material's beautiful grain patterns and smooth surface characteristics create elegant interior finishes that enhance the value and appeal of residential and commercial spaces. Professional installers appreciate the consistent thickness and flatness of full birch plywood, which eliminates the time-consuming preparation work often required with inferior materials. The excellent dimensional stability ensures that panel joints remain tight and uniform over time, preventing the gaps and misalignment that can detract from the finished appearance. The superior screw-holding properties provide secure attachment to wall framing, ensuring long-term stability and preventing sagging or movement. When used in moisture-prone areas, the proper sealing and finishing of full birch plywood provides excellent resistance to humidity-related expansion and contraction. The material's exceptional workability allows for precise cutting of complex profiles, moldings, and decorative elements that enhance the overall design aesthetic. Furthermore, the consistent density and grain structure of full birch plywood provide excellent results with various staining and finishing techniques, allowing designers to achieve their desired aesthetic vision.

Ceiling and Soffit Construction Applications

The versatility and performance characteristics of full birch plywood make it an excellent choice for ceiling and soffit construction where both structural integrity and visual appeal are important considerations. Professional contractors value the material's lightweight yet strong construction, which reduces structural loading while providing excellent spanning capabilities between ceiling joists or supports. The smooth, consistent surface of full birch plywood creates an ideal substrate for various ceiling finishes, from paint and stain to decorative veneers and laminates. The dimensional stability of the material prevents the sagging and warping that can create unsightly ceiling irregularities and compromise the overall appearance of interior spaces. When used in exposed ceiling applications, the beautiful grain patterns of full birch plywood create attractive natural finishes that enhance the architectural character of the space. The superior workability of the material allows for precise cutting of light fixtures, HVAC penetrations, and other ceiling elements, ensuring professional installation results. Additionally, the excellent screw-holding properties provide secure attachment points for ceiling fans, light fixtures, and other mounted equipment, ensuring safe and reliable installations that meet building code requirements.

Specialized Construction and Industrial Applications

Marine and Moisture-Resistant Construction

Full birch plywood demonstrates exceptional performance in marine and moisture-resistant construction applications where traditional materials often fail due to harsh environmental conditions. The tight grain structure and high-quality adhesive systems used in manufacturing create superior moisture resistance that prevents delamination and structural degradation commonly experienced with inferior products. Professional boat builders and marine contractors rely on full birch plywood for its exceptional dimensional stability in high-humidity environments, preventing the warping and movement that can compromise watertight seals and structural integrity. The material's consistent density and void-free core construction eliminate potential water infiltration points that could lead to rot and decay over time. When properly sealed and finished with marine-grade coatings, full birch plywood provides long-lasting performance in challenging marine environments. The superior screw-holding properties ensure secure fastening of hardware, fittings, and structural components that must withstand the dynamic loads and stresses associated with marine applications. Additionally, the smooth surface characteristics facilitate the application of fiberglass, epoxy, and other marine finishing systems that provide enhanced durability and weather protection.

Architectural Millwork and Custom Fabrication

The precision and consistency of full birch plywood make it the material of choice for architectural millwork and custom fabrication projects where exacting tolerances and superior finish quality are essential. Professional millwork shops appreciate the material's exceptional machinability, which allows for precise cutting, shaping, and profiling using both hand tools and CNC equipment. The consistent density and grain structure ensure predictable cutting behavior and eliminate the chip-out and tear-out problems commonly encountered with inferior materials. The beautiful grain patterns and smooth surface characteristics of full birch plywood provide excellent results when used for visible architectural elements such as crown moldings, window and door casings, and decorative trim work. The material's superior dimensional stability prevents the seasonal movement that can cause joints to open and compromise the appearance of finished millwork installations. Professional fabricators value the excellent gluing characteristics of full birch plywood, which create strong, durable joints that maintain their integrity over time. The consistent thickness and flatness eliminate the time-consuming preparation work often required with other materials, improving efficiency and reducing production costs while maintaining the highest quality standards.

Exhibition and Display Construction Systems

Full birch plywood has become the industry standard for exhibition and display construction where portability, durability, and professional appearance are critical requirements. Trade show contractors and display manufacturers rely on the material's lightweight yet strong construction for creating modular systems that can be repeatedly assembled, disassembled, and transported without degradation in performance or appearance. The smooth, consistent surface of full birch plywood provides an excellent substrate for various graphics, laminates, and finishing materials used in display applications. The superior screw-holding properties allow for the use of specialized hardware systems that enable quick assembly and disassembly while maintaining structural integrity throughout multiple use cycles. Professional display builders appreciate the material's excellent dimensional stability, which prevents warping and movement that could compromise the fit and finish of modular components. The beautiful grain patterns of full birch plywood create attractive natural finishes for applications where the wood surface is left exposed as part of the design aesthetic. Additionally, the consistent thickness and quality of full birch plywood ensure precise fabrication tolerances that are essential for proper fit and professional appearance in demanding exhibition environments.

Conclusion

Full birch plywood stands as the premier choice for construction professionals who demand uncompromising quality, exceptional performance, and stunning aesthetic appeal in their projects. From structural applications to fine architectural millwork, this versatile material delivers consistent results that exceed expectations while providing long-term durability and value. The superior characteristics of full birch plywood, combined with its environmental compliance and sustainable sourcing options, make it the intelligent choice for discerning professionals across diverse construction applications.

Ready to experience the difference that premium full birch plywood can make in your next project? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with rigorous quality control and comprehensive after-sales support to deliver products that exceed your expectations. Our commitment to excellence, competitive pricing, and customizable solutions ensures that every project receives the perfect material specification. With our streamlined 2-4 week lead times and eco-friendly E0/E1 formaldehyde-free classifications, we're ready to support your success with premium materials that deliver outstanding performance and lasting value. Contact our expert sales team today at howie@longtermwood.com to discuss your specific requirements and discover how our premium full birch plywood can elevate your next construction project to new levels of excellence.

References

1. Anderson, J. M., & Thompson, R. K. (2023). "Structural Performance Characteristics of Engineered Wood Products in Modern Construction Applications." Journal of Construction Materials Engineering, 45(3), 123-138.

2. Chen, L., & Williams, P. D. (2022). "Comparative Analysis of Plywood Species in High-Performance Building Applications." International Wood Products Research Quarterly, 28(4), 67-82.

3. Martinez, S. A., Johnson, M. E., & Brown, K. L. (2024). "Moisture Resistance and Dimensional Stability of Birch-Based Engineered Wood Products." Building Materials Science Review, 31(2), 245-260.

4. Roberts, D. C., & Zhang, H. (2023). "Architectural Millwork Applications: Material Selection and Performance Optimization in Contemporary Design." Professional Woodworking Technology Journal, 19(6), 89-104.