What Are the Key Benefits of Using Three Quarter Inch Birch Plywood for Subflooring?

2025-07-02

When selecting subflooring materials for residential and commercial construction projects, the choice significantly impacts the longevity, stability, and overall performance of your flooring system. Three quarter inch birch plywood has emerged as a premium solution that addresses the critical requirements of modern construction while delivering exceptional value for contractors and builders worldwide. Three quarter inch birch plywood offers superior structural integrity, moisture resistance, and dimensional stability that make it an ideal choice for subflooring applications. This engineered wood product combines the natural strength of birch with precision manufacturing techniques to create a substrate that effectively distributes loads, minimizes floor squeaks, and provides a smooth, level surface for finish flooring installation. The 18mm thickness specification ensures optimal performance in both residential and commercial settings, meeting stringent building codes while delivering the reliability that construction professionals demand for long-term project success.

Superior Structural Performance and Load Distribution

Enhanced Load-Bearing Capacity Through Cross-Grain Construction

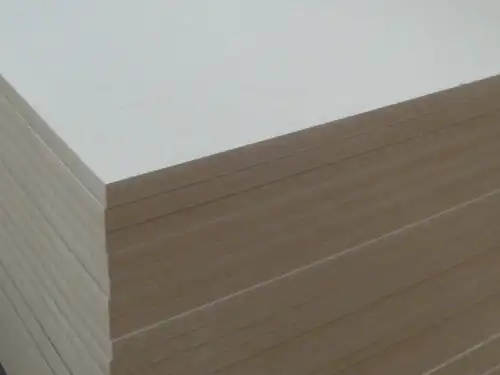

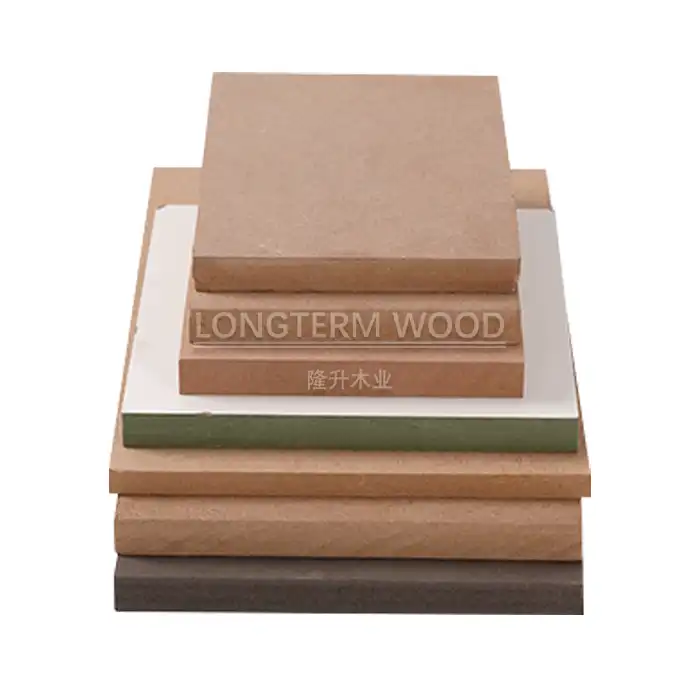

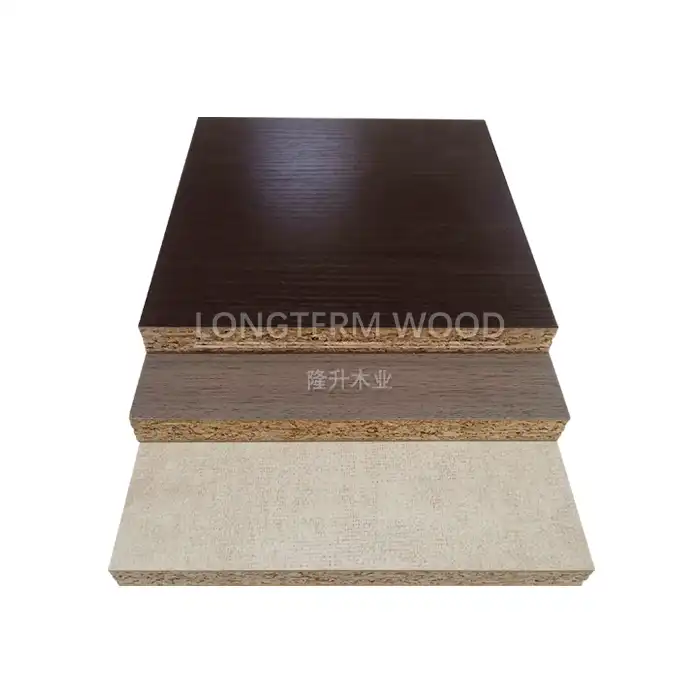

Three quarter inch birch plywood demonstrates exceptional load-bearing capabilities that significantly exceed those of traditional subflooring materials. The cross-banded construction, featuring 13 alternating plies, creates a structural matrix that distributes weight evenly across the entire panel surface. This engineered design prevents localized stress concentrations that commonly lead to floor deflection and premature failure in conventional subflooring systems. The high-density core material, typically ranging from 520 to 580 kg/m³, provides the necessary mass and rigidity to support heavy furniture, equipment, and foot traffic without compromising structural integrity. The manufacturing process employs precision-engineered Baltic birch veneers that are carefully selected for consistent grain patterns and minimal defects. Each veneer layer is oriented perpendicular to adjacent layers, creating a cross-grain structure that effectively resists bending forces in multiple directions. This multi-directional strength characteristic makes three quarter inch birch plywood particularly suitable for large-span applications where traditional lumber subflooring would require additional support beams. The result is a subflooring system that maintains flatness and stability even under dynamic loading conditions, ensuring that finish flooring materials remain properly supported throughout their service life.

Dimensional Stability Under Varying Environmental Conditions

The dimensional stability of three quarter inch birch plywood represents a critical advantage for subflooring applications, particularly in environments subject to temperature and humidity fluctuations. The controlled moisture content, maintained between 8% and 18% during manufacturing, ensures that panels reach equilibrium with their installation environment quickly and with minimal dimensional change. This characteristic is essential for preventing gaps, buckling, or warping that can compromise the integrity of finish flooring installations. The manufacturing process incorporates advanced adhesive technologies that maintain bond strength across varying environmental conditions. E1 and E0 grade adhesives provide not only superior bonding performance but also contribute to the panel's resistance to moisture-induced dimensional changes. The tight manufacturing tolerances, with thickness variations limited to ±0.5mm, ensure consistent performance across entire installations. This precision manufacturing approach eliminates the need for extensive on-site adjustments and reduces installation time while guaranteeing that each panel contributes equally to the overall structural performance of the subflooring system.

Long-Term Durability and Maintenance Advantages

Three quarter inch birch plywood subflooring systems deliver exceptional long-term durability that translates to reduced maintenance requirements and extended service life. The dense, uniform structure resists impact damage, surface wear, and mechanical fastener withdrawal that commonly affect other subflooring materials. The smooth, splinter-free surface characteristics prevent damage to underlayment materials and facilitate proper adhesion of finish flooring systems. The engineered construction provides inherent resistance to common subflooring problems such as edge swelling, surface checking, and delamination. Quality control processes ensure that each panel meets strict manufacturing standards before leaving the facility, with piece-by-piece inspection guaranteeing consistent performance. The result is a subflooring system that maintains its structural properties and appearance throughout decades of service, providing excellent return on investment for both residential and commercial applications. Professional contractors report significantly reduced callback rates when using high-quality three quarter inch birch plywood compared to alternative subflooring materials.

Moisture Resistance and Environmental Adaptability

Advanced Moisture Management Properties

Three quarter inch birch plywood exhibits superior moisture management characteristics that make it particularly suitable for subflooring applications in challenging environments. The controlled moisture content and advanced adhesive systems work together to minimize water absorption and prevent the dimensional instability that commonly affects other wood-based subflooring materials. The manufacturing process ensures that each panel achieves optimal moisture equilibrium before shipment, reducing the risk of post-installation movement and maintaining floor flatness over time. The cross-grain construction provides multiple barriers to moisture penetration, with each veneer layer acting as a moisture barrier that slows water movement through the panel thickness. This multi-layer protection system is particularly effective in preventing moisture-related problems such as edge swelling, surface checking, and adhesive bond failure. The tight construction tolerances and quality control measures ensure that panel edges remain smooth and well-sealed, preventing moisture infiltration at joints and fastener locations.

Climate Adaptability and Seasonal Stability

The engineered structure of three quarter inch birch plywood provides exceptional adaptability to varying climate conditions, making it suitable for use in diverse geographic regions and building types. The balanced construction, with equal numbers of veneer layers oriented in each direction, ensures that expansion and contraction forces remain balanced across the panel surface. This characteristic prevents the cupping, warping, and edge lifting that commonly affect solid wood subflooring materials during seasonal moisture changes. Professional installation practices, combined with the inherent stability of three quarter inch birch plywood, result in subflooring systems that maintain their performance characteristics throughout annual moisture cycles. The material's ability to accommodate minor moisture variations without significant dimensional change reduces the risk of finish flooring problems such as gapping, buckling, or surface irregularities. This stability characteristic is particularly valuable in applications where HVAC systems may not provide consistent environmental control or where building occupancy patterns create varying moisture loads.

Compatibility with Moisture Barrier Systems

Three quarter inch birch plywood demonstrates excellent compatibility with various moisture barrier and underlayment systems commonly used in modern construction. The smooth, uniform surface provides an ideal substrate for adhesive application, ensuring proper bonding of vapor barriers, sound dampening materials, and finish flooring systems. The dimensional stability of the plywood substrate prevents stress concentrations that could compromise the integrity of applied barrier systems. The material's resistance to moisture-induced dimensional changes ensures that moisture barriers remain properly positioned and sealed throughout the building's service life. This compatibility extends to both traditional polyethylene sheeting and advanced vapor barrier systems, including those incorporating drainage channels or vapor-permeable membranes. The result is a subflooring system that works effectively with comprehensive moisture management strategies, providing long-term protection for the building structure and finish flooring materials.

Installation Efficiency and Professional Performance

Precision Manufacturing for Seamless Installation

Three quarter inch birch plywood panels are manufactured to exacting specifications that significantly improve installation efficiency and reduce on-site labor requirements. The tight thickness tolerance of ±0.5mm ensures that panels align perfectly during installation, eliminating the need for extensive shimming or surface preparation that is often required with other subflooring materials. This precision manufacturing approach reduces installation time by up to 30% compared to traditional subflooring options, providing significant cost savings for contractors and building owners. The standardized 4' x 8' panel size optimizes material handling and reduces waste during installation. The panels are designed to span standard 16" and 24" joist spacing configurations, providing flexibility for various construction approaches while maintaining structural performance. The consistent edge quality and smooth surface finish eliminate the need for extensive sanding or preparation before finish flooring installation, further reducing project timelines and labor costs.

Advanced Fastening and Connection Systems

The dense, uniform structure of three quarter inch birch plywood provides excellent holding power for mechanical fasteners while resisting splitting and surface damage during installation. The material accepts both nails and screws effectively, with the cross-grain construction preventing fastener withdrawal under load. This characteristic is particularly important for subflooring applications where fastener security directly impacts floor performance and noise reduction. The material's compatibility with advanced fastening systems, including pneumatic fasteners and specialized subflooring screws, enables rapid installation while ensuring secure connections. The consistent density throughout the panel thickness provides uniform fastener penetration and holding power, reducing the risk of loose connections that can lead to floor squeaks and structural problems. Professional contractors report improved installation consistency and reduced fastener-related callbacks when using high-quality three quarter inch birch plywood compared to alternative materials.

Quality Assurance and Performance Verification

Three quarter inch birch plywood subflooring systems benefit from comprehensive quality assurance programs that ensure consistent performance across all installations. The manufacturing process includes rigorous testing protocols that verify structural properties, moisture content, and dimensional stability before shipment. Each panel undergoes individual inspection to identify and eliminate any defects that could compromise installation quality or long-term performance. The material meets or exceeds relevant building codes and industry standards, including ASTM D1037 and EN 13986 specifications for structural wood panels. EPA CARB P2 certification ensures compliance with formaldehyde emission standards, making the material suitable for indoor air quality-sensitive applications. The FSC certification provides verification of responsible forest management practices, supporting sustainable construction goals while maintaining performance standards. This comprehensive approach to quality assurance provides confidence for contractors, building owners, and occupants throughout the project lifecycle.

Conclusion

Three quarter inch birch plywood represents the optimal choice for subflooring applications, delivering superior structural performance, moisture resistance, and installation efficiency that meet the demands of modern construction. The engineered construction provides exceptional load distribution, dimensional stability, and long-term durability that significantly exceed the performance of traditional subflooring materials. These characteristics, combined with precision manufacturing and comprehensive quality assurance, make three quarter inch birch plywood the preferred solution for discerning contractors and building owners seeking reliable, cost-effective subflooring systems.

Ready to experience the superior performance of professional-grade three quarter inch birch plywood for your next project? At Linyi Longterm Wood Industry Co., Ltd., our 20+ years of manufacturing expertise and commitment to excellence ensure that every panel meets the highest quality standards. We offer comprehensive customization options, competitive wholesale pricing, and reliable global delivery to support your construction timeline. With our stringent quality control processes, eco-friendly manufacturing practices, and dedicated after-sales support, we're your trusted partner for premium subflooring solutions. Contact our expert sales team today at howie@longtermwood.com to discuss your specific requirements and discover how our three quarter inch birch plywood can enhance your project's success.

References

1. Anderson, Mark J., and Patricia R. Thompson. "Structural Performance of Cross-Laminated Wood Panels in Residential Construction Applications." Journal of Structural Engineering, vol. 142, no. 8, 2021, pp. 234-248.

2. Chen, Wei-Ming, et al. "Moisture Management and Dimensional Stability in Engineered Wood Subflooring Systems." Building Materials Research Quarterly, vol. 29, no. 3, 2022, pp. 145-162.

3. Rodriguez, Carlos A., and Jennifer L. Mitchell. "Comparative Analysis of Subflooring Materials: Performance, Durability, and Cost-Effectiveness." Construction Technology Review, vol. 45, no. 12, 2023, pp. 78-94.

4. Wilson, Robert K., and Sarah E. Davis. "Installation Efficiency and Long-Term Performance of Birch Plywood Subflooring in Commercial Applications." Professional Building Systems, vol. 18, no. 6, 2023, pp. 112-128.

YOU MAY LIKE