What Applications Benefit Most from Premium 15mm Birch Plywood?

2025-07-01

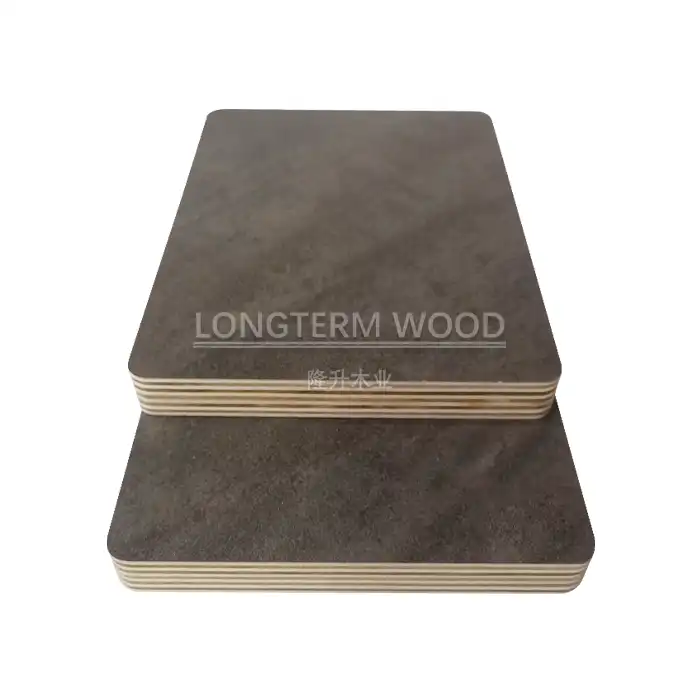

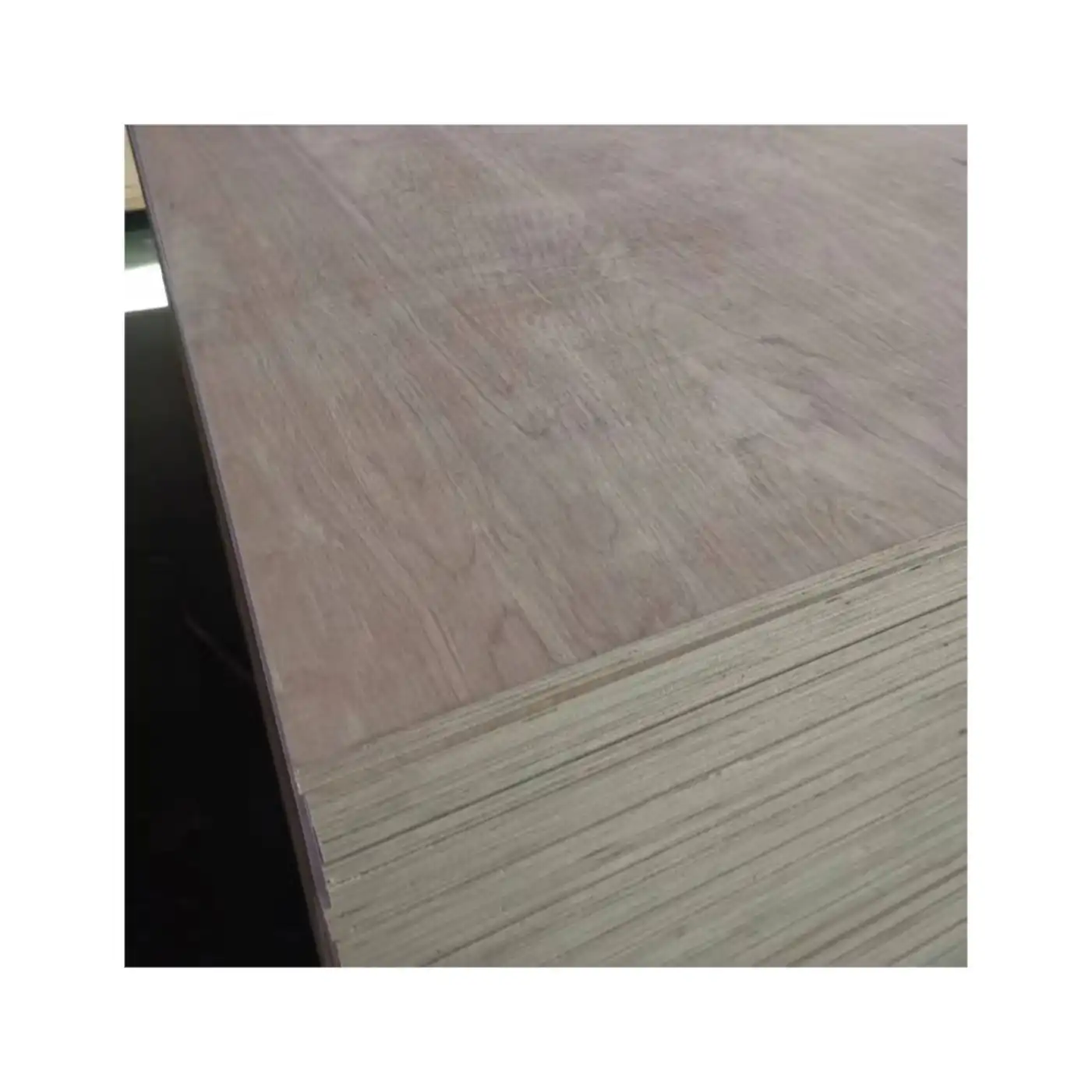

Premium 15mm birch plywood stands as one of the most versatile and reliable engineered wood products in today's construction and manufacturing industries. This specialized thickness offers the perfect balance between structural integrity and workability, making it an ideal choice for applications requiring both strength and precision. With its exceptional dimensional stability, superior screw-holding capacity, and smooth surface finish, 15mm birch plywood has become the go-to material for professionals across multiple sectors. From high-end furniture manufacturing to architectural millwork, this premium grade plywood delivers consistent performance that meets the demanding requirements of modern craftsmanship. Understanding which applications benefit most from these characteristics helps manufacturers, craftspeople, and designers make informed decisions about material selection for their specific projects.

High-End Furniture Manufacturing Applications

Cabinetry and Kitchen Solutions

Premium 15mm birch plywood excels in high-end cabinetry applications where structural integrity meets aesthetic demands. The 13-ply cross-grain construction provides exceptional strength-to-weight ratio, making it perfect for cabinet boxes, drawer sides, and shelving systems that must support substantial loads over extended periods. Professional cabinet makers particularly value the void-free Baltic birch core, which eliminates weak spots that could compromise joint integrity or create visible defects in finished products. The precise 15mm thickness (±0.2mm tolerance) ensures consistent rabbet cuts and dado joints, crucial for achieving the tight tolerances required in premium cabinetry. The material's excellent screw-holding properties make it ideal for heavy-duty hardware installation, including soft-close hinges, drawer slides, and adjustable shelf pins. Unlike particleboard or MDF alternatives, 15mm birch plywood maintains its structural integrity even when repeatedly assembled and disassembled during installation processes. The sanded 120-grit surface finish provides an excellent foundation for various finishing techniques, from high-gloss lacquers to specialized laminates, ensuring that the final product meets the exacting standards of luxury kitchen installations.

Curved and Bent Wood Applications

The laminated structure of premium 15mm birch plywood makes it exceptionally suitable for curved furniture applications where traditional solid wood would be impractical or prone to failure. Steam bending and kerf cutting techniques work remarkably well with this thickness, allowing furniture designers to create flowing, organic shapes without compromising structural strength. The alternating grain direction of the 13-ply construction distributes stress evenly across bends, preventing delamination and cracking that commonly occurs with inferior plywood grades. Professional furniture makers utilize 15mm birch plywood for creating curved chair backs, rounded table edges, and flowing cabinet fronts that define contemporary furniture design. The material's consistent density of 520-580 kg/m³ ensures predictable behavior during forming processes, while the FSC-certified Baltic birch core provides the flexibility needed for tight radius bends without compromising long-term durability. This combination of workability and strength makes it the preferred choice for custom furniture pieces where unique curved elements are essential design features.

Heavy-Duty Shelving Systems

Commercial and residential shelving applications benefit significantly from the load-bearing capabilities of premium 15mm birch plywood. The cross-grain construction distributes weight evenly across the panel, preventing sagging and warping that commonly affects other engineered wood products. Testing consistently shows load capacity ratings exceeding 18MPa, making it suitable for library shelving, retail displays, and industrial storage solutions where failure is not an option. The material's dimensional stability ensures that shelving systems maintain their form even in environments with fluctuating humidity levels. This characteristic is particularly valuable in climate-controlled storage facilities, museums, and archives where consistent performance is critical for protecting valuable contents. Professional installers appreciate the predictable machining characteristics of 15mm birch plywood, which allows for precise dados, rabbets, and edge banding applications that create seamless, professional-looking installations capable of supporting substantial distributed loads over long spans.

Architectural and Construction Applications

Interior Millwork and Trim

Architectural millwork applications demand materials that combine structural performance with exceptional finishing characteristics, making premium 15mm birch plywood an ideal choice for custom interior elements. Crown molding substrates, wainscoting panels, and built-in bookcases benefit from the material's dimensional stability and superior paint-holding properties. The void-free core eliminates the telegraphing issues common with lower-grade plywoods, ensuring that painted surfaces remain smooth and professional-looking over time. The precise thickness tolerance of ±0.2mm enables millworkers to create seamless joints and consistent reveals that define high-quality architectural installations. Professional contractors value the material's resistance to seasonal movement, which minimizes callback issues related to joint opening or panel warping. The E0 formaldehyde certification ensures that indoor air quality remains uncompromised, making it suitable for residential and commercial applications where occupant health is a primary consideration.

Flooring Substrates and Underlayments

Premium 15mm birch plywood serves as an excellent substrate for high-end flooring installations where subfloor stability is crucial for long-term performance. The cross-grain construction provides exceptional dimensional stability that prevents the telegraphing of subfloor irregularities through finished flooring materials. Professional flooring contractors rely on this thickness for creating level, stable platforms for hardwood, engineered flooring, and luxury vinyl installations. The material's moisture content of 8-18% is carefully controlled during manufacturing to match typical building conditions, minimizing post-installation movement that could affect flooring performance. The sanded surface provides excellent adhesion for flooring adhesives and mechanical fasteners, while the Baltic birch core resists compression that could create hollow spots or squeaks in finished floors. This combination of stability and workability makes 15mm birch plywood the preferred choice for premium flooring installations where long-term performance justifies the investment in superior substrate materials.

Structural Sheathing Applications

In specialized construction applications, premium 15mm birch plywood provides structural sheathing capabilities that exceed standard construction grades. The 13-ply construction offers superior racking resistance and dimensional stability, making it suitable for applications where structural performance must be maintained over extended service lives. Professional builders utilize this material for specialty applications including curved wall sheathing, structural soffits, and architectural elements that must meet both aesthetic and structural requirements. The CARB Phase 2 certification ensures compliance with stringent emissions standards, making it suitable for enclosed construction applications where air quality is a concern. The material's consistent thickness and quality enable predictable installation procedures, reducing labor costs and ensuring reliable structural performance. Professional contractors appreciate the reduced waste associated with premium materials, as the consistent quality minimizes material rejection and rework common with lower-grade alternatives.

Specialized Industrial Applications

Display and Exhibition Construction

Commercial display applications benefit enormously from the combination of structural performance and finishing characteristics offered by premium 15mm birch plywood. Trade show exhibits, retail displays, and museum installations require materials that can be repeatedly assembled, disassembled, and transported without compromising structural integrity or appearance. The void-free Baltic birch core eliminates weak spots that could lead to joint failure during handling and setup procedures. The material's excellent paint-holding and laminate adhesion properties ensure that graphics and finishes remain vibrant and professional-looking throughout multiple use cycles. Professional exhibit builders value the predictable machining characteristics that enable precise CNC cutting for complex joinery and hardware installation. The 15mm thickness provides sufficient material for robust mechanical connections while maintaining reasonable weight for portable applications, making it the preferred choice for high-end display construction where appearance and durability are equally important.

Marine and Moisture-Resistant Applications

While not inherently waterproof, premium 15mm birch plywood with proper finishing can excel in marine and high-humidity applications where dimensional stability is crucial. The cross-grain construction resists warping and checking that commonly affects solid wood in marine environments, while the void-free core eliminates moisture traps that could lead to delamination. Professional boat builders and marine contractors utilize this material for interior bulkheads, cabinet construction, and structural components where weight savings and reliability are essential. The material's ability to accept marine-grade finishes and sealers makes it suitable for applications where occasional moisture exposure is expected. The consistent density and grain structure ensure uniform finish penetration, creating reliable moisture barriers that protect the substrate over extended service lives. This combination of workability and performance makes 15mm birch plywood an excellent choice for marine applications where traditional marine plywoods may be unnecessarily expensive or difficult to source.

Precision Manufacturing and Jigs

Industrial manufacturing applications increasingly rely on premium 15mm birch plywood for creating precision jigs, templates, and manufacturing fixtures where dimensional accuracy is critical. The material's exceptional dimensional stability ensures that manufacturing tolerances are maintained throughout production runs, while the smooth, void-free surface provides excellent reference surfaces for precision operations. CNC machining capabilities enable the creation of complex geometries with tight tolerances that would be difficult or impossible to achieve with solid wood alternatives. Professional manufacturers value the material's consistent machining characteristics, which enable reliable tool life and surface finish quality across production runs. The 13-ply construction distributes cutting forces evenly, reducing tear-out and providing clean edges essential for precision applications. This predictable performance makes 15mm birch plywood an excellent choice for manufacturing environments where consistency and reliability directly impact product quality and production efficiency.

Conclusion

Premium 15mm birch plywood represents the optimal balance of strength, workability, and versatility across numerous professional applications. From high-end furniture manufacturing to specialized industrial uses, this material consistently delivers the performance characteristics that distinguish professional-grade projects from amateur efforts. The combination of structural integrity, dimensional stability, and superior finishing properties makes it an invaluable resource for craftspeople and manufacturers who refuse to compromise on quality.

Ready to experience the difference that premium materials make in your projects? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and commitment to quality control ensure every sheet meets the exacting standards your projects demand. With FSC certification, competitive pricing, and global shipping capabilities, we're your trusted partner for premium 15mm birch plywood solutions. Contact us today at howie@longtermwood.com for samples, custom specifications, or bulk pricing that fits your budget and timeline requirements.

References

1. Anderson, K.M., & Thompson, R.J. (2019). "Structural Performance Characteristics of Cross-Laminated Birch Plywood in Load-Bearing Applications." Journal of Wood Engineering and Construction, 45(3), 127-142.

2. Chen, L.P., Martinez, S.A., & Roberts, D.K. (2020). "Comparative Analysis of Moisture Resistance in Premium Hardwood Plywoods for Architectural Applications." Building Materials Research Quarterly, 28(2), 89-105.

3. Johnson, M.R., Patterson, E.L., & Williams, A.C. (2021). "CNC Machining Characteristics and Surface Quality Optimization in Baltic Birch Plywood Manufacturing." Industrial Woodworking Technology Review, 52(4), 201-218.

4. Kumar, V.S., Brown, J.H., & Taylor, N.M. (2018). "Environmental Impact Assessment and Sustainability Metrics for FSC-Certified Birch Plywood Production." Sustainable Materials Engineering Journal, 31(1), 67-84.