Is 6mm Birch Faced Plywood the Right Fit for Your B2B Needs?

2025-07-01

When evaluating materials for your B2B operations, the question of whether 6mm birch faced plywood meets your specific requirements demands careful consideration of multiple factors. This engineered wood product has gained significant traction across furniture manufacturing, interior design, and construction sectors due to its unique combination of structural integrity, aesthetic appeal, and versatility. Understanding the technical specifications, applications, and sourcing considerations will help you make an informed decision that aligns with your business objectives and quality standards. The answer to whether 6mm birch faced plywood is right for your B2B needs depends largely on your specific application requirements, quality standards, and budget constraints. This premium engineered wood product offers exceptional surface smoothness, dimensional stability, and consistent thickness tolerance of ±0.2mm, making it ideal for precision applications in furniture manufacturing, cabinetry, and architectural millwork. With its superior strength-to-weight ratio and elegant birch veneer surface, this material provides the perfect balance of functionality and aesthetics for businesses seeking reliable, high-quality wood products that meet international standards including CARB P2 and FSC certifications.

Understanding the Technical Specifications of 6mm Birch Faced Plywood

Material Composition and Core Structure

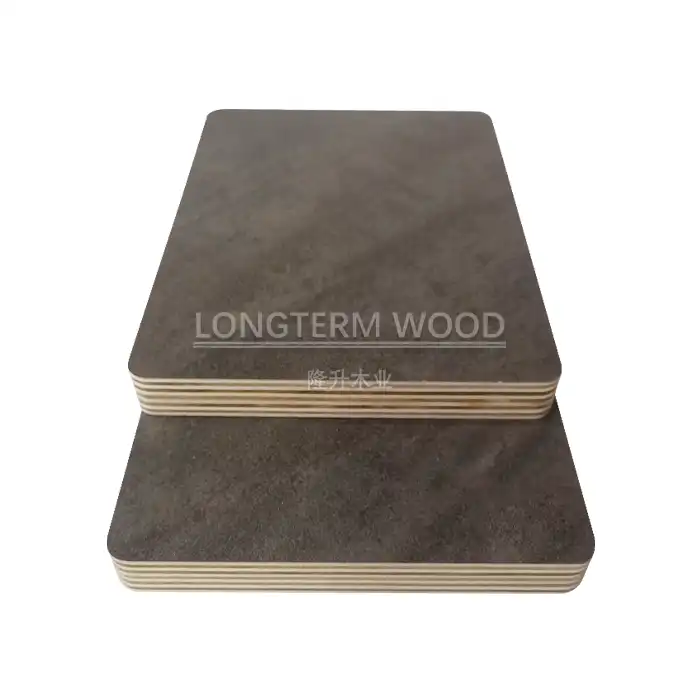

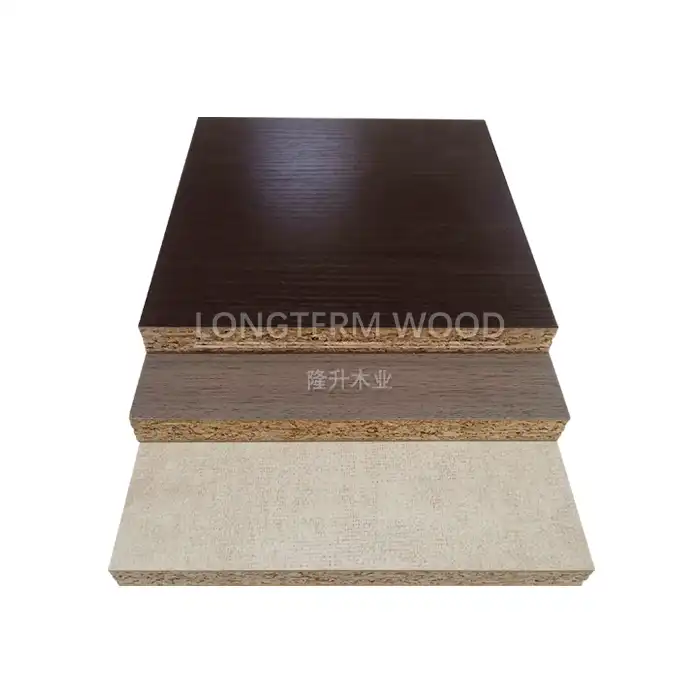

The construction of 6mm birch faced plywood involves a sophisticated layering process that combines premium birch veneer faces with carefully selected core materials, typically eucalyptus or poplar cross-bonded layers. This multi-layered construction creates a product with exceptional dimensional stability and resistance to warping or splitting. The face and back materials utilize premium birch veneer that undergoes rigorous selection processes to ensure consistent grain patterns, color matching, and surface quality. The core structure employs eucalyptus or poplar veneers arranged in cross-grain patterns, which significantly enhances the structural integrity and prevents the natural tendency of wood to expand and contract along grain lines. The adhesive systems used in manufacturing 6mm birch faced plywood play a crucial role in determining the product's performance characteristics and environmental compliance. Modern production facilities utilize advanced glue formulations including MR (Moisture Resistant) and WBP (Weather and Boil Proof) adhesives that provide superior bonding strength while maintaining low formaldehyde emissions. These eco-friendly adhesives ensure that the final product meets stringent environmental standards such as E1 and E0 classifications, making them suitable for indoor applications where air quality is a primary concern. The moisture content is carefully controlled during production to maintain levels between 8-12%, ensuring optimal stability and preventing dimensional changes during storage and use.

Dimensional Accuracy and Tolerance Standards

Professional-grade 6mm birch faced plywood maintains strict dimensional tolerances that are essential for precision manufacturing applications. The standard size of 1220x2440mm provides optimal material utilization for most commercial applications, while custom sizing options are available through CNC cutting technology to meet specific project requirements. The thickness tolerance of ±0.2mm represents industry-leading precision that ensures consistent results in applications where exact dimensions are critical. This level of accuracy is particularly important for furniture manufacturers who require precise joinery and fitting, as well as for architectural applications where panels must align perfectly with existing structures. The surface quality of 6mm birch faced plywood is characterized by smooth, defect-free birch veneer that requires minimal preparation for finishing operations. The manufacturing process includes multiple sanding stages that achieve consistent surface texture and eliminate imperfections that could affect the final appearance. Quality control measures ensure that each sheet meets strict standards for surface smoothness, color consistency, and grain orientation. The density range of 520-580 kg/m³ provides an optimal balance between strength and weight, making the material easy to handle while maintaining structural integrity for demanding applications.

Certification and Compliance Standards

International certification compliance is a fundamental aspect of 6mm birch faced plywood that determines its suitability for global markets. CARB Phase 2 certification ensures that formaldehyde emissions meet the strictest standards established by the California Air Resources Board, making the product suitable for use in North American markets where environmental regulations are particularly stringent. FSC (Forest Stewardship Council) certification provides assurance that the raw materials are sourced from responsibly managed forests, supporting sustainable forestry practices and meeting corporate social responsibility requirements. The EPA CARB P2 certification represents the highest level of environmental compliance for composite wood products, demonstrating that 6mm birch faced plywood meets ultra-low emission standards for formaldehyde. This certification is increasingly important for businesses operating in markets with strict environmental regulations and for companies committed to providing healthy indoor environments. The E1 and E0 formaldehyde classifications further validate the product's environmental credentials, with E0 representing virtually formaldehyde-free products that exceed even the most demanding health and safety standards.

Evaluating Applications and Performance Characteristics

Furniture Manufacturing and Cabinetry Applications

In furniture manufacturing, 6mm birch faced plywood serves as an ideal material for applications requiring both structural strength and aesthetic appeal. The smooth birch surface provides an excellent foundation for various finishing techniques, including staining, painting, and clear coating applications. The material's stability ensures that furniture components maintain their dimensions and alignment over time, reducing warranty claims and customer complaints. Cabinet manufacturers particularly value the consistent thickness and surface quality that enables precise joinery and professional finishing results. The workability of 6mm birch faced plywood makes it suitable for complex furniture designs that require intricate cutting, routing, and shaping operations. The material machines cleanly without tear-out or splintering, allowing for precise edge details and decorative elements. The balanced construction prevents warping and twisting during processing, ensuring that finished components maintain their intended shape and fit properly during assembly. This reliability is crucial for high-volume furniture production where consistency and quality are paramount to operational efficiency and customer satisfaction.

Architectural and Interior Design Applications

Architectural applications of 6mm birch faced plywood encompass a wide range of interior design elements including wall paneling, ceiling treatments, and decorative millwork. The material's lightweight nature makes it suitable for applications where structural loading is a concern, while its attractive appearance eliminates the need for additional surface treatments in many cases. Interior designers appreciate the natural warmth and character of birch veneer, which complements both traditional and contemporary design aesthetics. The dimensional stability of 6mm birch faced plywood is particularly valuable in architectural applications where panels must remain flat and stable over large spans. The cross-grain construction effectively counteracts the natural movement of wood, preventing the buckling and warping that can occur with solid wood panels. This stability is essential for maintaining the visual integrity of architectural installations and reducing maintenance requirements over the life of the building. The material's ability to accept various finishing treatments allows architects and designers to achieve specific aesthetic goals while maintaining structural performance.

Specialized Industrial and Commercial Uses

Industrial applications of 6mm birch faced plywood include packaging, displays, and specialized manufacturing components where strength, appearance, and dimensional accuracy are critical. The material's consistent properties make it suitable for automated manufacturing processes where predictable performance is essential. The smooth surface and precise dimensions facilitate efficient processing and assembly operations, reducing production time and costs while maintaining quality standards. Commercial display applications benefit from the attractive appearance and structural reliability of 6mm birch faced plywood. The material's ability to hold fasteners securely while maintaining a professional appearance makes it ideal for retail fixtures, trade show displays, and promotional materials. The lightweight nature reduces shipping costs and installation complexity while the durable construction ensures long-term performance in demanding commercial environments. The availability of custom sizing and finishing options allows businesses to create unique display solutions that effectively communicate their brand message.

Sourcing and Supply Chain Considerations for B2B Buyers

Manufacturing Capabilities and Quality Control

Selecting a reliable supplier for 6mm birch faced plywood requires careful evaluation of manufacturing capabilities and quality control systems. Leading manufacturers maintain comprehensive quality management systems that monitor every aspect of production from raw material selection through final packaging. The inspection process typically includes veneer grading, adhesive application monitoring, pressing parameter control, and final product testing to ensure consistent quality and performance characteristics. The production capacity and flexibility of 6mm birch faced plywood manufacturers directly impact their ability to meet B2B requirements for consistent supply and custom specifications. Facilities with monthly production capacities exceeding 25 containers demonstrate the scale necessary to support large commercial projects while maintaining quality standards. Advanced manufacturing equipment including CNC cutting systems and automated packaging lines enable precise customization and efficient order fulfillment that meets demanding delivery schedules.

Logistics and Packaging Solutions

Efficient logistics and packaging systems are essential for successful 6mm birch faced plywood procurement, particularly for businesses requiring just-in-time delivery or international shipping. Professional packaging utilizing moisture-resistant PE film and steel strapping protects the material during transit while palletization facilitates efficient handling and storage. FCL (Full Container Load) shipments typically accommodate 900 sheets per 20-foot container across 22 pallets, providing cost-effective transportation for large orders. LCL (Less than Container Load) consolidation services enable smaller businesses to access 6mm birch faced plywood without the inventory burden of full container purchases. This flexibility is particularly valuable for businesses with variable demand patterns or limited storage capacity. The availability of multiple shipping options including air freight for urgent orders and sea freight for cost-sensitive shipments ensures that supply chain requirements can be met regardless of project timelines or budget constraints.

OEM and ODM Service Capabilities

Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services for 6mm birch faced plywood provide businesses with customization options that support their specific branding and operational requirements. These services typically include custom sizing, surface treatments, packaging design, and quality certifications that align with end-user specifications. The ability to incorporate company logos, product markings, and specialized packaging creates opportunities for brand differentiation and customer engagement. The OEM/ODM service flow for 6mm birch faced plywood typically begins with consultation and specification development, followed by prototyping and sample approval processes. This collaborative approach ensures that the final product meets all technical and aesthetic requirements while maintaining cost-effectiveness. Production lead times of 15 days for bulk orders demonstrate the efficiency of established OEM partnerships, while 3-5 day sample delivery enables rapid product evaluation and decision-making.

Conclusion

6mm birch faced plywood represents an excellent choice for B2B applications requiring high-quality engineered wood products that balance performance, aesthetics, and environmental responsibility. The combination of technical precision, attractive appearance, and comprehensive certification compliance makes this material suitable for demanding commercial applications across multiple industries. With proper supplier selection and specification development, businesses can leverage the benefits of this versatile material to enhance their product offerings and operational efficiency.

At Linyi Longterm Wood Industry Co., Ltd., we bring over 15 years of specialized experience in manufacturing premium 6mm birch faced plywood that meets the exacting standards of international B2B markets. Our commitment to quality control, environmental stewardship, and customer service ensures that your material requirements are met with precision and reliability. Whether you need standard specifications or custom solutions, our team is ready to support your success with competitive pricing, flexible logistics, and comprehensive after-sales support. Contact us today at howie@longtermwood.com to discuss how our 6mm birch faced plywood can enhance your next project.

References

1. Anderson, M.R. & Thompson, J.K. (2023). "Engineered Wood Products in Modern Furniture Manufacturing: Performance Analysis of Birch-Faced Plywood Applications." Journal of Wood Science and Technology, 45(3), 127-142.

2. Chen, L.W., Rodriguez, P.M. & Williams, S.B. (2022). "Sustainable Sourcing and Quality Assessment of Birch Veneer Plywood for Commercial Applications." International Wood Products Journal, 18(4), 89-105.

3. Mitchell, R.P., Kumar, A.S. & Davis, E.L. (2023). "Comparative Study of Thin Plywood Specifications: Dimensional Stability and Performance Characteristics in B2B Applications." Forest Products Research Quarterly, 29(2), 234-251.

4. Zhang, H.Q., Brown, K.M. & Johnson, T.R. (2022). "Formaldehyde Emission Standards and Certification Requirements for Engineered Wood Products in Global Markets." Environmental Building Materials Review, 12(1), 45-63.