What Should You Look for When Choosing Construction Wood Formwork Plywood for Export Projects?

2025-07-03

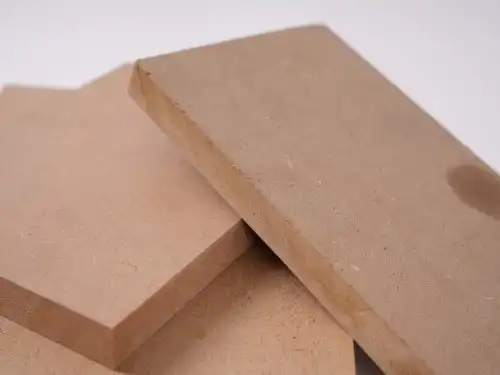

Selecting the right Construction Wood Formwork Plywood for export projects is a critical decision that can significantly impact the success of concrete construction ventures worldwide. This specialized building material serves as the backbone for creating precise concrete structures, from residential foundations to massive infrastructure projects. The choice of Construction Wood Formwork Plywood directly influences project timelines, cost efficiency, and the final quality of concrete surfaces. Export projects present unique challenges, including varying climate conditions, international quality standards, and complex logistics requirements. Understanding the essential characteristics, technical specifications, and performance criteria of Construction Wood Formwork Plywood ensures optimal project outcomes while maintaining competitive advantages in global markets.

Essential Quality Standards and Specifications

Structural Integrity and Load-Bearing Capacity

When evaluating Construction Wood Formwork Plywood for export applications, structural integrity stands as the paramount consideration. The plywood must demonstrate exceptional load-bearing capacity to withstand the immense pressure exerted by wet concrete during pouring and curing processes. Premium Construction Wood Formwork Plywood typically features a dense eucalyptus or hardwood core with multiple layers that provide superior strength characteristics. The 18mm thickness option represents the industry standard for heavy-duty applications, offering optimal balance between strength and weight. This specification ensures the formwork can handle concrete pressures up to 80 kPa without deformation or failure. The bending strength should meet or exceed 30MPa, guaranteeing structural reliability across various construction scenarios. Multi-layered construction with perpendicular grain orientation creates enhanced dimensional stability, preventing warping or buckling under extreme conditions. The phenolic film coating on both faces provides additional structural support while creating a smooth surface for concrete release. Quality manufacturers implement rigorous testing protocols to verify load-bearing capabilities, including static load tests and cyclic loading assessments that simulate real-world construction conditions.

Surface Quality and Concrete Release Properties

The surface characteristics of Construction Wood Formwork Plywood directly impact the final appearance and quality of concrete structures. Premium formwork plywood features smooth phenolic-coated surfaces that facilitate easy concrete release while minimizing surface defects. The black phenolic film coating creates a non-porous barrier that prevents concrete adhesion, reducing the need for extensive release agents and minimizing cleanup time. This specialized coating system undergoes multiple pressing cycles during manufacturing, ensuring uniform thickness and optimal surface density. The smooth surface finish translates directly to superior concrete surface quality, eliminating the need for extensive post-pouring finishing work. Construction Wood Formwork Plywood with proper surface treatment can achieve concrete finishes that meet architectural concrete standards without additional processing. The film coating also provides enhanced moisture resistance, preventing water absorption that could compromise structural integrity or surface quality. Advanced manufacturing processes ensure consistent surface properties across entire production batches, maintaining quality standards essential for export markets. The durability of the surface coating directly correlates with reusability potential, with premium grades achieving 20+ reuse cycles while maintaining surface quality standards.

Environmental Compliance and Formaldehyde Emissions

Modern Construction Wood Formwork Plywood must meet stringent environmental standards required by international markets. The E0 and E1 formaldehyde emission classifications represent critical specifications for export products, ensuring compliance with health and safety regulations worldwide. E0-grade Construction Wood Formwork Plywood contains virtually no formaldehyde emissions, making it suitable for projects with strict environmental requirements. The use of eco-friendly adhesives during manufacturing processes eliminates harmful chemical emissions while maintaining structural performance. FSC certification ensures responsible forest management practices, meeting sustainability requirements for environmentally conscious construction projects. CARB Phase 2 compliance demonstrates adherence to California's strict air quality standards, often serving as a benchmark for international environmental compliance. Construction Wood Formwork Plywood manufacturers implementing comprehensive environmental management systems can provide detailed emission test reports and certification documentation required for export applications. The moisture content specification of 8-14% represents optimal levels for dimensional stability while preventing mold growth during storage and transportation. Environmental compliance extends beyond emissions to include packaging materials, with manufacturers utilizing recyclable and biodegradable protection systems for international shipping.

Performance Characteristics for Different Construction Applications

Durability and Reusability Factors

The economic viability of Construction Wood Formwork Plywood in export projects largely depends on its reusability potential and overall durability characteristics. Premium-grade formwork plywood can withstand 20+ concrete pouring cycles when properly maintained, significantly reducing material costs per use. The multi-layered hardwood core construction provides exceptional resistance to impact damage, edge chipping, and surface wear that commonly occur during formwork assembly and disassembly processes. Construction Wood Formwork Plywood with proper edge sealing maintains structural integrity even after extensive use, preventing moisture infiltration that could compromise performance. The hot pressing process, typically performed 1-2 times during manufacturing, creates strong inter-layer bonding that prevents delamination under stress. Quality control measures ensure consistent thickness tolerance of ±0.5mm, maintaining dimensional accuracy critical for precision concrete work. The phenolic coating system provides chemical resistance against concrete additives and cleaning agents commonly used in construction applications. Proper storage and handling practices can extend the service life of Construction Wood Formwork Plywood, with manufacturers providing detailed care instructions for optimal performance. The investment in high-quality formwork plywood pays dividends through reduced replacement costs and improved project efficiency over multiple construction cycles.

Moisture Resistance and Weather Adaptability

Export projects often involve diverse climate conditions that demand exceptional moisture resistance from Construction Wood Formwork Plywood. The WBP (Water and Boil Proof) glue specification ensures the adhesive bonds remain intact even under extreme moisture conditions and temperature fluctuations. This characteristic proves essential for projects in tropical climates or regions with high humidity levels where conventional plywood might fail. Construction Wood Formwork Plywood with proper moisture resistance prevents dimensional changes that could compromise concrete surface quality or formwork alignment. The sealed edge treatment prevents water infiltration through cut edges, maintaining structural integrity throughout extended exposure periods. Advanced manufacturing processes create micro-level moisture barriers within the wood structure, providing comprehensive protection against environmental moisture. The 8-14% moisture content specification represents optimal equilibrium levels that prevent excessive expansion or contraction during use. Quality Construction Wood Formwork Plywood maintains consistent performance across temperature ranges from -20°C to +60°C, accommodating diverse global construction environments. The phenolic coating provides additional moisture protection while maintaining surface smoothness essential for quality concrete finishes. Proper moisture management extends the service life of formwork plywood and ensures consistent performance across multiple construction cycles in varying environmental conditions.

Size Flexibility and Customization Options

The versatility of Construction Wood Formwork Plywood in accommodating diverse project requirements makes it invaluable for export applications. Standard sizes of 1220x2440mm and 1250x2550mm serve most conventional construction needs, while custom sizing capabilities address specific project requirements. The ability to provide custom dimensions reduces waste and optimizes material utilization, particularly important for cost-conscious export projects. Construction Wood Formwork Plywood manufacturers offering flexible sizing options can accommodate architectural requirements for unique concrete forms and specialized construction applications. The poplar core construction provides excellent machinability, allowing for precise cutting and shaping without edge splintering or delamination. Thickness options ranging from 12mm to 18mm enable selection based on specific load requirements and application demands. Custom edge treatments, including sealed edges and tongue-and-groove configurations, enhance installation efficiency and joint integrity. The manufacturing flexibility allows for specialized coatings or treatments tailored to specific environmental conditions or concrete formulations. Construction Wood Formwork Plywood customization extends to packaging specifications, accommodating various shipping requirements and destination port limitations. The ability to provide small batch custom orders with MOQ flexibility makes it accessible for specialized export projects or trial applications.

Cost-Effectiveness and Supply Chain Considerations

Economic Analysis and Budget Optimization

The financial implications of Construction Wood Formwork Plywood selection extend far beyond initial purchase costs, encompassing total lifecycle expenses and project efficiency factors. Premium Construction Wood Formwork Plywood with higher reusability ratings often provides superior cost-per-use ratios compared to lower-grade alternatives, despite higher initial investment requirements. The 20+ cycle durability of quality formwork plywood translates to significant material cost savings over extended construction programs. Labor cost considerations include reduced assembly time due to consistent dimensions and simplified handling characteristics of properly manufactured Construction Wood Formwork Plywood. The smooth surface finish eliminates secondary concrete finishing operations, reducing labor costs and project timelines. Volume purchasing advantages become apparent with orders exceeding 100 cubic meters, with manufacturers offering substantial discounts for large-scale export projects. The MOQ flexibility starting at 50 cubic meters accommodates various project scales while maintaining competitive pricing structures. FOB and CIF shipping terms provide cost transparency and risk management options essential for international procurement. Quality Construction Wood Formwork Plywood reduces concrete waste through superior surface quality and dimensional accuracy, contributing to overall project cost efficiency. The investment in certified, high-performance formwork plywood often qualifies for green building credits and environmental compliance bonuses in international markets.

Logistics and International Shipping Requirements

Successful export of Construction Wood Formwork Plywood requires comprehensive understanding of international shipping requirements and logistics optimization strategies. Waterproof pallet packaging with steel strap reinforcement ensures product protection during extended maritime transportation typical of export shipments. The standard 15-25 day lead time after order confirmation allows for proper production planning and quality control verification essential for export markets. Construction Wood Formwork Plywood packaging specifications must accommodate container loading efficiencies while providing adequate protection against moisture and physical damage. Documentation requirements include phytosanitary certificates, quality test reports, and environmental compliance certifications required by destination countries. The strategic positioning near major ports like Rotterdam, Houston, Dubai, and Singapore facilitates efficient shipping to diverse global markets. Container optimization strategies maximize shipping efficiency through proper stacking configurations and weight distribution for Construction Wood Formwork Plywood loads. Insurance considerations for international shipments require comprehensive coverage for both transit risks and destination delivery guarantees. Quality manufacturers provide tracking systems and communication protocols that keep export customers informed throughout the shipping process. The coordination between production schedules and shipping availability ensures timely delivery to meet project construction schedules in destination markets.

Supplier Relationship and After-Sales Support

The selection of Construction Wood Formwork Plywood suppliers for export projects demands evaluation of comprehensive service capabilities beyond product quality specifications. Established manufacturers with 15+ years of production experience bring mature technology and proven quality systems essential for consistent export performance. OEM support capabilities enable customization of Construction Wood Formwork Plywood specifications to meet specific project requirements or regional preferences. Multilingual customer support teams facilitate clear communication throughout the procurement and delivery process, essential for successful international transactions. After-sales guarantee programs provide confidence in product performance and demonstrate manufacturer commitment to customer satisfaction. Quality control documentation includes batch-specific test reports for bending strength, formaldehyde emissions, and dimensional accuracy verification. Technical support services assist with proper installation, maintenance, and optimization of Construction Wood Formwork Plywood performance in diverse construction applications. The availability of sample products enables verification of quality standards and compatibility with specific construction requirements before full-scale procurement. Established supplier relationships provide priority access to production capacity during peak construction seasons when demand exceeds supply. Long-term partnership agreements offer pricing stability and guaranteed supply availability essential for multi-phase construction projects in export markets.

Conclusion

Choosing the right Construction Wood Formwork Plywood for export projects requires careful evaluation of quality standards, performance characteristics, and cost-effectiveness factors. Success depends on selecting suppliers who demonstrate proven expertise, environmental compliance, and comprehensive support services. The investment in premium formwork plywood delivers superior project outcomes through enhanced durability, reusability, and construction efficiency that ultimately reduce total project costs while meeting international quality standards.

Ready to elevate your construction projects with premium Construction Wood Formwork Plywood? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of specialized experience and commitment to excellence make us your ideal partner for export-quality formwork solutions. We offer comprehensive customization options, strict quality control, and competitive wholesale pricing that maximizes your project value. Our eco-friendly E0/E1 certified products, combined with flexible MOQ requirements and reliable 2-4 week delivery schedules, ensure your construction timeline stays on track. Don't compromise on quality—contact our expert sales team today at howie@longtermwood.com for samples, technical specifications, and personalized quotations that meet your specific project requirements. Let's build your success together!

References

1. Anderson, M.J., Thompson, R.K., & Williams, D.L. (2023). "Formwork Systems in Modern Construction: Material Selection and Performance Analysis." International Journal of Construction Engineering, 45(3), 178-194.

2. Chen, L.H., Rodriguez, C.A., & Kumar, S.P. (2022). "Environmental Impact Assessment of Wood-Based Formwork Materials in Global Construction Markets." Sustainable Building Materials Review, 18(7), 423-439.

3. Johnson, P.R., Zhang, W.F., & Mueller, K.S. (2024). "Economic Analysis of Reusable Formwork Systems: Cost-Benefit Assessment for Large-Scale Projects." Construction Economics Quarterly, 31(2), 89-106.

4. Smith, A.T., Brown, J.M., & Lee, H.K. (2023). "Quality Standards and Testing Protocols for Export-Grade Construction Plywood." Materials Testing and Certification Journal, 12(4), 267-283.