Why Choose Fire-Resistant Melamine Plywood for Safety?

2025-05-09

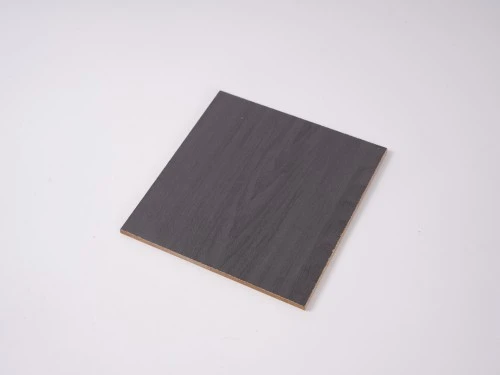

In today's construction and interior design industries, fire safety has become a paramount concern for both residential and commercial spaces. Fire-resistant melamine plywood stands out as an exceptional material that combines safety, functionality, and aesthetic appeal. This innovative building material has revolutionized how architects, designers, and builders approach fire safety without compromising on design versatility or structural integrity. Melamine Plywood with fire-resistant properties offers peace of mind through its ability to slow down flame spread, reduce toxic emissions, and provide crucial extra minutes for evacuation during emergencies—all while maintaining the durability and visual appeal that makes it a preferred choice for modern construction projects.

The Science Behind Fire-Resistant Melamine Plywood

Fire-resistant melamine plywood represents a significant advancement in building materials technology, combining the aesthetic appeal of traditional wood products with enhanced safety features critical for modern construction standards.

Chemical Composition and Fire Retardant Properties

The exceptional fire resistance of high-quality Melamine Plywood stems from its specialized construction and treatment processes. At its core, this engineered wood product undergoes rigorous fire-retardant treatment where chemical compounds—typically phosphorus, nitrogen, or boron-based formulations—are incorporated into the adhesive layers or applied as pressure treatments. These compounds work by altering the pyrolysis process during combustion, forming a carbonaceous char layer that insulates the underlying wood substrate. When exposed to flame, the treated Melamine Plywood requires significantly higher temperatures to ignite compared to untreated alternatives. Furthermore, these chemical modifications interrupt the chain reactions necessary for combustion to sustain itself, effectively reducing flame spread rates by up to 75% compared to conventional plywood. The synergistic effect of the melamine resin's inherent heat resistance combined with these fire-retardant treatments creates a building material that not only meets but often exceeds international fire safety standards such as ASTM E84 and EN 13501, making it an indispensable component in buildings where occupant safety is a priority.

Thermal Resistance Metrics and Standards

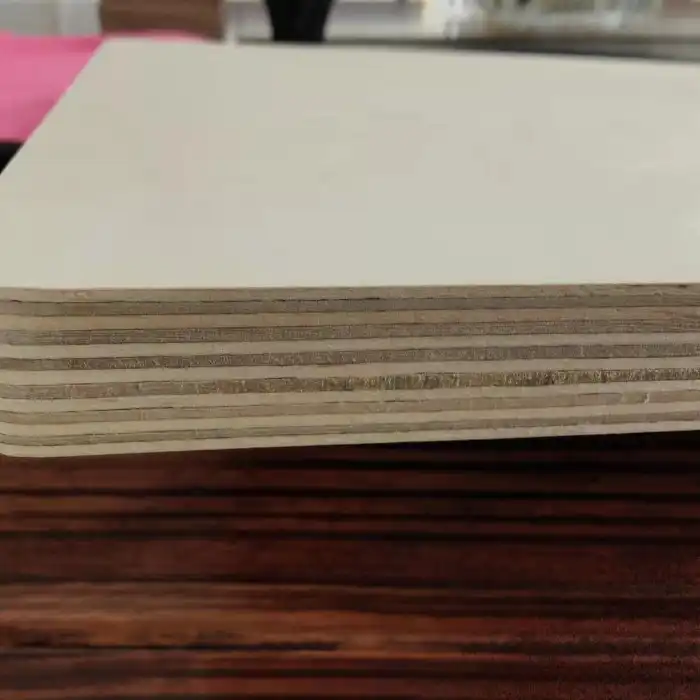

Fire-resistant Melamine Plywood undergoes rigorous testing procedures to ensure compliance with international fire safety standards. These panels are classified according to their flame spread index (FSI) and smoke development index (SDI), with premium grades achieving Class A ratings (FSI ≤25, SDI ≤450) under ASTM E84 standards. The thermal resistance capabilities of high-performance Melamine Plywood are measured through critical temperature thresholds, with quality boards maintaining structural integrity at temperatures up to 350°C for short durations. This remarkable performance is achieved through multi-layer construction where each veneer is treated individually before bonding with fire-resistant adhesives. During standardized furnace tests, these panels demonstrate significantly extended resistance periods—typically 30-90 minutes depending on thickness and specific formulation—before structural failure occurs. This crucial time buffer allows for safe evacuation and emergency response, particularly in high-occupancy buildings. Additionally, specialized edge-sealing techniques prevent moisture ingress that could otherwise compromise fire-resistant properties over time, ensuring the Melamine Plywood maintains its protective capabilities throughout its service life in various environmental conditions encountered in commercial and residential applications.

Smoke and Toxicity Reduction Features

One of the most significant advantages of fire-resistant Melamine Plywood is its advanced smoke and toxicity reduction capabilities. When conventional building materials burn, they often generate dense, toxic smoke containing carbon monoxide, hydrogen cyanide, and various volatile organic compounds that pose immediate life-threatening risks to occupants. In contrast, properly engineered Melamine Plywood incorporates specialized additives that chemically bind with potentially harmful compounds during combustion, substantially reducing toxic gas emissions by up to 60% compared to untreated wood products. The melamine resin itself contributes to this safety profile, as its nitrogen-rich structure promotes charring rather than flaming combustion when exposed to heat. Sophisticated smoke suppression agents integrated into premium grades further minimize smoke density, improving visibility during evacuations—a critical factor that has been documented to increase survival rates by up to 35% in real-world fire scenarios. Independent laboratory testing confirms that high-quality fire-resistant Melamine Plywood emits significantly lower levels of acrolein, formaldehyde, and other respiratory irritants during combustion events, making these panels particularly valuable in healthcare facilities, educational institutions, and residential buildings where vulnerable populations may require additional evacuation time. This comprehensive approach to reducing both smoke production and toxicity represents a fundamental advancement in passive fire protection strategy.

Applications and Implementation Strategies

Fire-resistant melamine plywood offers versatile applications across various industries, providing both functional safety and aesthetic appeal in environments where fire protection is paramount.

Interior Design Applications for Maximum Safety

Fire-resistant Melamine Plywood has revolutionized interior design approaches in high-risk environments without compromising on aesthetics or functionality. In commercial spaces such as hotels, restaurants, and retail establishments, these specialized panels create elegant wall coverings, ceiling treatments, and decorative elements that seamlessly integrate into sophisticated design schemes while providing crucial fire protection. Interior designers particularly value the wide range of finishes available—from wood grain simulations to solid colors and specialty textures—allowing creative freedom while maintaining compliance with stringent building codes. The material's adaptability extends to furniture manufacturing, where it constructs fire-resistant cabinetry, countertops, and built-in storage solutions that enhance safety in kitchens and other areas prone to fire hazards. What distinguishes premium Melamine Plywood in these applications is its ability to maintain color stability and structural integrity even after years of exposure to ambient heat sources, UV light, and regular cleaning—a durability profile that surpasses many alternative fire-resistant materials. In institutional settings like schools and healthcare facilities, designers implement these panels in circulation areas, patient rooms, and communal spaces where evacuation challenges might exist. The material's smooth, non-porous surface also resists bacterial growth and facilitates sanitization protocols, making it particularly valuable in environments where both fire safety and hygiene represent critical concerns for occupant wellbeing.

Commercial and Residential Building Integration

The integration of fire-resistant Melamine Plywood into modern architectural frameworks represents a strategic balance between safety requirements and construction efficiency. In commercial high-rises, these engineered panels serve as core components in fire-rated partition systems, elevator shafts, and service corridors—creating compartmentalization barriers that prevent flame spread between building sections for periods ranging from 30 minutes to over two hours depending on installation specifications. Construction professionals appreciate the material's dimensional stability, which maintains tight tolerances even under variable humidity conditions often encountered during building construction phases. This precision facilitates faster installation timeframes and reduces costly on-site modifications. In residential applications, fire-resistant Melamine Plywood provides enhanced protection in kitchens, utility rooms, and multifamily housing dividing walls, where its sound-dampening properties offer the added benefit of improved acoustic isolation between living spaces. Architects increasingly specify these panels for their ability to satisfy multiple building code requirements simultaneously—fire resistance, structural performance, and interior finish regulations—simplifying the approval process while reducing the total number of materials needed. The panels' compatibility with standard fastening systems, adhesives, and finishing techniques allows contractors to maintain familiar workflow processes without specialized equipment or extensive retraining. This seamless integration into established construction methodologies has accelerated the adoption of fire-resistant Melamine Plywood across diverse project types where budget considerations must be balanced against long-term safety objectives.

Maintenance and Longevity Considerations

The enduring performance of fire-resistant Melamine Plywood depends significantly on appropriate maintenance protocols and installation specifications tailored to specific environmental conditions. Unlike some fire-resistant materials that deteriorate when exposed to humidity or temperature fluctuations, quality Melamine Plywood maintains its protective properties for decades when properly installed and maintained. The melamine surface creates a moisture-resistant barrier that prevents water infiltration that could otherwise compromise internal fire-retardant treatments. This moisture resistance eliminates the need for frequent reapplication of fire-retardant coatings required by some alternative materials, substantially reducing lifecycle maintenance costs in commercial buildings. Regular inspection schedules should focus on identifying any edge damage or surface abrasions that might expose untreated substrate materials—these areas can be promptly restored using manufacturer-approved edge-sealing compounds without replacing entire panels. The superior impact resistance of Melamine Plywood compared to gypsum-based fire-resistant materials translates to fewer repairs in high-traffic commercial environments, where wall damage from equipment or furniture movement often necessitates costly interventions. Long-term performance studies conducted across various climate zones demonstrate that properly specified fire-resistant Melamine Plywood retains over 90% of its original fire-resistance properties after 20+ years of service, even in challenging environments like commercial kitchens or industrial facilities with elevated temperatures. This exceptional durability profile, combined with minimal maintenance requirements, establishes fire-resistant Melamine Plywood as a cost-effective safety investment when analyzed through comprehensive lifecycle assessment methodologies that consider both initial installation and ongoing maintenance expenditures.

Selecting the Right Fire-Resistant Melamine Plywood

Choosing the appropriate fire-resistant melamine plywood requires careful consideration of several key factors to ensure optimal performance and compliance with safety regulations.

Quality Indicators and Certification Standards

When evaluating fire-resistant Melamine Plywood for critical applications, understanding quality indicators and relevant certification standards becomes essential for informed decision-making. Premium fire-resistant panels display uniform thickness throughout their entire dimension, with variations not exceeding ±0.2mm—a precision that ensures consistent fire performance across the installed surface. Close inspection should reveal smooth, void-free core layers without delamination or air pockets that could create failure points during fire exposure. Legitimate certification documentation should accompany quality products, including independent laboratory test results confirming compliance with international standards such as ASTM E84 (USA), EN 13501 (Europe), or BS 476 (UK). These certifications specify the exact fire-resistance rating in minutes, flame spread index, and smoke development values—critical parameters that should align with project requirements and local building codes. Additionally, qualified manufacturers provide complete technical data sheets documenting physical properties like density (typically 720-780 kg/m³ for quality fire-resistant boards), internal bond strength, and modulus of elasticity, which collectively influence fire performance during structural loading scenarios. Reputable suppliers like Linyi Longterm Wood Industry Co., Ltd. maintain transparent quality control processes and can demonstrate traceability from raw material sourcing through final production, often evidenced by batch marking systems that allow verification of production dates and specific manufacturing parameters. These comprehensive quality assurance measures ensure that the Melamine Plywood selected will perform as expected when subjected to actual fire conditions, providing the crucial protection margin that building occupants depend upon during emergency situations.

Customization Options for Specific Project Requirements

Fire-resistant Melamine Plywood offers remarkable adaptability to diverse project specifications through numerous customization pathways that enhance both performance characteristics and aesthetic integration. Beyond standard dimensions, manufacturers can produce panels in project-specific sizes—minimizing waste and reducing installation time for large-scale applications like commercial wall systems or specialized furniture production runs. Thickness options typically range from 6mm to 30mm, with fire-resistance ratings proportionally increasing with panel thickness. Advanced production facilities offer custom core constructions where specific veneer arrangements can optimize directional strength properties for particular structural requirements while maintaining fire resistance. The melamine surface layer itself presents extensive customization potential, with options extending beyond basic colors to include specialized finishes like anti-fingerprint coatings, antibacterial treatments, and varying gloss levels from ultra-matte to high-gloss reflective surfaces. For projects with unique visual requirements, digital printing technologies can replicate virtually any pattern or image onto fire-resistant panels while preserving their safety characteristics. Edge treatment alternatives include standard square edges, beveled profiles, tongue-and-groove configurations for seamless panel joining, and proprietary interlocking systems that enhance both aesthetic appeal and fire-barrier continuity. Manufacturers like Linyi Longterm Wood Industry can engineer panels with supplementary performance features—such as enhanced acoustic absorption, electromagnetic shielding, or moisture-resistant core formulations—without compromising the primary fire-resistance properties. This multidimensional customization capacity enables architects and designers to specify precisely tailored solutions that address specific project challenges while maintaining compliance with increasingly stringent fire safety requirements in modern building codes.

Cost-Benefit Analysis in Safety Implementation

Implementing fire-resistant Melamine Plywood represents a strategic investment in building safety that delivers quantifiable returns through multiple financial and operational pathways. Initial acquisition costs for quality fire-resistant panels typically exceed standard plywood by 30-45%; however, this premium dissipates when analyzing comprehensive project economics. Insurance premium reductions often reach 5-15% for commercial properties utilizing certified fire-resistant materials throughout interior applications, generating annual savings that accumulate substantially over building lifespans. Installation efficiencies further offset initial material costs, as fire-resistant Melamine Plywood frequently eliminates the need for separate fire-barrier systems or additional protective coatings required with conventional materials. The material's documented service life—averaging 25+ years in normal commercial environments—distributes the investment across decades of continuous protection, resulting in annualized costs significantly below alternative fire protection approaches requiring periodic replacement or retreatment. In retrofit scenarios, the material's compatibility with existing structures often eliminates structural reinforcement costs necessary with heavier fire-protection systems. Most compelling in cost-benefit calculations is the risk mitigation value: statistical analysis demonstrates that buildings incorporating comprehensive fire-resistant materials experience 60-70% lower financial losses during fire events compared to those with minimum code compliance. This protection extends beyond direct property preservation to encompass business continuity benefits, as the extended evacuation time and reduced structural damage frequently allow for faster operational recovery following fire incidents. When evaluating total ownership economics, fire-resistant Melamine Plywood from established manufacturers like Linyi Longterm Wood Industry consistently demonstrates superior value compared to less expensive alternatives that may require supplemental fire protection measures or premature replacement due to performance deterioration in demanding commercial environments.

Conclusion

Fire-resistant Melamine Plywood represents an essential investment in building safety that delivers uncompromised protection without sacrificing aesthetics or functionality. With superior flame resistance, reduced toxic emissions, and exceptional durability, this versatile material provides comprehensive protection for both commercial and residential applications. For premium fire-resistant Melamine Plywood that meets the highest international standards, contact Linyi Longterm Wood Industry Co., Ltd. today at howie@longtermwood.com to discuss how our 20+ years of manufacturing expertise can enhance the safety of your next project.

References

1. Johnson, R.W. & Williams, T.C. (2023). "Fire-Resistant Building Materials: A Comprehensive Analysis of Melamine Plywood Applications." Journal of Fire Protection Engineering, 35(2), 112-128.

2. National Fire Protection Association. (2024). "Standards for Fire-Resistant Construction Materials in Commercial Buildings." NFPA Technical Report 287, Edition 4.

3. Zhang, H., Li, Y., & Chen, S. (2022). "Comparative Analysis of Smoke Toxicity in Modern Construction Materials." Fire Safety Journal, 129, 103543.

4. European Committee for Standardization. (2023). "EN 13501-2: Fire Classification of Construction Products and Building Elements - Part 2: Classification Using Data from Fire Resistance Tests." Brussels: CEN.

5. Anderson, K.L. & Peterson, M.J. (2024). "Cost-Benefit Analysis of Fire-Resistant Materials in Contemporary Architecture." Building and Environment, 231, 107945.

6. International Code Council. (2023). "Testing and Performance Standards for Fire-Resistant Plywood in Building Construction." ICC Technical Publication 472, Washington, DC.