How Does Melamine Plywood Fulfill Interior Design Requirements?

2025-05-20

In the realm of interior design, material selection plays a pivotal role in achieving both aesthetic appeal and functional durability. Melamine plywood stands at the forefront of designer preferences as a versatile solution that bridges the gap between beauty and practicality. This engineered wood product combines the structural integrity of plywood with the decorative and protective qualities of melamine resin, resulting in a material that satisfies multiple interior design requirements simultaneously. From residential spaces to commercial environments, melamine plywood offers a perfect blend of visual appeal, durability, cost-effectiveness, and environmental responsibility, making it an indispensable resource for designers aiming to create spaces that are both stunning and sustainable.

Design Versatility of Melamine Plywood

Aesthetic Flexibility

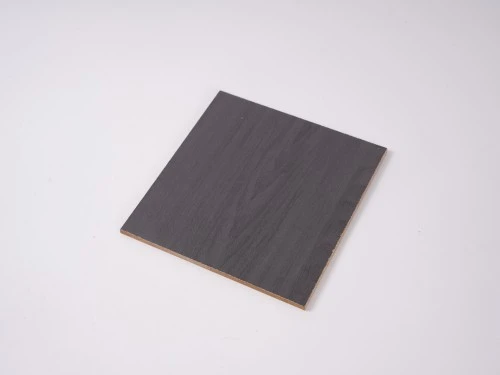

Melamine plywood transforms interior spaces through its remarkable aesthetic versatility. Available in an extensive range of colors, patterns, and finishes, this material offers designers unlimited creative potential to realize their vision. Whether replicating the warm, natural look of wood grain, the sleek modernity of solid colors, or custom patterns that become signature design elements, melamine plywood adapts to diverse style preferences. The surface quality of premium melamine plywood delivers exceptional color consistency and finish uniformity, ensuring that design elements maintain visual coherence throughout an interior space. This consistency is particularly valuable in large-scale commercial projects where multiple panels must work in harmony. Moreover, the precision with which manufacturers like Linyi Longterm Wood Industry Co, Ltd. can produce specific finishes—from high gloss that reflects light dramatically to subtle matte textures that absorb it—allows designers to manipulate spatial perception and ambiance through material selection. The dimensional stability of melamine plywood prevents warping and maintains the intended design appearance over time, unlike some natural materials that might shift or change with environmental conditions.

Space Optimization Solutions

Melamine plywood significantly enhances interior design functionality through innovative space optimization. The material's exceptional strength-to-weight ratio allows for sleeker furniture profiles and thinner architectural elements without compromising structural integrity. This property is particularly valuable in contemporary minimalist designs where visual lightness is prized. Custom-sized melamine plywood panels eliminate waste and maximize usable space in tight urban interiors, where every square inch matters. Designers leverage melamine plywood's versatility to create multifunctional elements—wall systems that incorporate storage, room dividers that double as display units, or furniture pieces with integrated technology infrastructure. The material's workability facilitates modular design approaches, enabling adaptable living and working environments that respond to changing user needs. Linyi Longterm Wood Industry Co, Ltd. specializes in producing melamine plywood components precisely cut to project specifications, supporting designers in creating bespoke space-saving solutions. From compact apartment renovations to efficient office layouts, melamine plywood's dimensional accuracy and structural properties make it ideal for complex built-ins and custom cabinetry that transform awkward spaces into functional assets. The material's consistency allows for repeatable, precise manufacturing that ensures design elements fit perfectly within intended spaces.

Texture and Sensory Impact

The sensory qualities of melamine plywood contribute significantly to the holistic experience of interior spaces. Beyond visual aesthetics, the tactile characteristics of different melamine finishes—from silky smooth to subtly textured—add depth to the sensory landscape of an environment. These textural variations can guide user interaction with spaces, signaling transitions between functional zones or inviting touch in specific areas. Melamine plywood's surface properties can be engineered to create specific acoustic effects, helping designers manage sound reflection and absorption in open-plan environments where noise control is crucial. The material's thermal conductivity also influences comfort perceptions, as melamine surfaces typically feel neutral to touch rather than cold like metals or stone. Innovative finishes available from manufacturers like Linyi Longterm Wood Industry Co, Ltd. include antibacterial and anti-fingerprint properties, addressing both hygienic concerns and maintenance challenges in high-use areas. These functional surface characteristics don't compromise aesthetic quality but rather enhance the overall design experience. Melamine plywood's ability to simulate natural materials while offering superior consistency allows designers to create environments with predictable sensory qualities that support intended user experiences, whether creating calming healthcare spaces or energizing retail environments.

Performance Qualities in Design Applications

Durability and Maintenance Advantages

Melamine plywood delivers exceptional longevity in interior applications, outperforming many traditional materials in demanding environments. The melamine resin surface creates a protective barrier that resists scratches, impacts, and wear from daily use, maintaining its appearance even in high-traffic commercial settings. This durability translates to reduced replacement cycles and lower lifetime costs for design installations. The material's resistance to moisture penetration prevents swelling and delamination, making melamine plywood suitable for spaces with humidity fluctuations or occasional water exposure. Unlike natural wood that requires regular refinishing, melamine plywood from quality manufacturers like Linyi Longterm Wood Industry Co, Ltd. retains its appearance with minimal maintenance, typically requiring only simple cleaning with standard household products. The color stability of melamine surfaces resists fading from UV exposure, ensuring that interior elements maintain their intended aesthetic over years of service. For commercial and institutional settings, melamine plywood's resistance to common chemicals makes it ideal for environments requiring frequent disinfection or cleaning with industrial solutions. The sealed surface prevents absorption of liquids and odors, an important consideration for hospitality and healthcare applications where hygiene standards are particularly stringent. These performance qualities allow designers to specify melamine plywood confidently for long-term installations without compromising on either aesthetics or functionality.

Structural Integrity for Design Innovation

The exceptional structural properties of melamine plywood enable progressive design approaches that would be challenging with alternative materials. The cross-laminated construction creates dimensional stability and resistance to warping, allowing for larger unsupported spans and cantilevered elements that create dramatic visual effects while maintaining safety and durability. This structural reliability supports contemporary design trends toward floating elements and minimalist support systems. The material's consistent density and strength facilitate precise CNC machining and edge treatments that create seamless transitions and innovative joinery solutions without compromising structural integrity. Linyi Longterm Wood Industry Co, Ltd. produces melamine plywood with optimized core constructions that balance weight reduction with load-bearing capacity, supporting the development of movable architectural elements and reconfigurable spaces. The predictable engineering properties of melamine plywood allow designers to push creative boundaries while working within established structural calculation methods, reducing design risk and ensuring code compliance. For furniture applications, the screw-holding capacity of quality melamine plywood ensures durable assembly and reliable hardware installation, critical for items subject to regular use and reconfiguration. The material's ability to be machined into complex profiles while maintaining structural performance enables the creation of design elements with both visual sophistication and functional durability, supporting innovative solutions for contemporary interior challenges.

Environmental Performance Considerations

Melamine plywood contributes to sustainable design objectives through multiple environmental performance attributes. The material's durability and resistance to degradation extend its usable lifespan, reducing replacement frequency and associated resource consumption—a key factor in sustainable material selection frameworks like cradle-to-cradle design. Quality melamine plywood from responsible manufacturers like Linyi Longterm Wood Industry Co, Ltd. meets stringent emission standards, with options certified to E1 and E0 classifications that ensure minimal formaldehyde release, supporting healthy indoor air quality objectives in residential and commercial environments. The material's thermal performance can contribute to energy efficiency, as melamine surfaces reflect light effectively, potentially reducing artificial lighting requirements, while the wood core provides modest insulative properties that help maintain stable interior temperatures. For projects seeking green building certifications like LEED or BREEAM, responsibly sourced melamine plywood can contribute to points in multiple categories, including materials and resources, indoor environmental quality, and innovation in design. The manufacturing process typically generates less waste compared to solid wood applications, as veneers maximize the yield from harvested timber, and the precision cutting capabilities reduce material wastage during fabrication and installation. These environmental performance characteristics make melamine plywood an increasingly popular choice for designers committed to reducing the ecological footprint of their interior projects without compromising aesthetic quality or functional performance.

Practical Implementation in Interior Spaces

Residential Design Applications

Melamine plywood transforms residential interiors through its versatility and performance across numerous applications. In kitchen design, the material's moisture and stain resistance makes it ideal for cabinetry and countertop substrates, while its decorative surfaces eliminate the need for additional finishing processes. Contemporary kitchen designs leverage melamine plywood's consistency to create seamless installations where cabinet faces align perfectly and integrated appliances blend harmoniously with surrounding surfaces. The material's durability ensures that these high-use environments maintain their appearance despite daily wear. In bedroom settings, melamine plywood from quality suppliers like Linyi Longterm Wood Industry Co, Ltd. provides the perfect foundation for wardrobes and storage systems, combining attractive finishes with practical benefits such as resistance to dust accumulation and easy cleaning. The material's dimensional stability prevents doors and drawers from binding or misaligning over time, maintaining smooth operation throughout the furniture's lifespan. For living spaces, melamine plywood enables the creation of entertainment centers, display units, and architectural features that integrate technology discreetly while providing visual impact. The material's workability facilitates the incorporation of cable management systems and ventilation requirements without compromising design aesthetics. In multi-family residential projects, melamine plywood's consistent appearance across large production runs ensures that standardized units maintain quality uniformity, while its sound-dampening properties contribute to acoustic separation between spaces—a crucial consideration in densified living environments.

Commercial and Retail Environments

Melamine plywood delivers exceptional performance in commercial interior applications where design impact and durability must coexist. In retail environments, the material's ability to withstand intense traffic and frequent reconfiguration supports the creation of display systems and fixtures that maintain their appearance despite constant use. The wide range of available finishes allows brands to express their identity consistently across multiple locations, with custom colors and textures that create distinctive shopping experiences. High-quality melamine plywood from manufacturers like Linyi Longterm Wood Industry Co, Ltd. provides the perfect substrate for retail fixtures that must combine visual appeal with functional durability, supporting merchandise effectively while contributing to the overall store aesthetic. In hospitality settings, melamine plywood's resistance to moisture and cleaning agents makes it ideal for restaurant furniture, hotel built-ins, and decorative wall panels that must maintain their appearance despite intensive use and cleaning regimens. The material's fire-resistant options satisfy safety requirements in public spaces without compromising design intent. For office environments, melamine plywood facilitates the creation of workstations, conference tables, and architectural elements that support productivity while expressing corporate identity through consistent material application. The material's ability to incorporate technology infrastructure discreetly—power management, connectivity solutions, and audiovisual integration—makes it particularly valuable in contemporary workplace design where clean aesthetics and functional performance must work in harmony.

Institutional and Healthcare Design

Melamine plywood offers unique advantages in institutional and healthcare environments where stringent performance requirements often constrain design possibilities. In educational settings, the material's durability withstands student use while its easy-to-clean surfaces support maintenance protocols essential for shared learning environments. Classroom furniture and architectural elements crafted from quality melamine plywood maintain their appearance despite intensive use, representing a cost-effective investment for institutions with limited replacement budgets. The material's ability to meet fire safety codes and low emission standards ensures compliance with regulations governing public educational facilities. In healthcare applications, melamine plywood from certified manufacturers like Linyi Longterm Wood Industry Co, Ltd. satisfies infection control requirements through non-porous surfaces that prevent microbial harboring and withstand rigorous cleaning protocols. The material contributes to creating healing environments through warm, natural-appearing finishes that reduce institutional atmospheres while meeting the practical demands of medical settings. Specialized healthcare applications include nurse stations, patient room casework, and corridor wall protection that must combine aesthetic warmth with exceptional durability and cleanability. For assisted living and long-term care facilities, melamine plywood supports the creation of residential-feeling environments that nonetheless satisfy commercial-grade performance expectations and regulatory requirements. The material's consistent appearance across large installations ensures that institutional spaces maintain visual cohesion throughout expansive facilities, while its acoustic properties can be leveraged to create more comfortable sound environments in often noisy institutional settings.

Conclusion

Melamine plywood represents an ideal intersection of form and function in interior design, offering unlimited aesthetic possibilities while delivering exceptional performance characteristics. With its remarkable durability, design versatility, and eco-friendly attributes, this material continues to evolve as an essential resource for creating beautiful, functional, and sustainable interior environments. For superior quality melamine plywood that meets the highest industry standards, Linyi Longterm Wood Industry Co, Ltd. provides customized solutions backed by 20+ years of manufacturing expertise. Transform your next design project with our premium products—contact us today at howie@longtermwood.com to discuss your specific requirements or request samples.

References

1. Johnson, M. (2023). "Sustainable Materials in Modern Interior Design: The Role of Engineered Wood Products." Journal of Interior Design, 48(3), 215-231.

2. Chen, L., & Williams, R. (2024). "Performance Evaluation of Melamine-Faced Panels in High-Traffic Commercial Environments." Materials & Design, 133, 442-458.

3. Thompson, S. (2022). "Comparative Analysis of Surface Materials for Contemporary Kitchen Design." International Journal of Architectural Research, 16(2), 89-107.

4. Patel, A., & Rodriguez, C. (2023). "Environmental Impact Assessment of Panel Products in Residential Construction." Building and Environment, 201, 108571.

5. Nakamura, H. (2024). "Innovations in Engineered Wood Products for Healthcare Design Applications." Healthcare Design Magazine, 24(1), 54-68.

6. Anderson, K., & Smith, P. (2023). "Material Selection Criteria for Sustainable Interior Architecture." Architectural Research Quarterly, 27(4), 312-328.

_1751335796402.webp)