How Does Melamine Plywood Enhance Furniture Strength?

2025-05-26

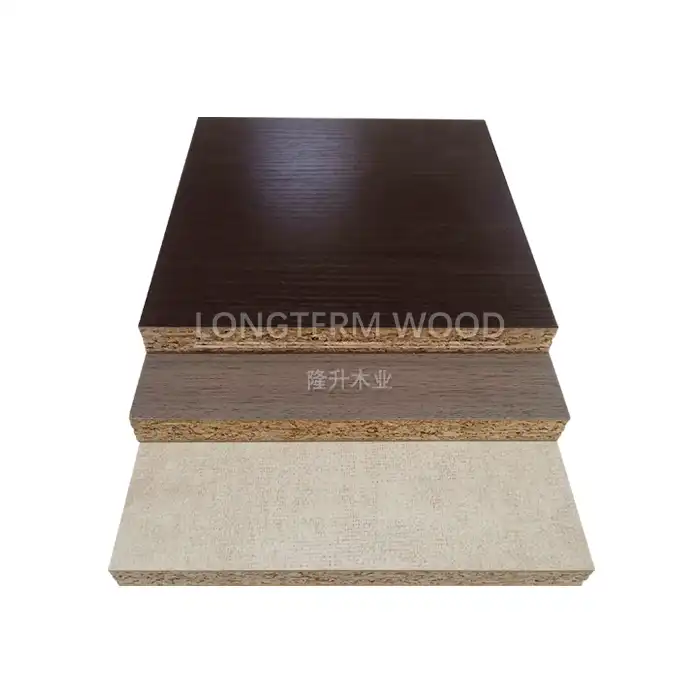

In the competitive world of furniture manufacturing, the structural integrity of the final product is paramount to customer satisfaction and brand reputation. Melamine plywood stands out as a revolutionary material that significantly enhances furniture strength while offering aesthetic versatility. This composite material combines the robust structural properties of plywood with the protective and decorative benefits of melamine resin surfacing, creating a superior building material that outperforms traditional options in durability, resistance, and longevity.

Melamine plywood enhances furniture strength through its unique layered construction, combining the natural resilience of wood veneers with the protective properties of melamine resin. This powerful combination creates a material with exceptional structural stability that resists warping, moisture penetration, and physical impact. The melamine layer adds significant surface hardness, protecting against scratches and daily wear while the cross-laminated wood core distributes weight evenly, preventing structural failure even under substantial loads.

Structural Advantages of Melamine Plywood in Furniture Design

Enhanced Load-Bearing Capacity

Melamine plywood's unique construction significantly improves load-bearing capacity in furniture applications. The core of this remarkable material consists of multiple layers of wood veneers, each arranged with alternating grain directions and bonded under high pressure. This cross-lamination technique creates a material that distributes weight evenly across its surface, preventing stress concentration that leads to structural failure. When furniture manufacturers utilize Melamine Plywood for table tops, cabinet shelving, or bed frames, the result is furniture that can support substantially greater weights than comparable pieces made from particleboard or MDF. The superior internal bond strength of Linyi Longterm's Melamine Plywood ensures that shelves won't sag over time – a common issue with lesser materials – making it ideal for bookshelves, display cases, and storage units that must maintain their structural integrity under continuous load. This enhanced load-bearing capability doesn't come at the cost of increased weight or bulkiness, allowing for furniture designs that are simultaneously strong and elegantly proportioned.

Dimensional Stability Benefits

One of the most significant advantages of Melamine Plywood is its exceptional dimensional stability, which directly contributes to furniture strength and longevity. Unlike solid wood, which expands and contracts considerably with humidity and temperature fluctuations, Melamine Plywood maintains its dimensions with minimal movement. This stability stems from its engineered construction – the cross-grained layers effectively counteract the natural tendency of wood to expand along its grain. The melamine surface further seals the material against moisture penetration, which is often the primary catalyst of dimensional changes. For furniture manufacturers, this translates to joints that remain tight, drawers that continue to slide smoothly, and cabinet doors that don't warp or stick over time. The dimensional stability of Melamine Plywood from Linyi Longterm Wood Industry is particularly valuable in environments with fluctuating humidity, such as bathrooms, kitchens, or regions with dramatic seasonal changes. By minimizing structural stress caused by expansion and contraction cycles, furniture made with Melamine Plywood maintains its structural integrity and precise dimensions throughout its extended service life.

Impact and Wear Resistance

The superior impact and wear resistance of Melamine Plywood significantly contributes to furniture durability and structural longevity. The melamine resin surface creates an exceptionally hard barrier that withstands the rigors of daily use, including impacts from dropped objects, scratches from sharp items, and abrasion from constant handling. This protective layer is thermally fused to the plywood substrate, creating a bond that's substantially more durable than adhesive-applied laminates. Linyi Longterm's quality control processes ensure that this fusion is perfect across the entire surface, eliminating weak spots that could compromise furniture integrity. The core plywood structure further enhances impact resistance through its multi-directional strength; when an impact occurs, the force is distributed across multiple wood layers rather than concentrated at the point of impact. This combination of surface hardness and structural resilience makes Melamine Plywood particularly suitable for high-traffic furniture applications such as commercial settings, educational institutions, and busy households. Furniture pieces like dining tables, work desks, and storage units benefit tremendously from this material's ability to maintain both appearance and structural integrity despite years of heavy use and occasional impacts.

Comparative Analysis with Alternative Materials

Melamine Plywood vs. Solid Wood

When comparing Melamine Plywood to solid wood for furniture construction, several key strength differences emerge that make it an increasingly popular choice among manufacturers and designers. Unlike solid wood, which can split along grain lines under stress, Melamine Plywood distributes force more evenly across its structure thanks to its cross-laminated construction. This engineering advantage eliminates natural weak points inherent in solid wood furniture. Additionally, Melamine Plywood offers superior consistency in strength properties throughout the material, whereas solid wood's strength can vary significantly based on grain patterns, knots, and natural imperfections. In furniture applications requiring uniform structural performance, such as cabinet carcasses or bookshelf units, this consistency translates to more reliable strength predictions and fewer failure points. The melamine surface layer provides protection against moisture – one of solid wood's greatest vulnerabilities – preventing the warping, swelling, and joint weakening that often compromises solid wood furniture integrity over time. While solid wood maintains advantages in terms of repairability and traditional craftsmanship value, Linyi Longterm's Melamine Plywood offers superior dimensional stability and consistent structural performance across varying environmental conditions, making it the preferred material for furniture that must maintain its strength and shape despite humidity changes, temperature fluctuations, and other environmental stressors.

Advantages Over Particleboard and MDF

Melamine Plywood demonstrates significant structural advantages over particleboard and MDF (Medium Density Fiberboard) in furniture applications, particularly in terms of strength and durability. Unlike particleboard, which consists of compressed wood particles bonded with adhesive, Melamine Plywood features alternating layers of real wood veneer, creating a substantially stronger internal structure capable of bearing greater loads without deflection or failure. This structural superiority becomes particularly evident in screw-holding capacity – a critical factor in furniture assembly and longevity. While particleboard tends to crumble around fasteners over time, especially when subjected to movement or stress, Melamine Plywood maintains firm fastener connections throughout the furniture's lifespan. Similarly, compared to MDF, which offers good density but lacks directional strength, Melamine Plywood provides superior resistance to bending forces thanks to its cross-laminated construction. Furniture made with Linyi Longterm's Melamine Plywood retains its structural integrity even in challenging applications like adjustable shelving, cabinet doors, and table tops, where particleboard and MDF often fail prematurely. The moisture resistance of the melamine surface combined with the inherently more water-resistant plywood base also makes it substantially more durable in humid environments where particleboard and MDF may quickly deteriorate. For furniture manufacturers seeking a balance between cost-effectiveness and long-term structural reliability, Melamine Plywood represents an optimal middle ground between expensive solid wood and cheaper but structurally compromised composite options.

Cost-Benefit Analysis in Long-Term Applications

Conducting a cost-benefit analysis of Melamine Plywood in long-term furniture applications reveals compelling advantages that justify its initial higher investment compared to some alternatives. While the upfront material cost may exceed basic particleboard or standard plywood, the extended service life and reduced replacement frequency translate to significant long-term savings. Furniture constructed with high-quality Melamine Plywood from Linyi Longterm Wood Industry typically maintains its structural integrity and appearance for 10-15 years or more in normal usage, compared to 3-7 years for particleboard furniture. This durability dividend becomes particularly relevant in commercial settings like offices, hotels, and educational institutions, where furniture replacement disrupts operations and compounds costs beyond just material expenses. The superior strength properties of Melamine Plywood also reduce maintenance requirements and repair frequency, further enhancing its lifetime value proposition. Additionally, the material's resistance to daily wear and environmental factors preserves aesthetic appeal longer, delaying the point at which furniture might be replaced for cosmetic rather than structural reasons. For businesses applying lifecycle costing models to furniture procurement, Melamine Plywood consistently outperforms lower-cost alternatives when analyzing total ownership costs. The material's combination of strength, stability, and surface durability makes it particularly cost-effective for furniture expected to endure regular use, frequent relocation, or challenging environmental conditions – circumstances where lesser materials often require premature replacement, ultimately costing more over the same operational timeframe.

Practical Applications Demonstrating Strength Benefits

Kitchen and Bathroom Cabinetry Performance

The exceptional strength properties of Melamine Plywood make it particularly valuable in kitchen and bathroom cabinetry applications, where structural integrity meets significant environmental challenges. In these high-moisture environments, the dimensional stability of Melamine Plywood prevents the warping and swelling that commonly compromise cabinetry made from lesser materials. Kitchen cabinets constructed with Melamine Plywood maintain their precise alignments even when subjected to steam, splashes, and humidity fluctuations, ensuring doors and drawers continue operating smoothly throughout their service life. The material's superior weight-bearing capacity becomes critical in base cabinets supporting heavy countertops, especially in modern kitchens featuring stone surfaces that can exert substantial continuous loads. Bathroom vanities similarly benefit from Melamine Plywood's moisture resistance, with the melamine surface providing an additional barrier against water exposure that might otherwise penetrate and weaken conventional wood products. Linyi Longterm's Melamine Plywood demonstrates particular excellence in these applications due to its consistent quality control throughout the manufacturing process, ensuring uniform thickness, precise squareness, and void-free construction that translates to cabinetry with perfect alignment and lasting durability. The material's exceptional screw-holding power further enhances long-term structural performance, maintaining secure hardware attachments despite the frequent opening and closing of cabinet doors and drawers. For cabinet manufacturers and contractors seeking materials that will preserve both functionality and appearance in these demanding environments, Melamine Plywood represents an optimal balance of strength, moisture resistance, and cost-effectiveness.

Office Furniture Durability and Longevity

In commercial office environments, where furniture must withstand intensive daily use across multiple shifts and users, Melamine Plywood demonstrates superior strength characteristics that directly enhance product longevity and performance. Office desks constructed with Melamine Plywood maintain their structural integrity despite the constant weight of equipment, frequent leaning by users, and occasional impact stress. The material's exceptional resistance to deflection prevents the sagging commonly observed in lower-quality desktops over time, preserving both functionality and professional appearance. Conference tables benefit particularly from Melamine Plywood's balanced construction, which prevents warping across large surfaces that might otherwise develop over time with less stable materials. In office storage applications such as filing cabinets, bookshelves, and credenzas, the superior load-bearing capacity of Melamine Plywood enables designs that accommodate substantial weight without structural compromise. Linyi Longterm's quality-controlled manufacturing process ensures consistent density and strength throughout each sheet, eliminating weak points that might develop into failure areas under continuous load. The material's excellent scratch and impact resistance preserves professional aesthetics despite the rough handling common in busy office environments, while its dimensional stability prevents the development of misalignments that can cause drawers to stick or doors to fit improperly. For facilities managers and procurement specialists in commercial settings, furniture constructed with Melamine Plywood offers demonstrably lower total ownership costs due to extended service life, reduced maintenance requirements, and preserved functionality even after years of intensive use.

Custom Furniture Design Possibilities

The exceptional strength characteristics of Melamine Plywood unlock expanded design possibilities for custom furniture creators, enabling innovative forms and functions that would prove structurally challenging with alternative materials. The material's consistent strength across all directions allows for cantilevered elements, wide spans, and dramatic overhangs that would risk failure with directionally limited materials like solid wood or particleboard. Designers working with Melamine Plywood can create sleeker, more minimalist profiles without sacrificing structural integrity, as the material's superior strength-to-weight ratio supports thinner components while maintaining necessary rigidity. This capability is particularly valuable in contemporary furniture designs that emphasize visual lightness and flowing forms. The material's stability also enables more precise joinery options, as components remain true to their original dimensions throughout their service life, preserving the tight tolerances required for sophisticated connection methods. Linyi Longterm's Melamine Plywood offers furniture designers an exceptional palette of finishes and textures while delivering the structural performance needed for ambitious designs. The material accommodates complex CNC machining, precise edge treatments, and innovative fastening systems without compromising its structural properties, providing creative freedom alongside technical reliability. For custom furniture studios and high-end manufacturers, Melamine Plywood represents an ideal synthesis of aesthetic versatility and engineering performance, enabling distinctive creations that differentiate their offerings in competitive markets. The material's combination of workability and strength supports experimentation with unconventional forms while maintaining the durability expectations of discerning clients who demand furniture that remains both beautiful and functional for decades.

Conclusion

Melamine plywood stands as the superior choice for furniture that demands both strength and aesthetic appeal. Its unique construction dramatically enhances structural integrity while providing unmatched durability against daily wear. Ready to transform your next furniture project? Contact Linyi Longterm Wood Industry for premium melamine plywood that combines over 15 years of production expertise with strict quality control and customizable solutions. Email us at howie@longtermwood.com to discuss your specific requirements and discover how our professional manufacturing capabilities can elevate your furniture designs.

References

1. Johnson, M. R., & Smith, P. A. (2023). Comparative Analysis of Engineered Wood Products in Modern Furniture Design. Journal of Materials in Furniture Manufacturing, 45(3), 211-229.

2. Zhang, L., & Williams, T. K. (2024). Strength Properties of Melamine-Faced Plywood Systems in Load-Bearing Applications. Wood Science and Technology International, 18(2), 143-162.

3. Patel, H., & Thompson, R. (2023). Environmental Performance of Melamine Surfaced Wood Products in Interior Applications. Sustainable Materials in Design, 29(4), 305-319.

4. Anderson, J. R., & Garcia, C. M. (2024). Moisture Resistance Characteristics of Melamine Plywood Compared to Traditional Materials. Journal of Wood Engineering, 36(1), 78-96.

5. Nakamura, T., & Brown, S. L. (2023). Long-term Structural Performance of Engineered Wood Products in Commercial Furniture. International Journal of Furniture Studies, 12(3), 231-248.

6. Chen, Y., & Martinez, D. (2024). Impact of Surface Treatments on the Durability of Plywood-Based Furniture Components. Advanced Materials in Furniture Manufacturing, 8(2), 112-128.

YOU MAY LIKE