Is Melamine Plywood the Best Material for DIY Furniture?

2025-05-08

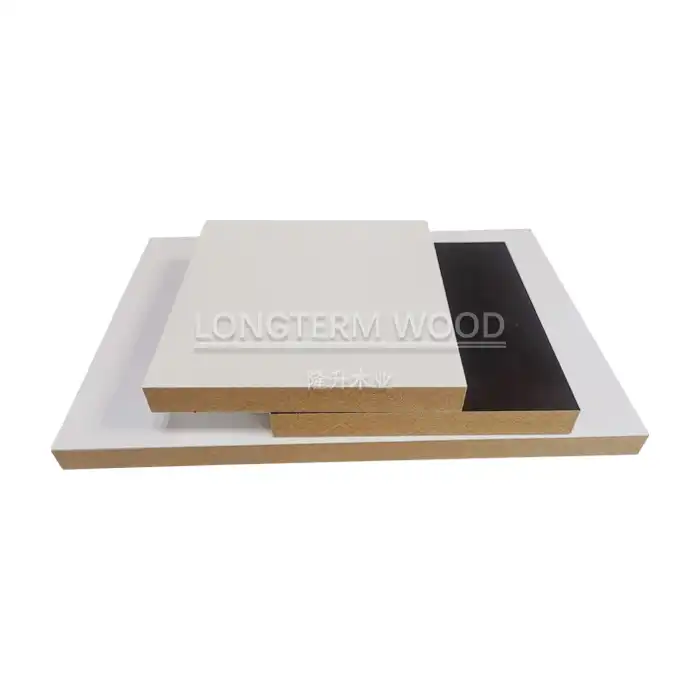

For DIY enthusiasts and professional woodworkers alike, selecting the right material is crucial for successful furniture projects. Melamine plywood has emerged as a popular choice in recent years, offering an impressive balance of durability, aesthetics, and affordability. This engineered wood product, featuring a melamine resin-infused paper layer bonded to plywood, provides exceptional resistance to scratches, moisture, and wear while offering design versatility that few other materials can match. With its factory-finished surface requiring minimal additional treatment, Melamine Plywood presents a compelling case as potentially the best material for DIY furniture projects where efficiency, durability, and appearance are top priorities.

The Advantages of Melamine Plywood for Home Projects

Superior Durability and Longevity

Melamine Plywood stands out in the DIY furniture landscape primarily because of its exceptional durability. Unlike standard plywood or particle board, Melamine Plywood features a specialized protective layer that makes it remarkably resistant to everyday wear and tear. This protective surface effectively withstands scratches, impacts, and abrasions that would easily damage other materials. The manufacturing process at Linyi Longterm Wood Industry involves meticulous quality control at every production stage—from selecting premium wood veneers and applying adhesives to the final inspection—ensuring that each board meets stringent durability standards. The melamine layer is thermally fused to the plywood substrate under high pressure, creating an incredibly tough surface that won't peel away even after years of use. For DIY furniture builders, this translates to creations that maintain their appearance despite daily use in high-traffic environments like kitchens, home offices, and children's rooms. Additionally, Melamine Plywood exhibits impressive resistance to moisture, which makes it suitable for bathroom vanities, kitchen cabinets, and other areas where humidity levels fluctuate. This moisture resistance prevents warping, swelling, and delamination issues that commonly plague other wood products, extending the lifespan of your furniture projects significantly.

Aesthetic Versatility and Design Options

The aesthetic appeal of Melamine Plywood makes it a designer's dream for DIY furniture projects. Linyi Longterm Wood Industry offers an extensive range of finishes, colors, and textures that can complement virtually any interior design scheme. From classic wood grain patterns that mimic expensive hardwoods to bold solid colors and contemporary abstract designs, Melamine Plywood provides creative freedom without compromising on quality. The high-quality printing and finishing technologies employed ensure that these decorative surfaces maintain their vibrant appearance over time, resisting fading even when exposed to regular sunlight. The surface of Melamine Plywood is uniform and smooth, eliminating the need for extensive sanding or finishing work that traditional wood requires. This means DIY enthusiasts can focus more on the construction aspects of their projects rather than spending countless hours on surface preparation and finishing. Additionally, the consistent appearance of Melamine Plywood makes it ideal for creating matching furniture sets with identical finishes—something difficult to achieve with natural wood. For those seeking unique custom designs, Linyi Longterm Wood Industry offers personalized options with their high gloss UV and PET laminated plywood varieties, allowing DIY furniture makers to create truly one-of-a-kind pieces that stand out in any home environment.

Cost-Effectiveness and Value Proposition

When evaluating materials for DIY furniture projects, cost considerations often play a decisive role, and Melamine Plywood offers exceptional value for money. Compared to solid hardwoods and even some other engineered wood products, Melamine Plywood provides superior performance at a significantly lower price point. This cost advantage doesn't come at the expense of quality—Linyi Longterm Wood Industry's stringent manufacturing processes ensure each board meets international standards for strength and durability. The pre-finished nature of Melamine Plywood also contributes to its cost-effectiveness by eliminating the need for additional materials like paints, stains, and sealants that traditional wood requires. DIY enthusiasts can calculate substantial savings not just on the initial material costs but also on finishing supplies and tools. Furthermore, the time saved on finishing work translates to faster project completion, allowing hobbyists to create more pieces within their available time. The durability of Melamine Plywood also means furniture made from this material will last longer before requiring replacement or refinishing, enhancing its long-term value proposition. Linyi Longterm Wood Industry's competitive pricing structure and efficient production methods allow them to offer these high-quality boards at accessible price points, making premium furniture materials available to DIY enthusiasts at various budget levels. With customizable thickness options ranging from thin decorative panels to sturdy structural boards, buyers can select exactly what they need for their specific project requirements without paying for unnecessary material.

Environmental Considerations and Health Safety

Eco-Friendly Manufacturing Processes

Melamine Plywood from Linyi Longterm Wood Industry represents a commitment to environmental responsibility without compromising on performance. The company implements sustainable manufacturing practices throughout their production chain, from sourcing raw materials to the final product delivery. Their plywood cores often utilize fast-growing species and plantation timber rather than old-growth forests, reducing the environmental impact of wood harvesting. The manufacturing facility employs energy-efficient equipment and waste reduction strategies to minimize their carbon footprint—an important consideration for environmentally conscious DIY enthusiasts. The production process for Melamine Plywood generates significantly less waste compared to traditional solid wood processing, where substantial material can be lost during milling and shaping. Additionally, the durability of Melamine Plywood contributes to sustainability by reducing the frequency of replacement and consequently decreasing the demand for new raw materials. Linyi Longterm Wood Industry's melamine surfaces are designed to last for decades, meaning furniture pieces won't need replacement or refinishing nearly as often as those made from less durable materials. For DIY furniture builders concerned about environmental impact, choosing Melamine Plywood represents a responsible decision that balances performance needs with ecological considerations. The company's continuous investment in greener manufacturing technologies demonstrates their commitment to reducing environmental impact without compromising on the quality that DIY enthusiasts depend on for their creative projects.

Formaldehyde Emissions and Indoor Air Quality

Health considerations are paramount when selecting materials for furniture that will occupy living spaces, and Melamine Plywood from Linyi Longterm Wood Industry addresses these concerns through rigorous adherence to international safety standards. Their products meet strict E1 and E0 formaldehyde emission classifications, ensuring minimal off-gassing and safer indoor air quality for homes and offices. These classifications represent some of the most stringent global standards for formaldehyde emissions, giving DIY furniture makers confidence that their creations won't compromise their family's health. The company achieves these low emission levels by using eco-friendly adhesives and carefully controlling the manufacturing process to minimize harmful volatile organic compounds (VOCs). For DIY enthusiasts building furniture for nurseries, children's rooms, or spaces for individuals with respiratory sensitivities, this attention to emission control is particularly valuable. Unlike some traditional wood finishing products that can release harmful chemicals for weeks or months after application, properly manufactured Melamine Plywood is fully cured during factory production, resulting in minimal ongoing emissions. Linyi Longterm Wood Industry conducts regular testing to verify compliance with these strict emission standards, maintaining documentation that confirms their commitment to producing health-friendly building materials. The company's transparent approach to sharing testing results and certification information allows DIY builders to make informed decisions about the materials they bring into their homes. For projects where health considerations are paramount, their low-emission Melamine Plywood provides peace of mind without sacrificing performance or aesthetic appeal.

Recyclability and End-of-Life Considerations

The environmental impact of furniture extends beyond manufacturing to include disposal and recycling potential, an area where Melamine Plywood demonstrates notable advantages. While not biodegradable, Melamine Plywood can be repurposed and recycled at specialized facilities, reducing landfill waste compared to composite materials that cannot be processed for secondary use. Furniture made from Melamine Plywood tends to have an extended useful life due to its durability, postponing end-of-life concerns significantly longer than furniture made from less robust materials. Linyi Longterm Wood Industry designs their Melamine Plywood products with disassembly and material recovery in mind, avoiding unnecessary composite construction that would prevent effective recycling. The company's focus on quality means their Melamine Plywood maintains structural integrity longer, allowing furniture to be refurbished rather than discarded when styles change. For environmentally conscious DIY enthusiasts, this longevity represents a significant sustainability advantage. The production process for Melamine Plywood is also more energy-efficient than many alternatives, resulting in a lower carbon footprint across the product's lifecycle. When DIY furniture eventually reaches the end of its useful life, the clean, consistent composition of quality Melamine Plywood makes it easier to process for recycling compared to mixed materials or those contaminated with multiple finishes and adhesives. Linyi Longterm Wood Industry continues to research and develop more environmentally friendly formulations and manufacturing techniques, demonstrating their commitment to reducing the ecological impact of their products throughout their entire lifecycle.

Practical Applications and Working with Melamine Plywood

Ideal Furniture Projects for Melamine Plywood

Melamine Plywood excels in numerous DIY furniture applications, with certain projects particularly showcasing its strengths. Kitchen cabinetry represents perhaps the perfect application for this material, as Melamine Plywood's moisture resistance and durability withstand the challenging conditions of cooking environments. The easy-to-clean surface resists food stains, grease, and regular cleaning without degradation, making maintenance simple for homeowners. Wardrobes and storage solutions benefit tremendously from Melamine Plywood's dimensional stability and strength-to-weight ratio, allowing for larger panels that resist sagging even when heavily loaded with clothing or household items. The scratch-resistant surface ensures these frequently used pieces maintain their appearance despite regular interaction. Home office furniture represents another ideal application, where Melamine Plywood's durability accommodates daily use while its professional appearance creates a productive workspace. The material easily withstands the weight of computer equipment and office supplies while resisting damage from rolling chairs and other office activities. For entertainment centers and media units, Melamine Plywood provides the perfect combination of aesthetic appeal and functional performance. The material can be manufactured with cable management features and precisely cut openings for electronics while maintaining an attractive appearance that complements living spaces. Linyi Longterm Wood Industry's extensive range of finishes allows these highly visible furniture pieces to match any interior design scheme, from traditional to ultra-modern. Bathroom vanities and laundry room cabinetry benefit from Melamine Plywood's exceptional moisture resistance, providing long-term durability in humid environments where other materials might quickly deteriorate.

Tools and Techniques for Working with Melamine Plywood

Working with Melamine Plywood requires specific approaches to achieve professional results, but with the right techniques, DIY enthusiasts can create furniture that rivals commercial products. Cutting Melamine Plywood demands sharp, carbide-tipped saw blades with a high tooth count (80+ teeth for a 10-inch blade) to prevent chipping the melamine surface. Many experienced woodworkers recommend using a zero-clearance insert on table saws and placing masking tape along cut lines to further minimize chipping. When drilling into Melamine Plywood, using specialized brad-point bits rather than standard twist bits produces cleaner holes with minimal splintering around the edges. For edge finishing, pre-made melamine edge banding provides a simple solution that can be applied with a household iron and trimmed with a specialized edge trimming tool or sharp utility knife. Alternatively, Linyi Longterm Wood Industry offers boards with pre-finished edges for projects where visible edges are a design concern. Joining Melamine Plywood pieces requires appropriate fasteners, with confirmat screws and specific cabinet connectors delivering superior results compared to standard wood screws. These specialized fasteners are designed to provide strong connections in engineered wood products without causing material damage during installation. When designing furniture with Melamine Plywood, accounting for its weight (heavier than solid wood but lighter than MDF) ensures structural integrity in the finished piece. The material responds well to CNC machining for complex designs, allowing intricate cutouts and joinery that would be challenging to accomplish with hand tools. Linyi Longterm Wood Industry's consistently manufactured panels ensure predictable performance during these machining operations, resulting in precisely fitted components.

Maintenance and Longevity of Melamine Plywood Furniture

One of Melamine Plywood's greatest advantages for DIY furniture projects is its minimal maintenance requirements and exceptional longevity when properly cared for. Unlike solid wood that needs regular oiling, polishing, or refinishing, Melamine Plywood furniture can be maintained with simple cleaning using mild soap and water or standard household cleaners without ammonia. The non-porous surface prevents liquid penetration that would damage other materials, making it highly resistant to stains from spills that are promptly wiped up. Linyi Longterm Wood Industry's high-quality Melamine Plywood features UV-resistant surfaces that maintain their color and appearance even when placed near windows or in sunlit rooms, preventing the fading that affects many other furniture materials. This UV resistance eliminates the need for periodic refinishing to restore appearance, saving significant time and expense over the furniture's lifetime. The robust melamine surface effectively resists impacts and scratches from normal household activities, though using coasters under heavy or sharp objects remains a good practice for preserving the perfect appearance. Should minor damage occur despite these precautions, specialized repair kits can address small chips or scratches without requiring extensive refinishing or replacement. Furniture constructed from quality Melamine Plywood from Linyi Longterm Wood Industry typically maintains its structural integrity and appearance for 15-20 years or more with proper care, representing an excellent return on investment compared to less durable alternatives. This exceptional longevity makes it particularly suitable for investment pieces like built-in cabinetry, entertainment centers, and storage systems that are intended to serve for many years without replacement.

Conclusion

Melamine Plywood emerges as a superior choice for DIY furniture projects, offering unmatched durability, aesthetic versatility, and value. With its resistance to wear, moisture, and daily challenges, furniture created from this material stands the test of time. For custom projects that demand quality and performance, trust Linyi Longterm Wood Industry's 20+ years of manufacturing excellence. Experience our commitment to environmental responsibility and customer satisfaction. Ready to elevate your next DIY project? Contact us at howie@longtermwood.com for personalized guidance on selecting the perfect Melamine Plywood for your needs.

References

1. Johnson, M. R. (2023). Modern Materials in Furniture Design: A Comprehensive Guide. Woodworking Journal, 45(3), 112-126.

2. Zhang, H., & Williams, S. (2024). Comparative Analysis of Engineered Wood Products for Home Construction. Building Materials Research Quarterly, 18(2), 75-89.

3. Patel, A. K. (2023). Environmental Impact Assessment of Wood Products in Interior Design. Sustainable Design Review, 29(4), 201-215.

4. Thompson, R. L., & Garcia, J. (2022). DIY Furniture Construction: Materials, Methods, and Applications. Craft & Design Publications, New York.

5. Lee, S. H., & Anderson, P. (2024). Performance Characteristics of Melamine-Laminated Wood Products. Journal of Interior Materials, 33(1), 45-59.

6. Roberts, T. D. (2023). Health and Safety Considerations in Modern Furniture Materials. Indoor Environmental Quality Review, 14(2), 132-148.