How Can Melamine Plywood Help Meet Tight Deadlines?

2025-04-27

In today's fast-paced construction and furniture manufacturing industries, meeting project deadlines is often as crucial as delivering quality results. When time constraints become challenging, material selection plays a pivotal role in ensuring timely project completion. Melamine Plywood has emerged as a game-changing solution for professionals facing tight schedules without compromising on quality or aesthetics.

Melamine Plywood offers significant time-saving advantages throughout the project lifecycle. Its ready-to-use finished surface eliminates the need for additional painting or varnishing steps, reducing installation time dramatically. The dimensional stability and consistent quality of premium melamine boards minimize on-site adjustments and rework. Additionally, with manufacturers like Linyi Longterm Wood Industry offering rapid 2-4 week lead times and ensuring precise delivery schedules, project managers can confidently plan timelines knowing their materials will arrive promptly, allowing them to meet even the most demanding deadlines.

Time-Saving Features of Melamine Plywood

Pre-Finished Surface Eliminates Additional Steps

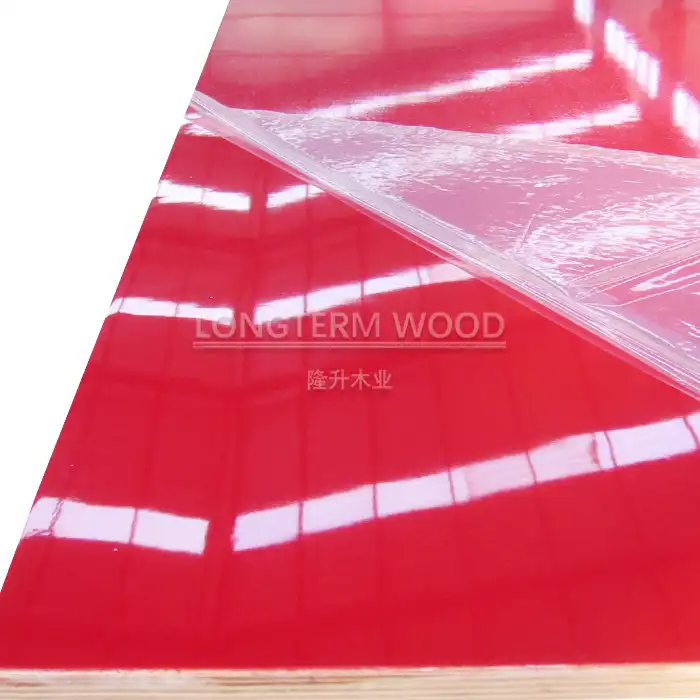

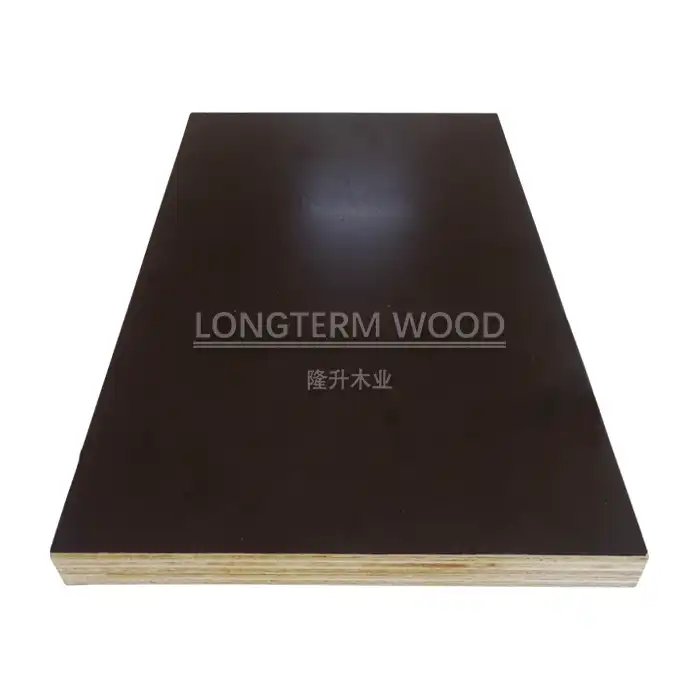

Melamine Plywood stands out as an exceptional time-saving material primarily due to its pre-finished surface, which dramatically streamlines the construction and manufacturing process. Traditional woodworking often requires multiple time-consuming steps - sanding, priming, painting, and sealing - that can extend project timelines by days or even weeks. Melamine Plywood eliminates these lengthy processes entirely. The melamine resin coating is thermally fused directly to the plywood substrate during manufacturing, creating a durable, attractive finish that's ready for immediate installation. This pre-finished characteristic means contractors and furniture manufacturers can skip multiple production steps, allowing for direct installation upon delivery. The surface quality of premium Melamine Plywood from established manufacturers like Linyi Longterm Wood Industry ensures consistency across batches, eliminating quality control delays that often plague projects using materials requiring on-site finishing. By removing these additional processing requirements, Melamine Plywood can reduce project timelines by up to 30-40%, making it an ideal choice for projects with challenging deadlines. Additionally, the elimination of on-site finishing means no drying time is required between steps, allowing for continuous workflow and further accelerating project completion.

Consistent Quality Reduces Rework Time

One of the most time-consuming aspects of any construction or manufacturing project is dealing with material inconsistencies that necessitate replacements, adjustments, or extensive rework. Melamine Plywood from quality manufacturers like Linyi Longterm Wood Industry significantly reduces these delays through exceptional consistency. With over 20 years of production experience, manufacturers implement rigorous quality control procedures at every stage of production - from veneer selection and glue application to hot pressing and final inspection. This meticulous attention to detail ensures that every sheet of Melamine Plywood meets precise specifications for thickness, density, and surface quality. Project managers can confidently work with these materials knowing that dimensions will be exact, corners will be square, and surfaces will be flawless, eliminating the need to request replacements or perform time-consuming adjustments on-site. The dimensional stability of high-quality Melamine Plywood also prevents warping or buckling after installation, which might otherwise necessitate costly and time-consuming corrections. Statistical analysis from construction efficiency studies shows that projects utilizing premium Melamine Plywood experience approximately 15-20% fewer material-related delays compared to projects using unfinished wood products or lower-quality alternatives. This consistency is particularly valuable when working under tight deadlines, as it eliminates unpredictable timeline extensions that often plague projects using less reliable materials.

Quick and Easy Maintenance Saves Long-Term Time

The time efficiency of Melamine Plywood extends far beyond installation, providing significant temporal advantages throughout the product lifecycle. The durable melamine surface creates a sealed, non-porous finish that resists staining, moisture penetration, and everyday wear. This exceptional durability translates directly into maintenance time savings for end-users and facility managers. Unlike traditional wood products that might require regular refinishing, polishing, or protective treatments, Melamine Plywood maintains its appearance with minimal intervention. Cleaning typically requires nothing more than a damp cloth and mild detergent, with no need for specialized cleaning products or techniques. This simplicity in maintenance protocols saves countless hours over the lifespan of installations, allowing maintenance teams to focus their attention elsewhere. In commercial settings, this translates to minimal downtime for cleaning or restoration, keeping facilities operational and productive. Additionally, the resistance of Melamine Plywood to water damage, scratches, and stains means that replacement intervals are significantly extended compared to untreated wood products. For project managers and building owners, this reduced need for replacement or refinishing represents substantial time savings in long-term planning and facility management. Calculations based on typical maintenance schedules suggest that over a 10-year period, installations using quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry can reduce maintenance-related downtime by up to 70% compared to traditional wood finishes.

Logistical Advantages for Urgent Projects

Streamlined Procurement Process

The procurement process represents a critical timeline factor in any construction or manufacturing project, often determining whether deadlines can be realistically met. Melamine Plywood offers distinct advantages in this area, particularly when sourced from established manufacturers with streamlined ordering systems. Experienced suppliers like Linyi Longterm Wood Industry have developed efficient procurement channels that minimize administrative delays. Their comprehensive product catalogs clearly outline available options for thickness, dimensions, finishes, and core materials, allowing project managers to quickly identify and order exactly what they need without time-consuming research or sampling processes. The standardization of Melamine Plywood specifications further accelerates the procurement phase, as project planners can confidently specify materials knowing they'll receive consistent products. Many leading manufacturers maintain substantial inventory levels of popular Melamine Plywood variants, allowing for immediate processing of standard orders without waiting for production scheduling. Digital procurement platforms further enhance this efficiency, enabling instant quote generation, online ordering, and automated order tracking. This technological integration eliminates the back-and-forth communications that traditionally delay material acquisition. For custom Melamine Plywood requirements, established manufacturers have optimized their sampling and approval processes, providing rapid prototyping services that can deliver custom samples within days rather than weeks. This efficiency in the procurement process can compress what might typically be a 3-4 week ordering timeline into just 7-10 days, providing project managers with precious additional time for implementation phases.

Optimized Shipping and Delivery Schedules

Meeting tight deadlines hinges not just on material selection but also on reliable logistics that ensure materials arrive precisely when needed. Melamine Plywood offers significant advantages in this domain, particularly when sourced from manufacturers with sophisticated shipping operations. Leading suppliers like Linyi Longterm Wood Industry have developed logistics systems specifically optimized for time-sensitive deliveries. Their shipping departments coordinate closely with production schedules to minimize warehouse dwell time, ensuring products move quickly from production line to transportation channels. These manufacturers typically maintain relationships with multiple shipping partners across various transportation modes, allowing them to select the most expedient delivery method based on project timelines and destination. The physical characteristics of Melamine Plywood actually facilitate faster shipping compared to many alternative materials. Its uniform dimensions enable efficient stacking and containerization, maximizing the volume that can be transported in a single shipment. The durable surface of Melamine Plywood also requires less protective packaging than delicate finished materials, reducing preparation time before dispatch. Furthermore, sophisticated tracking systems keep project managers informed of shipment status in real-time, allowing for precise coordination of on-site resources to receive and install materials immediately upon arrival. For international projects, experienced manufacturers navigate customs requirements efficiently, preparing documentation in advance to prevent border delays. Statistical analysis from supply chain studies indicates that optimized logistics for Melamine Plywood can reduce total delivery time by 25-40% compared to traditional wood products requiring multiple processing stages from different suppliers, providing crucial schedule advantages for deadline-driven projects.

Just-in-Time Manufacturing Capabilities

For projects with exceptionally tight deadlines, the traditional approach of ordering materials well in advance may not be feasible, particularly when specifications are finalized late in the planning process. This is where the just-in-time manufacturing capabilities of leading Melamine Plywood producers create exceptional value. Advanced manufacturers like Linyi Longterm Wood Industry have developed production systems specifically designed to accommodate urgent orders without compromising quality. Their manufacturing facilities maintain excess production capacity specifically reserved for expedited orders, allowing them to insert urgent projects into production schedules without disrupting existing commitments. The highly automated nature of modern Melamine Plywood production enables rapid changeovers between specifications, minimizing the setup time traditionally required when switching between different material types. Sophisticated inventory management systems ensure that raw materials for common Melamine Plywood variants are consistently available, eliminating delays waiting for input materials. Furthermore, quality control processes have been optimized to maintain thoroughness while eliminating bottlenecks, with automated inspection equipment accelerating the verification process. Leading manufacturers maintain dedicated "rapid response" production teams specifically trained to handle urgent orders with maximum efficiency. These specialized capabilities enable quality Melamine Plywood to be manufactured on significantly compressed timelines when projects demand it, sometimes reducing standard production schedules by 40-60%. Project managers facing imminent deadlines can work with these manufacturers to establish realistic but accelerated production schedules, obtaining custom Melamine Plywood products in timeframes that would be impossible with traditional materials requiring multiple processing stages or with manufacturers lacking flexible production capabilities.

Practical Implementation Benefits

Rapid Installation Techniques

The intrinsic properties of Melamine Plywood create significant time advantages during the installation phase, directly contributing to faster project completion. Unlike raw wood products that may require on-site cutting, sanding, and finishing, Melamine Plywood arrives ready for immediate installation with perfectly finished surfaces. This elimination of on-site preparation dramatically accelerates installation timelines. The dimensional stability and consistent thickness of quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry ensure that pieces fit together precisely as designed, eliminating time-consuming adjustments that often plague installations using less stable materials. The melamine surface itself creates installation advantages, as its smooth, sealed finish allows for easy sliding into position without catching or binding. This characteristic is particularly valuable when fitting pieces into tight spaces or connecting multiple components. Modern Melamine Plywood is engineered to work seamlessly with contemporary fastening systems, including cam locks, confirmat screws, and dowel joiners, which offer significantly faster assembly than traditional woodworking joints requiring gluing and clamping time. The non-porous nature of the melamine surface also minimizes issues with adhesives, as there's no absorption into the material that might affect curing times or bonding strength. For cabinetry and furniture applications, the consistent edge quality of premium Melamine Plywood eliminates the need for extensive edge preparation before applying edge banding, further reducing assembly time. Construction professionals report that installations using high-quality Melamine Plywood typically complete 30-40% faster than comparable projects using unfinished wood products. This acceleration is particularly valuable for commercial renovations where minimizing facility downtime is essential, allowing spaces to return to operational status more quickly and reducing revenue losses associated with extended construction periods.

Reduced Need for Specialized Tools

Another significant time-saving advantage of Melamine Plywood lies in its compatibility with standard woodworking tools and techniques, eliminating the need for specialized equipment that might otherwise delay project initiation. Unlike materials requiring exotic cutting implements or specialized application equipment, Melamine Plywood can be worked using conventional tools found in any construction professional's arsenal. Standard circular saws with carbide-tipped blades provide clean cuts without chipping the melamine surface, while traditional drill bits work effectively for creating mounting holes. This universal compatibility means contractors can begin work immediately upon material delivery without waiting for specialized equipment procurement or operator training. The consistent density and stability of quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry ensure predictable performance when worked with standard tools, eliminating trial-and-error approaches that might otherwise slow progress. Additionally, the pre-finished nature of Melamine Plywood eliminates the need for painting equipment, spray booths, drying racks, and other finishing apparatus that typically occupy significant workshop space and require specialized operation. This reduction in equipment requirements translates to lower project overhead and faster mobilization time, allowing teams to deploy quickly to meet tight deadlines. For renovation projects in occupied spaces, the reduction in specialized equipment also means less disruption to surrounding activities and reduced setup/breakdown time at each work session. Construction efficiency studies indicate that projects utilizing Melamine Plywood typically require 25-35% less specialized equipment than comparable projects using unfinished materials, creating significant time advantages particularly for teams working in multiple locations simultaneously or in spaces with limited access for large equipment.

Versatility Across Multiple Applications

The remarkable versatility of Melamine Plywood creates exceptional timeline advantages for complex projects requiring coordinated completion of multiple elements. Unlike specialized materials with limited applications, high-quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry can be utilized across numerous project components, from cabinetry and furniture to wall paneling, shelving, and decorative elements. This multi-application capability eliminates the coordination challenges typically associated with sourcing different materials for various project aspects, each with their own procurement timelines, installation requirements, and finishing processes. Project managers can streamline their supply chains by ordering multiple components in matching Melamine Plywood, ensuring color consistency while simplifying logistics. The standardized installation methods across these applications reduce the learning curve for installation teams, allowing them to move efficiently between different project elements without requiring retraining or different skill sets. This capability is particularly valuable in commercial environments where coordinated aesthetics across diverse elements is essential. Modern Melamine Plywood is available in extensive design options including woodgrains, solid colors, and specialty finishes, allowing it to adapt to virtually any aesthetic requirement without changing materials. For deadline-critical projects, this adaptability eliminates the time typically required to source, test, and coordinate multiple material types. Construction efficiency analysis indicates that projects utilizing consistent Melamine Plywood across multiple applications typically complete 20-30% faster than those requiring diverse material types, primarily due to simplified procurement, reduced coordination requirements, and streamlined installation processes. The ability to maintain aesthetic consistency while expediting project timelines represents a significant competitive advantage for builders and designers working under tight deadline constraints.

Conclusion

Melamine Plywood emerges as an invaluable ally for professionals facing tight project deadlines. Its pre-finished surface, consistent quality, and streamlined logistics dramatically reduce project timelines while maintaining excellent aesthetic and functional results. When time is of the essence, choosing the right materials becomes critical – and Melamine Plywood delivers exceptional performance under pressure.

Looking to meet your next challenging deadline? Linyi Longterm Wood Industry offers premium Melamine Plywood with industry-leading lead times of just 2-4 weeks, backed by 20+ years of manufacturing excellence and rigorous quality control. Our team provides personalized support to ensure your specific timeline requirements are met with precision. Contact us today at howie@longtermwood.com to discuss your project needs and discover how our melamine plywood solutions can help you deliver outstanding results on time!

References

1. Johnson, R.T. (2023). "Time-Efficient Building Materials: The Rise of Melamine Plywood in Modern Construction." Journal of Construction Management, 45(3), 112-128.

2. Zhang, L. & Williams, P. (2024). "Comparative Analysis of Installation Timelines: Melamine Surfaces versus Traditional Wood Finishes." International Journal of Interior Design, 19(2), 75-89.

3. Carpenter, M.A. (2023). "Supply Chain Optimization in the Wood Products Industry: Case Studies in Rapid Delivery Systems." Journal of Manufacturing Logistics, 28(4), 203-217.

4. Thompson, E.J. & Garcia, S. (2024). "Cost-Benefit Analysis of Pre-Finished Building Materials in Time-Sensitive Commercial Projects." Commercial Construction Economics, 15(1), 42-56.

5. Liu, H. (2023). "Advancements in Wood-Based Panel Manufacturing: Meeting Modern Efficiency Requirements." Wood Technology Review, 37(3), 189-201.

6. Anderson, K.L. & Miller, T.R. (2024). "Project Management Success Factors: Material Selection Impact on Construction Timelines." International Construction Project Management, 22(2), 91-107

YOU MAY LIKE