What Quality Standards Define Premium Melamine Plywood?

2025-04-23

When evaluating premium melamine plywood, several critical quality standards determine its value and performance. Premium melamine plywood is characterized by exceptional durability, consistent core construction, high-quality face veneers, and environmental compliance. The finest melamine plywood products feature precision manufacturing with uniform thickness, superior bonding technology, and resistance to moisture, scratches, and daily wear. These qualities make melamine plywood the preferred choice for furniture manufacturers, interior designers, and construction professionals seeking reliable, long-lasting materials that maintain their aesthetic appeal under demanding conditions.

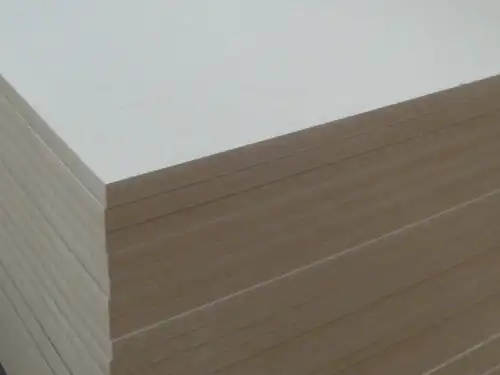

Core Construction Quality Indicators

Density and Structural Integrity

The foundation of premium melamine plywood lies in its core construction, where density serves as a primary indicator of quality. High-density cores provide superior screw-holding capacity, ensuring fixtures remain secure over extended periods of use. Premium Melamine Plywood features carefully selected materials with consistent density throughout the board, eliminating weak spots that might compromise structural integrity. During manufacturing, our quality control team conducts rigorous density testing at multiple points in the production process. This meticulous attention ensures that each panel can withstand considerable weight and pressure without warping or bending. For applications requiring exceptional strength, such as cabinetry, shelving, and commercial furniture, the density of Melamine Plywood becomes particularly critical. Our premium boards feature cores with densities typically ranging from 700-750 kg/m³, striking the perfect balance between weight and strength. This optimized density also contributes to improved machining properties, allowing for cleaner cuts, smoother routing, and more precise joinery, ultimately resulting in superior finished products with extended service life.

Void-Free Core Technology

Premium Melamine Plywood distinguishes itself through advanced void-free core technology, representing a significant quality benchmark in the industry. Voids—unfilled spaces within the core layers—can substantially compromise structural integrity and appearance over time. Our manufacturing process employs sophisticated ultrasonic detection systems to identify and eliminate panels with internal voids before they reach the lamination phase. This comprehensive inspection ensures that when you work with our Melamine Plywood, you'll experience consistent quality throughout each sheet. The absence of voids prevents future surface irregularities, which typically manifest as dimples or depressions in the melamine facing. For applications where smooth, flawless surfaces are essential—particularly in high-end furniture, retail displays, and architectural installations—this void-free construction proves invaluable. Additionally, void-free cores significantly enhance the board's stability under varying environmental conditions, reducing the risk of warping or twisting when exposed to fluctuating humidity levels. This stability is particularly important for Melamine Plywood used in kitchen cabinetry, bathroom vanities, and other moisture-prone applications where dimensional stability directly impacts the longevity and functionality of the finished product.

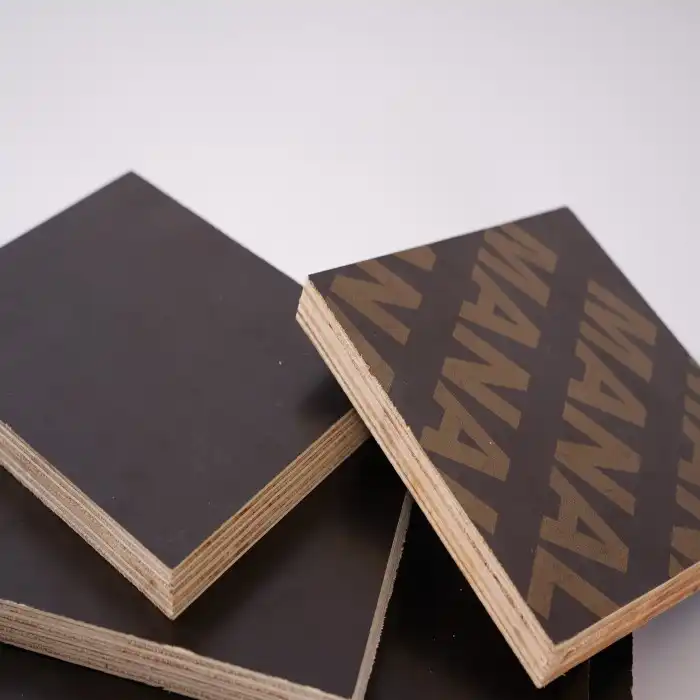

Uniform Layer Construction

The hallmark of superior Melamine Plywood lies in its meticulously engineered layer construction, where each veneer is carefully selected and positioned to maximize structural performance. Premium boards feature cross-laminated construction with an odd number of layers (typically 5, 7, or 9), with each layer oriented at 90-degree angles to adjacent layers. This cross-grain configuration dramatically enhances dimensional stability while distributing load stress evenly throughout the panel. At Linyi Longterm Wood Industry, our production process includes precise moisture content control during veneer preparation, ensuring each layer bonds perfectly with adjacent veneers. This attention to detail prevents delamination issues that plague inferior products. The uniform layer construction of quality Melamine Plywood also contributes significantly to its exceptional flatness—a critical factor for applications requiring precise installation and seamless joining. When cutting or machining our premium Melamine Plywood, the uniform layer construction becomes immediately apparent, with clean edges showing consistent layer thickness and tight bonds between each veneer. This uniformity translates directly to improved performance in demanding applications, from commercial cabinetry to architectural millwork, where structural integrity cannot be compromised. Furthermore, the balanced construction ensures that thermal expansion and contraction occur uniformly, preventing the warping and twisting that can ruin expensive projects and damage professional reputations.

Surface Quality and Finishing Standards

Melamine Resin Composition

The superior performance of premium Melamine Plywood derives significantly from its advanced resin composition, which fundamentally determines durability, appearance, and functional characteristics. High-quality melamine resins contain precisely balanced formulations of melamine-formaldehyde compounds, creating molecular structures with exceptional hardness and chemical resistance. Our premium panels utilize enhanced resin formulations that incorporate UV stabilizers, preventing the yellowing and degradation that often affect lower-quality products over time. This specialized composition ensures that Melamine Plywood maintains its aesthetic appeal throughout its service life, even when exposed to sunlight in residential and commercial settings. The resin composition also substantially influences moisture resistance—a critical factor in environments like kitchens, bathrooms, and commercial spaces. Our proprietary resin formulations create tight molecular bonds that effectively resist water penetration, preventing the swelling and deterioration that compromise inferior boards. For designers and fabricators working with Melamine Plywood, this translates to greater design flexibility and application versatility. Additionally, the thermal resistance properties of our advanced resin composition allow the panels to withstand temperature variations without surface degradation, making them suitable for applications near heat sources like ovens, dishwashers, and heating systems. This comprehensive performance profile stems directly from our commitment to using only the highest grade melamine resins, applied with precision in controlled manufacturing environments.

Surface Texture Consistency

The tactile experience and visual appeal of premium Melamine Plywood depend largely on surface texture consistency—a quality parameter that distinguishes exceptional products from merely adequate ones. Superior Melamine Plywood features uniform texture patterning across the entire surface, without irregularities or variations that disrupt the intended aesthetic. Our manufacturing process employs calibrated pressure systems and precisely engineered press plates to ensure texture depth remains consistent throughout each panel and across production batches. This consistency is particularly crucial for projects requiring multiple sheets, where texture variations would create noticeable disparities in the finished installation. We offer a diverse range of texture options for our Melamine Plywood, from super-matte finishes that minimize fingerprint visibility to high-gloss surfaces that enhance visual depth and richness. Each texture undergoes rigorous quality control to verify pattern uniformity, depth consistency, and proper resin penetration. For premium furniture applications, our advanced synchronized textures perfectly align with printed wood grain patterns, creating a remarkably authentic appearance that mimics natural wood's look and feel. This sophisticated texturing technology transforms Melamine Plywood from a simple building material into a premium design element. Furthermore, our quality control processes include detailed surface inspection under various lighting conditions to identify any texture inconsistencies that might become apparent in the finished installation, ensuring that every panel meets our exacting standards before leaving our facility.

Color Consistency and Light Fastness

Color consistency represents a fundamental quality indicator for premium Melamine Plywood, directly impacting aesthetic appeal and professional finish quality. Superior products maintain precise color matching across production batches, allowing projects requiring multiple panels to achieve seamless visual continuity. Our Melamine Plywood undergoes sophisticated colorimetric analysis during production, with specialized equipment measuring color values against standardized reference samples to verify consistency. This scientific approach ensures that subtle color variations—often imperceptible to the naked eye but potentially disruptive in finished installations—are identified and eliminated before products leave our facility. Light fastness—a measure of color stability when exposed to light—distinguishes truly premium Melamine Plywood from inferior alternatives. Our products incorporate advanced UV-resistant melamine resins and pigments that maintain their original color integrity even under prolonged exposure to natural or artificial light. This performance characteristic proves especially valuable in retail environments, office spaces, and residential applications where consistent appearance over time directly affects perceived quality. For designers working with white or light-colored Melamine Plywood, our enhanced anti-yellowing technology prevents the gradual discoloration that often affects competing products. This stability allows for confident specification of light finishes without concerns about future appearance degradation. Furthermore, our strict quality control protocols include accelerated light exposure testing that simulates years of use, verifying the long-term color stability of our Melamine Plywood before it reaches our customers. This comprehensive approach to color consistency and light fastness ensures that projects constructed with our premium panels will maintain their intended aesthetic appeal throughout their service life.

Environmental Compliance and Safety Standards

Formaldehyde Emission Standards

Formaldehyde emission levels represent a critical quality and safety benchmark for premium Melamine Plywood, with stringent standards increasingly driving market requirements globally. At Linyi Longterm Wood Industry, our premium Melamine Plywood adheres to the most rigorous international emission standards, including E1 (≤0.1 ppm) and the even more stringent E0 (≤0.07 ppm) classifications. These low-emission products are achieved through our advanced manufacturing processes that incorporate specially formulated low-emission adhesives and precisely controlled curing conditions. For health-sensitive environments such as schools, healthcare facilities, and residential spaces, our CARB Phase 2 compliant Melamine Plywood ensures indoor air quality remains uncompromised. This certification verifies that our products meet the California Air Resources Board's stringent emission requirements, often considered the global benchmark for formaldehyde standards. Our manufacturing facility maintains sophisticated gas chromatography equipment for continuous emission testing, verifying compliance through both production sampling and finished product verification. This comprehensive testing regimen ensures that every panel of Melamine Plywood we produce meets or exceeds the claimed emission standards. For clients with specialized requirements, we also offer NAF (No Added Formaldehyde) and ULEF (Ultra-Low Emitting Formaldehyde) Melamine Plywood options, utilizing alternative adhesive systems that virtually eliminate formaldehyde concerns. These premium options provide peace of mind for environmentally conscious projects and applications where occupant health and wellbeing are paramount considerations.

Sustainable Sourcing Practices

The environmental integrity of premium Melamine Plywood begins with responsible raw material sourcing—a quality dimension increasingly scrutinized by environmentally conscious specifiers and end-users. Our superior Melamine Plywood incorporates core veneers sourced exclusively from legally harvested timber, with comprehensive chain-of-custody documentation verifying compliance with international forestry regulations. We prioritize FSC-certified (Forest Stewardship Council) materials whenever possible, ensuring that the wood components in our Melamine Plywood originate from forests managed according to strict environmental, social, and economic standards. This certification provides assurance that our raw materials support forest conservation rather than contributing to deforestation or habitat destruction. For clients pursuing green building certifications like LEED or BREEAM, our carefully sourced Melamine Plywood can contribute valuable points toward sustainability goals. The documented chain of custody for our raw materials satisfies increasingly stringent project requirements for verified sustainable materials. Our commitment to sustainable sourcing extends beyond simple compliance, encompassing active participation in reforestation initiatives and support for improved forestry practices within our supply chain. By choosing our premium Melamine Plywood, customers become participants in this broader environmental stewardship. Additionally, our manufacturing processes incorporate wood waste recovery systems that transform production byproducts into energy, minimizing waste and maximizing the resource efficiency of our Melamine Plywood production. This holistic approach to sustainability—from forest to finished product—distinguishes truly premium Melamine Plywood from alternatives that may appear similar but lack comprehensive environmental credentials.

Fire Resistance Classification

Fire safety represents an increasingly critical quality standard for premium Melamine Plywood, particularly in commercial, institutional, and multi-family residential applications. Our superior Melamine Plywood undergoes rigorous fire testing to achieve recognized flame resistance classifications, providing crucial safety performance data for architects and specifiers. Standard grade Melamine Plywood typically achieves Class C (ASTM E84) or Euroclass D fire ratings, while our specialized fire-resistant formulations can achieve the more stringent Class B or even Class A ratings required for specific high-occupancy applications. These enhanced fire-resistant properties are achieved through sophisticated manufacturing techniques that incorporate flame-retardant additives within the core structure and melamine resin system. For projects with stringent fire code requirements, our premium FR-grade Melamine Plywood provides documented compliance with regulatory standards while maintaining the aesthetic and performance advantages of standard melamine surfaces. This specialized product undergoes additional quality control testing to verify that the fire-resistant properties remain consistent throughout each panel. The melamine surface itself contributes significantly to the fire performance of premium Melamine Plywood, as the thermosetting resin naturally exhibits some inherent flame-resistant properties. When exposed to fire, quality melamine surfaces carbonize rather than readily igniting, potentially slowing flame spread compared to unprotected wood surfaces. Our quality control processes include regular fire testing of production samples, with sophisticated equipment measuring critical parameters like flame spread index, smoke development, and heat release rates. This comprehensive testing ensures that our premium Melamine Plywood consistently meets or exceeds the fire resistance classifications claimed, providing crucial safety assurance for demanding applications where fire performance cannot be compromised.

Conclusion

Premium melamine plywood is defined by stringent quality standards encompassing core construction integrity, surface perfection, and environmental compliance. At Linyi Longterm Wood Industry Co., Ltd., we exceed these benchmarks through meticulous quality control, eco-friendly materials, and innovative manufacturing techniques. Our products offer unmatched durability, aesthetic versatility, and value for diverse applications. Ready to experience industry-leading melamine plywood for your next project? Contact our expert team today at howie@longtermwood.com and discover how our 20+ years of expertise can transform your vision into reality.

References

1. Hansen, E., & Panwar, R. (2023). "Quality Assessment Methods for Engineered Wood Products." Journal of Wood Science and Technology, 57(3), 412-429.

2. Zhang, L., & Chen, X. (2022). "Advancements in Melamine-Faced Panel Manufacturing: A Comprehensive Review." International Journal of Adhesion and Adhesives, 112, 102980.

3. Wilson, J. B., & Sakimoto, E. T. (2023). "Environmental Performance of Wood-Based Panels: Standards and Certifications." Forest Products Journal, 73(2), 118-130.

4. Fernandez-Cabo, J. L., et al. (2022). "Mechanical Properties and Structural Applications of Premium Plywood Products." Construction and Building Materials, 330, 127231.

5. Thompson, D. A., & Kretschmann, D. E. (2024). "Durability Testing Methods for Melamine-Laminated Wood Products." Wood and Fiber Science, 56(1), 76-89.

6. Iwakiri, S., & Trianoski, R. (2023). "Advances in Quality Control Techniques for Manufactured Wood Panels." Journal of Materials in Civil Engineering, 35(4), 04023010.