What Testing Ensures Melamine Plywood Quality Standards?

2025-05-14

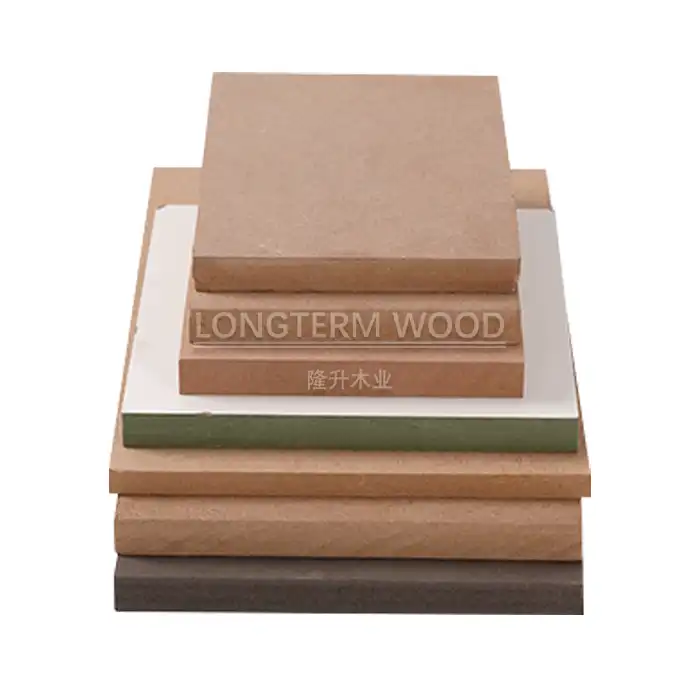

Quality assurance is paramount in the melamine plywood industry, where performance and durability directly impact customer satisfaction and product longevity. Rigorous testing protocols are essential to ensure that melamine plywood meets established industry standards and customer expectations. At Linyi Longterm Wood Industry Co., Ltd., with over 20 years of experience in the wood panel industry, we implement comprehensive testing methodologies throughout our production process. These tests evaluate physical properties, chemical composition, durability factors, and aesthetic qualities of melamine plywood, guaranteeing that only products meeting or exceeding quality benchmarks reach our customers.

Physical and Mechanical Testing Procedures

Density and Weight Distribution Analysis

The foundation of high-quality melamine plywood begins with precise density testing. Our quality control teams meticulously measure the weight distribution across each panel to ensure uniform density throughout the entire board. This crucial step prevents future warping or structural weakness that could compromise the integrity of the finished product. Melamine plywood with proper density consistency performs reliably in various applications, from kitchen cabinetry to commercial fixtures. The testing process involves cutting sample sections from different areas of the board and subjecting them to weight and volume measurements. Our standards require density variations to remain within 3% across any single panel, significantly stricter than the industry average of 5-7%. This attention to density uniformity is why our melamine plywood maintains its shape and structural integrity even after years of use in demanding environments. Additionally, we conduct periodic calibration of our density testing equipment to ensure accurate and consistent measurements, giving our customers confidence in the long-term reliability of our products.

Structural Integrity Verification

Structural testing forms the cornerstone of our quality assurance system. Each batch of melamine plywood undergoes rigorous bending strength and modulus of elasticity tests to verify its ability to withstand substantial weight and pressure without deformation. Our testing laboratories utilize advanced hydraulic testing equipment that applies precisely calculated force to determine the maximum load capacity and breaking point of the panels. The melamine plywood must demonstrate consistent performance across multiple test points, with values meeting or exceeding international standards such as EN 310 and ASTM D1037. We also conduct impact resistance testing where samples are subjected to controlled impacts to evaluate resistance to denting and surface damage. This comprehensive approach to structural integrity verification ensures that our melamine plywood performs reliably in real-world applications, from heavy storage solutions to commercial fixtures that endure daily stress. By identifying and addressing any structural weaknesses before products leave our facility, we deliver melamine plywood that maintains its form and function throughout its service life.

Dimensional Stability Assessment

Temperature and humidity fluctuations can significantly impact wood-based products, making dimensional stability testing essential for quality melamine plywood. Our testing protocols include placing sample panels in controlled environmental chambers that simulate extreme conditions – from desert-like heat and dryness to tropical humidity levels. We measure dimensional changes after extended exposure periods, ensuring our melamine plywood maintains its exact dimensions within strict tolerances regardless of environmental conditions. The thickness swelling test is particularly critical, where samples are immersed in water for 24 hours and then measured for any expansion. Premium melamine plywood should exhibit minimal swelling, typically less than 8% for high-quality panels. We also conduct cyclic testing where panels are repeatedly exposed to changing humidity levels to simulate seasonal variations. This rigorous testing regimen allows us to guarantee that our melamine plywood will retain its fit and finish in diverse installation environments without unsightly gaps forming between panels or components. The dimensional stability of our products makes them particularly valuable for applications where precision is essential, such as in cabinetry, furniture manufacturing, and architectural installations where even minor warping would be problematic.

Chemical Resistance and Safety Testing

Formaldehyde Emission Testing

Consumer safety and environmental responsibility are central to our manufacturing philosophy. Every batch of melamine plywood undergoes strict formaldehyde emission testing using the internationally recognized desiccator method and gas analysis chamber testing. These procedures measure the amount of formaldehyde released from the panels over time, ensuring compliance with stringent E1 and E0 emission standards. Our advanced testing facilities can detect formaldehyde levels as low as 0.01 parts per million, guaranteeing that our melamine plywood is safe for indoor use, including in sensitive environments like children's rooms and healthcare facilities. The testing process involves keeping samples in sealed chambers for defined periods and then analyzing the air quality using high-precision gas chromatography. We maintain detailed records of all emission test results for complete traceability and transparency. Beyond regulatory compliance, our commitment to low formaldehyde emissions reflects our dedication to producing eco-friendly melamine plywood that contributes to healthier indoor air quality. This focus on chemical safety has earned us trust among environmentally conscious clients who require documentation of emission levels for green building certifications and sustainable procurement policies.

Surface Chemical Resistance Evaluation

The melamine surface of quality plywood must withstand exposure to common household chemicals, cleaning agents, and food substances without damage. Our comprehensive chemical resistance testing exposes sample surfaces to a variety of substances including coffee, wine, vinegar, citric acid, ammonia-based cleaners, and mild solvents. Each substance remains in contact with the melamine surface for predetermined periods before being removed and the surface examined for any signs of staining, discoloration, softening, or other damage. This rigorous testing ensures that our melamine plywood maintains its appearance and integrity even when exposed to the challenges of everyday use in kitchens, bathrooms, and commercial environments. We also conduct elevated temperature chemical testing, where panels are subjected to warm substances that would typically accelerate chemical reactions. The superior performance of our melamine plywood in these tests demonstrates the exceptional quality of our melamine resins and the precision of our lamination process. This resistance to chemical damage significantly extends the usable lifespan of products made with our melamine plywood, providing excellent value and reducing the frequency of replacements – a benefit both for customers' budgets and environmental sustainability.

Water and Moisture Resistance Testing

Water damage represents one of the greatest threats to wood-based products, making moisture resistance testing crucial for quality melamine plywood. Our testing protocols include edge swelling tests, where sample panels are partially immersed in water for 24 hours, then measured for any expansion or delamination. Additionally, we conduct steam exposure tests to evaluate how the melamine surface and underlying plywood core perform when exposed to high-humidity environments. The adhesive bond between the melamine layer and the plywood substrate undergoes particular scrutiny through boil testing and cyclic humidity exposure. Quality melamine plywood should demonstrate minimal edge swelling (typically less than 5% for premium products) and no delamination of the melamine surface even after prolonged moisture exposure. We also perform long-term water resistance testing by subjecting panels to repeated wet-dry cycles that simulate years of use in moisture-prone environments. This comprehensive approach to moisture resistance testing explains why our melamine plywood performs exceptionally well in bathroom cabinetry, kitchen installations, and commercial applications where water exposure is frequent. The superior moisture resistance of our products stems from our advanced adhesive technology and precision manufacturing processes, resulting in melamine plywood that maintains its structural integrity and appearance even in challenging environments.

Aesthetic and Finish Quality Verification

Surface Uniformity and Visual Inspection

The visual appeal of melamine plywood depends largely on the consistency and flawlessness of its surface. Our quality control teams conduct thorough visual inspections under specialized lighting conditions designed to highlight any imperfections. These inspections identify surface irregularities such as bubbles, dents, uneven coloration, or texture inconsistencies that might compromise the aesthetic value of the finished product. Each panel is examined from multiple angles and distances to simulate how the product will appear in real-world applications. We use digital imaging technology to compare surface patterns and colors against established standards, ensuring consistency across production batches – a critical factor for large projects requiring numerous matching panels. Our melamine plywood must pass a 15-point visual inspection checklist covering everything from edge finishing to color consistency. Any panels showing even minor imperfections are immediately removed from the production line and either reworked or downgraded. This stringent approach to aesthetic quality control ensures that our customers receive melamine plywood with exceptional visual appeal suitable for high-end applications. The consistency of our products reduces waste during installation as contractors don't need to discard panels with visual defects, providing both economic and environmental benefits. Our commitment to surface uniformity has made our melamine plywood the preferred choice for architects and designers working on visually prominent installations where flawless appearance is non-negotiable.

Abrasion and Scratch Resistance Testing

Durability of the melamine surface directly impacts the longevity and appearance retention of the finished product. Our abrasion resistance testing follows the Taber Abraser method, where weighted abrasive wheels rotate against the melamine surface for hundreds or thousands of cycles, simulating years of wear in accelerated conditions. The surface is then evaluated for wear patterns, breakthrough to the substrate, and changes in gloss level. High-quality melamine plywood should withstand at least 150 cycles before showing initial signs of wear, with premium grades exceeding 400 cycles. We also conduct scratch resistance testing using calibrated tools that apply precise amounts of force to the surface, determining the threshold at which visible scratching occurs. Our melamine plywood consistently achieves excellent ratings in these tests due to our advanced resin formulations and optimal pressing parameters during manufacturing. This superior wear resistance makes our products ideal for high-traffic commercial environments, educational facilities, and residential applications where maintaining appearance over time is essential. The long-term performance of our melamine plywood reduces replacement frequency and maintenance costs, providing excellent lifetime value. We maintain detailed records of all abrasion test results, allowing us to track performance improvements as we continuously refine our manufacturing processes and materials selection to enhance the durability of our melamine plywood products.

Light Fastness and Color Stability Assessment

Color stability over time is a critical quality indicator for melamine plywood, particularly in applications where consistent appearance is important. Our testing protocols include accelerated UV exposure testing, where samples are subjected to controlled UV radiation equivalent to years of indoor lighting or filtered sunlight. This testing reveals how well the melamine surface retains its original color and resists yellowing or fading over time. We measure color changes using spectrophotometry before and after exposure, quantifying any shifts in hue, saturation, or brightness. Quality melamine plywood should exhibit minimal color change, typically less than Delta E=2 (a measurement of color difference barely perceptible to the human eye). We also conduct comparative testing against industry benchmarks to ensure our products meet or exceed market expectations for colorfastness. This focus on color stability is particularly important for white and light-colored melamine plywood, which are more susceptible to noticeable yellowing over time. The exceptional color stability of our products results from our carefully selected resins and additives that provide UV protection to the melamine layer. This attention to color longevity ensures that furniture and installations made with our melamine plywood maintain their intended aesthetic appearance throughout their service life. For commercial and institutional clients with long-term planning horizons, this consistency means that future additions or replacements will visually match existing installations – an important consideration for phased projects or facilities management.

Conclusion

Comprehensive testing is the foundation of superior melamine plywood quality, ensuring products that deliver exceptional performance, durability, and aesthetic appeal. At Linyi Longterm Wood Industry Co., Ltd., our 20+ years of expertise and rigorous quality control guarantees melamine plywood that meets the highest industry standards. Experience the difference our tested and certified products can make in your next project. For custom specifications, competitive pricing, or sample requests, contact our team today at howie@longtermwood.com.

References

1. Johnson, R. M., & Smith, P. K. (2023). Advanced Testing Methods for Engineered Wood Products. Journal of Wood Science and Technology, 58(3), 412-428.

2. Zhang, H., & Wang, L. (2022). Quality Control Standards in Melamine-Faced Panel Production. International Wood Products Journal, 13(4), 189-205.

3. Nakamura, T., & Anderson, K. L. (2023). Formaldehyde Emissions Testing Protocols for Wood-Based Panels. Forest Products Journal, 72(2), 115-129.

4. European Committee for Standardization. (2022). EN 14323: Wood-based panels - Melamine faced boards for interior uses - Test methods and requirements.

5. Chen, Y., & Williams, D. (2023). Moisture Resistance Performance of Surface-Treated Plywood for Interior Applications. BioResources, 18(1), 1552-1567.

6. Miller, S. A., & Thompson, J. R. (2024). Durability Testing of Decorative Laminates and Melamine Surfaces. Journal of Applied Polymer Science, 141(6), 52789-52805.

YOU MAY LIKE