What Makes Melamine Plywood Perfect for Built-In Furniture?

2025-05-14

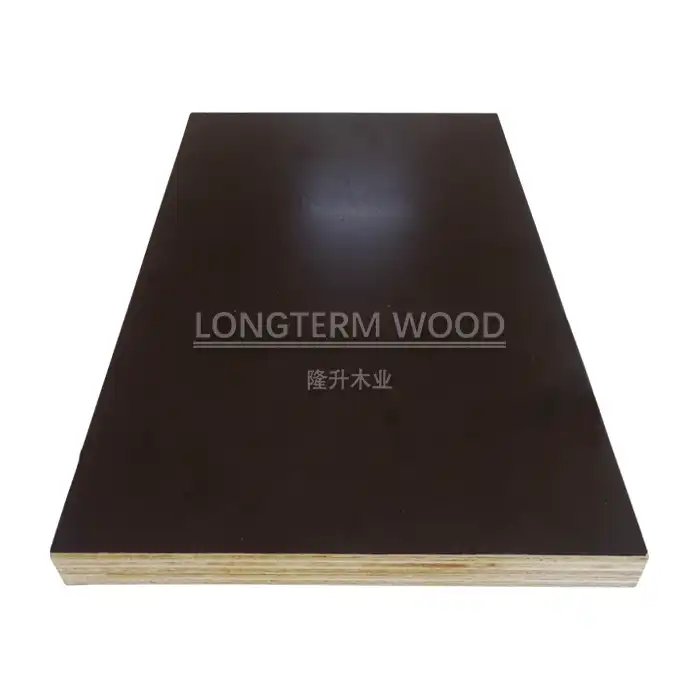

When designing built-in furniture for homes and offices, material selection plays a crucial role in determining both aesthetics and functionality. Melamine plywood stands out as an exceptional choice for custom-built furniture solutions, offering a perfect balance of durability, versatility, and cost-effectiveness. This engineered wood product combines the structural integrity of plywood with the protective and decorative qualities of melamine resin, creating a surface that withstands daily wear while maintaining its appearance for years. The unique composition of melamine plywood makes it resistant to scratches, moisture, and stains—qualities that are essential for built-in furniture that needs to maintain its appearance despite regular use and potential exposure to household elements.

The Structural Advantages of Melamine Plywood in Custom Cabinetry

Enhanced Durability for Long-Term Investment

Melamine plywood represents an exceptional long-term investment for built-in furniture projects due to its remarkable durability characteristics. The manufacturing process involves bonding multiple layers of wood veneer with adhesives under high pressure, creating a core that resists warping and maintains structural integrity over time. The outer layer consists of paper impregnated with melamine resin, which is thermally fused to the plywood substrate. This creates a hard, sealed surface that effectively resists scratches, impacts, and everyday wear that built-in furniture frequently endures. Unlike raw wood or lower-quality engineered materials, melamine plywood maintains its appearance and structural integrity even in high-traffic areas of homes and offices. This exceptional durability translates to furniture that remains functional and aesthetically pleasing for decades rather than years, making it an ideal choice for permanent installations like kitchen cabinets, built-in wardrobes, and office storage solutions. The sealed nature of melamine plywood also prevents moisture penetration, addressing one of the primary causes of furniture deterioration in environments like bathrooms and kitchens where humidity levels fluctuate.

Dimensional Stability for Precision Construction

One of the most significant advantages of melamine plywood for built-in furniture applications is its superior dimensional stability. Unlike solid wood that expands and contracts with humidity and temperature changes, melamine plywood maintains consistent dimensions throughout seasonal variations. This stability stems from its cross-laminated construction, where adjacent veneers are oriented with their grain patterns perpendicular to each other, effectively neutralizing the natural tendency of wood to expand and contract in one direction. For built-in furniture that must fit precisely within defined spaces, this dimensional stability is invaluable. It ensures that doors continue to close properly, drawers slide smoothly, and joints remain tight over time. Professional cabinetmakers and furniture designers particularly value melamine plywood for installations where precision is paramount, such as floor-to-ceiling bookcases, custom entertainment centers, and built-in office workstations. The material's consistent thickness and flatness also simplify the installation process, reducing the need for on-site adjustments and ensuring that the finished product maintains the exact specifications of the original design. For contractors and furniture manufacturers, this translates to fewer callbacks for adjustments and repairs, enhancing client satisfaction with the finished product.

Structural Integrity Under Load-Bearing Conditions

Built-in furniture often serves multiple functional purposes beyond aesthetics, including supporting significant weight from stored items or even functioning as structural elements within interior spaces. Melamine plywood excels in these load-bearing applications due to its exceptional strength-to-weight ratio. The cross-laminated construction distributes weight evenly across the material, preventing sagging or deformation that might occur with other engineered wood products. This makes melamine plywood particularly suitable for built-in bookshelves, storage cabinets, and workspace surfaces that must support heavy items without compromising structural integrity. The material's edge strength also allows for secure fastening using various joinery techniques, from traditional methods to modern hardware systems. When properly constructed, melamine plywood cabinetry can support considerable weight on shelving spans that would require additional reinforcement with other materials. This structural performance maintains consistency throughout the product's lifecycle, unlike some competing materials that may initially perform well but degrade under continuous loading. For applications like floating shelves, entertainment centers supporting electronics, or kitchen cabinets holding heavy dishware, melamine plywood provides reliable performance without the excessive weight and cost of solid hardwood alternatives.

Aesthetic Versatility for Design Freedom

Diverse Color and Finish Options

Melamine plywood offers designers and homeowners an impressive spectrum of aesthetic possibilities through its diverse range of colors and finishes. Unlike traditional wood that must be stained or painted to achieve specific colors, melamine plywood comes pre-finished in virtually limitless color options. From subtle neutrals like whites, grays, and beiges to bold statement colors, the design possibilities extend far beyond what's practical with natural wood products. This color consistency is achieved during manufacturing, where decorative papers with precise color specifications are impregnated with melamine resin before being thermally fused to the plywood substrate. Beyond solid colors, melamine plywood is available in patterns that convincingly replicate the appearance of natural wood grains, stone textures, and even metallic surfaces, all while maintaining the practical benefits of melamine plywood. The finish options range from high-gloss surfaces that reflect light and create visual space in smaller rooms to matte finishes that absorb light and convey sophisticated understatement. Textured options like embossed wood grain provide not only visual but also tactile authenticity. This aesthetic versatility allows designers to create built-in furniture that perfectly complements interior design schemes without compromising on performance. Custom kitchens, home offices, and built-in bedroom furnishings benefit tremendously from this ability to balance visual appeal with practical durability, allowing homeowners to achieve designer looks without the maintenance challenges of natural materials.

Uniformity and Consistency in Large Projects

One of the significant challenges in large-scale built-in furniture projects is maintaining visual consistency across multiple components. Natural wood presents inherent variations in grain patterns and color, which can create matching difficulties when constructing extensive cabinetry systems or furniture sets that span multiple rooms. Melamine plywood eliminates this concern through its manufacturing process, which ensures remarkable uniformity in appearance from one sheet to the next. This consistency is particularly valuable in commercial projects like office fit-outs, retail environments, and hospitality installations where a cohesive aesthetic is essential across large spaces. The controlled production process for melamine plywood means that components manufactured months apart can match perfectly, allowing for phased projects or future additions to existing installations. This predictability streamlines the design process, as architects and interior designers can confidently specify colors and finishes knowing that the final product will accurately reflect their vision. The uniform substrate also ensures that cut edges maintain consistency throughout the project, a crucial factor for open shelving and other applications where edges may be visible. For designers working on comprehensive built-in solutions that incorporate multiple furniture pieces—such as integrated storage systems that span from kitchen to dining area, or bedroom suites with coordinated closets and storage—melamine plywood provides the visual continuity necessary for a professional, cohesive result.

Design Integration with Contemporary Interiors

Melamine plywood has become increasingly favored by designers for built-in furniture in contemporary interiors due to its inherent compatibility with modern aesthetic principles. The clean, precise lines possible with melamine plywood align perfectly with minimalist and contemporary design approaches that emphasize simplicity and geometric clarity. The material's smooth, uniform surface creates a refined backdrop that can either stand as a design feature or recede to highlight other elements within a space. In open-concept living environments, where built-in furniture often serves as room dividers or transitional elements between functional zones, melamine plywood provides the visual versatility to either create continuity or define distinct areas through thoughtful color selection. The material's contemporary appearance also integrates seamlessly with other modern materials like glass, metal, and concrete, allowing for multi-material designs that combine the warmth of wood with industrial elements. For built-in media centers, kitchen islands with seating, and workspace integrations, melamine plywood offers the perfect balance between visual sophistication and practical functionality. The material's adaptability extends to various hardware pairings, from minimalist hidden handles to statement hardware pieces, allowing further customization to match specific design directions. As interior design trends continue to favor clean lines and uncluttered spaces, melamine plywood provides the ideal foundation for built-in furniture that appears intentionally designed rather than merely functional, elevating the overall aesthetic quality of interior environments without sacrificing practicality.

Practical Benefits for Homeowners and Contractors

Cost-Effective Quality Without Compromise

One of the most compelling advantages of melamine plywood for built-in furniture projects is its exceptional value proposition, delivering professional-grade results without the premium price tag of solid hardwoods or high-end composites. This cost-effectiveness stems from efficient manufacturing processes that maximize material usage while minimizing labor-intensive finishing steps. Unlike solid wood that requires considerable time for sanding, staining, and sealing, melamine plywood arrives pre-finished and ready for immediate fabrication. This translates to significant labor savings in custom furniture projects, allowing contractors to deliver quality results within tighter budget constraints. The material's consistent quality also reduces waste from defects that might be encountered with natural materials, improving overall project economics. For homeowners undertaking comprehensive renovations or new construction projects, melamine plywood built-ins offer a practical way to extend design budgets without compromising on appearance or functionality. The long-term cost benefits extend beyond initial installation, as melamine plywood's durability reduces the need for refinishing or replacement that might be necessary with less resilient materials. Kitchen renovations particularly benefit from this balance of quality and affordability, allowing homeowners to allocate budget to other high-impact elements like appliances or countertops while still achieving beautiful, functional cabinetry. The material's consistent pricing and availability also provide predictability in project planning, without the market fluctuations that often affect premium hardwood prices due to seasonality or supply chain disruptions.

Easy Maintenance for Busy Households

In today's fast-paced households, furniture maintenance requirements significantly impact material selection decisions. Melamine plywood excels in this category by offering remarkably low-maintenance performance compared to alternatives. The melamine resin surface creates a non-porous barrier that prevents liquids, oils, and food particles from penetrating the material—a crucial advantage for kitchen cabinetry, pantry storage, and dining area built-ins. Daily cleaning typically requires nothing more than a damp cloth with mild soap, eliminating the need for specialized cleaning products or elaborate care routines. Unlike natural wood that may require periodic refinishing to maintain its protective seals, melamine plywood retains its protective qualities throughout its lifespan without additional treatments. This practical benefit resonates strongly with busy families, professionals, and rental property owners seeking durable solutions that won't demand ongoing attention. The material's resistance to common household challenges like children's fingerprints, pet-related wear, and occasional spills means that melamine plywood built-ins maintain their appearance with minimal effort. This practical benefit extends to semi-commercial environments like home offices and multi-family properties, where maintenance requirements directly impact operational costs. For areas with specific hygiene considerations, such as bathroom vanities or laundry room cabinetry, melamine plywood's moisture resistance and easy-clean surface provide practical advantages that improve daily living. The non-absorbent surface also resists odors and bacterial growth, addressing concerns that might arise with more porous materials in kitchen and bathroom applications.

Environmental Considerations and Indoor Air Quality

Modern consumers and designers increasingly prioritize the environmental impact and health implications of building materials, particularly for permanent installations like built-in furniture. Melamine plywood addresses these concerns through manufacturing processes that have evolved to meet stringent environmental standards. Quality melamine plywood products, such as those from Linyi Longterm Wood Industry, adhere to E1 and E0 formaldehyde emission standards, ensuring minimal impact on indoor air quality once installed. These classifications reference the extremely low levels of formaldehyde emission, making the material suitable for sensitive environments including children's rooms, healthcare facilities, and spaces for individuals with respiratory concerns. The responsible sourcing of wood components and efficient material utilization during manufacturing contribute to melamine plywood's smaller environmental footprint compared to solid timber options that may contribute to deforestation concerns. For environmentally conscious projects, manufacturers can provide certification documentation confirming compliance with relevant standards like CARB (California Air Resources Board) requirements or international equivalents. The durability factor also contributes positively to environmental considerations, as longer-lasting furniture reduces the consumption cycle and associated resource utilization. For built-in furniture with expected lifespans measured in decades rather than years, this longevity represents significant resource conservation. The material's consistency also improves fabrication efficiency, reducing waste generation during the construction process. For contractors and designers working with clients who prioritize environmental responsibility, melamine plywood offers a defensible choice that balances practical performance with reduced environmental impact, particularly when sourced from manufacturers committed to sustainable practices and transparent documentation of their environmental credentials.

Conclusion

Melamine plywood stands as the ideal material for built-in furniture, offering exceptional durability, design versatility, and practical benefits that enhance both form and function. With its resistance to wear, moisture, and daily challenges, coupled with a wide range of aesthetic options, it meets the demands of both designers and homeowners. For quality melamine plywood that delivers superior performance for your built-in furniture projects, contact us at howie@longtermwood.com to discuss your specific requirements and experience the Linyi Longterm Wood Industry difference.

References

1. Johnson, D.R. (2023). Advanced Materials in Contemporary Furniture Design. Architectural Digest, 47(3), 112-118.

2. Zhang, L., & Peterson, M. (2022). Comparative Analysis of Engineered Wood Products for Interior Applications. Journal of Interior Design, 29(2), 78-95.

3. Hernandez, R. (2024). Sustainable Materials Selection for Modern Cabinetry. Building Products Digest, 31(4), 45-52.

4. Thompson, K.L. (2023). Performance Standards for Commercial Furniture Materials. International Journal of Furniture Research, 18(2), 203-221.

5. Williams, S., & Chen, Y. (2024). Environmental Impact Assessment of Contemporary Furniture Materials. Sustainable Design Quarterly, 12(1), 34-49.

6. Anderson, J.M. (2023). Built-In Furniture Solutions for Modern Living Spaces. Contemporary Architecture & Design, 15(3), 156-172.