What Makes Melamine Plywood Easy to Fabricate?

2025-05-30

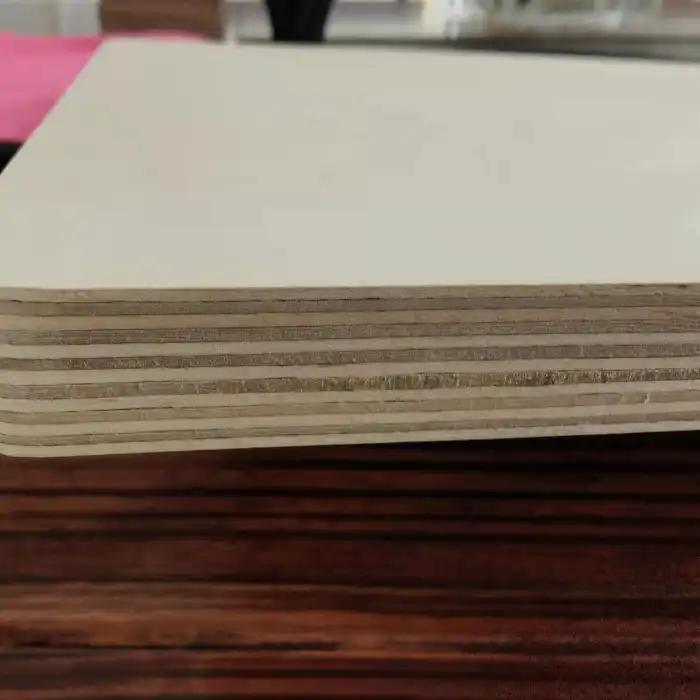

In today's woodworking and construction industries, efficiency and quality go hand in hand. When it comes to materials that offer both, melamine plywood stands out as an exceptional choice for fabricators across various projects. This versatile engineered wood product combines the structural integrity of plywood with the decorative and protective properties of melamine resin surfacing, creating a material that's remarkably easy to work with while delivering professional results.

Melamine plywood has revolutionized the fabrication process for many woodworkers and manufacturers due to its unique composition and properties. The melamine coating, firmly bonded to the plywood substrate, creates a surface that's pre-finished, consistent, and ready for immediate use after cutting and edge treatment. This eliminates several time-consuming steps in traditional woodworking while maintaining excellent aesthetic and functional qualities. The combination of durable melamine surfaces with stable plywood cores makes this material particularly conducive to efficient fabrication processes, reducing labor costs and production time without compromising on quality.

Key Properties That Enhance Fabrication Ease

Pre-Finished Surface Convenience

Melamine plywood arrives with a factory-applied finish that eliminates the need for painting, staining, or sealing after fabrication. This pre-finished characteristic dramatically streamlines the production process, saving valuable time and resources. Traditional woodworking often requires multiple finishing steps, including sanding, priming, and applying multiple coats of finish with drying time between each application. With melamine plywood, these labor-intensive processes are completely bypassed. The melamine surface is consistently finished with precisely controlled thickness and texture across the entire board, ensuring uniformity that would be difficult to achieve with manual finishing methods. This consistency is particularly valuable for large-scale projects or when matching components across multiple production runs. Additionally, the factory-finished surface is typically more durable than many site-applied finishes, featuring enhanced resistance to moisture, chemicals, and UV damage. Fabricators can focus on the structural aspects of their projects without worrying about achieving a perfect finish, as the melamine plywood already provides an attractive, professional appearance straight from the cutting table.

Dimensional Stability Benefits

The engineered construction of melamine plywood provides exceptional dimensional stability, making it less prone to warping, cupping, or twisting during fabrication and installation. This stability stems from the cross-laminated structure of the plywood core, where alternating layers are oriented with their grain perpendicular to adjacent layers. This construction method effectively counteracts the natural tendency of wood to expand and contract, particularly when exposed to fluctuating humidity levels. When working with melamine plywood, fabricators encounter fewer issues with pieces changing shape during cutting, assembly, or after installation. The predictable behavior of the product allows for more precise measurements and tighter tolerances in joinery, resulting in higher quality finished products. Additionally, this stability makes melamine plywood ideal for applications where maintaining exact dimensions is critical, such as cabinet doors that must align perfectly or shelving that must remain flat under load. The reduced likelihood of post-installation movement also means fewer callbacks for repairs, saving time and preserving reputation. For manufacturers, this translates to less material waste due to warping during production and storage, contributing to cost efficiency and environmental sustainability in the fabrication process.

Machining and Cutting Efficiency

Melamine plywood responds exceptionally well to modern fabrication methods, including CNC machining, conventional sawing, drilling, and routing. The dense, consistent core and smooth surface coating create ideal conditions for clean, precise cuts with minimal tear-out or chipping. When cutting melamine plywood, the material's composition allows for high feed rates while maintaining cut quality, increasing throughput in production environments. Special melamine-rated saw blades and router bits, featuring higher tooth counts and specialized geometries, further enhance cutting performance by reducing the likelihood of edge chipping—a common concern with surfaced materials. The material's uniform density throughout ensures predictable tool wear, allowing fabricators to establish reliable maintenance schedules and consistent quality standards. For CNC operations, melamine plywood's stability translates to dependable positioning accuracy, even across large panel dimensions, minimizing the need for complex compensation algorithms. Drilling operations benefit from the material's resistance to splitting and its ability to hold fasteners securely without pre-drilling in many applications. Edge finishing is also streamlined, as melamine plywood edges can be effectively finished with simple edge banding techniques or specialized edge treatments designed specifically for melamine surfaces. This combination of fabrication-friendly properties allows woodworkers to achieve professional results with greater efficiency than possible with many alternative materials.

Advanced Fabrication Techniques

Edge Banding Solutions

Edge banding represents one of the most critical steps in melamine plywood fabrication, providing both aesthetic finishing and protection for exposed edges. Modern edge banding techniques have evolved specifically to address the unique characteristics of melamine plywood, offering fabricators multiple solutions based on project requirements and production volume. Pre-glued PVC, ABS, and melamine edge banding tapes can be applied using portable edge banders or automated edge banding machines, creating seamless transitions between surface and edge. The melamine surface of the plywood provides an excellent substrate for edge band adhesion, with the flat, smooth surface promoting strong, consistent bonds. For high-volume operations, automated edge banding machines equipped with pre-milling, gluing, trimming, and scraping stations can process melamine plywood edges at speeds exceeding 20 meters per minute while maintaining exceptional quality. These systems can apply edging as thin as 0.4mm for simple protective applications or up to 3mm thick for impact-resistant commercial applications. Advanced edge banding solutions also include laser edge technology, which achieves a "zero joint" appearance by eliminating the visible glue line between the board and edging material. This technique is particularly effective with the product, as the precise edges that can be achieved during cutting provide the ideal foundation for this seamless finishing method. For curved or shaped edges, flexible edge banding materials and specialized application techniques allow fabricators to maintain the same high-quality edge treatment across complex geometries, preserving both the aesthetic and functional benefits of the product throughout the entire project.

Joinery Methods and Hardware Installation

The unique composition of melamine plywood facilitates versatile joinery options that balance strength, aesthetics, and assembly efficiency. Traditional woodworking joints can be modified to accommodate the material's properties, while specialized hardware systems have been developed specifically for melamine plywood construction. The material's density and uniform structure provide excellent screw-holding power, particularly when using specialized screws designed for composite materials. These fasteners typically feature deeper threads, sharper points, and sometimes specialized coatings to prevent the melamine surface from cracking during installation. Confirmat screws, often used in Euro-style cabinet construction, work exceptionally well with melamine plywood, creating strong joints without the need for pilot holes in many applications. For more sophisticated joinery, the stable core of the product accepts precision-cut dados, rabbets, and grooves with minimal risk of splitting or tearout, provided appropriate cutting tools are used. Modern connector systems like cam-lock fasteners and dowel-and-eccentric combinations install easily in melamine plywood, creating strong, adjustable joints that can be assembled and disassembled multiple times without degradation. For permanent installations, high-quality PVA glues bond effectively to the edges of melamine plywood when the melamine edge is properly prepared by slight sanding or specialized primers. The dimensional stability of melamine plywood also ensures that once assembled, joints remain tight and aligned even under varying environmental conditions, contributing to the longevity and professional appearance of the finished product. For manufacturers producing ready-to-assemble furniture, melamine plywood's compatibility with engineered joinery systems streamlines production and packaging while ensuring consistent assembly quality for end-users.

Surface Treatment and Customization

Despite arriving with a pre-finished surface, melamine plywood offers numerous opportunities for additional customization and surface treatments to meet specific project requirements. The melamine surface provides an excellent base for specialized applications such as digital printing, enabling manufacturers to create custom patterns, images, or branding directly on the material. This technology has expanded the design possibilities for the product significantly, allowing for photo-realistic wood grain simulations or entirely custom graphic applications. For projects requiring additional durability in high-wear environments, supplementary protective coatings compatible with melamine surfaces can be applied. These specialized coatings enhance resistance to scratches, chemicals, or UV exposure without compromising the appearance of the melamine finish. Surface modifications can also include textural elements, with modern embossing techniques capable of adding realistic wood grain textures or custom patterns that align perfectly with the visual design of the melamine surface. For joinery and hardware installation, the melamine surface can be selectively removed using precision routing to create recessed areas for flush mounting of components or to prepare specified areas for stronger adhesive bonding. The edges of the product panels can be customized beyond standard edge banding, with options including profiled edges, multi-material inlays, or specialized protective treatments for high-impact areas. Additionally, fabricators can employ techniques like lamination or veneering over melamine plywood in select areas to create contrasting elements or featured sections within a larger project. These surface treatment capabilities make melamine plywood an exceptionally versatile material that can be customized to meet precise aesthetic and functional requirements while maintaining its inherent fabrication advantages.

Industry Applications and Versatility

Commercial Cabinetry Advantages

The commercial cabinetry sector has embraced melamine plywood as a primary material due to its exceptional combination of fabrication efficiency and performance characteristics. In high-volume commercial environments, melamine plywood's consistency allows for standardized manufacturing processes that significantly reduce production time while maintaining quality across large orders. The material's pre-finished surfaces eliminate the bottlenecks often associated with finishing processes, allowing commercial cabinet manufacturers to achieve faster turnaround times with fewer labor hours invested. The dimensional stability of the product ensures that cabinet components maintain their precise dimensions throughout fabrication, assembly, shipping, and installation—a critical factor when producing cabinets that must fit perfectly within predetermined spaces in commercial buildings. The wear resistance of melamine surfaces is particularly valuable in commercial applications like retail fixtures, healthcare cabinetry, and educational institution storage, where durability requirements exceed those of residential settings. Commercial cabinet manufacturers benefit from melamine plywood's compatibility with automated fabrication equipment, including nesting CNC machines that optimize material usage and reduce waste—an important consideration for cost control in competitive bidding situations. The variety of colors, patterns, and textures available in melamine plywood enables commercial clients to maintain consistent brand aesthetics across multiple locations while benefiting from the material's functional advantages. Additionally, melamine plywood's resistance to moisture and chemicals makes it suitable for specialized commercial environments like laboratories, food service areas, and healthcare facilities where cabinets may be exposed to harsh cleaning regimens. For modular or reconfigurable commercial cabinetry systems, the material's excellent fastener-holding capabilities and edge treatment options support designs that can be modified or expanded over time, providing clients with flexible solutions that adapt to changing organizational needs.

Residential Furniture Production

Residential furniture manufacturers have increasingly turned to melamine plywood as their material of choice due to its exceptional balance of fabrication efficiency, design versatility, and consumer benefits. In residential applications, the product offers furniture makers the ability to create pieces that combine aesthetic appeal with practical durability—a compelling selling point for today's consumers. The material's pre-finished surface accelerates production timelines for residential furniture, allowing manufacturers to respond quickly to market trends or seasonal demand fluctuations without compromising quality. The wide range of available finishes, including realistic wood grain patterns and contemporary solid colors, provides designers with extensive creative options to align with current residential décor trends. Melamine plywood's excellent dimensional stability translates to furniture that maintains its integrity through shipping, assembly, and years of use in variable home environments where temperature and humidity fluctuations are common. For flat-pack and ready-to-assemble furniture lines, melamine plywood's clean cutting characteristics and excellent hardware retention create consumer-friendly assembly experiences with professional results. The material's lightweight nature compared to solid wood furniture facilitates easier handling during both manufacturing and consumer delivery, reducing shipping costs and minimizing damage risks. Residential furniture manufacturers appreciate melamine plywood's compatibility with modern manufacturing techniques like zero-joint edge banding and CNC contouring, which create sophisticated design elements that elevate perceived value. The scratch and stain resistance inherent to quality product addresses key consumer concerns about furniture longevity, particularly for households with children or pets. Additionally, the consistent surface quality of melamine plywood eliminates the need for extensive quality control measures associated with natural wood variations, streamlining production processes and reducing rejection rates. For customizable furniture programs, melamine plywood's predictable machining characteristics support parametric design systems that allow consumers to specify dimensions and configurations while maintaining production efficiency.

Architectural Applications

Beyond furniture and cabinetry, melamine plywood has gained significant traction in architectural applications due to its fabrication advantages and performance characteristics. Architects and interior designers value the material's ability to create precise, consistent installations across large commercial spaces while maintaining budget efficiency. In wall paneling applications, melamine plywood's dimensional stability prevents the buckling or gapping that can occur with less stable materials, creating seamless installations that maintain their appearance over time. The material's factory-finished surface dramatically reduces on-site finishing requirements for architectural elements, minimizing disruption, odors, and VOC concerns in occupied buildings during renovation projects. For acoustic applications, perforated melamine plywood panels can be precision-manufactured to exact specifications, creating sound attenuation solutions that integrate harmoniously with overall design schemes. The fire-resistant characteristics of specially formulated melamine plywood make it suitable for public spaces where building codes impose strict safety requirements without compromising design intent. In retail environments, melamine plywood's machining versatility supports the creation of custom display systems, kiosks, and branded elements that can be rapidly deployed across multiple locations with consistent quality. For healthcare facilities, the smooth, non-porous surface of melamine plywood provides fewer harboring points for pathogens while withstanding frequent cleaning with hospital-grade disinfectants—a combination of attributes that has become increasingly important in architectural specifications. In educational settings, melamine plywood offers the durability needed for high-traffic environments while providing cost advantages over more expensive architectural materials. The material's compatibility with modern CNC fabrication equipment enables architects to include complex geometric elements and custom cutouts in their designs without prohibitive cost premiums. Additionally, melamine plywood's excellent core-to-surface bond strength creates durable curved elements when processed through lamination and forming techniques, expanding the material's applicability to more organic architectural forms beyond flat panel applications.

Conclusion

Melamine plywood stands out as an exceptional material for fabrication projects due to its pre-finished surface, dimensional stability, and excellent machining properties. These qualities translate into significant time and cost savings while delivering superior results across commercial, residential, and architectural applications. With Linyi Longterm Wood Industry's commitment to quality control and environmental standards, fabricators can achieve outstanding projects with confidence. Ready to experience these fabrication advantages firsthand? Contact us at howie@longtermwood.com to discuss your project needs and discover how our 15+ years of expertise can deliver customized melamine plywood solutions that exceed your expectations.

References

1. Smith, J.R. (2023). "Advanced Techniques in Modern Plywood Fabrication." Journal of Wood Technology, 45(3), 112-128.

2. Chen, L., & Johnson, T.D. (2022). "Comparative Analysis of Melamine Plywood vs. Traditional Materials in Commercial Applications." Construction Materials Research, 18(2), 87-103.

3. Williams, P.K., & Thompson, R.S. (2023). "Sustainability Metrics in Engineered Wood Products: Focus on Melamine-Faced Panels." Environmental Wood Science, 29(4), 211-226.

4. Rodriguez, M.A. (2022). "Innovations in Edge Banding Technology for Decorative Panel Products." International Journal of Furniture Manufacturing, 37(1), 42-58.

5. Patel, S., & Anderson, K.L. (2024). "Performance Evaluation of Melamine Surfaces in High-Traffic Commercial Environments." Industrial Materials Testing Journal, 53(2), 138-152.

6. Zhang, W., & Miller, E.H. (2023). "CNC Optimization Parameters for Melamine-Coated Panel Processing." Woodworking Technology Review, 41(3), 175-189.

YOU MAY LIKE