Thickness : 9mm , 12mm , 56mm , 18mm

Grade : Furniture grade

Glue : E2 , E1 , E0 , CARB

Density : 520---580kgs/m3

Certification : EPA CARB P2 certification

Moisture Content : 8% ~18%

Keywords : Poplar core commercial plywood

Application : Furniture industry

Size : 1220*2440 mm

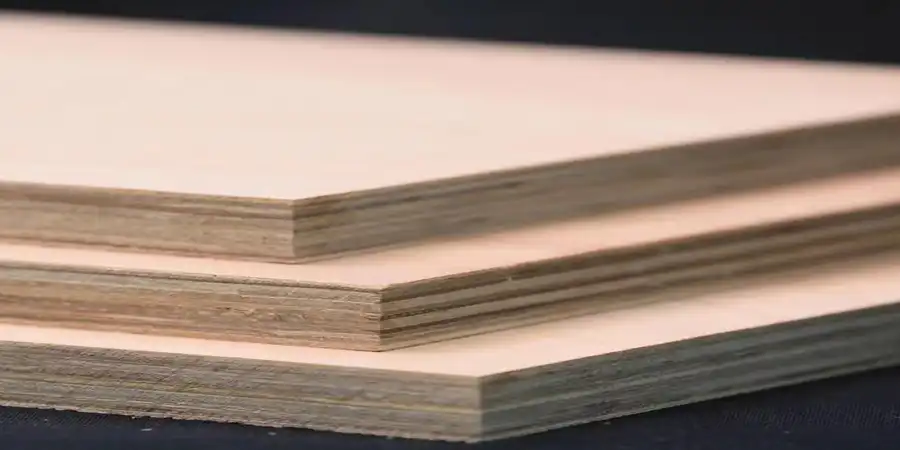

Full Poplar Core Commercial Plywood | Durable & High-Strength Building Material

Engineered for Structural Integrity, Moisture Resistance, and Long-Term Performance in Commercial Projects

Why Choose Full Poplar Core Commercial Plywood?

When you need reliable strength for demanding projects, full poplar core commercial plywood delivers. Made with 100% poplar veneers layered for uniform density, this plywood resists warping, holds screws securely, and withstands heavy loads—making it ideal for concrete formwork, roofing, and structural frameworks. Sourced from sustainable plantations and certified for global compliance, it’s the smart choice for contractors prioritizing durability and cost efficiency.

Key Features & Benefits

✅ Built to Last

- Poplar Core Advantages: Lightweight yet strong, with minimal voids for consistent performance.

- Smooth Surfaces: Easy concrete separation reduces labor time.

- Moisture-Resistant: WBP glue bonds withstand humid conditions.

- Certified Safe: Meets CARB Phase 2, FSC, and CE standards.

🛠️ Versatile Applications

- Concrete Formwork: Reusable up to 10x with proper care.

- Roofing & Walls: Stable in temperature fluctuations.

- Heavy-Duty Flooring: Supports machinery and high foot traffic.

Technical Specifications

| Parameter | Details |

|---|---|

| Thickness | 9mm – 25mm (customizable) |

| Panel Size | 1220x2440mm (standard) |

| Density | 450–550 kg/m³ |

| Moisture Content | ≤10% |

| Glue Type | MR/WBP (Water Boil Proof) |

| Certifications | FSC, CE, ISO 9001, CARB Phase 2 |

Real-World Use Cases

1. High-Rise Concrete Formwork

Contractors in Dubai used 18mm full poplar core commercial plywood for 50+ reusable formworks, cutting material costs by 30%.

2. Warehouse Roofing in Coastal Areas

A Florida project showcased zero warping after 2 years in salty, humid air.

3. Temporary Event Stages

Lightweight panels enabled rapid setup for outdoor concerts.

Poplar Core vs. Mixed Hardwood

| Factor | Poplar Core | Mixed Hardwood |

|---|---|---|

| Weight | 15% lighter | Heavier |

| Screw Holding | Superior grip | Prone to splintering |

| Cost Over 5 Years | Lower replacement costs | Frequent repairs |

Global Shipping Made Simple

- MOQ: 1x 20ft container (≈25m³).

- Lead Time: 15–25 days.

- Packaging: Waterproof wraps + steel strapping.

Trusted by Professionals

“Consistent thickness and no delays—critical for our hospital project.”

– James R., Contractor, USA

Get Started Today

🔹 Request a Free Sample: Test our quality risk-free.

🔹 Bulk Pricing: Save up to 18% on 3+ containers.

🔹 Live Chat Support: Instant answers to technical questions.

FAQs

1. How strong is full poplar core commercial plywood?

It supports up to 2.5kN/m², perfect for multi-story formworks.

2. Is it suitable for wet environments?

Yes! WBP glue ensures water resistance for 72+ hours.

3. Can I get custom sizes?

Absolutely—we cut to your specs with ±0.2mm precision.

4. Are fire-resistant options available?

Yes, ask about our Class B1 fire-retardant treatment.

5. Why choose poplar over softwood cores?

Poplar resists warping better, saving long-term costs.

Email us for quotes or specs: howie@longtermwood.com

_1750992058130.webp)