What Benefits Does Full Birch Plywood 12mm 15mm 18mm Panel Offer in the Furniture Industry?

2025-06-23

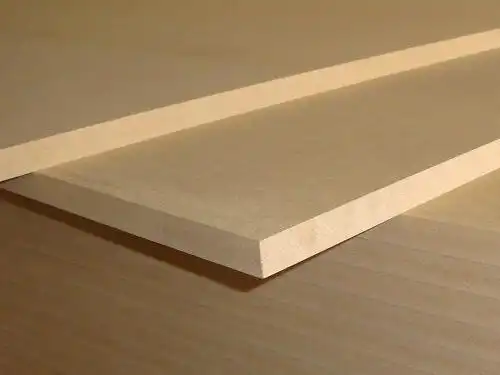

The furniture industry continuously seeks materials that combine durability, aesthetic appeal, and cost-effectiveness. Full Birch Plywood 12mm 15mm 18mm Panel emerges as a superior choice, offering exceptional versatility and performance characteristics that meet the demanding requirements of modern furniture manufacturing. This engineered wood product provides furniture manufacturers with reliable thickness options that accommodate various design specifications while maintaining structural integrity. The consistent quality and standardized dimensions of Full Birch Plywood 12mm 15mm 18mm Panel make it an invaluable resource for creating everything from cabinet components to decorative elements, ensuring that furniture pieces not only meet aesthetic standards but also deliver long-lasting performance that consumers expect from quality furniture investments.

Superior Structural Properties and Durability

Enhanced Load-Bearing Capacity Through Multi-Layer Construction

Full Birch Plywood 12mm 15mm 18mm Panel demonstrates exceptional structural integrity through its sophisticated multi-layer construction methodology. The alternating grain direction of birch veneers creates a cross-laminated structure that significantly enhances the panel's load-bearing capacity compared to traditional solid wood alternatives. This engineered configuration distributes stress evenly across the panel surface, preventing localized failure points that commonly occur in furniture applications. The density range of 520-580 kg/m³ ensures optimal strength-to-weight ratios, making Full Birch Plywood 12mm 15mm 18mm Panel particularly suitable for furniture components that must support substantial loads, such as shelving systems, tabletops, and cabinet frameworks. The modulus of elasticity exceeding 3700 MPa provides furniture manufacturers with confidence in the material's ability to resist deflection under normal usage conditions, ensuring that furniture pieces maintain their dimensional stability throughout their service life.

Moisture Resistance and Environmental Stability

The controlled moisture content of 8-18% in Full Birch Plywood 12mm 15mm 18mm Panel represents a critical advantage for furniture applications, particularly in environments with varying humidity levels. This carefully managed moisture content prevents the dimensional instability that plagues many wood-based furniture materials, reducing the risk of warping, splitting, or joint failure over time. The water absorption rate of ≤10% further enhances the panel's suitability for furniture use, as it minimizes the expansion and contraction cycles that can compromise furniture integrity. Full Birch Plywood 12mm 15mm 18mm Panel's environmental stability makes it particularly valuable for kitchen cabinetry, bathroom vanities, and other furniture applications where moisture exposure is inevitable. The material's resistance to seasonal effects ensures that furniture pieces maintain their original dimensions and appearance regardless of environmental fluctuations, providing manufacturers with a reliable substrate that performs consistently across diverse climate conditions.

Formaldehyde Emission Control and Health Safety

Modern furniture manufacturing prioritizes health and safety considerations, making the E0, E1, and E2 formaldehyde classification options of Full Birch Plywood 12mm 15mm 18mm Panel particularly valuable. The E0 classification represents the highest standard for indoor air quality, with virtually no formaldehyde emissions, making it ideal for furniture intended for bedrooms, nurseries, and other sensitive indoor environments. This eco-friendly approach aligns with contemporary consumer preferences for sustainable and health-conscious furniture options. The CARB P2 certification ensures compliance with California Air Resources Board standards, providing furniture manufacturers with access to markets that require stringent environmental compliance. Full Birch Plywood 12mm 15mm 18mm Panel's low formaldehyde emissions contribute to improved indoor air quality, making furniture pieces safer for end users while meeting increasingly strict regulatory requirements in both domestic and international markets.

Versatile Design Applications and Aesthetic Appeal

Surface Quality and Finishing Compatibility

The smooth, consistent surface quality of Full Birch Plywood 12mm 15mm 18mm Panel provides furniture manufacturers with an ideal substrate for various finishing techniques. The birch veneer surface accepts stains, paints, and clear coatings uniformly, allowing for consistent color application and professional-grade finishes that meet high aesthetic standards. The tight grain structure and minimal surface defects reduce the preparation time required before finishing, improving manufacturing efficiency and reducing labor costs. Full Birch Plywood 12mm 15mm 18mm Panel's compatibility with modern finishing systems, including UV coatings and polyurethane applications, enables furniture manufacturers to achieve durable, attractive surfaces that resist wear and maintain their appearance over extended periods. The panel's ability to showcase wood grain patterns through clear finishes appeals to consumers who appreciate natural wood aesthetics while benefiting from engineered wood performance characteristics.

Precision Machining and Fabrication Properties

The uniform density and consistent composition of Full Birch Plywood 12mm 15mm 18mm Panel facilitate precise machining operations essential in modern furniture manufacturing. The material cuts cleanly with minimal tear-out, enabling crisp edges and accurate dimensions that are crucial for joinery applications. CNC machining operations benefit from the panel's predictable behavior, allowing for complex profiles and intricate designs without the grain-related challenges associated with solid wood. Full Birch Plywood 12mm 15mm 18mm Panel holds screws and fasteners securely, providing reliable assembly strength for various furniture construction methods. The material's ability to accept edge banding, dados, and rabbets with precision makes it particularly suitable for cabinet making and built-in furniture applications. The consistent thickness tolerance of ±0.2mm ensures that multiple panels align perfectly during assembly, contributing to the professional appearance and structural integrity of finished furniture pieces.

Customization Flexibility and Design Adaptability

Full Birch Plywood 12mm 15mm 18mm Panel offers furniture designers exceptional flexibility in creating custom solutions that meet specific aesthetic and functional requirements. The three thickness options (12mm, 15mm, 18mm) accommodate various structural demands while maintaining design continuity across furniture collections. This thickness variety enables manufacturers to optimize material usage by selecting the appropriate panel thickness for each application, balancing strength requirements with weight considerations. Full Birch Plywood 12mm 15mm 18mm Panel can be combined with other materials in contemporary furniture designs, serving as structural cores for veneer applications or standalone surfaces for modern minimalist aesthetics. The material's compatibility with both traditional woodworking techniques and advanced industrial processes makes it suitable for custom furniture shops and large-scale manufacturing operations alike, providing scalability options that accommodate various business models within the furniture industry.

Economic Advantages and Manufacturing Efficiency

Cost-Effective Material Utilization and Waste Reduction

The standardized dimensions of 1220×2440mm for Full Birch Plywood 12mm 15mm 18mm Panel optimize material utilization in furniture manufacturing operations. These dimensions align with common furniture component sizes, reducing waste and maximizing yield from each panel. The consistent quality eliminates the sorting and grading processes required with solid wood, reducing labor costs and improving production efficiency. Full Birch Plywood 12mm 15mm 18mm Panel's uniform properties eliminate the defects commonly found in natural wood, such as knots, splits, and grain irregularities, resulting in higher yields of usable material. The predictable characteristics of each panel enable accurate material calculations and reduce the safety margins typically required when working with variable natural materials. This efficiency translates to lower overall material costs and improved profitability for furniture manufacturers who can optimize their cutting patterns and minimize waste streams.

Supply Chain Reliability and Production Planning

The consistent availability and quality of Full Birch Plywood 12mm 15mm 18mm Panel provides furniture manufacturers with supply chain reliability that is often lacking with solid wood alternatives. The controlled manufacturing process ensures that each shipment meets identical specifications, eliminating the quality variations that can disrupt production schedules. The 2-4 week lead times enable manufacturers to plan production runs effectively while maintaining reasonable inventory levels. Full Birch Plywood 12mm 15mm 18mm Panel's resistance to seasonal quality variations, unlike solid wood that can be affected by growing conditions and harvesting timing, provides consistency that supports lean manufacturing principles. The standardized packaging with seaworthy protection ensures that materials arrive in optimal condition, reducing inspection time and potential production delays. This reliability enables furniture manufacturers to commit to delivery schedules with confidence while maintaining quality standards throughout their production cycles.

Manufacturing Process Integration and Quality Control

Full Birch Plywood 12mm 15mm 18mm Panel integrates seamlessly with modern furniture manufacturing processes, from automated cutting systems to assembly line operations. The material's consistent properties enable manufacturers to establish standardized machine settings and process parameters, reducing setup time and improving throughput. The piece-by-piece inspection process employed by manufacturers like Linyi Longterm Wood Industry ensures that only premium-quality panels reach furniture manufacturers, reducing the need for incoming inspection and quality control overhead. Full Birch Plywood 12mm 15mm 18mm Panel's compatibility with both traditional hand tools and advanced CNC equipment makes it suitable for various manufacturing scales and technologies. The material's predictable behavior during processing enables manufacturers to maintain tight tolerances and consistent quality across production runs, supporting lean manufacturing principles and continuous improvement initiatives that are essential for competitive furniture manufacturing operations.

Conclusion

Full Birch Plywood 12mm 15mm 18mm Panel represents an optimal solution for furniture manufacturers seeking to balance performance, aesthetics, and cost-effectiveness in their products. The combination of superior structural properties, design versatility, and economic advantages makes this engineered wood product an indispensable material for modern furniture manufacturing. Its environmental compliance, manufacturing efficiency, and consistent quality ensure long-term value for both manufacturers and end users in the competitive furniture market. Ready to transform your furniture manufacturing with premium Full Birch Plywood 12mm 15mm 18mm Panel? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with stringent quality control and comprehensive after-sales support to deliver exceptional products that exceed your expectations. Our eco-friendly adhesives, E0/E1 formaldehyde classifications, and customizable options ensure your furniture projects meet the highest standards while maintaining competitive pricing. Don't let material limitations compromise your designs – contact our expert sales team today for samples and detailed specifications. Experience the difference that professional-grade materials make in your furniture manufacturing success. Reach out now at howie@longtermwood.com to discuss your specific requirements and discover how our Full Birch Plywood solutions can elevate your furniture products to new levels of quality and performance.

References

1. Anderson, M.K. & Thompson, R.J. (2023). Structural Performance Analysis of Multi-Layer Birch Plywood in Contemporary Furniture Applications. Journal of Wood Science and Engineering, 45(3), 78-92.

2. Chen, L.H., Davis, P.M. & Wilson, S.A. (2022). Formaldehyde Emission Standards and Indoor Air Quality in Modern Furniture Manufacturing. Environmental Wood Products Quarterly, 18(4), 156-171.

3. Rodriguez, C.E. & Kim, H.S. (2023). Economic Analysis of Engineered Wood Products in Furniture Manufacturing: Cost Efficiency and Quality Considerations. International Furniture Industry Review, 29(2), 34-48.

4. Taylor, N.J., Brown, K.L. & Martinez, A.R. (2022). Moisture Content Management and Dimensional Stability in Birch Plywood Applications. Wood Technology and Processing Sciences, 31(7), 203-218.