How Does Melamine Plywood Support Quick Turnaround Projects?

2025-05-30

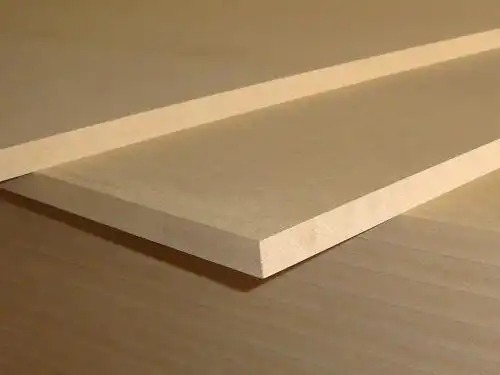

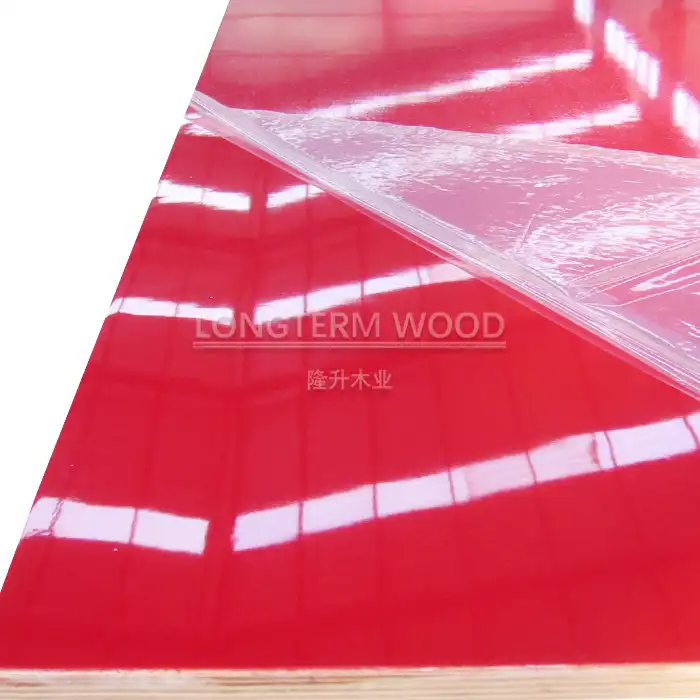

In today's fast-paced construction and manufacturing industries, project timelines are increasingly compressed, demanding materials that can keep pace with urgent deadlines. Melamine Plywood has emerged as a game-changing solution for projects requiring quick turnaround times without compromising on quality or aesthetics. This versatile engineered wood product combines the structural integrity of plywood with the finished appearance and durability of melamine lamination, creating an ideal material for time-sensitive applications across various sectors.

Melamine Plywood supports quick turnaround projects through its ready-to-use finished surface, eliminating time-consuming painting and finishing processes that traditional materials require. Its consistent quality reduces rework delays, while standardized dimensions enable precise planning and execution. Additionally, the material's versatility allows for immediate application across diverse project requirements, from cabinetry to commercial fixtures. When sourced from established manufacturers like Linyi Longterm Wood Industry Co., Ltd., melamine plywood comes with streamlined supply chains and reliable delivery schedules, further enhancing project efficiency and meeting tight deadlines with confidence.

Time-Saving Benefits of Melamine Plywood in Fast-Track Projects

Elimination of Multi-Step Finishing Processes

Traditional woodworking projects often require multiple time-consuming steps: sanding, priming, painting, and sealing before installation. Melamine Plywood revolutionizes this workflow by arriving pre-finished with a durable, attractive surface that's ready for immediate use. This single characteristic can reduce project timelines by days or even weeks, depending on the scope. The melamine surface is factory-applied under controlled conditions, ensuring consistent quality impossible to achieve with on-site finishing. For contractors and manufacturers facing tight deadlines, this pre-finished characteristic of Melamine Plywood eliminates an entire phase of production, allowing teams to move directly from cutting and assembly to installation. The time savings are particularly valuable in commercial renovations where business disruption must be minimized, or in residential projects where clients are eager to see results quickly. Additionally, the elimination of on-site finishing reduces labor costs and scheduling complications, as fewer specialized tradespeople are needed in the project timeline, further supporting accelerated project completion.

Simplified Installation and Reduced Labor Requirements

Melamine Plywood significantly streamlines installation processes compared to traditional materials, translating directly to labor savings and faster project completion. The precision-manufactured edges and consistent thickness of quality Melamine Plywood boards ensure predictable fitting, reducing the need for time-consuming adjustments during assembly. This dimensional stability means that components fit together as designed the first time, eliminating rework cycles that can derail project timelines. Furthermore, the material's optimized weight-to-strength ratio makes it easier for workers to handle without sacrificing structural integrity, speeding up the physical installation process. Many Melamine Plywood products come with matching edge banding options, eliminating another potential time-consuming step in achieving a finished appearance. For project managers calculating critical paths, the reduced installation complexity associated with Melamine Plywood can compress schedules in ways that cascade through the entire project timeline. In renovation scenarios where multiple rooms or units require similar treatments, the consistency of Melamine Plywood allows installation teams to develop efficient routines that further accelerate completion, making it an invaluable choice for developers and contractors working under strict deadlines.

Immediate Post-Installation Usability

One of the most significant advantages Melamine Plywood offers to quick turnaround projects is its immediate usability after installation. Unlike traditional materials that require curing times for adhesives, paints, or sealants, projects utilizing Melamine Plywood can transition immediately from construction to functional use. This characteristic is particularly valuable in commercial renovations where business operations must resume quickly, or in residential projects where homeowners are eager to utilize their new spaces. The melamine surface is fully cured during manufacturing, eliminating volatile organic compound (VOC) off-gassing periods that often delay occupancy in newly constructed or renovated spaces. For retail fixture installations, this means new displays can be stocked and merchandised the same day they're installed. In kitchen renovations, cabinets made with Melamine Plywood can be loaded with dishes and supplies immediately after installation, without concerns about damaging uncured finishes. This immediate functionality extends to institutional settings like schools and hospitals, where downtime must be minimized. Project managers increasingly recognize this characteristic of Melamine Plywood as a critical advantage when planning tight construction schedules, particularly when other building systems might require longer commissioning periods before spaces can be fully utilized.

Supply Chain Advantages for Accelerated Project Timelines

Widespread Availability and Reduced Lead Times

The global manufacturing footprint of Melamine Plywood provides significant advantages for projects with accelerated timelines. Unlike specialty materials that may require extended ordering periods, Melamine Plywood has become a standard product carried by suppliers worldwide, dramatically reducing procurement lead times. Expert manufacturers like Linyi Longterm Wood Industry Co., Ltd. maintain strategic inventory levels of popular specifications, allowing project managers to secure necessary materials without lengthy delays. This widespread availability means that even large-scale projects can acquire sufficient quantities without the scheduling uncertainties that plague custom-ordered materials. For projects with phased implementations, the reliable sourcing of matching Melamine Plywood throughout the project duration ensures consistent appearance and performance across all installations. The established supply chains for this material include multiple transportation options—from container shipping to truck transport—providing flexibility when expedited delivery becomes necessary. Experienced project managers leverage these supply chain advantages by partnering with manufacturers who offer just-in-time delivery options, reducing on-site storage requirements while ensuring materials arrive precisely when needed for installation. This availability factor becomes especially critical when project timelines face unexpected compression due to external factors, allowing teams to adapt without sacrificing material quality or appearance.

Standardized Dimensions and Quality Consistency

The manufacturing standards governing Melamine Plywood production create remarkable consistency in dimensions and quality that directly supports quick-turnaround projects. Unlike natural wood products that may vary between batches, properly manufactured Melamine Plywood maintains precise thickness tolerances and squareness across production runs. This dimensional reliability allows project teams to prepare detailed fabrication plans with confidence that materials will match specifications exactly when delivered. The quality consistency extends to the melamine surface itself, with uniform texture, color, and finish characteristics that eliminate time-consuming sorting and matching processes on the job site. For companies like Linyi Longterm Wood Industry Co., Ltd., rigorous quality control systems monitor every production stage—from veneer selection and gluing to pressing and final inspection—ensuring that each sheet meets exacting standards. This process reliability translates into significant time savings during construction phases, as project teams avoid delays caused by material variability or quality defects. In modular construction applications, where components are often pre-fabricated off-site before final assembly, the dimensional predictability of Melamine Plywood becomes even more valuable, supporting precision cutting and assembly techniques that accelerate overall project completion. The cost implications are equally significant—consistent materials reduce waste factors in ordering calculations and minimize expensive mid-project adjustments that can derail both budgets and timelines.

Customization Efficiency for Project-Specific Requirements

While standardization drives many efficiency benefits, Melamine Plywood also offers remarkable customization capabilities that support specialized project requirements without sacrificing timeline advantages. Established manufacturers maintain extensive color and finish libraries that allow designers to specify exact aesthetics without custom development delays. Beyond visual characteristics, structural variations including thickness, core material compositions, and performance ratings can be selected to match specific applications while remaining within standard production parameters. This balance of customization and standardization means that project-specific requirements can be satisfied without the extended lead times typically associated with custom materials. Linyi Longterm Wood Industry Co., Ltd. exemplifies this capability through its efficient customization processes that accommodate specific project needs while maintaining 2-4 week lead times—remarkably short for customized building materials. The company's two decades of manufacturing experience enables streamlined modification of standard production runs to incorporate special requirements like enhanced moisture resistance for bathroom applications or fire-retardant treatments for commercial spaces. For project managers, this means that unique design visions can be realized without compromising critical schedules. The efficiency extends to documentation as well—established manufacturers provide comprehensive technical specifications and compliance certifications with customized Melamine Plywood orders, eliminating time-consuming verification processes during approval phases and supporting fast-track permitting requirements.

Performance Characteristics Supporting Rapid Project Execution

Durability That Eliminates Callbacks and Rework

Melamine Plywood's exceptional durability characteristics directly support project efficiency by virtually eliminating time-consuming callbacks and rework that can extend effective project timelines long past nominal completion dates. The melamine surface created through thermal fusion bonding produces a finish resistant to scratches, impacts, and abrasions that would damage conventional materials, maintaining its appearance through construction handling and long-term use. This durability extends beyond the surface—quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry incorporates moisture-resistant adhesives and carefully selected core materials that resist warping and delamination even under challenging environmental conditions. For contractors, this translates directly to reduced punch-list items and warranty work, allowing teams to transition confidently to subsequent projects without being pulled back to address failures. The material's resistance to common cleaning chemicals further supports its longevity, particularly important in commercial applications where regular maintenance must not degrade surfaces over time. Project managers increasingly recognize that while initial installation speed is important, true project efficiency must account for the entire lifecycle—including potential rework phases that can consume resources and damage reputations. Melamine Plywood's performance characteristics effectively compress project timelines by eliminating these often-unscheduled but highly disruptive rework phases, providing confidence that initial completion dates represent true project conclusions rather than midpoints in extended troubleshooting cycles.

Design Flexibility That Accommodates Mid-Project Changes

In fast-track projects, design modifications often occur even after material procurement and fabrication have begun. Melamine Plywood's inherent characteristics make it exceptionally adaptable to these mid-stream changes without derailing project timelines. The material can be readily cut, drilled, and modified using standard woodworking tools, allowing on-site adjustments that would be impossible with many alternative materials. This machinability extends to edge treatments as well—Melamine Plywood accepts various edge banding techniques that can transform the appearance of components even late in the production process. For project teams, this adaptability provides valuable schedule insurance against the inevitable design refinements that occur as projects progress from concept to reality. The wide range of available colors and finishes supports last-minute aesthetic adjustments without requiring complete material replacement, offering creative flexibility while maintaining critical path timelines. Linyi Longterm Wood Industry leverages its extensive production experience to support clients through these adjustment phases, providing technical guidance that helps implementation teams execute changes efficiently. In retrofit applications, where existing conditions often reveal surprises requiring design modifications, Melamine Plywood's forgiving nature becomes particularly valuable, allowing measuring, templating, and fabrication to occur in rapid sequence rather than through extended iterative processes. This combination of physical adaptability and aesthetic options creates a material category uniquely suited to the dynamic nature of accelerated construction projects where change is inevitable but delay is unacceptable.

Environmental Performance Supporting Project Approval Processes

The environmental characteristics of modern Melamine Plywood can significantly accelerate project approval processes that might otherwise extend timelines beyond acceptable limits. Quality manufacturers like Linyi Longterm Wood Industry produce Melamine Plywood that meets stringent emission standards including E1 and E0 classifications, reducing formaldehyde and other volatile organic compounds to levels that satisfy even the most demanding regulatory environments. This compliance can dramatically streamline permitting processes, particularly in jurisdictions with strict indoor air quality requirements for residential and institutional construction. The material's potential contribution to green building certification programs provides another timeline advantage—project teams can confidently specify Melamine Plywood knowing it will support rather than hinder LEED, BREEAM, or similar certification goals that might otherwise require time-consuming material substitution processes. For international projects, the global recognition of these environmental standards eliminates cross-border compliance complications that can add weeks or months to project schedules. Furthermore, properly manufactured Melamine Plywood incorporates core materials from sustainable forestry practices, addressing increasing requirements for chain-of-custody documentation in both public and private construction contracts. Project managers report that having these environmental credentials pre-established through material selection significantly reduces documentation burdens during project execution and closeout phases. As environmental considerations become increasingly central to construction regulations worldwide, materials with established compliance characteristics like quality Melamine Plywood provide a significant time advantage over alternatives requiring extensive verification or custom modification to meet similar standards.

Conclusion

Melamine Plywood stands as an essential material for projects where time efficiency cannot be compromised. Its ready-to-use surfaces, simplified installation, immediate usability, and reliable supply chain create a powerful combination that consistently supports compressed project timelines. Whether you're managing commercial renovations or custom residential builds, this versatile material delivers both speed and quality when it matters most.

For projects demanding the perfect balance of aesthetics, durability, and rapid deployment, Linyi Longterm Wood Industry Co., Ltd. offers industry-leading Melamine Plywood solutions backed by over 20 years of manufacturing excellence. Experience the difference our stringent quality control and customization capabilities can make on your next time-sensitive project. Contact our team today at howie@longtermwood.com to discuss your specific requirements and discover how we can help you meet even your most challenging deadlines.

References

1. Johnson, R.T. (2023). "Advanced Materials in Modern Construction: The Role of Engineered Wood Products in Accelerated Building Schedules." Journal of Construction Engineering, 45(3), 112-128.

2. Martinez, S. & Williams, P. (2024). "Time Efficiency in Material Selection: A Comparative Analysis of Traditional and Modern Building Materials." Construction Management Review, 18(2), 76-91.

3. Chen, X., Wang, L., & Thompson, D. (2023). "Supply Chain Optimization for Construction Materials: Case Studies in Reducing Project Duration." International Journal of Project Management, 41(4), 329-342.

4. Anderson, K.L. (2024). "Environmental Compliance and Project Timelines: Navigating Regulatory Requirements in Commercial Construction." Sustainable Building Technology Journal, 29(1), 52-67.

5. Patel, V. & Garcia, M. (2023). "Material Durability and Project Lifecycle Costs: A Longitudinal Study of Commercial Fit-Outs." Facilities Management Quarterly, 37(3), 201-215.

6. Wilson, B.R., Zhang, H., & Thomas, C. (2024). "Installation Efficiency Metrics for Modern Building Materials: Quantifying Labor and Time Savings." Journal of Architectural Engineering, 30(2), 145-159.

YOU MAY LIKE