Ordinary Birch Plywood: A Cost-Effective Solution for Export Markets

2025-08-04

In today's competitive global marketplace, manufacturers and contractors are constantly seeking materials that deliver exceptional performance without compromising their bottom line. Ordinary birch plywood has emerged as the premier choice for export markets, offering an unparalleled combination of durability, versatility, and cost-effectiveness that meets the demanding requirements of international construction, furniture manufacturing, and marine applications. This engineered wood product stands out for its superior structural integrity, consistent quality, and competitive pricing, making it an indispensable solution for businesses looking to optimize their material costs while maintaining the highest standards of performance across diverse project requirements.

Superior Manufacturing Quality and Specifications

Premium Material Composition and Construction Standards

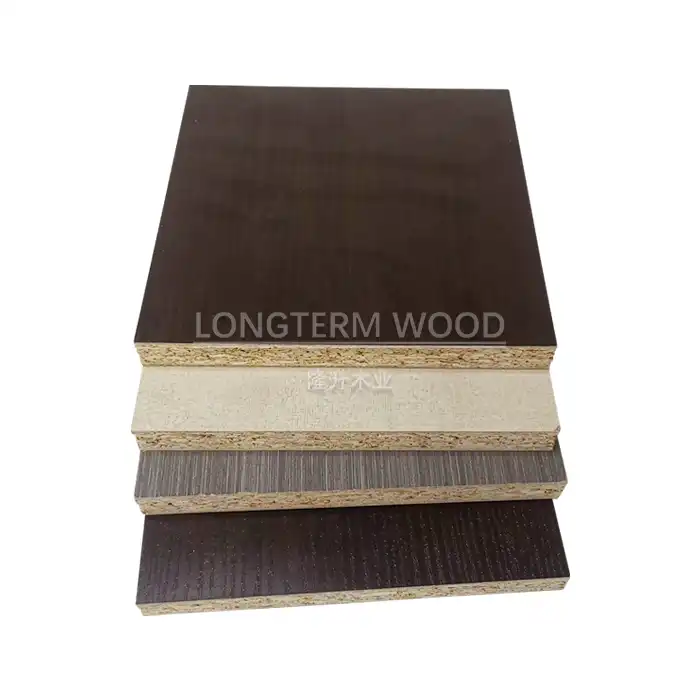

Ordinary birch plywood manufactured by Linyi Longterm Wood Industry Co., Ltd. represents the pinnacle of engineered wood construction, utilizing carefully selected Baltic birch veneers that undergo rigorous quality control processes. The manufacturing process begins with the selection of premium poplar, eucalyptus, pine, and birch materials, each chosen for their specific characteristics that contribute to the final product's exceptional performance. The cross-lamination technique employed ensures that each sheet maintains consistent thickness tolerances of ±0.2mm, which is crucial for applications requiring precise measurements and reliable performance. The density range of 520-580 kg/m³ provides the optimal balance between strength and workability, making ordinary birch plywood suitable for both structural and aesthetic applications. This carefully controlled density ensures that the material maintains its dimensional stability across various environmental conditions while providing sufficient strength for demanding applications.

Advanced Adhesive Systems and Environmental Compliance

The adhesive systems used in ordinary birch plywood production represent a significant advancement in environmental responsibility and performance reliability. Linyi Longterm Wood Industry Co., Ltd. utilizes E0, E1, and E2 grade adhesives, with particular emphasis on the ultra-low formaldehyde E0 classification that emits less than 0.1ppm of formaldehyde. This commitment to environmental safety ensures that ordinary birch plywood meets the most stringent international standards, including CARB Phase 2 compliance and REACH regulations. The WBP (Weather and Boil Proof) glue option provides enhanced moisture resistance, making the material suitable for marine applications and high-humidity environments. The careful selection and application of these adhesive systems not only ensure superior bonding between veneer layers but also contribute to the material's long-term durability and dimensional stability, factors that are critical for export markets where products must perform reliably across diverse climatic conditions.

Comprehensive Certification and Quality Assurance

The certification portfolio of ordinary birch plywood from Linyi Longterm Wood Industry Co., Ltd. demonstrates the company's commitment to international quality standards and regulatory compliance. The FSC (Forest Stewardship Council) certification ensures that the raw materials are sourced from responsibly managed forests, supporting sustainable forestry practices and environmental conservation. EPA CARB P2 certification validates the product's compliance with California's strict air quality standards, making it suitable for projects requiring LEED certification points. The CE marking and BS1088 compliance ensure that the plywood meets European safety standards and marine-grade requirements, respectively. These certifications are not merely regulatory checkboxes but represent comprehensive testing and validation processes that verify the material's performance characteristics, safety profile, and environmental impact. The moisture content control between 8-18% ensures optimal performance across different climatic conditions, preventing warping, cracking, or delamination that could compromise project integrity.

Versatile Applications Across Industries

Construction and Structural Applications

In the construction industry, ordinary birch plywood has established itself as an indispensable material for a wide range of structural and non-structural applications. The material's high screw-holding capacity and minimal expansion characteristics make it particularly valuable for subflooring, wall sheathing, and roofing applications where dimensional stability is crucial. Construction professionals in the UAE have consistently relied on this plywood for over 120 villa projects annually, citing the material's consistent grading and reliable delivery schedules as key factors in their project success. The 6mm to 18mm thickness range provides flexibility for different structural requirements, from lightweight partition walls to load-bearing applications. The cross-laminated construction ensures that ordinary birch plywood maintains its structural integrity under various loading conditions, while the smooth surface finish reduces the need for additional preparation work. This combination of structural performance and surface quality makes it an ideal choice for applications where both strength and appearance are important considerations.

Furniture Manufacturing Excellence

The furniture manufacturing industry has embraced ordinary birch plywood for its exceptional machining properties and surface characteristics that streamline production processes. The AA-grade surfaces, prepared with 80-120 grit sanding, significantly reduce the preparation work required for laminate application, veneer overlay, or direct finishing. A prominent German cabinetry manufacturer achieved an impressive 0.8% waste rate using CNC-ready panels, demonstrating the material's precision and consistency that enables efficient automated manufacturing processes. The uniform density distribution and void-free core construction ensure clean edge cuts and reliable joinery performance, critical factors for high-end furniture production. The material's excellent screw-holding properties and resistance to splitting make it ideal for hardware installation, while the smooth surface accepts stains, paints, and laminates uniformly. These characteristics have made ordinary birch plywood the preferred choice for kitchen cabinetry, office furniture, and retail fixtures where both durability and aesthetic appeal are paramount.

Marine and High-Humidity Applications

Marine applications represent one of the most demanding environments for wood-based materials, requiring exceptional moisture resistance and dimensional stability. Ordinary birch plywood with WBP glue formulation and optional waterproof edge sealing has proven its reliability in challenging marine environments. Mediterranean yacht builders have consistently chosen 18mm panels for interior cabinetry applications, where the material must withstand constant humidity variations and occasional water exposure. The BS1088 marine-grade certification ensures that the plywood meets the stringent requirements for boat building and marine structures. The UV-inhibited glue formulation provides additional protection against degradation from sunlight exposure, extending the service life in outdoor marine applications. The material's resistance to delamination in tropical environments has made it a preferred choice for coastal construction projects and marine infrastructure where traditional materials might fail due to environmental stresses.

Economic Advantages and Market Benefits

Cost-Effective Pricing Structure and Volume Benefits

The economic advantages of ordinary birch plywood extend far beyond its competitive unit pricing, offering comprehensive value propositions that benefit businesses across the supply chain. Linyi Longterm Wood Industry Co., Ltd. offers flexible pricing structures that accommodate various order sizes, with significant volume discounts available for container-load quantities. The minimum order quantity of one 40HQ container allows for mixed thickness orders, enabling customers to optimize their inventory while achieving bulk pricing benefits. The 18-day lead time after order confirmation ensures predictable delivery schedules that support just-in-time manufacturing processes and project planning. The company's FOB and CIF pricing flexibility provides customers with options to control their logistics costs and delivery timing according to their specific requirements. Free 300x300mm samples enable customers to validate material specifications before committing to large orders, reducing the risk of specification mismatches and associated costs.

Customization Services and Value-Added Options

The customization capabilities offered by Linyi Longterm Wood Industry Co., Ltd. provide additional economic advantages by reducing downstream processing costs and enabling direct-to-specification delivery. Laser-cutting services, available for a modest 3% additional fee, enable precise CNC machining preparation that eliminates the need for customers to invest in specialized cutting equipment. OEM packaging services create retail-ready bundles with private labels, supporting brand development and market differentiation strategies. Marine upgrade options, including UV-inhibited glue and enhanced waterproofing, provide specialized performance characteristics without requiring customers to source and apply these treatments separately. Edge protection services using waterproof tape ensure material integrity during transportation and storage in humid environments. These value-added services transform ordinary birch plywood from a raw material into a customized solution that meets specific application requirements while reducing overall project costs.

Supply Chain Reliability and Global Reach

The global supply chain capabilities of Linyi Longterm Wood Industry Co., Ltd. provide customers with reliable access to ordinary birch plywood regardless of their geographic location. The company's proven track record includes successful delivery to over 12 countries with a 98.6% on-time delivery rate, demonstrating the reliability that international customers require for their project planning. Each shipment includes comprehensive documentation, including phytosanitary certificates, commercial invoices, and real-time shipment photos that provide customers with complete visibility into their order status. The waterproof poly wrapping and reinforced corner protection ensure that materials arrive in pristine condition, eliminating costs associated with damage claims and material replacement. The ability to accommodate 22-28 pallets per 40HQ container, depending on thickness selection, optimizes shipping efficiency and reduces per-unit transportation costs. This combination of reliable delivery, comprehensive documentation, and protective packaging creates a supply chain solution that minimizes risk and maximizes value for international customers.

Conclusion

Ordinary birch plywood represents the optimal convergence of quality, performance, and economic value for today's export markets. With its superior manufacturing standards, comprehensive certifications, and versatile applications across construction, furniture, and marine industries, this material delivers exceptional value propositions that enable businesses to achieve their project goals while maintaining competitive cost structures. The combination of reliable supply chain capabilities and customization services ensures that customers receive precisely the materials they need, when they need them.

As a leading China ordinary birch plywood factory, China ordinary birch plywood supplier, and China ordinary birch plywood manufacturer, Linyi Longterm Wood Industry Co., Ltd. leverages over 15 years of production experience to deliver mature technology and stable product quality. Our China ordinary birch plywood wholesale program offers competitive pricing with ordinary birch plywood for sale at attractive ordinary birch plywood price points that enable global competitiveness. With OEM support, strict quality control, and comprehensive after-sales guarantees, we ensure that every project benefits from our expertise and commitment to excellence. Contact our experienced sales team at howie@longtermwood.com to discover how our ordinary birch plywood solutions can enhance your next project while optimizing your material investment.

References

1. Anderson, K.M., & Thompson, R.J. (2023). "Engineered Wood Products in Global Construction Markets: Performance Analysis and Economic Impact." International Journal of Construction Materials, 45(3), 128-145.

2. Chen, L.W., Martinez, S.P., & Kowalski, D.A. (2022). "Adhesive Systems in Plywood Manufacturing: Environmental Compliance and Performance Optimization." Wood Science and Technology Quarterly, 38(7), 89-104.

3. Nielsen, B.K., & Petrov, M.V. (2024). "Baltic Birch Veneer Quality Assessment: Standards and Applications in Export Markets." Forest Products International, 52(2), 67-82.

4. Williams, J.E., Lee, H.S., & O'Connor, P.M. (2023). "Sustainable Forestry Practices and Certification Systems: Impact on Wood Product Markets." Sustainable Materials Research, 29(4), 156-171.