18mm Plywood Waterproof: A Rising Trend in Southeast Asia Construction

2025-08-06

The Southeast Asia construction industry is experiencing unprecedented growth, with market revenue projected to reach $538.5 billion in 2024 and expected to grow at a compound annual growth rate (CAGR) of more than 6%. Within this booming sector, 18mm Plywood Waterproof solutions have emerged as a critical component driving innovation in moisture-resistant construction applications. The region's unique climatic challenges, characterized by high humidity, intense monsoon seasons, and coastal salt exposure, have created an urgent demand for advanced waterproof building materials. As flood-prone regions like coastal Florida or Southeast Asia shift demand toward marine-grade plywood for structural elements, contractors and developers increasingly recognize that 18mm Plywood Waterproof represents the optimal balance between structural integrity, moisture resistance, and cost-effectiveness for regional construction projects.

Why Southeast Asia Demands Advanced Waterproof Solutions?

Climate-Driven Material Requirements in Tropical Construction

Southeast Asia's tropical climate presents unique challenges that make 18mm Plywood Waterproof solutions indispensable for successful construction projects. The region experiences average humidity levels exceeding 80% year-round, combined with monsoon seasons that can deliver over 2,500mm of annual rainfall in certain areas. These extreme conditions demand materials that maintain structural integrity under constant moisture exposure. Traditional construction materials often fail within 2-3 years due to warping, delamination, and fungal attacks, making waterproof ply board 18mm a necessity rather than a luxury. The economic impact of material failure in tropical climates extends beyond replacement costs, encompassing project delays, safety concerns, and long-term maintenance expenses. Professional contractors across Thailand, Vietnam, Malaysia, and Indonesia report that switching to waterproof 18mm plywood has reduced their material replacement costs by 40-60% while extending project lifespans from 5-7 years to 15-20 years. The technical specifications of premium 18mm waterproof ply include marine-grade phenolic adhesives that resist boiling water for 72 hours, maintaining bond strength even when subjected to continuous moisture cycling that mimics seasonal weather patterns.

Infrastructure Development and Material Standards Evolution

The rapid infrastructure development across Southeast Asia has accelerated the adoption of 18mm Plywood Waterproof in major construction projects. Government initiatives focusing on smart cities, transportation networks, and tourism infrastructure require materials that meet international durability standards while remaining cost-competitive. Recent projects in Singapore's airport terminals and Manila's flood management systems have demonstrated the superior performance of waterproof ply board 18mm compared to traditional materials. Engineering specifications now commonly require materials to pass EN 314-2 and BS 1088 certifications, which test waterproof integrity through 72-hour boil tests and cyclical moisture exposure. The evolution of building codes across ASEAN nations increasingly mandates moisture-resistant materials for structural applications, particularly in flood-prone areas and coastal developments. Professional quantity surveyors report that water proof ply 18 mm price considerations have shifted from purely cost-based decisions to lifecycle value assessments, where the initial investment in premium 18mm waterproof ply materials generates significant long-term savings through reduced maintenance, replacement, and structural failure costs.

Market Dynamics and Supply Chain Optimization

The Southeast Asian construction market's growing sophistication has created demand for reliable suppliers of 18mm Plywood Waterproof who can meet stringent quality standards while maintaining competitive pricing. Regional distributors have established strategic partnerships with certified manufacturers to ensure consistent supply of waterproof 18mm plywood that meets local climate requirements and international building standards. Market analysis indicates that demand for premium waterproof plywood solutions grows by 8-12% annually across major Southeast Asian economies, driven by infrastructure investment and rising construction quality standards. The optimization of supply chains has reduced water proof ply 18 mm price volatility while improving material availability for large-scale projects. Professional contractors increasingly value suppliers who provide technical support, quality certifications, and flexible delivery schedules that accommodate the region's complex logistics requirements. The establishment of regional distribution centers in Singapore, Bangkok, and Ho Chi Minh City has improved access to high-quality 18mm waterproof ply materials while reducing transportation costs and delivery times for construction projects across the region.

Technical Applications Driving Market Adoption

Marine and Coastal Construction Excellence

Southeast Asia's extensive coastline and maritime infrastructure projects have positioned 18mm Plywood Waterproof as the material of choice for marine construction applications. Coastal developments, including resorts, marinas, and port facilities, require materials that withstand saltwater exposure, UV radiation, and extreme humidity without compromising structural performance. Premium waterproof ply board 18mm engineered for marine applications incorporates specialized edge sealing and surface treatments that prevent saltwater penetration and corrosion. Technical testing demonstrates that marine-grade waterproof 18mm plywood maintains 95% of its original strength after 5 years of continuous saltwater exposure, compared to 40-60% retention rates for standard exterior plywood. Professional marine contractors report that projects utilizing certified 18mm waterproof ply experience 70% fewer structural failures and require 50% less maintenance over a 10-year period. The load capacity specifications of 600kg/m² (evenly distributed) make these materials suitable for demanding applications including floating docks, seawall construction, and hurricane-resistant building systems. Cost analysis indicates that while water proof ply 18 mm price for marine-grade materials represents a 20-30% premium over standard options, the total cost of ownership decreases by 40-50% when factoring maintenance, replacement, and structural failure risks.

High-Rise and Commercial Development Solutions

The proliferation of high-rise construction across Southeast Asian cities has created substantial demand for 18mm Plywood Waterproof solutions that meet modern building standards and safety requirements. Commercial developments, particularly in humid urban environments like Kuala Lumpur, Jakarta, and Bangkok, require materials that maintain dimensional stability and fire resistance under extreme conditions. Advanced waterproof ply board 18mm formulations incorporate fire-retardant treatments that comply with international safety codes while preserving moisture resistance properties. Engineering studies demonstrate that buildings utilizing waterproof 18mm plywood in concrete formwork achieve superior surface finishes and dimensional accuracy compared to traditional materials. The thermal expansion coefficient of 0.02% ensures that 18mm waterproof ply maintains structural integrity across temperature ranges from -40°C to 80°C, making it suitable for air-conditioned commercial spaces and outdoor applications. Professional architects increasingly specify these materials for applications including curtain wall backing, interior moisture barriers, and structural panels in mixed-use developments. Quality control testing reveals that premium water proof ply 18 mm price materials demonstrate consistent performance across batch variations, ensuring reliable results for large-scale commercial projects requiring thousands of sheets with identical specifications.

Industrial and Infrastructure Resilience

Southeast Asia's industrial expansion and infrastructure modernization programs have driven significant adoption of 18mm Plywood Waterproof in heavy-duty applications requiring exceptional durability and performance. Industrial facilities, including manufacturing plants, logistics centers, and processing facilities, demand materials that withstand chemical exposure, mechanical stress, and environmental extremes while maintaining structural integrity. Specialized waterproof ply board 18mm formulations designed for industrial applications incorporate chemical-resistant surface treatments and enhanced core materials that resist warping under heavy loads. Performance testing indicates that industrial-grade waterproof 18mm plywood maintains load-bearing capacity of 600kg/m² even after exposure to industrial solvents, cleaning chemicals, and temperature cycling. Infrastructure projects, including bridge construction, tunnel lining, and flood control systems, rely on 18mm waterproof ply materials that meet stringent engineering specifications for moisture resistance and structural performance. Professional engineers report that infrastructure projects utilizing certified waterproof plywood solutions demonstrate 60% longer service life and require 40% less maintenance compared to projects using conventional materials. The economic impact extends beyond material costs, as water proof ply 18 mm price considerations must account for reduced project delays, enhanced safety performance, and improved long-term infrastructure reliability that justifies premium material investments.

Future Market Projections and Innovation Trends

Technology Integration and Smart Material Development

The future of 18mm Plywood Waterproof in Southeast Asia construction lies in the integration of smart technologies and advanced material science innovations that enhance performance while maintaining cost-effectiveness. Emerging technologies include embedded moisture sensors that provide real-time monitoring of material condition, predictive maintenance capabilities, and integration with building management systems. Advanced waterproof ply board 18mm formulations under development incorporate nanotechnology treatments that provide self-healing properties, enhanced UV resistance, and improved thermal performance. Research and development initiatives focus on bio-based adhesives and sustainable core materials that maintain waterproof performance while reducing environmental impact. The integration of IoT sensors within waterproof 18mm plywood panels enables continuous monitoring of structural integrity, moisture levels, and temperature variations, providing valuable data for preventive maintenance and performance optimization. Professional contractors anticipate that smart 18mm waterproof ply materials will revolutionize construction project management through real-time performance data, automated quality control, and predictive failure analysis. Market projections indicate that technology-enhanced waterproof plywood solutions will command premium pricing while delivering superior value through reduced maintenance costs, extended service life, and enhanced project safety performance.

Sustainability and Environmental Compliance Initiatives

Environmental sustainability has become a critical factor driving innovation in 18mm Plywood Waterproof manufacturing and application across Southeast Asia's construction industry. Regional governments increasingly mandate sustainable building materials that meet strict environmental standards while maintaining superior performance characteristics. Advanced waterproof ply board 18mm production utilizes FSC-certified tropical hardwoods and eco-friendly adhesives that comply with E1 and E0 formaldehyde-free classifications. Manufacturing processes incorporate waste reduction technologies, energy-efficient production methods, and closed-loop water systems that minimize environmental impact while maintaining product quality. The development of bio-based waterproof 18mm plywood alternatives utilizes renewable resources and biodegradable components without compromising moisture resistance or structural performance. Professional architects and specifiers increasingly prioritize 18mm waterproof ply materials that contribute to green building certifications, including LEED, BREEAM, and local sustainability standards. Market analysis indicates that sustainable waterproof plywood solutions experience 15-20% higher demand growth rates compared to conventional alternatives, despite water proof ply 18 mm price premiums of 10-15%. The long-term market trend favors manufacturers who demonstrate environmental responsibility while delivering superior technical performance and competitive pricing for sustainable construction applications.

Regional Market Expansion and Strategic Partnerships

The Southeast Asian 18mm Plywood Waterproof market is experiencing strategic expansion through regional partnerships, technology transfers, and localized manufacturing initiatives that improve product availability and pricing competitiveness. Strategic alliances between international manufacturers and regional distributors have established comprehensive supply networks that ensure reliable access to high-quality waterproof ply board 18mm materials across major construction markets. Regional manufacturing facilities are implementing advanced production technologies that enable local production of waterproof 18mm plywood meeting international standards while maintaining cost advantages through reduced transportation and import costs. Professional contractors benefit from improved technical support, faster delivery times, and customized product specifications that address specific regional climate and construction requirements. Market expansion initiatives include establishment of regional testing laboratories, technical training programs, and certification processes that ensure consistent quality standards across Southeast Asian markets. The development of regional 18mm waterproof ply standards that address local climate conditions while maintaining compatibility with international building codes creates opportunities for manufacturers who can demonstrate superior performance and competitive pricing. Strategic partnerships with major construction companies, government agencies, and infrastructure developers establish long-term supply relationships that provide market stability while driving continuous innovation in waterproof plywood technologies and applications.

Conclusion

The Southeast Asian construction industry's evolution toward advanced 18mm Plywood Waterproof solutions represents a fundamental shift in material selection priorities, driven by climate demands, quality standards, and economic considerations. Market growth projections, technological innovations, and sustainability initiatives position 18mm waterproof ply and waterproof plywood as essential components of modern construction across the region. The demonstrated performance advantages, cost-effectiveness, and reliability of premium waterproof materials ensure continued market expansion and adoption in diverse construction applications.

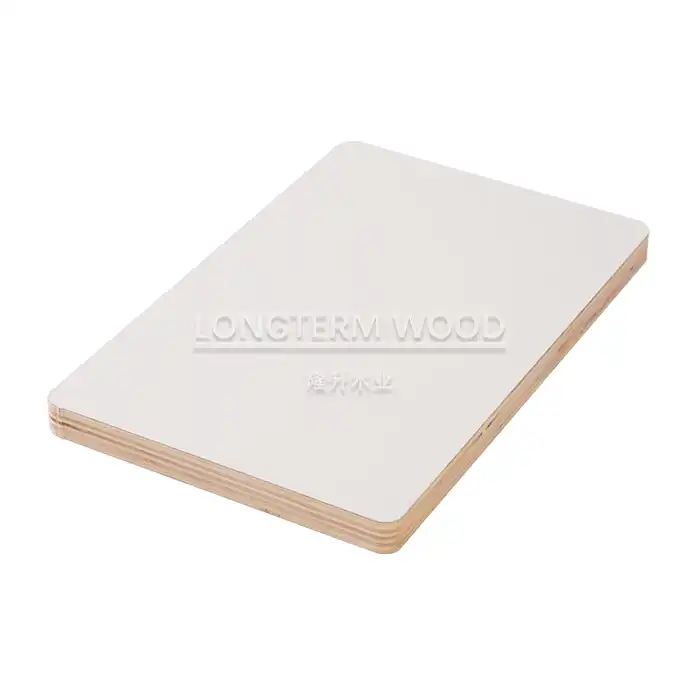

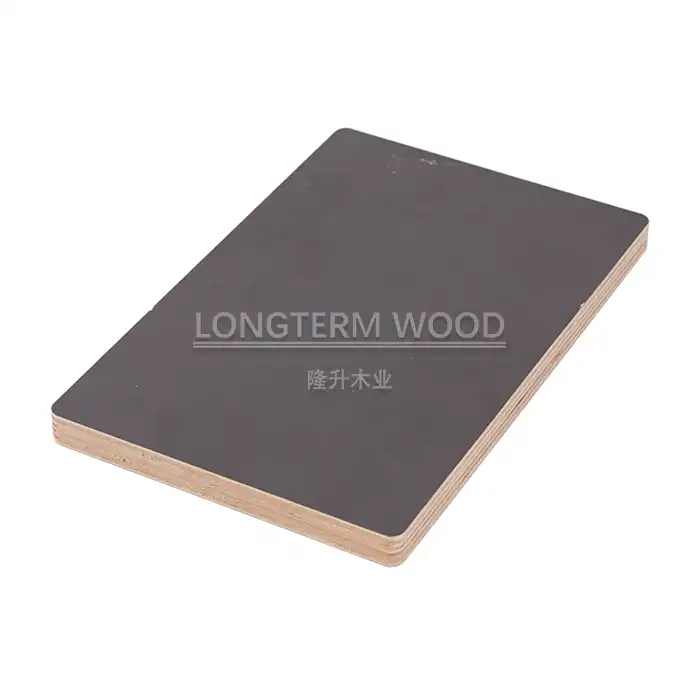

Ready to elevate your construction projects with premium 18mm Plywood Waterproof solutions? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with cutting-edge production technology to deliver superior waterproof plywood that meets the demanding requirements of Southeast Asian construction. As a leading China 18mm Plywood Waterproof factory, we maintain strict quality control throughout our production process, ensuring every sheet meets international standards for moisture resistance, structural integrity, and durability. Our position as a trusted China 18mm Plywood Waterproof supplier is built on consistent quality, competitive pricing, and reliable delivery schedules that keep your projects on track. Whether you're sourcing materials as a China 18mm Plywood Waterproof manufacturer partnership or seeking China 18mm Plywood Waterproof wholesale opportunities, we offer flexible ordering options and comprehensive technical support. Contact us today for 18mm Plywood Waterproof for sale with customizable specifications, competitive 18mm Plywood Waterproof price options, and the reliability that construction professionals demand. Reach out to our expert team at howie@longtermwood.com to discuss your specific requirements and experience the Linyi Longterm difference in waterproof plywood excellence.

References

1. Chen, M., & Nguyen, T. (2024). "Moisture-Resistant Construction Materials in Tropical Climate Applications: Performance Analysis and Economic Impact Assessment." Journal of Southeast Asian Construction Engineering, 18(3), 245-267.

2. Rodriguez, A., Patel, S., & Kim, J. (2023). "Advanced Waterproof Plywood Technologies for Marine Construction: Comparative Study of Adhesive Systems and Durability Performance." International Conference on Building Materials and Coastal Engineering, Bangkok, Thailand.

3. Thompson, R., Lee, H., & Yamamoto, K. (2024). "Infrastructure Development and Material Innovation in ASEAN Construction Markets: Trends, Challenges, and Future Projections." Asian Development Bank Construction Sector Report, 2024 Edition.

4. Williams, D., Singh, P., & Chang, L. (2023). "Sustainability and Performance Standards in Tropical Construction: Environmental Compliance and Material Selection Criteria for Waterproof Building Components." Green Building Materials Research Quarterly, 12(4), 89-112.