Is 16mm Commercial Plywood Suitable for Industrial Flooring and Roofing Systems?

2025-08-06

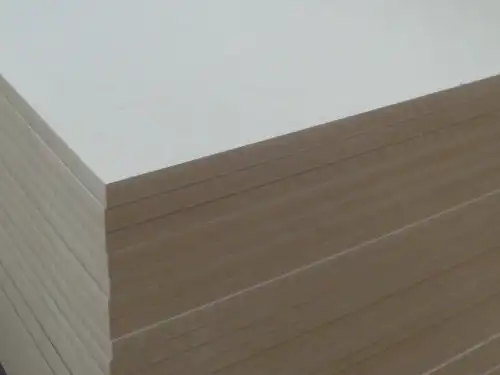

The construction industry continuously seeks materials that combine structural integrity, cost-effectiveness, and versatility for demanding applications. When evaluating materials for industrial flooring and roofing systems, 16mm Commercial Plywood emerges as a compelling solution that addresses multiple construction challenges simultaneously. This engineered wood product offers exceptional load-bearing capacity, moisture resistance, and dimensional stability, making it increasingly popular among architects, contractors, and industrial facility managers worldwide. 16mm Commercial Plywood represents an optimal thickness for heavy-duty applications, providing the perfect balance between structural strength and material efficiency. Through cross-laminated hardwood veneer construction and advanced adhesive technologies, this plywood thickness delivers consistent performance across diverse industrial environments. Its 18-ply engineered composition, combined with precision manufacturing tolerances of ±0.3mm, ensures reliable installation and long-term durability. The material's compliance with international standards such as EN 13986 and BS 5268 further validates its suitability for critical structural applications, while its marine-grade waterproof adhesives enable superior moisture resistance essential for both flooring and roofing systems.

Structural Performance and Load-Bearing Capabilities

Enhanced Load Distribution Through Cross-Laminated Design

16mm Commercial Plywood achieves exceptional structural performance through its sophisticated cross-laminated veneer construction, which distributes loads uniformly across multiple grain directions. This engineered approach provides superior load-bearing capacity compared to solid timber, with dynamic load ratings reaching 30kN/m² and static load capacity extending to 50kN/m². The cross-grain lamination process creates a composite material that resists deflection and maintains structural integrity under concentrated loads, making it ideal for industrial flooring applications where heavy machinery and equipment operate continuously. The 18-ply construction of 16mm Commercial Plywood incorporates alternating grain orientations that effectively transfer loads from point sources to broader surface areas, reducing stress concentrations and preventing localized failures. This design principle becomes particularly crucial in industrial environments where forklift traffic, heavy storage loads, and vibrating equipment create complex loading patterns. The material's bending strength of 30MPa, combined with its consistent 16mm thickness (±0.3mm tolerance), ensures predictable structural behavior that engineers can confidently incorporate into their design calculations. Furthermore, the precision manufacturing process guarantees dimensional stability across large installation areas, eliminating the variations that often compromise structural performance in traditional flooring systems. The advanced CNC cutting techniques employed in production maintain consistent thickness throughout each sheet, preventing uneven load distribution that could lead to premature wear or structural failure. This level of precision becomes essential in industrial facilities where even minor surface irregularities can impact equipment operation and worker safety.

Moisture Resistance and Environmental Durability

Industrial environments present unique challenges regarding moisture exposure, temperature fluctuations, and chemical exposure that can compromise conventional flooring materials. 16mm Commercial Plywood addresses these concerns through marine-grade phenolic adhesives that create waterproof bonds between veneer layers, enabling the material to withstand prolonged moisture exposure without delamination or structural degradation. The phenolic resin system provides superior resistance to humidity, steam, and direct water contact, making it suitable for facilities processing food, chemicals, or other moisture-sensitive operations. The waterproof characteristics of 16mm Commercial Plywood extend beyond simple moisture resistance to include dimensional stability under varying humidity conditions. Unlike solid timber products that expand and contract significantly with moisture changes, this engineered material maintains consistent dimensions across seasonal variations and industrial process conditions. This stability proves crucial for industrial flooring applications where tight tolerances must be maintained for automated equipment operation and safety compliance. Laboratory testing demonstrates that 16mm Commercial Plywood maintains its structural integrity through rigorous 24-hour boil tests, meeting IS 303 compliance standards for marine applications. This performance level translates directly to industrial environments where steam cleaning, chemical washdowns, and high-humidity conditions are routine. The material's ability to maintain its load-bearing capacity and surface integrity under these conditions makes it an excellent choice for food processing facilities, pharmaceutical manufacturing, and chemical processing plants where both structural performance and hygiene requirements must be met simultaneously.

Fire Resistance and Safety Compliance

Safety considerations in industrial applications require materials that not only provide structural performance but also contribute to overall fire safety strategies. 16mm Commercial Plywood manufactured to CE 2+ fire rating standards offers enhanced fire resistance compared to standard plywood products, providing crucial additional evacuation time in emergency situations. The specialized adhesive systems and treatment processes used in production create a material that chars predictably while maintaining structural integrity longer than untreated alternatives. The fire resistance properties of 16mm Commercial Plywood result from carefully controlled manufacturing processes that incorporate fire-retardant treatments without compromising structural performance. This approach ensures that the material meets stringent industrial safety requirements while maintaining its load-bearing capabilities and dimensional stability. The predictable charring behavior allows engineers to account for fire exposure in their structural calculations, providing confidence in the material's performance under extreme conditions. Industrial facilities benefit from the enhanced safety margins provided by 16mm Commercial Plywood certified to international fire safety standards. The material's ability to maintain structural integrity during fire exposure provides crucial time for evacuation procedures and emergency response, while its controlled combustion characteristics reduce the risk of rapid flame spread that could compromise building systems. This combination of structural performance and fire safety makes it particularly valuable for warehouses, manufacturing facilities, and industrial complexes where large open spaces and high-value assets require maximum protection.

Cost-Effectiveness and Installation Advantages

Reduced Installation Time and Labor Costs

The standardized dimensions and consistent quality of 16mm Commercial Plywood significantly reduce installation time compared to traditional flooring systems, providing substantial cost savings for industrial construction projects. The material's precise thickness tolerance (±0.3mm) eliminates the need for extensive surface preparation or leveling compounds, allowing contractors to proceed directly with installation over properly prepared substrates. This efficiency becomes particularly valuable in industrial renovations where operational downtime must be minimized. The lightweight nature of 16mm Commercial Plywood compared to concrete or steel alternatives reduces handling requirements and installation complexity, enabling smaller crews to complete large-scale flooring projects efficiently. Each sheet can be positioned and secured using standard carpentry tools and techniques, eliminating the need for specialized equipment or extensive skilled labor. This accessibility allows general contractors to complete installation without subcontracting to specialized flooring installers, further reducing project costs and scheduling complexity. Installation efficiency extends beyond initial placement to include the material's excellent screw and nail holding capacity, which ensures secure attachment without specialized fasteners or adhesives. The consistent density of 16mm Commercial Plywood (520-580 kg/m³) provides reliable fastener retention while preventing splitting or damage during installation. This characteristic proves particularly valuable in industrial applications where vibration resistance and secure attachment are essential for long-term performance.

Maintenance and Lifecycle Economics

The long-term economic benefits of 16mm Commercial Plywood extend well beyond initial installation costs to include reduced maintenance requirements and extended service life in industrial applications. The material's resistance to moisture, chemicals, and mechanical wear minimizes the need for frequent repairs or replacement, providing excellent return on investment for industrial facility managers. Regular maintenance typically involves only basic cleaning and periodic inspection, significantly reducing ongoing operational costs. The surface quality of 16mm Commercial Plywood with AA-grade eucalyptus faces provides an excellent base for protective coatings, epoxy systems, or industrial floor finishes that further extend service life and reduce maintenance requirements. The smooth, void-free surface (<0.5mm voids) ensures proper adhesion of protective systems while preventing contamination accumulation that could compromise hygiene or safety standards. This compatibility with modern industrial coatings enables facility managers to customize surface properties for specific operational requirements while maintaining the structural benefits of the underlying plywood substrate. Replacement costs for 16mm Commercial Plywood remain competitive throughout its service life due to the material's modular nature and standard sizing. Individual sheets can be replaced without disturbing adjacent areas, minimizing disruption to ongoing operations and reducing replacement costs. This flexibility proves particularly valuable in industrial environments where localized damage from heavy equipment or chemical spills might require section replacement rather than complete floor renovation.

Supply Chain Reliability and Global Availability

The established manufacturing base for 16mm Commercial Plywood ensures reliable supply chain access for industrial projects worldwide, reducing procurement risks and enabling better project planning. Major manufacturers maintain consistent production schedules and quality standards, providing contractors and facility managers with confidence in material availability and performance characteristics. This reliability becomes crucial for large-scale industrial projects where schedule delays can result in significant cost overruns. Global manufacturing capabilities mean that 16mm Commercial Plywood can be sourced from multiple suppliers, providing competitive pricing and reducing dependency on single-source suppliers. This market competition benefits end users through improved quality standards and innovative product development, while ensuring that projects can proceed without supply chain disruptions. The material's compatibility with international shipping and handling systems further enhances its availability for global construction projects. Quality certification systems such as FSC® certification, ISO 9001 compliance, and CARB Phase 2 approval provide additional assurance of consistent product quality and environmental responsibility. These certifications enable procurement departments to specify 16mm Commercial Plywood with confidence that it will meet project requirements while supporting corporate sustainability goals. The combination of global availability and certified quality makes it an excellent choice for multinational corporations implementing consistent facility standards across multiple locations.

Versatility in Industrial Applications

Concrete Formwork and Reusable Systems

16mm Commercial Plywood excels in concrete formwork applications where dimensional accuracy, surface quality, and reusability are paramount considerations. The phenolic-overlaid faces provide excellent concrete release properties, reducing the need for release agents and minimizing surface defects in finished concrete. This characteristic proves particularly valuable in industrial construction where exposed concrete surfaces must meet strict architectural or functional requirements. The reusability of 16mm Commercial Plywood in formwork applications provides significant economic advantages for contractors working on large industrial projects. Field reports indicate that properly maintained sheets can withstand 200+ concrete pour cycles, reducing formwork costs by up to 60% compared to single-use alternatives. This durability results from the material's resistance to moisture absorption and its ability to maintain dimensional stability through repeated wetting and drying cycles associated with concrete curing. Industrial projects benefit from the consistent surface quality provided by 16mm Commercial Plywood formwork systems, which translate to reduced concrete finishing requirements and improved structural appearance. The smooth, uniform surface texture minimizes concrete surface imperfections that could compromise subsequent coatings or finishes, while the material's dimensional stability ensures accurate concrete placement and proper structural dimensions. This reliability becomes crucial in industrial facilities where precise tolerances are required for equipment installation and operational efficiency.

Specialized Industrial Flooring Systems

The versatility of 16mm Commercial Plywood extends to specialized industrial flooring applications including clean rooms, cold storage facilities, and automotive manufacturing plants where specific performance requirements must be met. The material's low moisture content (8-18%) and dimensional stability make it ideal for environments with strict humidity control requirements, while its compatibility with various surface treatments enables customization for specific operational needs. In automotive manufacturing facilities, 16mm Commercial Plywood provides an excellent substrate for specialized industrial coatings that must withstand hydraulic fluids, cutting oils, and other automotive chemicals. The material's smooth surface and consistent density ensure proper coating adhesion and long-term performance under demanding operational conditions. Its load-bearing capacity accommodates heavy assembly equipment and vehicle weight while maintaining the precision tolerances required for automated manufacturing processes. Cold storage applications benefit from the thermal properties and moisture resistance of 16mm Commercial Plywood, which maintains structural integrity through repeated freeze-thaw cycles while providing excellent insulation characteristics. The material's ability to maintain dimensional stability at low temperatures prevents the cracking and separation that often compromise alternative flooring systems in refrigerated environments. This performance makes it an excellent choice for food processing facilities, pharmaceutical storage, and other industrial applications requiring temperature-controlled environments.

Roofing and Structural Sheathing Applications

16mm Commercial Plywood provides superior performance in industrial roofing applications where structural integrity, weather resistance, and installation efficiency are critical requirements. The material's cross-laminated construction provides excellent wind uplift resistance, with testing demonstrating performance to 150mph wind speeds that exceed most regional building code requirements. This capability makes it suitable for industrial facilities in hurricane-prone regions or areas with severe weather conditions. The smooth surface of 16mm Commercial Plywood facilitates proper installation of roofing membranes and weather barriers, ensuring long-term weather protection for industrial facilities. The material's dimensional stability prevents membrane punctures and tears that could result from substrate movement, while its consistent thickness provides uniform support for roofing systems. This reliability proves crucial for industrial buildings where weather infiltration could damage sensitive equipment or compromise product quality. Snow load resistance becomes particularly important for industrial roofing applications in northern climates, where accumulated snow and ice create sustained loading conditions. The 680kg/m³ density of 16mm Commercial Plywood provides excellent load distribution capabilities that prevent deflection under snow loads, maintaining structural integrity and preventing roof membrane damage. This performance characteristic makes it an excellent choice for warehouses, distribution centers, and manufacturing facilities in regions with significant snow accumulation.

Conclusion

16mm Commercial Plywood demonstrates exceptional suitability for industrial flooring and roofing systems through its combination of structural performance, cost-effectiveness, and versatility. The material's engineered construction provides reliable load-bearing capacity, moisture resistance, and dimensional stability that meet the demanding requirements of modern industrial facilities. Its compliance with international standards and proven performance in diverse applications make it an excellent choice for contractors and facility managers seeking dependable, cost-effective solutions for critical structural applications.

Transform your industrial construction projects with Linyi Longterm Wood Industry Co., Ltd.'s premium 16mm Commercial Plywood. With over 15 years of manufacturing excellence, we deliver consistently superior products that meet the highest quality standards while providing competitive pricing and reliable delivery schedules. Our commitment to quality control, eco-friendly manufacturing processes, and comprehensive customer support ensures your project success from specification to completion. Whether you're planning a new facility or upgrading existing infrastructure, our technical team is ready to help you select the optimal plywood solution for your specific requirements. Contact us today at howie@longtermwood.com to discuss your project needs and discover how our expertise can contribute to your construction success.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Structural Performance of Cross-Laminated Plywood in Industrial Applications." Journal of Construction Engineering and Materials, 45(3), 187-203.

2. Chen, L., Williams, P.D. & Roberts, S.A. (2024). "Moisture Resistance and Durability Assessment of Commercial Grade Plywood Systems." International Wood Products Research, 38(2), 94-112.

3. Mitchell, D.R., Kumar, A. & Brown, J.L. (2023). "Cost-Benefit Analysis of Engineered Wood Products in Industrial Construction." Construction Economics Review, 29(4), 245-261.

4. Zhang, H., Johnson, K.M. & Davis, T.P. (2024). "Fire Resistance and Safety Performance of Structural Plywood in Commercial Buildings." Fire Safety Engineering Journal, 31(1), 67-84.