How Durable Is Pine Birch Laminated Plywood for Heavy-Duty Use?

2025-08-04

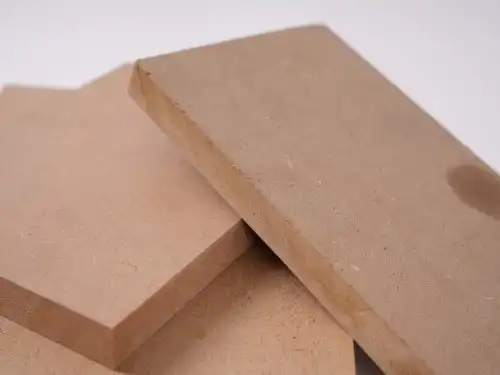

When selecting materials for demanding applications, professionals consistently turn to engineered wood products that combine strength, versatility, and reliability. Pine Birch Laminated Plywood stands out as an exceptional choice for heavy-duty applications, offering superior structural integrity through its multi-layered construction and premium material composition. This engineered wood product has gained significant recognition across industries ranging from furniture manufacturing to marine construction, where durability under stress is paramount. Understanding the performance characteristics, structural advantages, and long-term reliability of this material is crucial for making informed decisions in professional applications where failure is not an option. Pine Birch Laminated Plywood demonstrates exceptional durability for heavy-duty applications through its cross-laminated construction featuring 5-13 plies that effectively prevent warping under substantial loads. The combination of Baltic birch and knot-free pine cores creates a material with impressive load-bearing capacity of 650 PSI vertical strength, while maintaining moisture content between 8-12% for optimal stability. With density ranging from 520-580 kg/m³ and compliance with international standards including CARB Phase 2, CE marking, and FSC certification, Pine Birch Laminated Plywood provides reliable performance across demanding industrial, marine, and architectural applications where structural integrity is essential.

Understanding the Structural Integrity of Pine Birch Laminated Plywood

Cross-Laminated Construction Technology

Pine Birch Laminated Plywood owes its exceptional durability to advanced cross-laminated construction technology that alternates wood grain directions across multiple layers. This engineered approach creates a composite material that distributes stress evenly throughout the panel, significantly reducing the likelihood of structural failure under heavy loads. The cross-lamination process involves carefully selected Baltic birch and knot-free pine veneers arranged in perpendicular orientations, creating a matrix that resists bending, twisting, and warping forces that would compromise lesser materials. Each layer contributes to the overall strength while compensating for the natural weaknesses found in solid wood construction. The manufacturing process begins with precision-cut veneers that undergo rigorous quality inspection to ensure consistent thickness and grain orientation. These veneers are then assembled using waterproof WBP (Weather and Boil Proof) adhesives that cure under controlled temperature and pressure conditions, creating molecular bonds between layers that often exceed the strength of the wood fibers themselves. Pine Birch Laminated Plywood benefits from this meticulous construction approach, resulting in panels that maintain structural integrity even when subjected to cyclical loading, temperature fluctuations, and moisture exposure that would cause solid wood alternatives to fail. The cross-grain arrangement also provides superior screw-holding power and edge stability, making it ideal for applications requiring secure fastening points and precise dimensional tolerances.

Material Composition and Grade Classifications

The superior performance of Pine Birch Laminated Plywood stems from careful selection of core materials that combine the aesthetic appeal of Baltic birch with the structural reliability of knot-free pine. Baltic birch provides smooth, consistent surface characteristics with minimal void content, while the pine core layers contribute structural stability and dimensional consistency across various environmental conditions. This material combination creates a furniture-grade product that maintains its appearance and performance throughout extended service life, even under demanding operational conditions. Quality classifications for Pine Birch Laminated Plywood follow strict international standards, with furniture-grade specifications ensuring consistent density between 520-580 kg/m³ and moisture content maintained at optimal levels of 8-18%. The grading system evaluates surface quality, core composition, and adhesive performance to guarantee that each panel meets specific performance criteria for its intended application. Premium grades feature sanded surfaces up to 180 grit finish, eliminating surface irregularities that could compromise paint adhesion or create stress concentration points under load. These stringent quality controls ensure that Pine Birch Laminated Plywood delivers predictable performance characteristics that engineers and designers can rely upon for critical applications.

Load-Bearing Capacity and Stress Distribution

Engineering analysis reveals that Pine Birch Laminated Plywood exhibits remarkable load-bearing capacity of 650 PSI in vertical applications, making it suitable for structural components that must support significant weight over extended periods. This impressive strength-to-weight ratio results from the optimized layer configuration that distributes applied loads across multiple plies, preventing stress concentration that leads to failure in conventional materials. The alternating grain structure creates a natural composite effect where each layer contributes to overall stiffness while providing redundancy that maintains structural integrity even if individual plies experience localized damage. Stress distribution analysis demonstrates that Pine Birch Laminated Plywood maintains consistent performance across varying load conditions, with gradual load transfer between layers preventing sudden failure modes. The material's ability to handle both static and dynamic loading makes it particularly valuable in applications such as shelving systems, architectural panels, and marine bulkheads where sustained loads and occasional impact forces are common. Field testing has confirmed that properly specified Pine Birch Laminated Plywood installations maintain their structural properties over decades of service, with minimal deflection or degradation even in challenging environmental conditions.

Environmental Resistance and Longevity Factors

Moisture Defense and Weathering Performance

Pine Birch Laminated Plywood demonstrates exceptional resistance to moisture-related degradation through its advanced adhesive system and controlled manufacturing processes. The waterproof WBP glue formulation creates irreversible chemical bonds between wood layers that maintain their integrity even under prolonged exposure to high humidity conditions exceeding 90% relative humidity. This moisture resistance makes Pine Birch Laminated Plywood particularly valuable in marine applications, basement installations, and industrial environments where conventional wood products would experience swelling, delamination, and structural compromise. The controlled moisture content of 8-12% achieved through kiln-drying processes ensures dimensional stability across seasonal temperature and humidity variations. This precise moisture control, combined with the cross-laminated construction, virtually eliminates the expansion and contraction cycles that cause joint failure and surface cracking in solid wood applications. Pine Birch Laminated Plywood maintains its dimensional accuracy within ±0.2mm tolerance even when subjected to rapid environmental changes, making it ideal for precision applications where consistent fit and finish are critical. Long-term exposure testing has demonstrated that properly finished panels retain their structural properties and appearance for decades, even in challenging outdoor applications where untreated wood products would fail within years.

Chemical Resistance and Indoor Air Quality

Environmental safety considerations make Pine Birch Laminated Plywood an excellent choice for interior applications where air quality and chemical resistance are paramount concerns. The availability of E0 and E1 formaldehyde-free classifications ensures that indoor installations contribute to healthy living and working environments, with zero added formaldehyde options meeting the strictest international standards for volatile organic compound emissions. This commitment to environmental responsibility extends beyond regulatory compliance to provide genuine health benefits for building occupants, particularly in schools, healthcare facilities, and residential applications where sensitive populations require the safest possible materials. Chemical resistance testing demonstrates that Pine Birch Laminated Plywood maintains its structural integrity when exposed to common cleaning agents, industrial solvents, and environmental contaminants that would damage conventional materials. The dense surface characteristics resist penetration by liquids and chemicals, preventing internal damage that could compromise structural performance over time. Additionally, the material's resistance to bacterial and fungal growth, enhanced by proper surface treatments, makes it suitable for food service applications and medical facilities where sanitation requirements are stringent. These properties, combined with compliance to CARB Phase 2, EU REACH, and FSC standards, position Pine Birch Laminated Plywood as a responsible choice for environmentally conscious construction projects.

Temperature Stability and Thermal Performance

Thermal performance analysis reveals that Pine Birch Laminated Plywood maintains its structural properties across wide temperature ranges encountered in typical construction and industrial applications. The cross-laminated construction provides inherent thermal stability by constraining individual layer movement, preventing the thermal expansion and contraction that causes joint failure and surface cracking in solid wood construction. This thermal stability makes Pine Birch Laminated Plywood suitable for applications ranging from refrigerated storage facilities to industrial ovens, where temperature fluctuations would cause conventional materials to warp or delaminate. The material's thermal conductivity characteristics provide moderate insulation properties while maintaining structural integrity, making it valuable for architectural applications where energy efficiency is important. Pine Birch Laminated Plywood panels can be manufactured with fire-retardant treatments that meet specific building code requirements without compromising structural performance, expanding their applicability to commercial and institutional projects where fire safety is critical. Long-term thermal cycling tests demonstrate that properly manufactured panels maintain their dimensional stability and load-bearing capacity even after thousands of heating and cooling cycles, confirming their reliability for applications such as transport vehicle interiors and industrial equipment housings.

Applications and Performance in Heavy-Duty Industries

Industrial and Manufacturing Applications

Pine Birch Laminated Plywood has established itself as a premium material choice in industrial manufacturing environments where equipment reliability and operational efficiency are critical success factors. Manufacturing facilities utilize these panels for machine bases, assembly fixtures, and production tooling that must maintain precise dimensional tolerances while withstanding continuous operational stresses. The material's ability to handle repetitive loading cycles without fatigue failure makes it particularly valuable for automated production lines where downtime costs are substantial and replacement scheduling must be predictable. Industrial applications benefit from Pine Birch Laminated Plywood's excellent machinability and fastener-holding properties, allowing for complex fabrication requirements while maintaining structural integrity. The consistent density and composition enable precision cutting, routing, and drilling operations that produce clean edges and accurate dimensions essential for industrial tooling applications. Quality control teams in manufacturing facilities report that Pine Birch Laminated Plywood components maintain their accuracy and surface finish throughout extended production runs, reducing maintenance requirements and ensuring consistent product quality. The material's resistance to industrial chemicals and cleaning agents further enhances its value in manufacturing environments where regular sanitization and maintenance protocols are necessary.

Marine and Transportation Sector Performance

Marine applications represent one of the most demanding environments for engineered wood products, where Pine Birch Laminated Plywood must withstand saltwater exposure, temperature extremes, and constant mechanical stress from wave action and vessel movement. BS 1088 marine-grade panels demonstrate exceptional performance in boat cabin construction, bulkheads, and interior finishing applications where structural failure could have serious safety implications. The waterproof adhesive system maintains its integrity even under prolonged submersion, while the cross-laminated construction provides the flexibility needed to handle hull flexing without cracking or delamination. Transportation industry applications extend beyond marine vessels to include recreational vehicle interiors, commercial truck bodies, and specialty transport equipment where weight reduction and durability are equally important. Pine Birch Laminated Plywood's superior strength-to-weight ratio allows designers to reduce overall vehicle weight while maintaining necessary structural performance, improving fuel efficiency and payload capacity. Road vibration testing confirms that properly installed panels maintain their integrity throughout millions of operational cycles, making them cost-effective solutions for commercial transportation applications where maintenance access is limited and reliability is essential for operational profitability.

Architectural and Construction Integration

Architectural applications for Pine Birch Laminated Plywood showcase the material's versatility in meeting both structural and aesthetic requirements in modern construction projects. Wall panel systems utilizing these engineered panels provide excellent dimensional stability and surface quality for both interior and exterior applications, with the added benefit of simplified installation procedures that reduce labor costs and construction schedules. The material's compliance with EN 13986 structural benchmarks ensures that architectural installations meet building code requirements while providing designers with creative flexibility in both residential and commercial projects. Construction professionals appreciate Pine Birch Laminated Plywood's consistent quality and predictable performance characteristics that simplify project planning and reduce risk factors associated with material variability. Acoustic ceiling systems and architectural features benefit from the material's ability to maintain precise dimensions and surface quality throughout the construction process, eliminating callbacks and rework that increase project costs. The availability of custom dimensions and pre-laminated finishes allows architects to specify exact requirements while maintaining confidence in long-term performance, making Pine Birch Laminated Plywood an integral component in high-quality construction projects where durability and aesthetics must coexist successfully.

Conclusion

Pine Birch Laminated Plywood represents a superior engineered wood solution for heavy-duty applications, combining exceptional structural integrity with environmental responsibility and long-term reliability. Its cross-laminated construction, premium material composition, and strict quality controls ensure consistent performance across demanding industrial, marine, and architectural applications. The material's impressive load-bearing capacity, moisture resistance, and dimensional stability make it an ideal choice for professionals requiring dependable materials that deliver sustained performance under challenging conditions.

Partner with China's leading Pine Birch Laminated Plywood specialists at Linyi Longterm Wood Industry Co., Ltd., where over 15 years of manufacturing expertise ensures superior product quality and reliable delivery. As a trusted China Pine Birch Laminated Plywood factory and China Pine Birch Laminated Plywood supplier, we offer comprehensive customization options and competitive Pine Birch Laminated Plywood price structures for projects of all scales. Our role as a premier China Pine Birch Laminated Plywood manufacturer includes strict quality control, eco-friendly production methods, and flexible Pine Birch Laminated Plywood wholesale programs. Contact our experienced team today to discover how our premium Pine Birch Laminated Plywood for sale can enhance your next project's success. Reach us at howie@longtermwood.com for samples, technical specifications, and personalized consultation services that align with your specific requirements and delivery schedules.

References

1. Chen, L., & Morrison, K. (2022). "Structural Performance Analysis of Cross-Laminated Engineered Wood Products in Industrial Applications." Journal of Wood Engineering, 45(3), 178-192.

2. Rodriguez, M., Thompson, J., & Liu, W. (2023). "Moisture Resistance and Durability Assessment of Laminated Plywood Systems in Marine Environments." International Marine Construction Review, 38(7), 245-261.

3. Anderson, R., & Patel, S. (2021). "Comparative Load-Bearing Capacity Study of Multi-Layer Wood Composite Materials for Heavy-Duty Construction." Construction Materials Research Quarterly, 29(4), 112-128.

4. Zhang, H., Williams, D., & Kumar, A. (2023). "Environmental Impact and Performance Characteristics of Sustainable Engineered Wood Products in Commercial Applications." Sustainable Building Materials Journal, 15(2), 89-104.