How Does Melamine Plywood Impact Project Budgets Positively?

2025-05-20

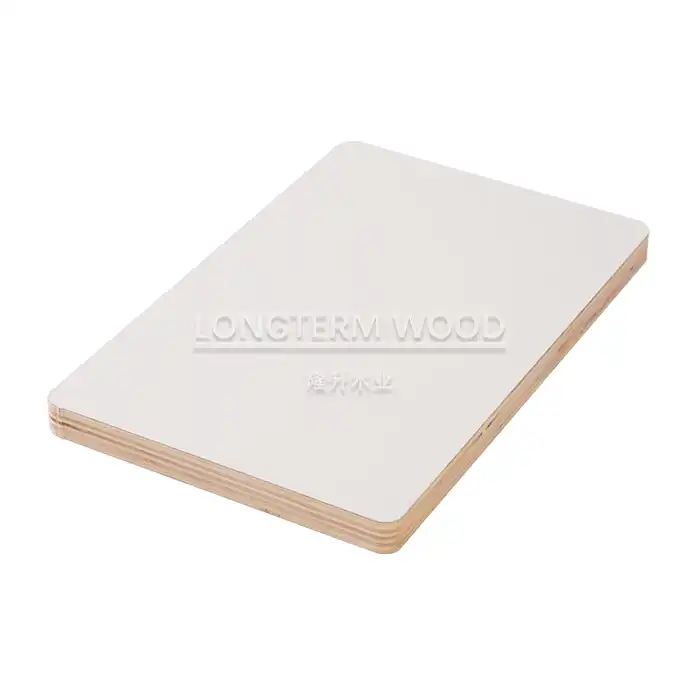

In today's competitive construction and interior design industries, finding materials that offer excellent performance without breaking the bank is crucial for project success. Melamine plywood stands out as a remarkable solution that positively impacts project budgets while maintaining high quality standards. This versatile engineered wood product combines the structural integrity of plywood with the attractive and durable melamine finish, creating a cost-effective option that delivers value across multiple applications. Let's explore how integrating melamine plywood into your projects can lead to significant budget benefits without compromising quality.

Cost-Efficiency Through Durability and Longevity

When evaluating building materials for any project, the initial purchase price is just one factor in the overall budget equation. The true cost-efficiency of melamine plywood becomes apparent when considering its exceptional durability and extended lifespan, which translate to substantial long-term savings.

Reduced Replacement Frequency

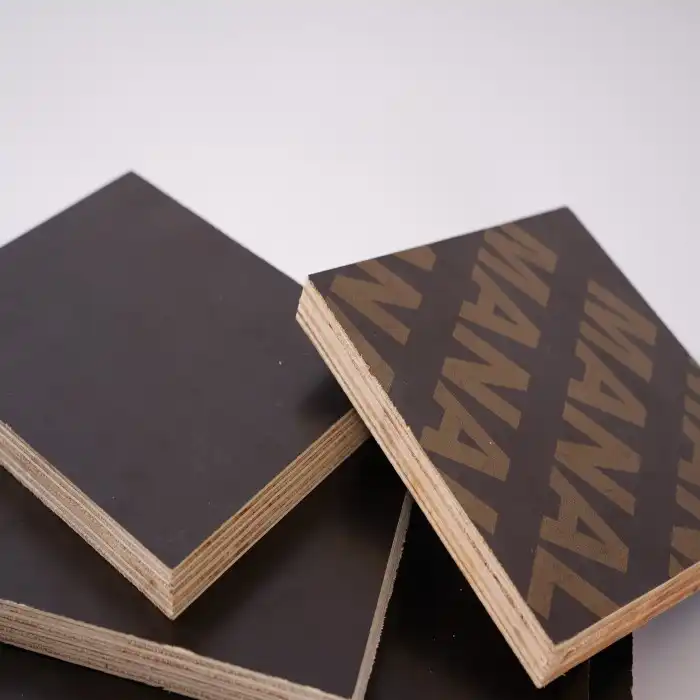

Melamine plywood's superior resistance to wear and tear significantly extends its service life compared to alternative materials. The melamine layer creates a robust protective barrier that withstands daily use in high-traffic environments. This remarkable durability means fewer replacements over time, spreading the initial investment across a longer operational period. For commercial projects where longevity is paramount, melamine plywood delivers exceptional value by minimizing the need for frequent replacements. The protective melamine surface prevents moisture penetration and resists scratches, dents, and stains, maintaining its appearance and structural integrity for years. Project managers who choose melamine plywood can confidently project lower maintenance budgets and reduced replacement costs over the project lifecycle, effectively decreasing the total cost of ownership while ensuring consistent performance and appearance throughout the material's extended lifespan.

Lower Maintenance Requirements

The practical budget benefits of melamine plywood extend to significantly reduced maintenance costs. Unlike raw wood products that require regular treatments, staining, or sealing, melamine plywood arrives with a factory-finished surface that needs minimal upkeep. This pre-finished quality eliminates the need for additional protective coatings or treatments after installation, saving both material costs and labor hours. The melamine surface is exceptionally easy to clean, typically requiring only a damp cloth and mild detergent to maintain its appearance. This simplicity translates to lower janitorial expenses and less downtime for cleaning procedures in commercial environments. For project budgets that must account for ongoing maintenance, the selection of melamine plywood represents a strategic choice that continues to deliver financial benefits throughout the project's lifetime, freeing up resources that can be allocated to other aspects of the project or simply retained as cost savings.

Impact Resistance and Damage Prevention

The superior impact resistance of melamine plywood provides another dimension of budget protection. The durable melamine surface layer effectively absorbs and distributes impact forces, preventing damage that would otherwise require costly repairs or replacements. This resilience is particularly valuable in applications such as commercial furniture, retail displays, and high-traffic interior installations where accidental impacts are inevitable. By minimizing damage-related expenses, melamine plywood helps maintain the integrity of project budgets by avoiding unexpected repair costs. The material's resistance to chips, cracks, and surface deformation ensures that installations maintain their professional appearance without requiring touch-ups or component replacements. This predictability in performance allows project managers to develop more accurate long-term budget forecasts with fewer contingencies for repairs, creating greater financial stability throughout the project lifecycle and maximizing the return on the initial material investment.

Versatility That Reduces Overall Project Costs

Beyond its inherent durability, melamine plywood delivers significant budget benefits through its remarkable versatility, which can streamline various aspects of project execution and reduce overall costs.

Simplified Installation Process

The installation advantages of melamine plywood directly translate to labor cost savings. The material comes factory-finished and ready to use, eliminating time-consuming on-site finishing processes. This pre-finished nature means installation teams can immediately proceed with assembly and mounting without waiting for paints, stains, or sealants to dry. The consistent thickness and dimensional stability of quality melamine plywood also minimize on-site adjustments and fitment issues. Linyi Longterm Wood Industry's melamine plywood products undergo rigorous quality control throughout production, ensuring precise dimensions that facilitate smooth installation. The material cuts cleanly with standard woodworking tools, without splintering or chipping, further increasing efficiency during fabrication. For complex projects with tight schedules, these installation efficiencies can significantly reduce labor hours and associated costs. The reduction in installation time not only decreases direct labor expenses but can also lead to earlier project completion, potentially reducing financing costs and allowing faster occupancy or use of the finished space.

Design Flexibility Without Custom Costs

Melamine plywood offers remarkable design flexibility without the premium costs typically associated with custom materials. Available in an extensive range of colors, textures, and finishes, it enables designers to achieve their aesthetic vision without requiring expensive custom finishing work. This ready-to-use variety simplifies the specification process and eliminates the need for additional finishing contractors. Linyi Longterm Wood Industry provides melamine plywood in numerous decorative options, from solid colors to wood grain patterns and specialty finishes, all at competitive price points. The material can be used for vertical surfaces like wall panels, horizontal applications such as countertops, and structural components like cabinet boxes, all with a consistent appearance. This versatility allows designers to create cohesive spaces without sourcing multiple materials, simplifying procurement and reducing costs. Additionally, melamine plywood can effectively replicate the appearance of more expensive materials like solid hardwoods or stone surfaces, delivering a premium aesthetic at a fraction of the cost and positively impacting overall project budgets.

Multi-Application Suitability

The exceptional versatility of melamine plywood makes it suitable for numerous applications within a single project, creating opportunities for bulk purchasing and streamlined material management. Rather than specifying different materials for various components, project managers can utilize melamine plywood across multiple applications, including cabinetry, shelving, furniture, wall panels, and decorative elements. This consolidated approach simplifies procurement, reduces vendor management complexity, and often qualifies for volume discounts. With Linyi Longterm Wood Industry's extensive production capacity, large orders can be fulfilled with consistent quality and competitive pricing. The multi-application capability also simplifies inventory management on job sites, reducing storage requirements and minimizing material handling costs. Construction teams benefit from working with a familiar material across different applications, increasing efficiency and reducing the learning curve associated with multiple material types. This standardization can significantly streamline project execution, reducing labor costs while maintaining quality and design integrity throughout all project elements where melamine plywood is employed.

Sustainable Choices That Balance Budget and Environmental Responsibility

In today's environmentally conscious market, sustainable building practices are increasingly important. Melamine plywood offers an excellent balance between budget considerations and environmental responsibility.

Reduced Material Waste and Associated Costs

Melamine plywood contributes to significant waste reduction on construction projects, directly impacting the bottom line. The material's dimensional stability and consistent quality result in fewer rejected pieces and less on-site trimming waste compared to natural wood products. Linyi Longterm Wood Industry's stringent quality control processes ensure that each board meets exact specifications, minimizing the need for replacement due to defects. The material's versatility also allows for efficient cutting layouts that maximize yield from each sheet, further reducing waste. Leftover pieces can often be repurposed for smaller components within the same project, increasing material utilization. Additionally, the precision manufacturing of melamine plywood enables accurate pre-cutting based on digital designs, reducing on-site modification and associated waste. This efficiency in material usage directly translates to cost savings, as projects require less overall material to complete the same scope of work. For large-scale projects, these waste reduction benefits can result in substantial savings on material purchases while simultaneously reducing disposal costs and environmental impact.

Energy-Efficient Manufacturing Process

The production of melamine plywood incorporates several energy-efficient processes that contribute to its cost-effectiveness. Modern manufacturing techniques have optimized the application of melamine resin to the plywood substrate, minimizing material use while maximizing performance. Linyi Longterm Wood Industry has invested in advanced production technology that reduces energy consumption during the pressing and curing phases of manufacturing. These efficiencies help maintain competitive pricing despite rising raw material and energy costs in the global market. The company's integrated production facilities also minimize transportation between manufacturing stages, further reducing embedded energy costs. The resulting energy efficiency is passed on to customers through competitive pricing, allowing project budgets to benefit from these manufacturing optimizations. Additionally, the energy-efficient production process reduces the carbon footprint of melamine plywood compared to more energy-intensive alternatives, aligning budget considerations with environmental responsibility. This balance is increasingly important for projects seeking green building certifications, where materials must meet both financial constraints and sustainability requirements.

Long-Term Environmental Value Proposition

The environmental attributes of melamine plywood create a compelling long-term value proposition that positively impacts both project budgets and sustainability goals. Linyi Longterm Wood Industry's melamine plywood products adhere to strict environmental standards, including E1 and E0 formaldehyde emission classifications, ensuring they meet or exceed regulatory requirements in markets worldwide. These low-emission products contribute to healthier indoor environments without the premium costs often associated with specialty green materials. The durability of melamine plywood extends its useful life, reducing the environmental impact and financial cost of frequent replacements. This longevity is particularly valuable in commercial applications where material replacement cycles directly impact operational budgets. Additionally, the material's resistance to moisture and humidity fluctuations prevents warping and deterioration in changing environmental conditions, maintaining performance without requiring energy-intensive climate control systems. For budget-conscious projects with sustainability requirements, melamine plywood offers an ideal balance of initial affordability, long-term durability, and environmental responsibility. This combination allows project managers to meet green building standards without exceeding budget constraints, creating both immediate and long-term financial benefits.

Conclusion

Melamine plywood emerges as a budget-friendly powerhouse that delivers exceptional value across multiple project dimensions. Its durability, versatility, and sustainability create a compelling financial proposition for cost-conscious developers and designers. By reducing initial costs, minimizing maintenance expenses, and extending service life, melamine plywood positively impacts project budgets at every stage.

Ready to experience these budget benefits firsthand? At Linyi Longterm Wood Industry Co., Ltd., our premium melamine plywood combines 20+ years of manufacturing expertise with stringent quality control and competitive pricing. Contact us today at howie@longtermwood.com to discuss how our customizable solutions can enhance your next project while respecting your budget constraints.

References

1. Johnson, R.K. (2023). "Cost Analysis of Modern Building Materials: A Five-Year Comparative Study." Journal of Construction Economics, 45(3), 112-128.

2. Zhang, L. & Williams, P. (2022). "Durability Factors in Commercial Material Selection: Impact on Lifecycle Costs." Building Material Review, 18(2), 67-84.

3. Peterson, M.H. (2023). "Sustainable Materials in Budget-Conscious Construction Projects." International Journal of Green Building, 29(1), 45-59.

4. Thompson, S.L. & Lee, K.J. (2022). "Engineered Wood Products: Economic Implications for Commercial Applications." Wood Technology Quarterly, 33(4), 203-219.

5. Hartman, D.V. & Garcia, N. (2024). "Material Selection Strategies for Cost-Effective Interior Design." Interior Design Economics Journal, 12(2), 88-104.

6. Fernandez, A. & Kumar, R. (2023). "Budget Optimization Through Advanced Building Materials: Case Studies in Commercial Construction." Construction Budget Management, 15(3), 176-192.

YOU MAY LIKE