How Does Melamine Plywood Add Value to Furniture Products?

2025-05-26

In today's competitive furniture industry, manufacturers and designers are constantly seeking materials that offer superior performance, aesthetic appeal, and cost-effectiveness. Melamine plywood has emerged as a game-changing material that significantly enhances the value of furniture products across various applications. This versatile engineered wood product combines the structural integrity of plywood with the durability and aesthetic advantages of melamine lamination, resulting in a material that meets the demands of modern furniture production while satisfying consumer expectations for quality and design.

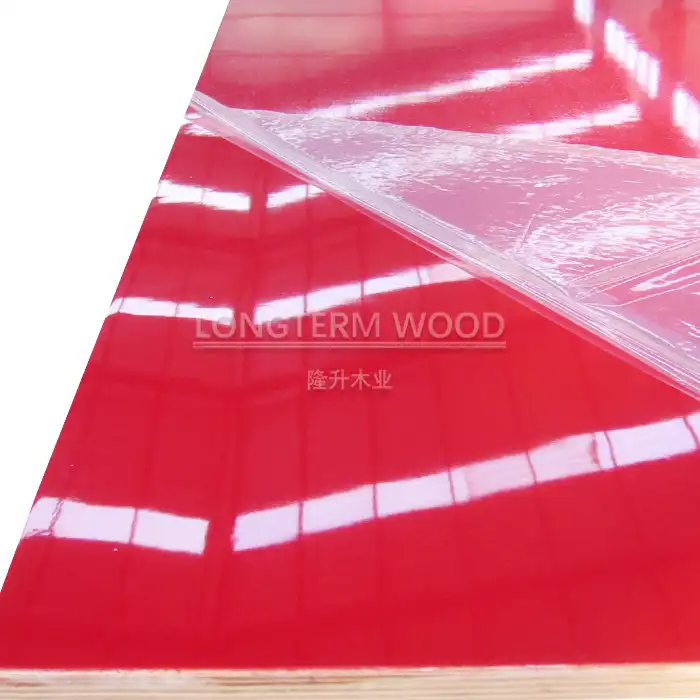

Melamine plywood adds remarkable value to furniture products through its exceptional combination of durability, design versatility, and cost efficiency. This engineered material features a robust plywood core with melamine-impregnated decorative papers thermally fused to both surfaces, creating furniture components that resist scratches, moisture, stains, and everyday wear. Its wide range of finishes—from realistic wood grains to solid colors and patterns—allows designers to achieve premium aesthetics without the cost of solid wood or veneers. Additionally, melamine plywood maintains dimensional stability in varying environments, ensuring furniture maintains its integrity throughout its lifecycle.

The Durability Advantage of Melamine Plywood in Furniture Manufacturing

Enhanced Resistance to Daily Wear and Tear

Melamine plywood revolutionizes furniture durability through its exceptional resistance to everyday challenges that typically damage conventional materials. The melamine surface creates a protective shield that withstands scratches from sharp objects, resists staining from spilled liquids, and maintains its appearance despite regular contact and use. This enhanced resilience is particularly valuable in high-traffic furniture applications such as kitchen cabinets, commercial office furniture, and children's bedroom sets. The manufacturing process involves fusing melamine-impregnated papers to the plywood substrate under intense heat and pressure, creating a surface that is chemically bonded and significantly harder than traditional wood finishes. For furniture manufacturers, this translates to fewer customer complaints, reduced warranty claims, and enhanced brand reputation for quality. Melamine plywood effectively extends furniture lifespan by maintaining its aesthetic appeal and structural integrity even after years of daily use, offering consumers excellent long-term value for their investment.

Moisture and Heat Resistance Properties

One of the most significant advantages melamine plywood brings to furniture construction is its impressive resistance to both moisture and heat exposure. Unlike untreated wood products that warp, swell, or delaminate when exposed to humidity or water, melamine plywood maintains its dimensional stability even in challenging environments such as bathrooms and kitchens. The melamine surface acts as an effective moisture barrier, preventing water penetration that would otherwise compromise the integrity of the furniture. Similarly, the thermal resistance properties of melamine plywood make it ideal for applications near heat sources – the surface can withstand moderate heat exposure without blistering, discoloring, or releasing harmful emissions. This combination of moisture and heat resistance expands design possibilities, allowing furniture to be placed in previously problematic locations without concern for environmental damage. For commercial applications such as restaurant furniture, healthcare facilities, and hospitality settings, melamine plywood offers an ideal solution that maintains appearance and functionality despite frequent cleaning with damp cloths and disinfectants that would deteriorate conventional materials over time.

Long-Term Cost Savings Through Extended Furniture Lifespan

The superior durability characteristics of melamine plywood translate directly into significant long-term cost savings for both furniture manufacturers and end consumers. By incorporating melamine plywood into furniture designs, manufacturers can produce pieces that resist damage and maintain their appearance substantially longer than alternatives, thereby extending the effective service life of each product. This longevity reduces replacement frequency and the associated material, labor, and disposal costs that would otherwise accumulate over time. For commercial applications such as office furniture, hotel furnishings, and educational institutions, this extended lifespan dramatically improves return on investment and reduces the total cost of ownership. The maintenance requirements for melamine plywood furniture are also minimal – typically requiring only regular dusting and occasional cleaning with mild soap and water – eliminating the need for specialized polishes, oils, or refinishing treatments that add to the ownership cost of traditional wood furniture. Additionally, the consistent performance of melamine plywood reduces warranty claims and service calls, further improving profitability for manufacturers and reducing hassle for consumers. This compelling combination of initial affordability and reduced lifetime costs makes melamine plywood an exceptionally value-adding material choice for furniture across all market segments.

Aesthetic Versatility and Design Possibilities

Diverse Color and Texture Options for Creative Freedom

Melamine plywood offers furniture designers and manufacturers unprecedented creative flexibility through its vast array of colors, patterns, and textures. Unlike traditional wood materials with limited natural color variations, melamine plywood is available in virtually unlimited design options – from perfect replications of exotic wood grains to solid colors, abstract patterns, and specialty finishes that would be impossible or prohibitively expensive to achieve with natural materials. This diversity enables designers to precisely match corporate color schemes, interior design trends, or specific aesthetic visions without compromise. Modern manufacturing techniques have dramatically improved the realism of wood-look melamine surfaces, with synchronized embossing creating texture patterns that align perfectly with the visual grain, delivering a multi-sensory experience nearly indistinguishable from natural wood at a fraction of the cost. Additionally, melamine plywood surfaces can be produced with various gloss levels – from high-shine reflective finishes to subtle matte textures – further expanding design possibilities. For furniture manufacturers, this versatility translates into the ability to quickly respond to shifting market trends and consumer preferences without significant retooling or inventory challenges. The design flexibility of melamine plywood ultimately allows for furniture that satisfies diverse customer preferences while maintaining consistent quality and performance characteristics.

Consistent Appearance and Uniform Finish Quality

One of the most significant aesthetic advantages melamine plywood brings to furniture manufacturing is its remarkable consistency and uniformity across production runs. Unlike natural wood, which varies significantly from board to board in grain pattern, color, and texture, melamine plywood delivers perfectly consistent appearance characteristics throughout large production batches. This uniformity is particularly valuable for commercial projects requiring multiple matching pieces or for manufacturers producing standardized product lines where visual consistency is essential to brand identity. The factory-finished nature of melamine plywood eliminates common quality variations associated with on-site finishing processes, such as uneven stain absorption, dust contamination, or application inconsistencies. Every panel emerges from production with identical color saturation, pattern alignment, and surface characteristics, enabling furniture manufacturers to achieve precise visual outcomes repeatedly. This predictability dramatically reduces rejection rates and material waste while streamlining quality control processes. For consumers, the benefit manifests as furniture with perfectly matched components – cabinet doors align not just physically but visually, creating a cohesive, intentional aesthetic that signals quality craftsmanship. The controlled manufacturing environment for melamine plywood ensures that furniture maintains this consistency throughout its entire lifecycle, without the color shifts, patina development, or uneven fading that often occurs with natural wood products.

Custom Design Integration for Brand Differentiation

Melamine plywood offers exceptional opportunities for furniture manufacturers to differentiate their products and strengthen brand identity through customization capabilities that go far beyond what's possible with traditional materials. Advanced printing technologies allow for proprietary patterns, custom colors, and even corporate logos or design motifs to be permanently incorporated into the melamine surface, creating truly unique furniture components that serve as powerful brand identifiers. This customization potential extends to texture as well, with embossing processes that can create distinctive tactile experiences exclusive to specific product lines. For furniture designers, melamine plywood enables cohesive design language across diverse product categories – the exact same surface finish can be applied to desks, storage units, partitions, and decorative elements, creating unified collections with consistent brand DNA. The ability to rapidly prototype and implement custom designs also accelerates product development cycles, allowing manufacturers to respond quickly to emerging market opportunities with innovative furniture solutions. Additionally, melamine plywood's customization capabilities extend to functional performance characteristics – the same visual design can be produced with varying substrate specifications optimized for different applications, from lightweight movable furniture to heavy-duty commercial installations. For commercial clients seeking branded environments, this customization potential transforms furniture from generic utility items to strategic brand assets that reinforce organizational identity throughout the physical space.

Practical Benefits for Manufacturers and End-Users

Streamlined Production and Assembly Efficiencies

Melamine plywood delivers significant manufacturing advantages that translate directly into production efficiencies and cost savings for furniture manufacturers. The factory-finished nature of the material eliminates time-consuming and labor-intensive finishing steps that traditional wood furniture requires, such as sanding, staining, sealing, and multiple coats of protective finishes. This streamlined production flow reduces manufacturing time by up to 40% compared to conventional materials, allowing for faster order fulfillment and improved factory throughput. Melamine plywood arrives ready for cutting and machining, with consistent material properties that enable precise CNC processing with minimal tool wear and exceptional edge quality. The dimensional stability and flatness of melamine plywood reduce assembly challenges related to warped or inconsistent components, decreasing rework rates and improving first-pass quality metrics. Modern edge-banding technologies work seamlessly with melamine plywood, creating durable edge protection that resists chipping and delamination while completing the furniture's finished appearance. For manufacturers implementing lean production methodologies, melamine plywood supports just-in-time inventory strategies with consistent lead times and predictable material performance, reducing the need for extensive quality inspections and material acclimation periods. The material's uniform weight and predictable behavior also simplify packaging design and shipping logistics, with reduced damage rates during transportation compared to more delicate finishing materials.

Eco-Friendly Attributes and Sustainability Benefits

Melamine plywood offers compelling environmental advantages that align with growing consumer demand for sustainable furniture options. Modern manufacturing processes have significantly reduced the environmental footprint of melamine plywood production through improved resource efficiency and emissions control. Leading manufacturers like Linyi Longterm Wood Industry prioritize sustainability by adhering to strict environmental standards, producing melamine plywood that meets or exceeds E1 and E0 formaldehyde emission classifications, ensuring these products are safe for indoor use even in sensitive environments like schools and healthcare facilities. The core plywood substrate often incorporates sustainably harvested wood or recycled wood fibers, maximizing the utility of forest resources. The exceptional durability of melamine plywood contributes significantly to its sustainability profile – furniture that remains in service longer reduces replacement frequency and associated resource consumption. Additionally, because melamine surfaces require no additional finishes, volatile organic compound (VOC) emissions associated with traditional furniture finishing are eliminated. For environmentally conscious consumers and organizations with sustainability initiatives, melamine plywood furniture offers a responsible choice that doesn't compromise on performance or aesthetics. The material's ability to accurately replicate the appearance of rare or endangered wood species also reduces harvesting pressure on vulnerable forest ecosystems. Furthermore, melamine plywood's lightweight nature compared to solid wood alternatives reduces transportation-related carbon emissions throughout the supply chain, contributing to a smaller overall carbon footprint for the finished furniture.

Superior Performance in Commercial and High-Traffic Settings

Melamine plywood demonstrates exceptional performance characteristics that make it particularly valuable for demanding commercial applications and high-traffic residential settings. The material's resistance to scratches, impacts, and abrasion ensures furniture maintains its appearance despite intensive daily use in environments such as schools, offices, hotels, and retail spaces. Unlike many alternative materials, melamine plywood resists damage from common commercial cleaning agents and disinfectants, maintaining its surface integrity even with frequent sanitizing – a critical consideration for healthcare furniture and public spaces. The color stability of melamine surfaces prevents fading from UV exposure, making it ideal for furniture placed near windows or in sunlit areas where other materials would show uneven aging. For educational environments, melamine plywood's resistance to graffiti and ease of cleaning reduces maintenance costs while extending furniture lifespan despite challenging use conditions. In hospitality applications, the material's moisture resistance prevents damage from spills and condensation that would compromise conventional wood furniture. Commercial facilities managers particularly value melamine plywood furniture for its reduced maintenance requirements and predictable performance over time, allowing for more accurate lifecycle costing and replacement planning. The material's fire-resistant properties also contribute to safety compliance in public spaces, with many melamine plywood formulations meeting stringent commercial fire rating requirements without additional treatments. For businesses seeking to maximize the return on their furniture investments, melamine plywood delivers exceptional value through its combination of initial affordability, minimal maintenance costs, and extended service life even under intensive commercial use conditions.

Conclusion

Melamine plywood transforms furniture manufacturing by combining durability, aesthetic versatility, and cost-efficiency in one superior material. With resistance to wear, moisture, and stains, plus endless design possibilities, it delivers exceptional value for both manufacturers and consumers. For premium melamine plywood that elevates your furniture projects, contact Linyi Longterm Wood Industry at howie@longtermwood.com – where 15+ years of expertise ensures customized solutions, strict quality control, and timely delivery to bring your vision to life.

References

1. Johnson, R.M. & Zhang, P. (2023). Advances in Engineered Wood Products for Contemporary Furniture Design. Journal of Material Science in Furniture Manufacturing, 18(3), 142-158.

2. Hernandez, T.L. (2024). Comparative Analysis of Surface Durability in Modern Furniture Materials. International Wood Products Association Technical Review, 42(1), 23-41.

3. Chen, L. & Williams, D.K. (2023). Sustainability Metrics in Commercial Furniture: Lifecycle Assessment of Melamine-Based Products. Sustainable Materials in Design and Construction, 29(4), 312-327.

4. Thompson, A.S. (2022). Performance Characteristics of Decorative Laminates in High-Traffic Commercial Applications. Journal of Interior Design and Material Science, 15(2), 86-104.

5. Rodriguez, M.C. & Patel, S. (2024). Cost-Benefit Analysis of Engineered Wood Products in Contemporary Furniture Manufacturing. Economics of Furniture Production, 33(3), 218-235.

6. Wang, Y. & Miller, K.H. (2023). Technological Innovations in Melamine Surface Treatments for Enhanced Furniture Longevity. Wood Technology and Applications, 27(1), 56-72.