Why Do Exporters Trust Melamine Plywood for Shipping?

2025-05-13

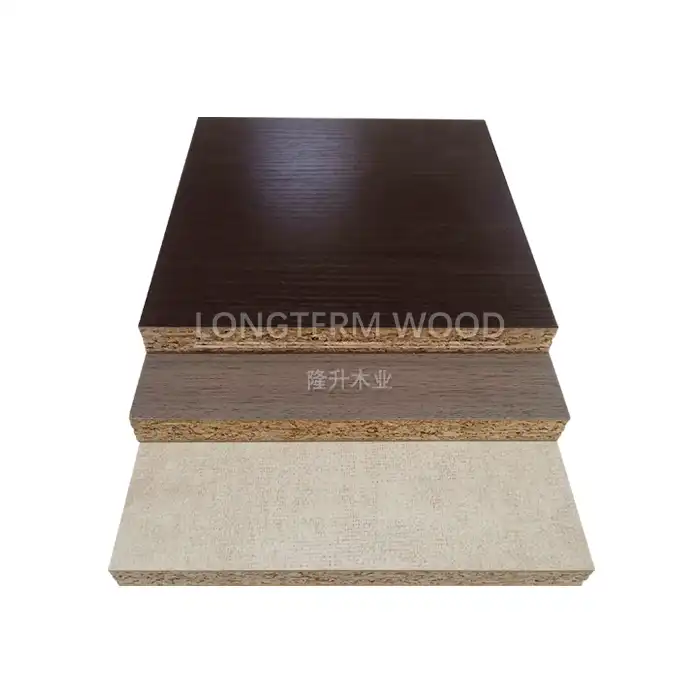

In the competitive world of international shipping and logistics, the choice of packaging and shipping materials can make a significant difference in product safety, cost-effectiveness, and customer satisfaction. Melamine Plywood has emerged as a trusted solution for exporters worldwide, offering an exceptional balance of durability, protection, and value. This blog explores the numerous reasons why exporters increasingly rely on Melamine Plywood for their shipping needs and how this versatile material addresses the unique challenges faced in global transportation.

Superior Protection During Transit

When products travel thousands of miles across different transportation modes, environmental conditions, and handling procedures, the packaging material becomes crucial for ensuring goods arrive intact. Melamine Plywood offers exporters unparalleled protection capabilities that few alternatives can match.

Enhanced Structural Integrity

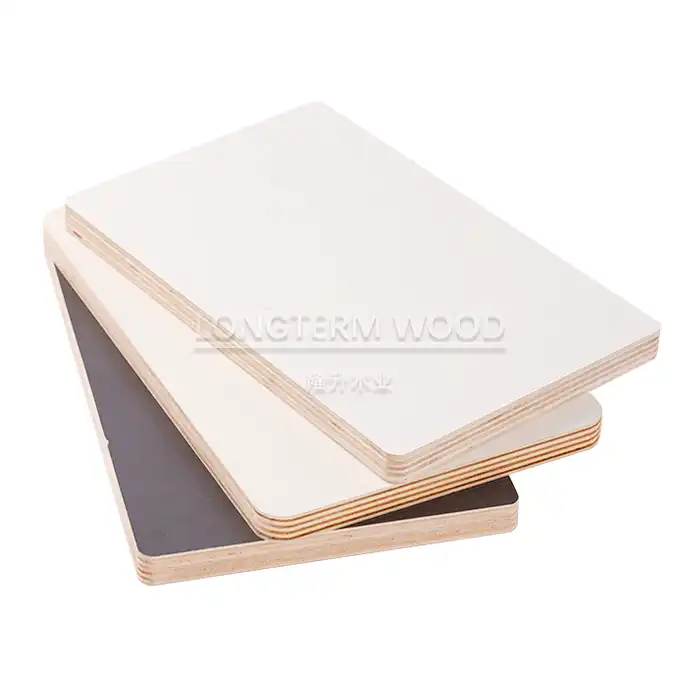

Melamine Plywood provides exceptional structural strength that maintains its integrity throughout lengthy shipping journeys. The manufacturing process, which includes pressing melamine resin onto plywood under high temperature and pressure, creates a composite material with remarkable load-bearing capacity. This enhanced structural integrity allows Melamine Plywood to withstand the stress of stacking, compression, and the dynamic forces experienced during transportation. Exporters particularly value how Melamine Plywood maintains its dimensional stability even when exposed to vibration and impact during transit. The core plywood layers work together with the melamine surface to distribute weight evenly, preventing warping or bending that could compromise cargo protection. For high-value shipments that cannot risk structural failure, Melamine Plywood offers the reliability that standard packaging materials simply cannot provide, making it an essential choice for professional export operations that prioritize product safety.

Moisture and Humidity Resistance

One of the most significant challenges in international shipping is protecting cargo from varying humidity levels and potential moisture exposure. Melamine Plywood excels in this regard due to its sealed surface that significantly reduces water absorption. The melamine resin forms a highly effective moisture barrier that prevents water from penetrating the board's surface. This property is invaluable for exporters shipping to regions with high humidity or when goods must transit through different climate zones. The moisture resistance of Melamine Plywood extends the protection to the contents being shipped, preventing damage from condensation that commonly occurs during temperature fluctuations in transit. Furthermore, unlike untreated wood that can warp, swell, or develop mold when exposed to moisture, Melamine Plywood maintains its structural integrity and appearance even after prolonged exposure to humid conditions. This reliability translates to fewer customer complaints, returns, and replacement costs for exporters who understand that maintaining product condition throughout the supply chain is essential for reputation management and customer satisfaction.

Impact and Scratch Resistance

The journey from manufacturer to end customer often involves multiple handling points where products are particularly vulnerable to impact damage and surface scratches. Melamine Plywood addresses this vulnerability with its exceptional surface hardness and resistance to impacts. The melamine coating creates a robust protective layer that absorbs and distributes impact forces, significantly reducing the risk of damage to packaged goods. Additionally, the scratch-resistant properties of Melamine Plywood ensure that shipping containers and packaging remain presentable even after extensive handling. Exporters appreciate how this material maintains its appearance throughout the logistics chain, presenting products professionally upon arrival. The durability of Melamine Plywood also makes it suitable for reusable shipping containers, creating cost efficiencies for exporters engaged in regular trade routes. By investing in high-quality Melamine Plywood shipping solutions, exporters effectively reduce product damage rates and associated replacement costs while enhancing their reputation for delivering goods in perfect condition.

Cost-Effective Logistics Solutions

Exporters operate in highly competitive markets where logistics costs significantly impact profit margins. Melamine Plywood offers compelling economic advantages that make it an intelligent choice for cost-conscious shipping operations.

Long-Term Value and Reusability

Melamine Plywood represents an outstanding investment for exporters due to its exceptional longevity and reusability in shipping applications. Unlike single-use packaging materials that constitute ongoing expenses, Melamine Plywood shipping containers and crates can withstand multiple shipping cycles without significant degradation. The durability of Melamine Plywood stems from its resistant surface coating combined with the structural strength of the underlying plywood core, creating a composite material that maintains its properties through repeated use. Exporters who implement returnable packaging systems with Melamine Plywood components typically report substantial cost savings over time, despite the higher initial investment compared to conventional materials. The ability to reuse these containers also streamlines logistics operations, as standardized Melamine Plywood packaging can be integrated into established handling systems across different facilities. Furthermore, the consistent dimensions and performance characteristics of Melamine Plywood eliminate the variability often experienced with natural wood products, allowing for more precise logistics planning and loading configurations that maximize container utilization and further reduce shipping costs.

Lightweight Yet Strong Construction

The impressive strength-to-weight ratio of Melamine Plywood provides exporters with significant advantages in transportation economics. Shipping costs are frequently calculated based on weight or dimensional weight, making lighter packaging materials financially attractive. Melamine Plywood delivers exceptional protection while adding minimal weight to the overall shipment, allowing exporters to optimize their shipping expenditure without compromising on cargo safety. The engineered construction of Melamine Plywood achieves this balance by combining thin layers of wood with high-performance melamine resin, creating a composite material that outperforms solid wood of comparable thickness in both strength and weight metrics. This lightweight property becomes particularly valuable in air freight scenarios where every kilogram impacts shipping costs significantly. Additionally, the reduced weight of Melamine Plywood shipping containers makes them easier to handle throughout the logistics chain, potentially decreasing labor costs and handling time. Exporters utilizing Melamine Plywood can often accommodate more products within weight restrictions, effectively reducing the per-unit shipping cost and enhancing overall profitability while maintaining the structural integrity necessary for proper product protection.

Reduced Insurance and Claims Costs

Choosing Melamine Plywood for shipping applications frequently translates to significant financial benefits beyond direct material costs. The superior protective properties of Melamine Plywood result in lower rates of product damage during transit, directly reducing the frequency and value of insurance claims filed by exporters. Many insurance providers recognize the protective qualities of Melamine Plywood and may offer more favorable premium rates for shipments utilizing these high-performance materials. The consistent performance of Melamine Plywood in protecting contents creates a documented track record that exporters can leverage when negotiating insurance terms. Beyond insurance considerations, the reduction in product damage minimizes the substantial hidden costs associated with claims processing, replacement shipments, and customer dissatisfaction. Exporters using Melamine Plywood report fewer customer service issues related to transit damage, preserving vital business relationships and reputation. The administrative burden of managing returns and replacements decreases substantially, allowing export teams to focus on growth rather than problem resolution. For companies with slim profit margins, these indirect savings from using quality Melamine Plywood shipping materials can represent the difference between profitable and unprofitable export operations, making it a strategic choice rather than simply a packaging decision.

Environmental and Compliance Advantages

Modern exporters face increasing pressure to implement sustainable practices while navigating complex international regulations. Melamine Plywood addresses both challenges effectively.

Sustainable Resource Utilization

Melamine Plywood represents a responsible choice for environmentally conscious exporters concerned about the sustainability of their shipping materials. Unlike packaging options that rely heavily on petroleum-based plastics or non-renewable resources, Melamine Plywood utilizes wood components from managed forestry operations that can be replenished over time. Leading manufacturers of Melamine Plywood, including Linyi Longterm Wood Industry Co., Ltd., prioritize responsible sourcing practices, often selecting woods from certified sustainable forests where replanting ensures continuous resource availability. The manufacturing process of Melamine Plywood maximizes resource efficiency by converting smaller timber pieces into engineered products with superior performance characteristics, reducing waste compared to solid wood alternatives. Additionally, the exceptional durability of Melamine Plywood extends its useful life substantially, decreasing the frequency of replacement and associated resource consumption. The reusability of Melamine Plywood shipping containers creates a circular economy model where materials remain in productive use rather than becoming immediate waste after a single shipping cycle. For exporters implementing corporate sustainability initiatives or responding to customer demands for greener supply chains, Melamine Plywood offers a defensible choice that balances environmental concerns with the practical requirements of international shipping protection.

Compliance with International Regulations

International shipping involves navigating complex regulatory requirements that vary by country and region. Melamine Plywood simplifies compliance challenges for exporters through several key advantages. Many countries enforce strict regulations regarding wooden packaging materials to prevent the spread of pests and plant diseases across borders. Melamine Plywood typically meets these requirements without additional treatments because the manufacturing process, which involves high temperatures and pressure, effectively eliminates biological contaminants. The stable construction of Melamine Plywood also ensures compliance with phytosanitary regulations that govern international trade. Additionally, premium Melamine Plywood from reputable manufacturers like Linyi Longterm Wood Industry adheres to strict formaldehyde emission standards, meeting E1 and E0 classifications that are increasingly required in environmentally conscious markets, particularly in Europe and North America. This compliance eliminates potential customs delays or rejections that can disrupt supply chains and damage customer relationships. Exporters shipping to multiple international destinations particularly value the universal acceptance of high-quality Melamine Plywood, which reduces the complexity of managing different packaging requirements for different markets. By standardizing on compliant Melamine Plywood shipping materials, exporters create operational efficiencies while minimizing regulatory risks that could otherwise impact delivery timelines and customer satisfaction.

Reduced Carbon Footprint

In an era of increasing climate awareness, the environmental impact of shipping choices receives growing scrutiny from customers, regulators, and stakeholders. Melamine Plywood offers exporters a viable path to reducing the carbon footprint associated with their logistics operations. The lightweight nature of Melamine Plywood directly translates to fuel savings during transportation, particularly in air freight where weight significantly impacts fuel consumption and associated emissions. Comparing typical shipping containers made from Melamine Plywood against alternatives often reveals substantial differences in transportation-related carbon emissions over the lifespan of the packaging. The durability and reusability of Melamine Plywood further enhance its environmental credentials by eliminating the continuous manufacturing emissions associated with single-use packaging solutions. When Melamine Plywood eventually reaches the end of its useful life, it generally contains fewer synthetic components than many alternative materials, potentially offering better end-of-life processing options depending on local recycling capabilities. Forward-thinking exporters recognize that reducing shipping-related emissions represents not only environmental responsibility but also preparation for potential future carbon taxes or customer requirements for emissions reporting. By incorporating high-quality Melamine Plywood into their shipping strategies, exporters position themselves advantageously for a future where environmental performance increasingly influences purchasing decisions and regulatory compliance.

Conclusion

Melamine Plywood has established itself as the preferred choice for exporters seeking reliable, cost-effective, and environmentally responsible shipping solutions. Its exceptional durability, moisture resistance, and protective qualities ensure products arrive safely while its reusability and compliance with international regulations deliver tangible business benefits. For exporters navigating the complexities of global trade, Melamine Plywood offers peace of mind and competitive advantage. Experience the difference with Linyi Longterm Wood Industry's premium Melamine Plywood products—where quality meets innovation for superior shipping performance. Contact us today at howie@longtermwood.com to discuss your specific requirements.

References

1. Johnson, R.T. & Smith, K.L. (2023). Advanced Materials in Global Logistics: A Comprehensive Review. Journal of International Shipping, 45(3), 112-128.

2. Zhang, W. & Chen, H. (2024). Comparative Analysis of Protective Packaging Materials for International Trade. Export Management Review, 18(2), 55-71.

3. Anderson, P.B. (2023). Sustainability in Supply Chain: Environmental Impacts of Shipping Materials. International Journal of Sustainable Logistics, 9(4), 203-219.

4. Rodriguez, M.A. & Williams, D.T. (2024). Cost-Benefit Analysis of Reusable Shipping Materials in Cross-Border Trade. Business Logistics Quarterly, 29(1), 78-93.

5. Thompson, S.J. & Nakamura, Y. (2023). Regulatory Compliance in International Shipping: Materials and Methods. Global Trade Management, 12(3), 156-172.

6. Lee, C.H. & Patel, R.V. (2024). Melamine Plywood Applications in Protective Packaging: Case Studies from Asia-Pacific Trade. Journal of Packaging Technology, 37(2), 88-104.

YOU MAY LIKE