Thickness : 9mm , 12mm , 56mm , 18mm

Grade : Furniture grade

Glue : E2 , E1 , E0 , CARB

Density : 520---580kgs/m3

Certification : EPA CARB P2 certification

Moisture Content : 8% ~18%

Keywords : Poplar core commercial plywood

Application : Furniture industry

Size : 1220*2440 mm

18mm Poplar Plywood | Durable & Lightweight Panels for Furniture Manufacturing

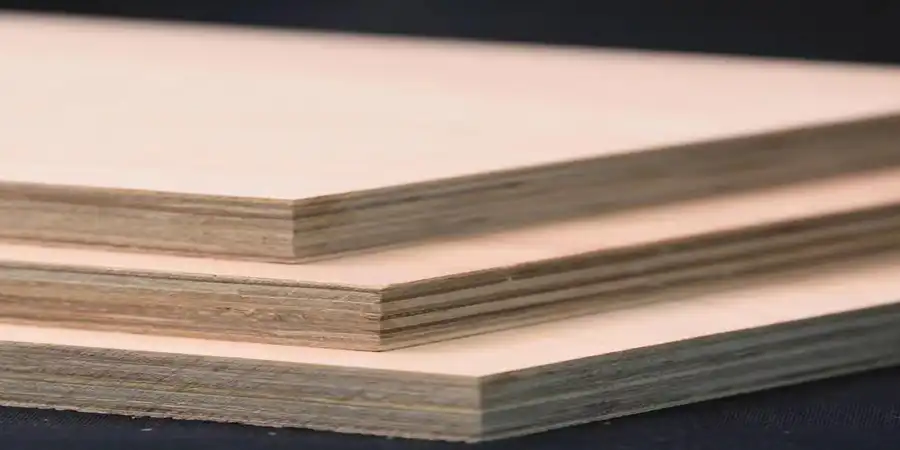

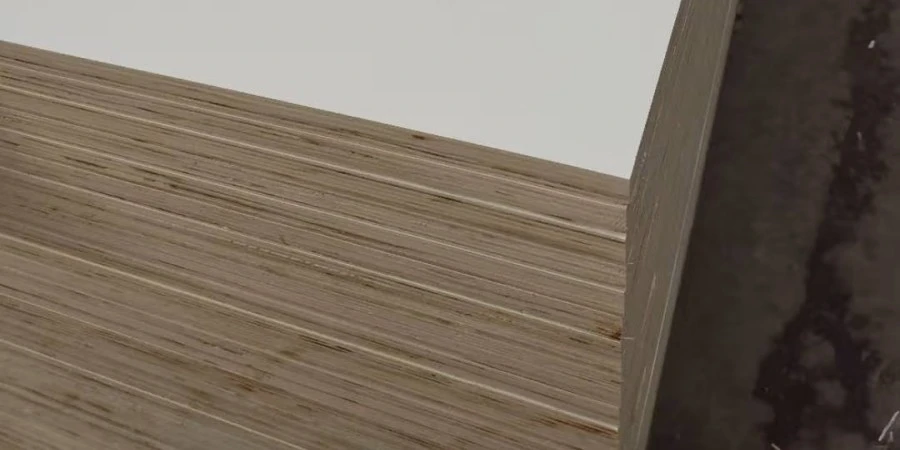

Looking for reliable 18mm poplar plywood that balances strength and workability? Our panels are engineered for furniture makers who demand precision. With a lightweight poplar core and 13-layer cross-banded construction, this 18mm thickness delivers exceptional screw-holding power and warp resistance—perfect for cabinet backs, drawer bases, and structural frames. CARB Phase 2 and FSC-certified, it meets strict global standards while keeping your projects eco-friendly.

Why Choose Our 18mm Poplar Plywood?

1. Built for Heavy-Duty Furniture

- 18mm thickness (±0.2mm tolerance) ensures uniform strength for load-bearing components.

- 450-500 kg/m³ density core resists denting, even under 220kg/m² edge loads.

- Pre-sanded surfaces (120-180 grit) save 15-20% finishing time for veneers or paint.

2. Smarter Material Handling

- 20% lighter than birch plywood—cut shipping costs without sacrificing durability.

- Custom-cut panels (1220x2440mm standard) minimize workshop waste.

- Optional CNC pre-drilling for faster assembly line integration.

3. Climate-Adaptive Performance

- MR (Moisture Resistant) glue and 8-10% moisture content prevent warping in 85% RH environments.

- Phenolic resin upgrade available for bathroom or kitchen furniture projects.

Technical Specifications

| Property | Specification |

|---|---|

| Core Material | Grade A Poplar |

| Panel Size | 1220x2440mm (Custom Sizes Available) |

| Surface Finish | Sanded, Knot-Free |

| Formaldehyde Emission | E0 (≤0.05ppm) |

| Edge Load Capacity | 220kg/m² |

| Certifications | FSC, CARB Phase 2, ISO 9001 |

Where It Works Best?

🛋️ Cabinet Backs & Drawers

- Non-load-bearing panels with screw-holding strength that lasts.

- Warp-resistant design keeps drawer slides aligned over years of use.

🏢 Commercial Furniture Systems

- Meets EN 314-2 shear strength requirements for office partitions.

- Fire-retardant treatment (Class B1) available for public spaces.

🌿 Eco-Conscious Projects

- FSC-certified sheets qualify for LEED green building points.

- Near-zero VOC emissions ideal for schools/hospitals.

What Sets Us Apart?

✅ 12-Year Warp-Free Guarantee

Our precision kiln-drying technology eliminates internal stresses.

✅ Mixed Container Batches

Combine 18mm poplar plywood with other thicknesses in one shipment.

✅ Door-to-Door Logistics

40HQ containers optimized for 1,100-1,300 sheets with real-time tracking.

✅ Defect-Free Promise

Three-stage quality checks ensure <0.5% void content and seamless edges.

Trusted by Global Manufacturers

"We’ve used 50+ containers annually of their product for IKEA-tier cabinet production. The ±0.2mm thickness consistency is unmatched."

– Procurement Manager, German Furniture Group

"20% lighter than birch alternatives—a game-changer for our export drawer systems."

– Production Director, Vietnam OEM Factory

Get Started Today

📦 Free Sample Kit

Test our product with your CNC/hardware—no cost.

📋 Instant Bulk Pricing

FOB/CIF quotes for 100+ sheet orders ready in 1 business hour.

⏱️ Fast Turnarounds

12-18 day lead times, even for custom sizes or edge sealing.

FAQs

1. How does the product handle humidity?

Our MR glue and controlled 8-10% moisture content prevent warping in up to 85% relative humidity.

2. Can I get panels cut to my CAD files?

Yes! We accept DXF/DWG files for precision CNC cutting (±1mm accuracy).

3. What’s the MOQ?

1 container (1,100-1,300 sheets), but we accommodate trial orders of 100+ sheets.

4. How does it compare to MDF for cabinet backs?

18% lighter than MDF with 3x better screw retention—no pilot holes needed.

5. Are edges splinter-free for visible areas?

Laser-guided saws create clean edges, but we recommend veneer tape for A-grade finishes.

Have More Questions?

Reach our plywood specialists at howie@longtermwood.com for 18mm Poplar Plywood within 4 hours on weekdays.