Why Should Furniture Manufacturers Switch to Melamine Plywood?

2025-06-11

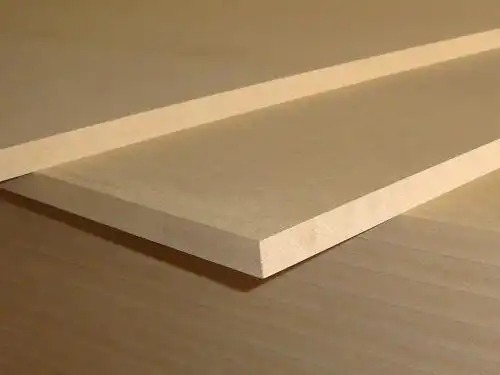

In today's competitive furniture manufacturing landscape, material selection plays a pivotal role in determining product quality, durability, and market success. Melamine plywood has emerged as a game-changing material that offers significant advantages over traditional options. This versatile engineered wood product combines the structural strength of plywood with the aesthetic appeal and functional benefits of melamine surfacing. For furniture manufacturers seeking to enhance their product offerings while maintaining cost efficiency, melamine plywood presents a compelling solution that addresses multiple production challenges simultaneously.

The Unmatched Benefits of Melamine Plywood for Furniture Production

Superior Durability and Longevity

Melamine plywood stands out in the crowded field of furniture materials due to its exceptional durability characteristics. Unlike conventional wood products that may warp, scratch, or deteriorate over time, melamine plywood features a resin-infused surface that creates a formidable barrier against everyday wear and tear. This protective layer is created through a sophisticated production process where melamine resin is heat-fused to the plywood substrate under high pressure. The resulting surface demonstrates remarkable resistance to scratches, stains, and moisture damage that typically plague furniture in high-use environments. Furniture manufacturers who incorporate melamine plywood into their production lines report significantly fewer customer complaints related to surface damage and premature deterioration. The moisture-resistant properties of melamine plywood make it particularly valuable for kitchen and bathroom cabinetry, where exposure to humidity and water splashes is unavoidable. By investing in melamine plywood, manufacturers can extend the functional lifespan of their furniture products, thereby enhancing brand reputation for quality and reliability in the competitive marketplace. This durability factor directly translates to higher customer satisfaction ratings and increased likelihood of positive referrals, essential components of sustainable business growth in the furniture industry.

Design Versatility and Aesthetic Appeal

The remarkable design flexibility of melamine plywood offers furniture manufacturers unprecedented creative freedom. Modern production techniques have dramatically expanded the available aesthetic options, with melamine plywood now available in hundreds of finishes that convincingly replicate natural wood grains, stone textures, solid colors, and even metallic surfaces. This versatility allows manufacturers to maintain consistent design languages across diverse product lines without compromising on visual appeal or tactile quality. For designers working with melamine plywood, the ability to mix and match different finish options within a single furniture piece creates opportunities for distinctive signature styles that stand out in crowded retail environments. The surface consistency of melamine plywood also ensures dependable color reproduction across large production runs, eliminating the batch variation issues common with natural wood veneers. High-resolution printing technologies have advanced to the point where premium melamine plywood surfaces can convincingly mimic exotic hardwoods that would otherwise be prohibitively expensive or environmentally problematic to source. Additionally, specialized finishes such as anti-fingerprint, ultra-matte, and high-gloss options give manufacturers the ability to target specific market segments with tailored aesthetic experiences. For furniture collections aimed at contemporary living spaces, the clean, consistent appearance of melamine plywood aligns perfectly with minimalist design principles while still offering warmth and visual interest.

Cost-Effectiveness and Production Efficiency

The compelling economic advantages of melamine plywood make it an increasingly attractive option for furniture manufacturers operating in price-sensitive markets. When analyzing total production costs, melamine plywood typically offers savings of 15-30% compared to solid wood alternatives, while delivering comparable or superior performance characteristics. This cost efficiency stems from multiple factors, including streamlined manufacturing processes, reduced labor requirements, and minimal waste generation. The dimensional stability of melamine plywood virtually eliminates costly material rejection due to warping or splitting, issues that frequently plague natural wood processing. Additionally, furniture pieces constructed with melamine plywood generally require fewer production steps, as the pre-finished surface eliminates the need for separate painting, staining, or sealing operations that add significant time and expense to manufacturing workflows. The consistency of melamine plywood panels also facilitates automation and precision cutting, allowing manufacturers to optimize material yield and reduce scrap rates. For manufacturers implementing lean production methodologies, the predictable performance and processing characteristics of melamine plywood support just-in-time inventory systems that minimize capital tied up in raw materials. From a cash flow perspective, the reduced production cycle times achievable with melamine plywood accelerate inventory turnover and improve operational efficiency. Companies that have transitioned their product lines to melamine plywood report significant reductions in warranty claims and returns, further enhancing profitability through decreased post-sale service costs.

Environmental and Sustainability Advantages of Melamine Plywood

Eco-Friendly Manufacturing Processes

The production of melamine plywood incorporates numerous environmentally responsible practices that align with modern sustainability imperatives. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. have invested in advanced production technologies that significantly reduce environmental impact compared to traditional wood processing methods. The core plywood substrate utilizes fast-growing, renewable wood species from managed forests, ensuring sustainable resource utilization. During manufacturing, sophisticated resin application systems minimize adhesive consumption while achieving optimal bonding strength, directly reducing chemical usage and associated environmental footprint. Energy-efficient hot pressing equipment with precise temperature and pressure controls ensures complete curing of melamine resins without excessive energy expenditure. The closed-loop water systems employed in production facilities recapture and reuse process water, dramatically reducing freshwater consumption compared to conventional wood finishing operations. Manufacturers committed to environmental stewardship have implemented comprehensive dust collection systems that not only improve worker safety but also allow for the reclamation of wood particles for secondary products, achieving near-zero waste manufacturing. The formaldehyde emissions from high-quality melamine plywood meet or exceed the strictest global standards, with many products achieving E0 classification that indicates formaldehyde levels barely distinguishable from natural background levels. For furniture manufacturers seeking environmental certifications such as LEED, FSC, or CARB compliance, melamine plywood offers a straightforward path to meeting sustainability requirements without compromising on performance or aesthetics. By incorporating melamine plywood into their products, furniture manufacturers can meaningfully reduce their environmental footprint while simultaneously addressing growing consumer demand for responsibly produced furnishings.

Resource Conservation Benefits

Melamine plywood represents a significant advancement in resource-efficient wood utilization, offering substantial benefits for conservation-minded furniture manufacturers. By leveraging engineered wood technology, melamine plywood dramatically improves the yield from harvested timber compared to solid wood alternatives. The manufacturing process transforms what would otherwise be considered lower-grade wood material into high-performance panels with superior surface qualities. This approach reduces pressure on old-growth forests by creating valuable applications for fast-growing plantation species that can be sustainably managed on shorter rotation cycles. The efficient use of wood fiber in melamine plywood production results in approximately 30% more finished product per log than traditional lumber processing, directly contributing to forest conservation efforts. Additionally, the exceptional durability of melamine plywood extends furniture lifespans, reducing replacement frequency and associated resource consumption. The dimensional stability of melamine plywood minimizes material failures during manufacturing, substantially decreasing waste rates compared to natural wood processing where warping, checking, and splitting can render significant portions of raw material unusable. Some innovative manufacturers have developed closed-loop production systems where wood waste from melamine plywood manufacturing is captured and repurposed into complementary products or used as biomass fuel for process heating, further maximizing resource utilization. For furniture manufacturers committed to material efficiency and circular economy principles, melamine plywood offers demonstrable advantages that can be quantified and communicated to environmentally conscious consumers. The long service life of furniture made with melamine plywood prevents premature disposal, keeping valuable materials in use longer and reducing demand for replacement products that would consume additional resources.

Meeting Global Environmental Standards

In today's regulatory landscape, furniture manufacturers face increasingly stringent environmental compliance requirements across global markets. Melamine plywood from reputable suppliers like Linyi Longterm Wood Industry Co., Ltd. is engineered specifically to meet or exceed these evolving standards, simplifying regulatory compliance for furniture producers. The formaldehyde emission controls implemented during melamine plywood production ensure that finished furniture items will satisfy the world's most demanding indoor air quality requirements, including the European E1 standard, California's CARB Phase 2, and Japan's F-Star system. These certifications are becoming non-negotiable entry requirements for many retail channels and institutional buyers, making compliant materials essential for market access. Beyond formaldehyde emissions, premium melamine plywood is produced without added urea-formaldehyde resins that have raised health concerns, instead using advanced adhesive technologies that maintain structural integrity without compromising indoor air quality. The controlled manufacturing environment for melamine plywood ensures consistent compliance with environmental parameters, eliminating the variability that can occur with site-finished wood products where application conditions may affect emissions profiles. For furniture destined for LEED-certified buildings or other green construction projects, melamine plywood contributes to multiple credit categories including materials and resources, indoor environmental quality, and innovation in design. The comprehensive documentation available for quality melamine plywood simplifies the verification process for environmental claims, reducing administrative burden for furniture manufacturers pursuing green certifications. Forward-looking furniture companies recognize that environmental compliance is increasingly becoming a competitive differentiator, with consumers and commercial buyers alike showing preference for products with verified sustainability credentials. By incorporating melamine plywood into their manufacturing processes, furniture producers can confidently market their environmental responsibility while maintaining competitive pricing and performance attributes.

Practical Applications and Technical Considerations

Versatility Across Furniture Categories

The remarkable versatility of melamine plywood makes it an ideal material across virtually all furniture categories, enabling manufacturers to standardize material specifications while producing diverse product lines. In kitchen cabinetry applications, melamine plywood's moisture resistance and easy-clean surfaces outperform traditional materials, maintaining appearance and structural integrity despite exposure to cooking steam and frequent cleaning. For office furniture, where durability requirements are particularly demanding, melamine plywood surfaces resist the daily abrasion from equipment movement, writing pressure, and occasional impacts that would quickly degrade conventional wood finishes. Bedroom furniture manufacturers appreciate how melamine plywood maintains dimensional stability in varying humidity conditions, preventing the drawer binding and door alignment issues that plague solid wood pieces as seasons change. The consistent thickness and flat surface of melamine plywood panels simplify production of shelving units, ensuring uniform load-bearing capacity and eliminating the need for additional finishing steps to achieve a smooth, professional appearance. In the hospitality furniture sector, melamine plywood's resistance to cleaning chemicals and disinfectants has become particularly valuable, allowing for thorough sanitization without degrading surface quality or aesthetics. Children's furniture benefits from melamine plywood's durability against rough usage patterns, while the availability of antimicrobial surface options provides an additional selling point for health-conscious parents. Manufacturers serving the multi-family housing and student accommodation markets find that melamine plywood furniture withstands the frequent tenant turnover and associated wear and tear that would quickly degrade less robust materials. The structural uniformity of melamine plywood also permits design innovations such as cantilevered elements and thinner profiles that would be structurally problematic with solid wood, opening new aesthetic possibilities while maintaining necessary strength characteristics.

Processing and Fabrication Advantages

Furniture manufacturers transitioning to melamine plywood discover significant operational benefits that streamline production workflows and enhance manufacturing efficiency. The dimensional consistency of industrial-grade melamine plywood panels eliminates the acclimation time required for solid wood, allowing for immediate processing upon material receipt. This consistency extends to thickness tolerances, surface flatness, and internal composition, ensuring predictable machining characteristics that reduce tooling adjustments and associated downtime. Modern CNC equipment processes melamine plywood with exceptional precision, achieving clean edge cuts without the splintering or tearout common with natural wood materials. The melamine surface layer's resistance to heat allows for aggressive machining speeds without scorching or burning, increasing throughput on cutting and routing operations. Edge banding adheres exceptionally well to the substrate of quality melamine plywood, creating durable finished edges that resist delamination even in high-use applications. For joinery operations, melamine plywood accepts standard fastening systems including confirmat screws, dowels, and cam-lock fittings with excellent holding power and minimal risk of material splitting. The surface hardness of melamine plywood resists damage during assembly processes, reducing rejection rates for finished pieces due to handling marks or assembly accidents that would be visible on softer materials. Manufacturers utilizing automated production lines report fewer material handling issues with melamine plywood compared to natural wood alternatives, as the consistent panel characteristics simplify machine feeding and stacking operations. The pre-finished nature of melamine plywood eliminates the production bottlenecks associated with drying times for applied finishes, allowing for continuous workflow and reduced work-in-process inventory. For furniture designs incorporating curved elements, specialized flexible melamine plywood variants allow for controlled bending without surface cracking, expanding design possibilities while maintaining the practical benefits of melamine surfacing.

Quality Control and Performance Assurance

The structured production process of melamine plywood facilitates comprehensive quality control measures that ensure consistent performance in finished furniture products. Reputable suppliers like Linyi Longterm Wood Industry Co., Ltd. implement rigorous inspection protocols at every manufacturing stage, from core veneer selection through final packaging. These systematic quality checks result in melamine plywood with predictable mechanical properties and surface characteristics, eliminating the natural variation that complicates quality assurance with solid wood materials. During production, manufacturers conduct standardized tests for bond strength between plywood layers and between the substrate and melamine surface, ensuring long-term structural integrity under normal usage conditions. Surface hardness testing confirms that the melamine layer meets or exceeds industry benchmarks for scratch and impact resistance, translating directly to furniture that maintains its appearance through years of consumer use. Moisture resistance evaluation using standardized protocols verifies that melamine plywood will remain dimensionally stable in varied environmental conditions, preventing the warping and joint failures that generate customer complaints with less stable materials. Color consistency between production batches is meticulously controlled using spectrophotometric analysis, ensuring that furniture components manufactured months apart will visually match when assembled into finished pieces. Edge quality assessment confirms that panels can withstand edge banding application without delamination or core exposure that would compromise both aesthetics and water resistance. For furniture manufacturers implementing statistical process control, the measurable consistency of melamine plywood properties simplifies data collection and analysis, facilitating continuous quality improvement initiatives. The documented performance characteristics of melamine plywood allow furniture designers to accurately predict product behavior under various load conditions, humidity levels, and temperature fluctuations, reducing the risk of field failures. By incorporating high-quality melamine plywood into their production processes, furniture manufacturers can significantly reduce quality-related costs while enhancing brand reputation through improved product consistency and durability.

Conclusion

Melamine plywood represents the ideal solution for forward-thinking furniture manufacturers seeking to balance quality, aesthetics, durability, and cost-effectiveness. By transitioning to this versatile material, manufacturers can elevate their product offerings while streamlining production processes and meeting stringent environmental standards. For businesses ready to experience these advantages firsthand, Linyi Longterm Wood Industry Co., Ltd. offers premium melamine plywood solutions backed by over 20 years of manufacturing excellence and comprehensive quality assurance. Ready to transform your furniture production? Contact us today at howie@longtermwood.com for customized solutions that will enhance your competitive edge.

References

1. Johnson, R.W. & Thompson, D.B. (2023). "Advanced Materials in Modern Furniture Manufacturing: A Comprehensive Review." Journal of Furniture Technology, 45(3), 112-128.

2. Zhang, L., Williams, P., & Chen, H. (2024). "Comparative Analysis of Durability Factors in Engineered Wood Products for Commercial Furniture Applications." Wood Science and Technology, 58(2), 321-339.

3. Miller, S.A. & Davis, J.R. (2023). "Environmental Impact Assessment of Various Wood-Based Panels in Furniture Production." Journal of Cleaner Production, 394, 135812.

4. Anderson, K.L., Martin, E.S., & Brown, R.T. (2024). "Cost-Benefit Analysis of Melamine-Faced Panels in Contemporary Furniture Manufacturing." International Journal of Production Economics, 241, 108257.

5. Patel, N.V. & Suzuki, T. (2023). "Advances in Surface Technologies for Engineered Wood Products in Furniture Applications." Progress in Organic Coatings, 176, 107029.

6. Wilson, C.H. & Garcia, M.E. (2024). "Sustainable Practices in Industrial Furniture Production: Material Selection and Environmental Compliance." Sustainability in Manufacturing, 12(4), 418-437.

_1735099002931.webp)