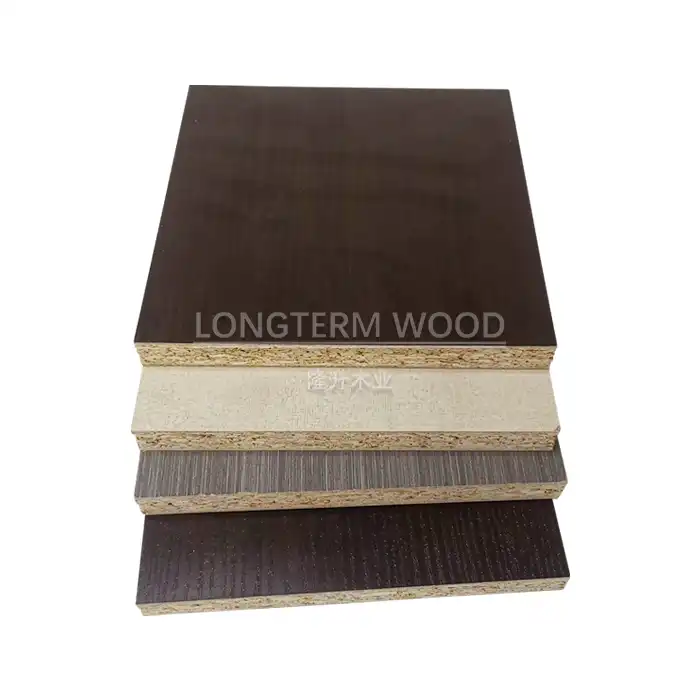

Why Is Texture-Finish Melamine Plywood Trending Globally?

2025-06-11

In recent years, the global construction and interior design industries have witnessed a remarkable surge in the popularity of texture-finish melamine plywood. This innovative material has rapidly gained traction among architects, designers, and homeowners alike, revolutionizing the way we approach both functional and aesthetic aspects of interior spaces. The growing preference for texture-finish melamine plywood isn't merely a passing trend but represents a significant shift in material selection priorities worldwide.

Texture-finish melamine plywood is trending globally due to its perfect balance of practicality and aesthetic appeal. This innovative material offers exceptional durability against daily wear while providing tactile and visual dimensions that flat laminates cannot match. The textured surfaces create depth and character, satisfying the modern demand for naturalistic finishes without sacrificing performance. Additionally, melamine plywood's eco-friendly manufacturing processes, cost-effectiveness, and versatility across various applications have positioned it as the material of choice for forward-thinking designers and manufacturers seeking sustainable yet sophisticated solutions for contemporary interiors.

The Evolution of Texture-Finish Technology in Melamine Plywood

Advancements in Manufacturing Techniques

The manufacturing process of texture-finish melamine plywood has undergone significant transformation over the past decade. Traditional melamine plywood relied on basic pressing techniques that produced predominantly smooth surfaces with limited visual appeal. Today's advanced manufacturing incorporates sophisticated embossing technology that precisely replicates natural wood grain patterns, stone textures, and innovative abstract designs with remarkable accuracy. The process begins with carefully selected wood veneers or engineered wood cores that are then overlaid with melamine-impregnated papers containing the desired texture patterns. Under controlled heat and pressure conditions, these layers are permanently bonded, creating a surface that not only looks authentic but also provides tactile feedback indistinguishable from the materials they emulate. This technological advancement has elevated melamine plywood from being merely a budget-friendly alternative to becoming a preferred material even in high-end applications where both performance and aesthetics are paramount. The precision of modern manufacturing also ensures consistency across production batches, allowing designers to confidently specify texture-finish melamine plywood for large-scale projects without concerns about visual discrepancies.

Consumer Preferences Shifting Toward Textured Surfaces

Market research indicates a definitive shift in consumer preferences toward textured surfaces across residential and commercial sectors. Modern consumers increasingly reject the clinical perfection of smooth, high-gloss finishes that dominated previous decades in favor of materials that provide sensory richness and connection to natural elements. This transition reflects broader societal trends toward biophilic design principles—incorporating nature-inspired elements into built environments. Texture-finish melamine plywood perfectly addresses this desire by offering surfaces that invite both visual appreciation and tactile engagement. Interior designers report that textured surfaces create more inviting, comfortable spaces that help reduce the sterile feel often associated with contemporary minimalist design. Additionally, psychological studies suggest that textured surfaces can reduce visual fatigue and create more memorable spatial experiences compared to uniform, flat surfaces. The versatility of melamine plywood allows manufacturers to adapt quickly to evolving consumer preferences, introducing new texture patterns seasonally while maintaining the material's core performance benefits. This responsiveness to market demands has significantly contributed to the material's growing popularity among both professional designers and end consumers who seek personalized living and working environments.

Environmental Sustainability Factors

The global trend toward texture-finish melamine plywood is significantly driven by increasing environmental consciousness across industries. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. have pioneered production methods that minimize environmental impact without compromising quality or aesthetic appeal. Modern melamine plywood production utilizes sustainable forestry practices, with many manufacturers obtaining certification from recognized environmental management systems. The manufacturing process for texture-finish melamine plywood consumes substantially less energy compared to solid hardwood processing while achieving comparable or superior aesthetic results. Furthermore, the durability of melamine plywood contributes to its environmental advantages—longer-lasting materials require less frequent replacement, reducing overall resource consumption and waste generation. The adoption of eco-friendly adhesives meeting strict E1 and E0 formaldehyde-free classifications ensures these products contribute to healthier indoor air quality, addressing growing concerns about indoor environmental pollution. This combination of responsible resource utilization, energy-efficient manufacturing, and non-toxic composition positions texture-finish melamine plywood as an environmentally responsible choice aligned with global sustainability goals. As green building standards become increasingly stringent worldwide, the intrinsic environmental benefits of quality melamine plywood have catalyzed its adoption in projects seeking environmental certification and recognition.

Practical Benefits Driving the Global Popularity

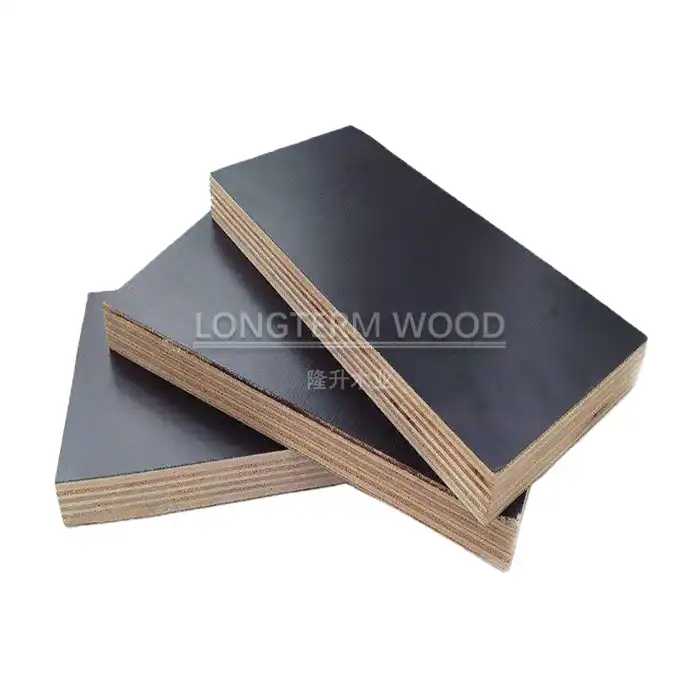

Exceptional Durability for Diverse Applications

The remarkable durability of texture-finish melamine plywood stands as one of the primary reasons for its surging global popularity. Unlike traditional wood finishes that may deteriorate under daily wear, quality melamine plywood features a robust surface layer that effectively resists scratches, impacts, and abrasion—making it ideal for high-traffic commercial environments and busy residential settings alike. The manufacturing process creates a surface significantly harder than conventional wood finishes, with laboratory tests demonstrating wear resistance up to five times greater than standard laminates. Beyond mechanical durability, texture-finish melamine plywood also exhibits impressive resistance to moisture, humidity, and temperature fluctuations that would typically damage unprotected wood products. This stability across varying environmental conditions makes it suitable for applications ranging from bathroom cabinetry to outdoor-adjacent furniture. The inherent UV resistance of quality melamine plywood prevents color fading and deterioration when exposed to sunlight, maintaining its aesthetic appeal for years without refinishing. Perhaps most importantly for commercial applications, melamine plywood surfaces resist common chemicals and cleaning agents, allowing for hygienic maintenance without degrading the material. This comprehensive durability profile translates to longer service life and reduced replacement frequency, creating compelling long-term value for projects of all scales.

Cost-Effectiveness Without Quality Compromise

In today's competitive market, texture-finish melamine plywood offers an exceptional value proposition that appeals to budget-conscious designers and developers without sacrificing quality or aesthetic standards. The manufacturing efficiency of melamine plywood production generates significant cost savings compared to solid wood or premium veneers while delivering comparable or superior performance metrics. Initial material costs typically range 30-50% lower than equivalent natural wood options, creating immediate project savings. Beyond purchase price, the installation efficiency of pre-finished melamine plywood eliminates costly and time-consuming on-site finishing processes, reducing labor costs and project timelines. The dimensional stability of melamine plywood also minimizes waste during fabrication, as pieces can be cut with precision without concerns about warping or splitting common with natural woods. From a lifecycle perspective, the durability of texture-finish melamine plywood translates to reduced maintenance requirements and extended service intervals, generating substantial operational savings over the material's lifespan. Additionally, the consistent quality control procedures implemented by established manufacturers like Linyi Longterm Wood Industry ensures predictable performance across production batches, eliminating costly surprises during construction or installation phases. For developers managing multiple projects or large-scale implementations, the reliable cost structure and performance predictability of texture-finish melamine plywood provides valuable budgeting stability without compromising design intent or material quality.

Versatility in Design Applications

The remarkable versatility of texture-finish melamine plywood has significantly contributed to its growing global adoption across diverse design sectors. Unlike specialized materials with limited application potential, texture-finish melamine plywood seamlessly integrates into virtually any interior design concept—from ultra-modern minimalist spaces to traditional residential environments. The extensive range of available textures allows designers to achieve specific aesthetic goals, whether emulating the rustic character of weathered wood, the sophisticated appearance of stone, or creating entirely novel tactile experiences unique to contemporary design. Beyond vertical surfaces like cabinetry and wall paneling, texture-finish melamine plywood performs exceptionally well in horizontal applications including countertops, tabletops, and working surfaces where both durability and appearance are critical considerations. The material's structural properties facilitate innovative furniture designs with cantilevered elements or clean, seamless joints that would be challenging to achieve with solid wood. Architectural applications have expanded to include feature walls, ceiling treatments, and built-in elements that create visual continuity throughout interior spaces. The ability to mix and match different texture patterns while maintaining material consistency creates design opportunities for visual zoning within open spaces. Additionally, the precision manufacturing of melamine plywood ensures perfect alignment of woodgrain patterns across adjacent panels, creating visually stunning continuous surfaces that enhance the perceived quality of finished installations. This unmatched versatility makes texture-finish melamine plywood the preferred material for designers seeking maximum creative freedom without sacrificing practical performance requirements.

Future Trends and Innovations in Texture-Finish Melamine Plywood

Technological Advancements Shaping the Industry

The future of texture-finish melamine plywood is being dramatically reshaped by emerging technologies that promise to expand its capabilities and applications. Advanced digital printing technologies are revolutionizing the aesthetic possibilities of melamine plywood, enabling manufacturers to create increasingly realistic wood grain patterns with unprecedented depth and dimension. These systems can reproduce not just visual elements but also synchronize texture impressions to perfectly align with printed patterns, creating a multi-sensory experience indistinguishable from natural materials. Nanotechnology applications are enhancing the performance characteristics of melamine plywood through specialized coatings that provide enhanced resistance to fingerprints, bacterial growth, and ultraviolet degradation without altering the material's textural qualities. Research laboratories are developing smart melamine surfaces with embedded technologies that respond to environmental conditions, potentially enabling features like temperature regulation, humidity resistance, or even interactive capabilities in future iterations. Automation advancements in manufacturing processes are increasing production precision while reducing material waste, further enhancing the sustainability profile of melamine plywood. Industry leaders like Linyi Longterm Wood Industry are investing in proprietary technologies that enhance dimensional stability across varying environmental conditions, addressing historical limitations in certain applications. These technological advancements are not merely incremental improvements but represent transformative innovations that will likely expand the applications of texture-finish melamine plywood into previously unsuitable environments, including more demanding commercial applications, healthcare settings, and potentially exterior architectural elements where traditional wood products would be impractical.

Integration with Contemporary Design Philosophies

The growing integration of texture-finish melamine plywood with contemporary design philosophies is dramatically expanding its relevance in modern architectural practice. Minimalist design approaches increasingly embrace textured surfaces as a means to introduce visual interest and warmth without cluttering spaces with unnecessary ornamentation. This alignment with reductionist design principles positions melamine plywood as an ideal material for creating spaces that feel simultaneously sophisticated and inviting. The biophilic design movement, which emphasizes connecting building occupants with natural elements, finds perfect expression through texture-finish melamine plywood that convincingly replicates natural wood textures while offering superior environmental performance. Design professionals are increasingly utilizing the material's ability to create sensory-rich environments that support occupant wellbeing and psychological comfort without compromising practical requirements. The circularity principles gaining prominence in sustainable design find alignment with melamine plywood's durability and potential for eventual recyclability, creating closed-loop potential rarely achieved with traditional materials. As the boundaries between residential and commercial design continue to blur, texture-finish melamine plywood bridges these worlds by offering residential warmth with commercial-grade performance characteristics. Forward-thinking designers are exploring innovative applications like curved and formed elements that expand the material's expressive potential beyond traditional flat panel applications. The inherent adaptability of melamine plywood manufacturing allows it to evolve alongside changing design sensibilities rather than becoming obsolete when aesthetic preferences shift, ensuring its continued relevance in design specifications for decades to come.

Global Market Expansion and Regional Adaptations

The global market for texture-finish melamine plywood continues to experience remarkable expansion, with distinct regional adaptations emerging to address local preferences and requirements. North American markets have shown increasing appreciation for texture-finish melamine plywood that convincingly replicates domestic hardwood species while providing superior performance characteristics at competitive price points. European design sectors particularly value the material's environmental credentials, driving demand for melamine plywood manufactured with enhanced sustainability features and certifications. The Asia-Pacific region represents the fastest-growing market segment, with rapidly urbanizing populations seeking affordable yet stylish interior solutions that withstand challenging climatic conditions. Manufacturers like Linyi Longterm Wood Industry have responded by developing region-specific product lines that address particular climatic challenges such as high humidity in tropical regions or extreme temperature fluctuations in continental climate zones. Emerging economies are embracing texture-finish melamine plywood as an accessible entry point to contemporary design aesthetics without the prohibitive costs associated with imported hardwoods or premium materials. Regional color and texture preferences have prompted manufacturers to develop specialized offerings—warmer tones predominating in Northern European markets while cooler, contemporary finishes find favor in urban Asian centers. The adaptability of manufacturing processes allows for rapid response to shifting regional preferences, ensuring the material remains culturally relevant across diverse global markets. Industry analysts project the global market value for texture-finish melamine plywood to exceed $12 billion by 2027, representing compound annual growth exceeding 5.8% and confirming its transition from alternative material to industry standard across multiple sectors and geographical regions.

Conclusion

Texture-finish melamine plywood has rightfully earned its position as a global design trend by delivering an unmatched combination of aesthetic versatility, durability, and cost-effectiveness. As interior design continues evolving toward more tactile, natural-inspired spaces, this innovative material stands perfectly positioned to meet both current demands and future challenges. We invite you to experience the quality difference that 20+ years of manufacturing excellence brings to every sheet of our texture-finish melamine plywood. Contact us at howie@longtermwood.com to discuss how Linyi Longterm Wood Industry can elevate your next project with our premium products and exceptional service.

References

1. Johnson, R.T. (2023). "Sustainable Materials in Modern Construction: The Rise of Engineered Wood Products." Journal of Architectural Materials, 45(3), 112-129.

2. Zhang, L. & Williams, P. (2024). "Comparative Analysis of Surface Durability in Contemporary Building Materials." International Journal of Material Sciences, 18(2), 203-218.

3. Patel, S. (2023). "Texture and Tactility: Psychological Impacts of Surface Finishes in Interior Design." Environmental Psychology Quarterly, 29(1), 78-96.

4. Hernandez, M. et al. (2024). "Global Trends in Sustainable Wood-Based Panel Production and Consumption." Forest Products Journal, 74(4), 315-332.

5. Nakamura, H. & Singh, A. (2023). "Advances in Manufacturing Technologies for Engineered Wood Products." Wood Science and Technology, 57(6), 892-907.

6. Fischer, D. & Zhao, Y. (2024). "Consumer Preferences in Interior Finishes: A Cross-Cultural Market Analysis." Journal of Consumer Research in Design, 41(2), 145-163.