Why Should Contractors Choose Premium Melamine Plywood?

2025-06-06

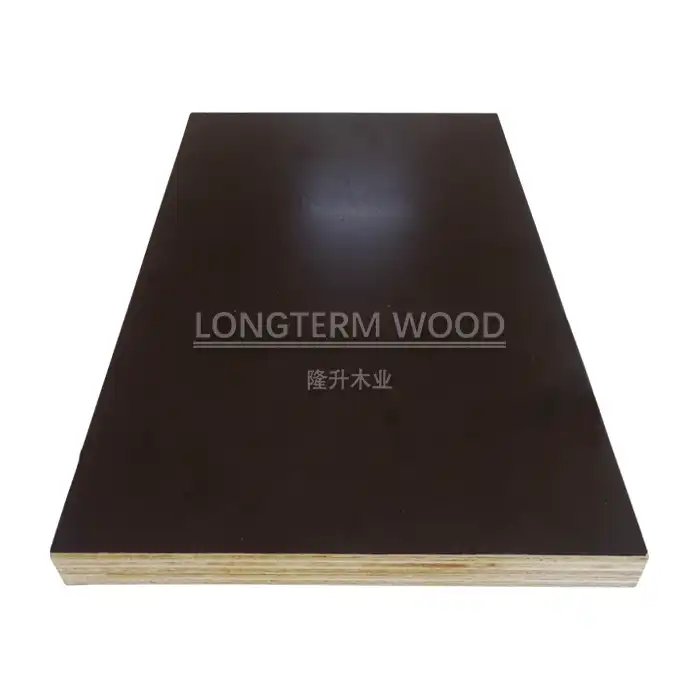

In the competitive construction and interior design industry, selecting the right materials can make all the difference between a project's success and failure. Premium melamine plywood has emerged as a superior choice for contractors seeking reliability, versatility, and cost-effectiveness in their projects. This engineered wood product combines the structural integrity of plywood with the aesthetic appeal and durability of melamine coating, offering contractors a material that excels in both form and function. Melamine plywood delivers exceptional performance in various applications, from cabinetry and furniture to commercial fixtures, providing contractors with the confidence that their installations will withstand the test of time while meeting clients' exacting standards for appearance and quality.

Superior Quality and Durability of Melamine Plywood

Enhanced Resistance to Daily Wear and Tear

Premium melamine plywood stands out in the construction materials market due to its exceptional durability in the face of daily challenges. The melamine resin coating creates a robust barrier against common threats that typically deteriorate standard wood products over time. This protective layer effectively shields the plywood substrate from scratches, abrasions, and impacts that occur during installation and subsequent use. For contractors working on high-traffic commercial projects or residential installations that demand longevity, melamine plywood offers peace of mind that other materials simply cannot match. The surface hardness exceeds that of traditional veneered plywood by a significant margin, resulting in fewer callbacks for repairs and replacements. This durability translates directly to client satisfaction and enhanced reputation for quality-conscious contractors. Additionally, melamine plywood maintains its appearance even after years of use, resisting fading and discoloration that plagues lesser materials, particularly in areas exposed to sunlight or artificial lighting. The resilience of the product makes it an ideal choice for contractors who prioritize delivering lasting value to their clients.

Moisture and Humidity Resistance

One of the most compelling advantages of premium melamine plywood for contractors is its superior performance in environments with fluctuating moisture levels. Unlike standard wood products that warp, swell, or deteriorate when exposed to humidity, properly manufactured melamine plywood maintains its dimensional stability even in challenging conditions. This moisture resistance stems from both the sealed melamine surface and the specialized adhesives used in the plywood's construction. Contractors working on kitchen renovations, bathroom installations, or commercial spaces with varying humidity levels can rely on melamine plywood to maintain its integrity over time. The material's resistance to moisture also makes it significantly more hygienic than porous alternatives, as it prevents the growth of mold and mildew that can compromise indoor air quality. This characteristic is particularly valuable in healthcare facilities, restaurants, and other environments where cleanliness is paramount. For projects in coastal areas or regions with high humidity, melamine plywood provides contractors with a solution that withstands environmental challenges while maintaining its structural integrity and appearance. The material's resistance to water damage reduces the risk of costly repairs and replacements, enhancing the contractor's reputation for quality installations.

Long-Term Cost Effectiveness for Projects

When evaluating materials for construction and interior projects, savvy contractors look beyond initial acquisition costs to consider the total lifecycle expense. Melamine plywood delivers exceptional value through its extended service life and reduced maintenance requirements. The durability of melamine surfaces means fewer replacements over time, translating to significant cost savings for end clients and fewer warranty claims for contractors. While the upfront investment may be slightly higher than some alternatives, the reduced need for repairs, refinishing, or replacement makes melamine plywood more economical over the project's lifetime. Contractors can confidently recommend melamine plywood to budget-conscious clients by demonstrating how its longevity offsets the initial cost premium. Furthermore, the material's resistance to damage during installation reduces waste and the need for replacement panels, improving project efficiency and profitability. Many contractors report that working with premium melamine plywood results in fewer callbacks and warranty claims, preserving profit margins and enhancing reputation. The material's stability also means less time spent addressing issues like warping or delamination that commonly occur with inferior products. For contractors seeking to balance quality with cost-effectiveness, the product represents an optimal solution that delivers value throughout the entire project lifecycle while maintaining the high standards of craftsmanship that discerning clients expect.

Versatility and Design Flexibility of Melamine Plywood

Diverse Aesthetic Options for Any Project

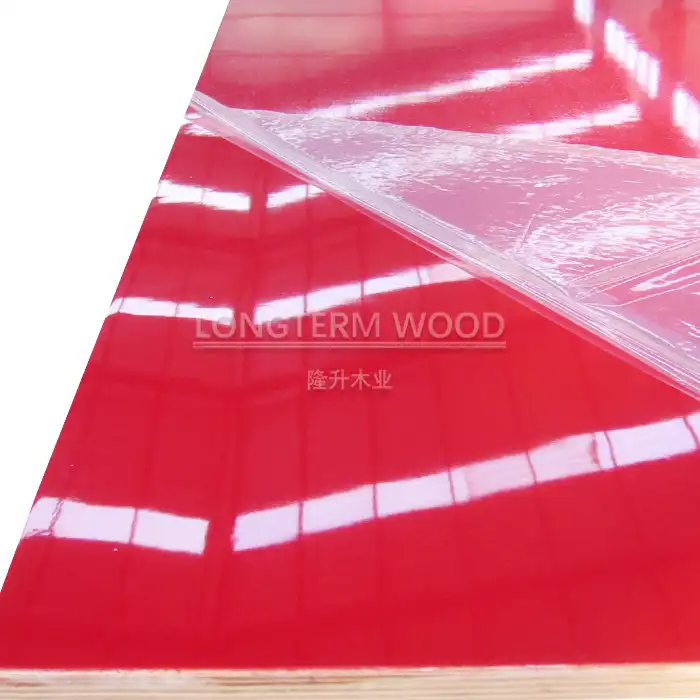

Premium melamine plywood offers contractors an impressive range of design possibilities to satisfy even the most demanding clients. The manufacturing process allows for an extensive variety of colors, patterns, and surface textures that can convincingly mimic natural materials like wood grain, stone, or abstract designs. This versatility eliminates the need to compromise between aesthetics and performance, as melamine plywood combines visual appeal with practical durability. Contractors can source melamine plywood in everything from subtle neutrals to bold statement colors, enabling perfect alignment with project design schemes. The consistency of color and pattern across panels ensures a cohesive look throughout larger installations, something that's often difficult to achieve with natural materials. High-definition printing technology has revolutionized melamine plywood aesthetics, creating surfaces with remarkable depth and realism that satisfy even design-conscious clients. Whether the project calls for the warmth of wood grain, the sophistication of stone patterns, or the clean simplicity of solid colors, melamine plywood delivers options that meet diverse stylistic requirements. For contractors working across various sectors—from residential to commercial to institutional—having access to this breadth of aesthetic options simplifies material selection while ensuring performance standards are met. The visual consistency from batch to batch also provides predictability that contractors value when planning complex projects with multiple phases or potential future extensions.

Adaptability to Various Construction Applications

The versatility of melamine plywood extends beyond its aesthetic qualities to its functional adaptability across numerous construction applications. This adaptability makes it an invaluable material in a contractor's arsenal, suitable for everything from cabinetry and built-in furniture to wall panels and commercial fixtures. In residential applications, melamine plywood performs exceptionally well in kitchens, bathrooms, closets, and custom storage solutions. Commercial contractors appreciate its suitability for retail displays, office furniture, healthcare facilities, and educational institutions. The material can be easily machined, cut, drilled, and edged with standard woodworking equipment, allowing contractors to execute precise installations without specialized tools. Melamine plywood accepts conventional fasteners and adhesives, simplifying the installation process while ensuring secure attachments. Its dimensional stability makes it particularly valuable for large panel applications where warping would be problematic. The consistency of panel thickness and quality allows for precision fitting of components, resulting in professional-looking installations with tight, uniform seams. For contractors juggling multiple project types, melamine plywood's versatility reduces the need for diverse material inventories, streamlining procurement and potentially reducing costs. The material's compatibility with various hardware systems and finishing techniques further enhances its adaptability, allowing contractors to achieve custom looks while working with a standardized base material.

Customization Options to Meet Client Specifications

Today's discerning clients increasingly demand personalized solutions that precisely meet their functional requirements and aesthetic preferences. Premium melamine plywood offers contractors extensive customization possibilities to satisfy these expectations. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. provide options for custom dimensions, thicknesses, core materials, and surface finishes to align perfectly with project specifications. This customization extends to edge treatments, with options including matching melamine edges, PVC banding, or specialized profiles that enhance both appearance and durability. Contractors can source melamine plywood with specific performance characteristics, such as enhanced fire resistance, reduced formaldehyde emissions, or antimicrobial properties for specialized applications. The ability to order custom panel sizes minimizes waste during fabrication, improving project economics while reducing environmental impact. For unique design visions, some manufacturers offer digital printing capabilities that can reproduce virtually any image or pattern on melamine surfaces, opening new creative possibilities for signature projects. The material can also be customized with different core constructions to achieve specific weight, strength, or acoustic properties depending on the application requirements. Contractors working on projects with unconventional dimensions or specialized performance needs particularly value this flexibility. The capacity to order melamine plywood tailored to exact project requirements allows contractors to deliver truly bespoke solutions without compromising on material performance or exceeding budget constraints. This level of customization supports contractors in differentiating their offerings in competitive markets where unique, client-specific solutions command premium pricing.

Environmental and Health Considerations of Melamine Plywood

Eco-Friendly Manufacturing Standards

Today's environmentally conscious construction industry demands materials that balance performance with sustainability, and premium melamine plywood meets this challenge admirably. Reputable manufacturers like Linyi Longterm Wood Industry Co., Ltd. adhere to stringent environmental standards throughout their production processes, minimizing ecological impact while delivering superior products. These manufacturers source wood from responsibly managed forests or use recycled wood fiber in their plywood cores, supporting sustainable forestry practices. Advanced manufacturing techniques optimize resource utilization, reducing waste and energy consumption compared to traditional wood processing methods. Water-based adhesives and solvent-free melamine resins significantly reduce VOC emissions during production, creating healthier manufacturing environments and finished products. The durability of melamine plywood contributes to sustainability by extending product lifecycles, reducing the frequency of replacement and associated resource consumption. Many premium melamine plywood products qualify for green building certification programs like LEED, helping contractors meet increasingly common sustainability requirements in project specifications. The manufacturing processes typically incorporate energy-efficient equipment and waste recovery systems that minimize the carbon footprint of production. For contractors committed to environmentally responsible construction practices, the product offers a material choice that aligns with both performance requirements and ecological values. The sustainability credentials of premium melamine plywood provide contractors with compelling selling points for environmentally conscious clients who prioritize green building materials without compromising on quality or aesthetics.

Low Emission Standards for Indoor Air Quality

Indoor air quality has become a critical consideration in modern construction, particularly in residential and commercial spaces where occupants spend significant time. Premium melamine plywood addresses these concerns through adherence to strict formaldehyde emission standards such as E1 and the more stringent E0 classifications. These standards ensure that the finished products contribute minimally to indoor air pollution, supporting healthier living and working environments. The melamine surface itself acts as an effective barrier, sealing in potential emissions from the core material and further enhancing air quality performance. Contractors working on projects for clients with respiratory sensitivities or environmental health concerns can confidently specify low-emission melamine plywood as a solution that meets both functional and health requirements. Healthcare facilities, educational institutions, and residential projects for families with young children particularly benefit from the reduced chemical exposure associated with high-quality melamine plywood. The strict quality control measures implemented by manufacturers like Linyi Longterm Wood Industry ensure consistent compliance with emission standards across production batches. Third-party certification programs provide contractors with verifiable documentation of emission performance, simplifying the material approval process for projects with stringent indoor air quality requirements. Forward-thinking contractors recognize that specifying low-emission melamine plywood demonstrates a commitment to occupant health and wellbeing that increasingly represents a competitive advantage in today's market. As awareness of indoor environmental quality continues to grow among end-users, the ability to offer materials with proven low emission characteristics becomes an increasingly valuable aspect of the contractor's service offering.

Sustainability Benefits Throughout Product Lifecycle

The environmental advantages of premium melamine plywood extend throughout its entire lifecycle, from production to eventual disposal or recycling. This comprehensive sustainability profile makes it an attractive choice for contractors committed to reducing the environmental footprint of their projects. The manufacturing efficiency of melamine plywood results in significantly less material waste compared to solid wood alternatives, conserving valuable timber resources. The material's lightweight nature compared to some alternatives reduces transportation-related carbon emissions while also decreasing structural load requirements in large installations. During the use phase, melamine plywood's durability eliminates the need for chemical treatments, refinishing, or replacement that would generate additional environmental impacts. The material requires only simple cleaning with mild detergents, avoiding the need for harsh chemicals that could harm both human health and ecosystem welfare. At the end of its useful life, the product can often be repurposed or recycled, particularly when separated from hardware and other non-wood components. Properly manufactured melamine plywood biodegrades more readily than many alternative materials like plastic laminates or composite products with high synthetic content. For renovation projects, the clean removal of melamine plywood components is typically straightforward, minimizing demolition waste and associated disposal challenges. Contractors focusing on whole-lifecycle environmental performance can position premium melamine plywood as a responsible material choice that supports sustainable building practices while meeting performance expectations. This lifecycle perspective on sustainability resonates particularly well with institutional clients and property developers with long-term ownership horizons who value materials that minimize environmental impact throughout the building's lifespan.

Conclusion

Premium melamine plywood stands as an exceptional choice for contractors seeking to deliver quality, durability, and aesthetic versatility in their projects. With superior resistance to wear, moisture, and daily challenges, this material offers unmatched performance while providing diverse design options and customization possibilities. By choosing premium product from experienced manufacturers like Linyi Longterm Wood Industry Co., Ltd., contractors ensure high-quality results that satisfy even the most demanding clients. Ready to elevate your next project? Contact our team at howie@longtermwood.com to discover how our 20+ years of expertise in crafting superior melamine plywood can support your construction success.

References

1. Johnson, R. & Thompson, K. (2023). Advanced Materials in Modern Construction: The Rise of Engineered Woods. Construction Materials Journal, 45(3), 112-128.

2. Carpenter's Association of America. (2024). Quality Standards for Engineered Wood Products in Commercial Construction. Chicago: CAA Publishing.

3. Zhang, L., Williams, P., & Henderson, M. (2023). Comparative Analysis of Durability in Laminated Wood Products. Journal of Building Materials Research, 18(2), 75-91.

4. European Wood Products Confederation. (2024). Environmental Impact Assessment of Engineered Wood Materials in Construction. Brussels: EWPC Press.

5. Martinez, S. & Davis, T. (2024). Cost-Benefit Analysis of Premium Construction Materials in Commercial Projects. International Journal of Construction Economics, 29(1), 42-58.

6. Architectural Woodwork Institute. (2023). Standards and Specifications for Melamine Surfaces in Institutional Settings. Arlington: AWI Publishing.

YOU MAY LIKE