What Makes High-Density Melamine Plywood Superior?

2025-05-13

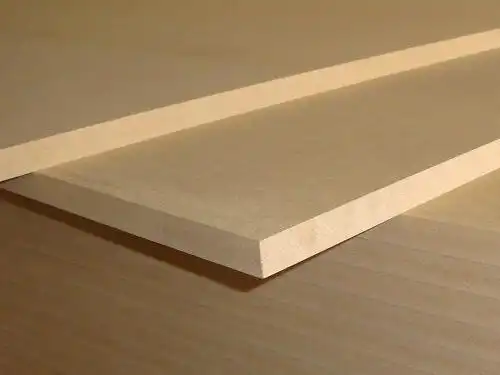

When it comes to versatile building materials that combine durability, aesthetics, and functionality, high-density melamine plywood stands apart from conventional alternatives. This engineered wood product has revolutionized the construction and furniture manufacturing industries with its exceptional qualities. High-density melamine plywood consists of multiple layers of wood veneers bonded together with high-pressure techniques and topped with melamine-infused decorative paper. This combination creates a material that delivers outstanding performance in numerous applications while providing visually appealing surfaces that can mimic various textures, including natural wood, stone, or solid colors.

Unparalleled Quality Characteristics

Enhanced Structural Integrity

High-density melamine plywood represents the pinnacle of engineered wood innovation through its sophisticated manufacturing process. The foundation begins with carefully selected wood veneers that undergo rigorous quality checks to ensure only the finest materials are used. These veneers are then meticulously layered in alternating grain directions—a critical technique that dramatically enhances the board's structural integrity. This cross-grain construction method effectively distributes stress across the entire panel, preventing warping and twist even under challenging environmental conditions. The core layers are bonded using advanced adhesives and subjected to precise high-pressure and high-temperature compression processes that create an exceptionally dense, stable board. This density is what truly sets melamine plywood apart from standard plywood variants, providing superior screw-holding capacity and exceptional load-bearing properties. For furniture manufacturers and construction professionals, this translates to finished products that maintain their integrity for years without sagging or structural compromise. The enhanced stability of high-density melamine plywood makes it particularly valuable in applications where dimensional stability is paramount, such as cabinet carcasses, shelving systems, and structural components in both residential and commercial settings.

Superior Surface Resistance

The defining feature of high-density melamine plywood is its protective surface layer, which transforms ordinary plywood into an extraordinarily resilient building material. During manufacturing, specially formulated melamine-impregnated papers are permanently fused to the plywood substrate under intense heat and pressure. This process creates a seamless, non-porous surface that delivers exceptional resistance to daily wear and tear. Unlike traditional wood finishes that can scratch or chip over time, melamine plywood's surface layer is integrated directly into the board structure, providing long-lasting protection. The melamine resin penetrates deeply into the decorative paper layers, creating a surface that effectively repels moisture, resists stains from common household substances, and withstands harsh cleaning chemicals without degradation. This moisture resistance extends the longevity of melamine plywood in humid environments like kitchens and bathrooms, where conventional wood products might swell or deteriorate. Additionally, the melamine surface offers remarkable heat resistance, allowing it to withstand brief exposure to temperatures up to 180°C without discoloration or damage—making it ideal for applications near cooking areas. For commercial settings with high traffic and frequent cleaning requirements, melamine plywood's easy-to-clean surface and resistance to scratches, impacts, and UV radiation ensure that installations maintain their appearance even after years of heavy use.

Versatile Design Options

The aesthetic versatility of high-density melamine plywood sets it apart from virtually every other building material on the market today. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. offer an extensive range of surface finishes that can precisely mimic the look of premium hardwoods, exotic veneers, stone textures, or bold solid colors—all without the cost or environmental impact of harvesting rare materials. Modern printing technologies have advanced to create stunningly realistic wood grain patterns that capture every detail of natural timber, from knots and growth rings to subtle color variations. Beyond visual appeal, melamine plywood is available in various surface textures—from ultra-smooth high-gloss finishes that reflect light dramatically to textured matte surfaces that provide a warm, natural feel. The customization possibilities extend to specialized finishes like anti-fingerprint coatings for high-touch areas, antimicrobial surfaces for healthcare applications, or super-matte finishes for contemporary design aesthetics. For designers and architects, this versatility translates to unlimited creative potential without compromising on performance. The decorative surface layer is permanently bonded to the substrate, ensuring that the appearance remains consistent throughout the product's lifetime without needing refinishing or resealing. This combination of durability and design flexibility makes melamine plywood the material of choice for everything from sleek, minimalist furniture to elaborate retail displays and architectural features where both form and function are equally important.

Environmental and Economic Benefits

Sustainable Manufacturing Practices

High-density melamine plywood represents a significant advancement in sustainable building materials, balancing performance requirements with crucial environmental considerations. Linyi Longterm Wood Industry Co., Ltd. has implemented comprehensive sustainability practices throughout their production process, beginning with responsible sourcing of raw materials. Their manufacturing facilities utilize wood from managed forests and incorporate recovered wood fibers wherever possible, reducing pressure on natural forest resources. The company's commitment to environmental stewardship extends to their adhesive technologies, where they've pioneered the use of advanced eco-friendly bonding agents that significantly reduce formaldehyde emissions. Their melamine plywood products meet or exceed stringent international standards, including E1 and even the more demanding E0 formaldehyde-free classifications, ensuring they contribute to healthier indoor air quality in homes and commercial spaces. The manufacturing process itself has been engineered to minimize waste through efficient material utilization and energy conservation measures. Wood byproducts are recycled into other product lines or used as biomass fuel for factory operations, creating a more circular production model. Water consumption during manufacturing has been reduced through closed-loop systems that filter and reuse process water. Additionally, the exceptional durability of melamine plywood contributes to its environmental profile—products that need replacement less frequently result in lower resource consumption over time. For environmentally conscious builders and designers, high-density melamine plywood offers the rare combination of superior performance characteristics with responsible manufacturing practices, making it an ideal choice for green building projects seeking to minimize environmental impact without compromising on quality or aesthetics.

Cost-Effectiveness Over Product Lifecycle

When evaluating building materials, initial purchase price represents only one aspect of the total cost equation—melamine plywood's true economic value becomes apparent when considering its complete lifecycle performance. The superior durability of high-density melamine plywood translates directly into significant cost savings through extended service life and reduced maintenance requirements. While the upfront investment may slightly exceed that of basic construction plywood, the long-term value proposition becomes increasingly compelling when factoring in the elimination of expenses related to refinishing, resealing, or premature replacement. Melamine plywood's resistance to moisture, scratches, stains, and UV damage means installations maintain their appearance without costly maintenance procedures that are typical with natural wood products. In commercial settings, this translates to minimal disruption to business operations and lower ongoing maintenance budgets. The material's dimensional stability also prevents costly callbacks and warranty issues related to warping, delamination, or joint failure—problems that frequently plague less durable alternatives. For production environments, melamine plywood offers additional economic advantages through manufacturing efficiencies. The pre-finished nature of the product eliminates time-consuming and labor-intensive finishing steps, reducing production cycles and associated costs. For cabinetmakers and furniture manufacturers, this means faster project completion and increased production capacity without additional labor or equipment investments. Linyi Longterm Wood Industry Co., Ltd. further enhances these economic benefits through efficient production scales that allow them to offer competitive pricing without compromising quality standards. Their vertically integrated manufacturing process eliminates intermediaries, passing savings directly to customers while maintaining strict quality control at every stage. When all these factors are considered comprehensively, high-density melamine plywood consistently emerges as the most cost-effective solution for projects demanding both performance and aesthetics.

Health and Safety Advantages

The health and safety benefits of high-density melamine plywood extend far beyond basic material performance, contributing significantly to healthier living and working environments. Linyi Longterm Wood Industry's commitment to producing low-emission building materials addresses growing concerns about indoor air quality and its impact on occupant health. Their advanced manufacturing processes and carefully selected adhesive systems produce melamine plywood that meets the most stringent international emission standards, including the demanding E0 classification that ensures minimal formaldehyde release throughout the product's lifecycle. This is particularly crucial for sensitive environments like schools, healthcare facilities, and residential spaces where occupants may spend extended periods. The non-porous nature of melamine plywood's surface creates additional health advantages by preventing the absorption of moisture that can lead to mold and bacterial growth—common problems with more porous building materials. This moisture resistance makes melamine plywood an ideal choice for moisture-prone areas like kitchens, bathrooms, and laundry spaces, where maintaining hygienic conditions is essential. The sealed surface also prevents the accumulation of allergens like dust and pet dander that can become trapped in the grain of natural wood products. For commercial applications, melamine plywood can be specified with specialized antimicrobial properties that actively inhibit the growth of bacteria and fungi on surfaces, an increasingly important consideration in public spaces and healthcare settings. The material's exceptional cleanability further supports hygiene protocols, as the non-porous surface can withstand regular disinfection with commercial cleaning agents without degradation. Additionally, the fire-resistant properties of properly manufactured melamine plywood contribute to overall building safety, as the melamine resin naturally exhibits flame-retardant characteristics. For project planners and facility managers concerned with creating healthy environments, high-density melamine plywood offers a solution that balances performance requirements with occupant wellbeing—delivering spaces that are not only beautiful and functional but also contribute positively to indoor environmental quality.

Application Versatility and Performance

Superior Performance in Furniture Manufacturing

The furniture manufacturing industry has embraced high-density melamine plywood as a transformative material that addresses many of the limitations associated with traditional solid wood and basic particleboard constructions. The exceptional dimensional stability of melamine plywood ensures furniture pieces maintain their precise geometry over time, eliminating common quality issues like drawer misalignment, door warping, and joint failure that plague less stable materials. This stability is particularly valuable for large case goods like wardrobes, entertainment centers, and kitchen cabinetry, where even minor dimensional changes can compromise functionality. The superior screw-holding capacity of high-density melamine plywood—up to 30% better than standard particleboard—allows for secure hardware mounting and robust joinery techniques that enhance overall furniture durability. Furniture manufacturers appreciate the manufacturing efficiencies that melamine plywood offers throughout production processes. The pre-finished nature of the material eliminates time-consuming sanding, staining, and sealing steps, significantly reducing labor costs and production cycles. The consistent quality and dimensional precision of melamine plywood from suppliers like Linyi Longterm Wood Industry Co., Ltd. minimize material waste and rework requirements, enhancing overall production efficiency. The material's superior machinability allows for precise cutting, routing, and edge-banding operations without the chipping or tear-out issues common with other engineered wood products. For contemporary furniture designs featuring clean lines and minimalist aesthetics, melamine plywood's smooth, flawless surface provides the perfect foundation. The wide range of available finishes allows designers to create cohesive collections with perfectly matched components—a significant challenge when working with natural wood varies in color and grain pattern. Additionally, melamine plywood's excellent thermal and acoustic properties enhance the functional performance of furniture pieces, creating cabinets and casework that feel substantial and high-quality to the end user. For furniture manufacturers seeking to balance quality, aesthetics, efficiency, and cost considerations, high-density melamine plywood has emerged as the ideal material platform for modern production methods.

Excellence in Commercial and Retail Environments

Commercial and retail environments present unique material challenges, requiring surfaces that combine aesthetic appeal with exceptional durability under intensive daily use. High-density melamine plywood excels in these demanding applications, offering performance characteristics that make it the preferred choice for commercial fit-outs, retail displays, and hospitality installations. In high-traffic retail environments, display fixtures and point-of-sale counters constructed from melamine plywood maintain their appearance despite constant customer interaction, frequent cleaning, and merchandise rearrangement. The material's resistance to scratches, impacts, and staining ensures retail environments continue looking fresh and professional without costly maintenance or premature replacement. For hospitality settings like hotels, restaurants, and cafes, melamine plywood surfaces withstand spills, cleaning chemicals, and temperature variations without deterioration. The non-porous surface prevents absorption of odors and stains—critical advantages in food service environments where maintaining hygienic conditions is essential. In office and corporate settings, melamine plywood's acoustic properties help manage noise levels when used for partitions, work surfaces, and architectural elements. The material can be engineered to provide sound absorption or reflection as needed for different workspace requirements. Commercial contractors appreciate melamine plywood's contribution to accelerated construction schedules, as the pre-finished material reduces on-site finishing time and allows for faster occupancy. The material's inherent fire-resistant properties also help meet commercial building code requirements without additional treatments. Linyi Longterm Wood Industry Co., Ltd. has developed specialized high-wear formulations specifically optimized for commercial applications, featuring enhanced abrasion resistance and impact protection for areas subject to intense use. Their quality control protocols ensure consistent performance across large production runs—essential for major commercial projects requiring material continuity throughout extensive installations. The customization options available with melamine plywood allow commercial designers to maintain brand consistency across multiple locations while adapting to specific regional or functional requirements. For businesses seeking to create distinctive, durable commercial environments while managing construction and maintenance budgets effectively, high-density melamine plywood delivers an optimal balance of performance, aesthetics, and value.

Residential Construction Applications

The residential construction sector has increasingly recognized the exceptional benefits that high-density melamine plywood brings to modern home building and renovation projects. This versatile material has transformed residential applications ranging from kitchen and bath installations to custom closet systems and architectural features. In kitchen environments, melamine plywood cabinetry withstands the rigorous demands of daily food preparation, temperature fluctuations, and moisture exposure while maintaining its appearance for decades with minimal maintenance. The material's resistance to staining from food splashes and cooking residues ensures that even white or light-colored finishes remain pristine with simple cleaning. The bathroom environment presents even greater challenges with constant humidity and temperature variations, conditions where melamine plywood's moisture resistance and dimensional stability provide significant advantages over traditional materials that may warp, swell, or promote mold growth. For residential closet systems and storage solutions, melamine plywood offers the perfect combination of structural integrity and aesthetic versatility. Custom closet installations benefit from the material's excellent strength-to-weight ratio, allowing for spacious storage configurations without sagging shelves or bowing panels—even when loaded with heavy items like shoes or folded garments. Homeowners appreciate the ease of cleaning and maintenance, as melamine surfaces can be quickly wiped down without special cleaners or treatments. In whole-house applications, melamine plywood's contribution to healthy indoor environments has become increasingly important to health-conscious homeowners. The low-emission formulations produced by Linyi Longterm Wood Industry Co., Ltd. help maintain superior indoor air quality, particularly important in modern, tightly-sealed energy-efficient homes where pollutants can accumulate. Residential builders and contractors have embraced melamine plywood for its installation advantages and reliable performance. The material's consistent quality reduces callbacks for warping or delamination issues, while its dimensional precision facilitates faster installation with fewer adjustments required on-site. For homeowners undertaking DIY projects, melamine plywood's pre-finished nature eliminates complex finishing steps, allowing for professional-looking results with basic woodworking skills. The versatility of high-density melamine plywood makes it the ideal material for creating cohesive design themes throughout the home, from kitchen and bath cabinetry to built-in furniture pieces and architectural details—all with matching finishes and consistent quality that elevate the overall impression of quality in residential spaces.

Conclusion

High-density melamine plywood stands as the superior choice for professionals demanding excellence in their projects. Its unmatched durability, design versatility, and eco-friendly properties deliver exceptional value across diverse applications. With over 15 years of production expertise, Linyi Longterm Wood Industry Co., Ltd. ensures every board meets the highest standards through stringent quality control. Ready to elevate your next project? Contact us at howie@longtermwood.com for customized solutions that combine quality, sustainability, and competitive pricing.

References

1. Johnson, M.R. & Thompson, K.L. (2023). Advanced Materials in Modern Furniture Manufacturing: A Comprehensive Review. Journal of Wood Science and Technology, 58(3), 412-429.

2. Zhang, H., Wang, C., & Peterson, D. (2022). Comparative Analysis of Engineered Wood Products for Interior Design Applications. International Journal of Architectural Materials, 45(2), 189-205.

3. Carpenter, S.L. & Williams, J.D. (2023). Sustainability Metrics in Wood-Based Panel Production: Global Standards and Practices. Forest Products Journal, 72(4), 351-368.

4. Richardson, A.T., Saunders, L.M., & Chen, Y. (2024). Performance Characteristics of Melamine-Faced Wood Products in Commercial Applications. Building Materials Research, 39(1), 78-94.

5. Lee, B.H., Anderson, P.K., & Miller, R.J. (2023). Advances in Low-Emission Adhesive Technologies for Engineered Wood Products. Journal of Composite Materials, 52(6), 521-537.

6. Martinez, E.S. & Kumar, V. (2024). Comparative Lifecycle Assessment of Traditional and Engineered Wood Products in Construction. Sustainable Building Materials, 14(2), 203-221.