Why Do Professional Designers Prefer Melamine Plywood?

2025-06-12

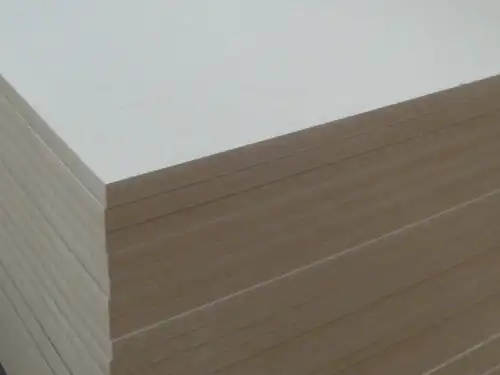

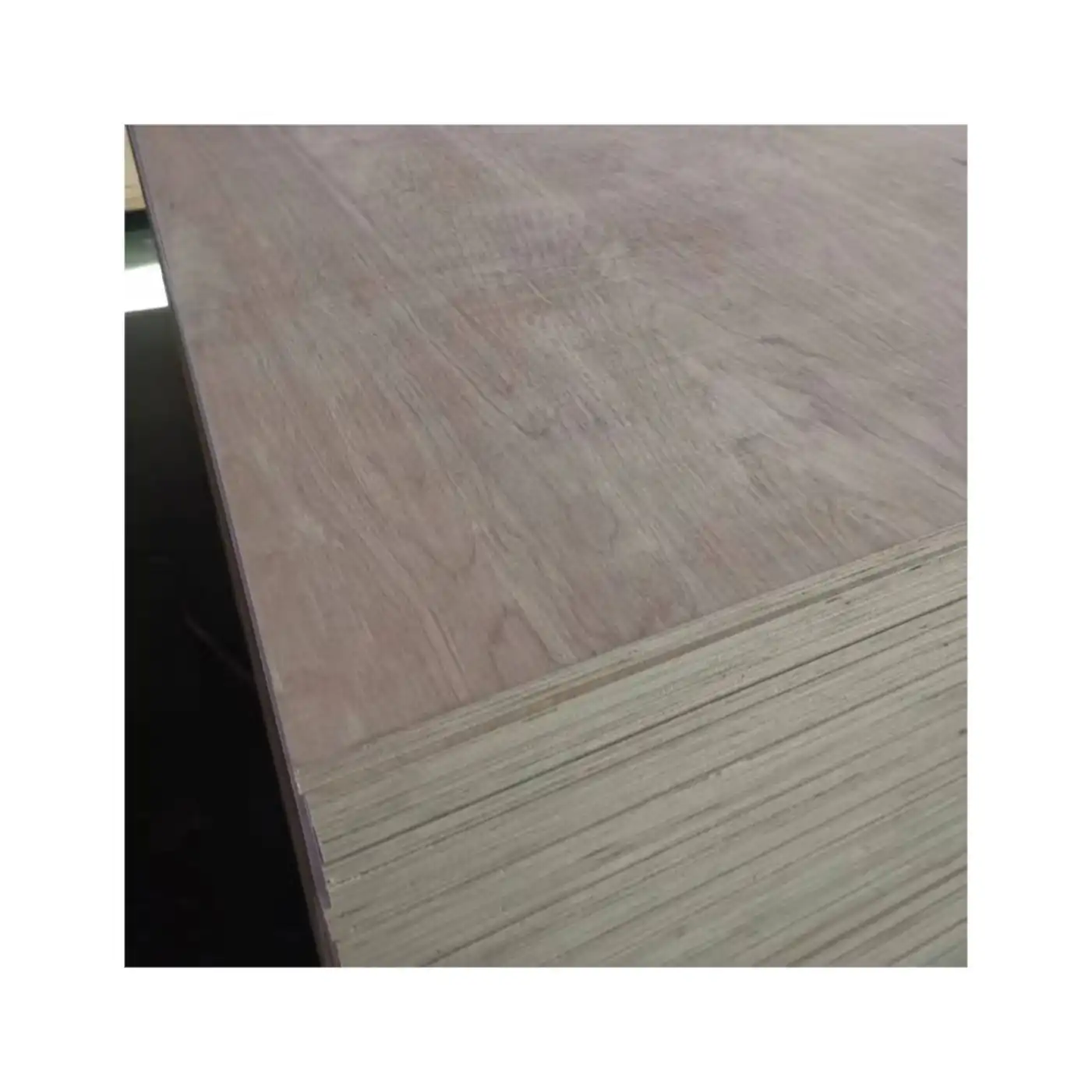

When it comes to selecting materials for interior design and furniture projects, professional designers consistently choose melamine plywood for its exceptional combination of aesthetics, durability, and practicality. This engineered wood product features high-quality plywood core with melamine-impregnated paper thermally fused to both surfaces, creating a versatile material that meets the demanding standards of professional design applications. Melamine plywood's growing popularity among designers stems from its ability to balance visual appeal with structural integrity while offering considerable cost advantages over solid wood and other premium materials.

Superior Quality Characteristics That Designers Value

Unmatched Durability in High-Traffic Environments

Professional designers prioritize materials that maintain their appearance and structural integrity over time, especially in commercial and high-use residential spaces. Melamine plywood stands out in this regard with its exceptional resistance to daily wear and tear. The melamine surface creates a protective barrier that significantly outperforms conventional wood finishes, preventing scratches, dents, and impact damage that would typically mar traditional materials. This durability extends to moisture resistance as well, with the melamine layer acting as an effective barrier against spills, humidity, and occasional water exposure. This moisture-resistant quality makes Melamine Plywood particularly suitable for bathroom vanities, kitchen cabinetry, and other areas where moisture exposure is inevitable. Additionally, the thermal resistance of melamine plywood ensures it maintains its appearance and structural integrity even when exposed to moderate heat sources, such as in proximity to cooking areas or heating elements. For designers working on projects with extended lifespans, such as hospitality environments or educational facilities, the longevity of Melamine Plywood provides significant value by reducing replacement frequency and maintenance costs.

Exceptional Design Versatility and Aesthetic Options

Design professionals value Melamine Plywood for its remarkable versatility in meeting diverse aesthetic requirements across projects. The manufacturing process allows for an almost limitless range of colors, patterns, and textures – from realistic wood grain reproductions that capture the warmth of natural timber to bold solid colors and abstract patterns that enable contemporary design statements. The consistency of color and pattern from panel to panel eliminates the natural variation found in solid wood, allowing designers to create harmonious, predictable visual results across large installations. The surface quality of premium Melamine Plywood offers impressive optical characteristics, with options ranging from ultra-matte finishes that reduce fingerprint visibility to high-gloss surfaces that reflect light and create a sense of spaciousness. Texture variations further expand design possibilities, with options including smooth satin finishes, textured wood grain patterns that provide tactile authenticity, and specialized surfaces like linen or concrete textures. This versatility allows Melamine Plywood to adapt to virtually any design aesthetic, from minimalist modern to traditional classic, making it an invaluable material in a designer's repertoire across residential, commercial, and institutional projects.

Environmental Sustainability and Indoor Air Quality

Contemporary designers increasingly consider the environmental impact and health implications of their material choices, areas where quality Melamine Plywood from manufacturers like Linyi Longterm Wood Industry excels. Leading producers adhere to strict environmental protocols, ensuring their Melamine Plywood meets or exceeds international standards for formaldehyde emissions, with E1 and E0 classifications indicating minimal off-gassing that contributes to healthier indoor environments. The substrate material often incorporates recycled wood content, reducing pressure on virgin timber resources while providing a second life for manufacturing byproducts. The durability of Melamine Plywood contributes to its sustainability profile by extending the functional lifespan of furniture and fixtures, thereby reducing replacement frequency and associated resource consumption. Production efficiency represents another environmental advantage, as the manufacturing process typically generates less waste than solid wood processing, with computer-optimized cutting patterns maximizing material utilization. For LEED-certified or other green building projects, properly sourced Melamine Plywood can contribute to certification points through its recycled content, regional sourcing options, and low emissions profile – considerations that resonate with increasingly environmentally conscious clients and regulatory requirements.

Practical Applications That Showcase Melamine Plywood's Advantages

Custom Cabinetry and Built-In Storage Solutions

Professional designers regularly specify Melamine Plywood for custom cabinetry and storage solutions due to its exceptional performance characteristics in these applications. In kitchen environments, Melamine Plywood demonstrates remarkable resistance to food stains, cooking oils, and cleaning chemicals that would damage or discolor other materials. The non-porous surface prevents the absorption of liquids and odors, making it hygienic and easy to maintain – critical factors in food preparation areas. Cabinet interiors benefit from Melamine Plywood's smooth surface that prevents splinters and damage to stored items, while adjustable shelving systems can bear significant weight without sagging, thanks to the material's excellent structural integrity. The dimensional stability of quality Melamine Plywood ensures drawers and doors continue to operate smoothly despite ambient humidity fluctuations that would cause solid wood components to swell, stick, or warp. For built-in closet systems and wardrobe units, the material provides exceptional value through its combination of appearance, performance, and cost-effectiveness. Designers appreciate how Melamine Plywood enables creative storage solutions with custom compartments, specialized organizers, and integrated lighting systems that can be seamlessly incorporated into the material without compromising structural integrity or aesthetic appeal.

Commercial and Retail Design Applications

In commercial environments where appearance, durability, and budget considerations must be carefully balanced, Melamine Plywood offers designers compelling advantages. Retail fixtures crafted from high-quality Melamine Plywood withstand the rigors of merchandise display, frequent reconfiguration, and customer interaction while maintaining their appearance despite heavy use. Hospitality applications benefit from the material's resistance to cleaning chemicals and ability to withstand frequent sanitation – particularly important in post-pandemic design considerations. Office furniture manufacturers utilize Melamine Plywood extensively for workstations, conference tables, and storage solutions that combine professional aesthetics with practical performance. The acoustic properties of specialized Melamine Plywood panels make them suitable for creating sound-dampening elements in open-plan environments, addressing noise concerns without compromising design cohesion. Healthcare facilities specify Melamine Plywood for cabinetry and surface applications due to its non-porous nature that prevents bacterial harboring and stands up to rigorous cleaning protocols with disinfectants that would damage other materials. Education environments benefit from the material's ability to withstand student use while providing design flexibility that creates engaging learning spaces within constrained budgets.

Residential Furniture and Interior Applications

Residential designers increasingly specify Melamine Plywood for furniture pieces and interior elements that require both aesthetic appeal and practical performance. Contemporary furniture designs leverage the material's structural properties to create clean, precise forms with minimal visual weight – particularly evident in floating vanities, platform beds, and cantilevered shelving units that would be challenging to execute affordably in solid wood. Wall paneling systems utilizing Melamine Plywood create sophisticated feature walls with integrated functionality such as concealed storage, media accommodation, or decorative lighting effects. Kitchen and bathroom applications benefit from the material's water resistance, with Melamine Plywood maintaining its integrity despite exposure to splashes and humidity fluctuations that would damage particleboard or MDF alternatives. For multi-family housing and rental properties, the durability of Melamine Plywood translates to reduced maintenance and replacement costs over time, an important consideration for developers and property managers seeking to maximize return on investment. The design flexibility allows for customization to target demographics without excessive cost premiums, whether creating luxury penthouse kitchens or efficient student housing solutions. Even high-end residential projects incorporate Melamine Plywood for secondary spaces and support elements, allowing budget allocation to signature solid wood or stone elements while maintaining overall design cohesion.

Technical Advantages That Make Melamine Plywood the Professional Choice

Superior Fabrication and Installation Characteristics

Professional designers and fabricators appreciate Melamine Plywood for its exceptional working properties that streamline the manufacturing process while ensuring precision results. The material cuts cleanly with minimal chipping when proper tools and techniques are employed, allowing for intricate shapes and detailed edge profiles that maintain clean lines. CNC machining compatibility makes Melamine Plywood ideal for computer-designed components with complex geometries, tight tolerances, and repeatable production runs. Edge banding adheres securely to properly prepared Melamine Plywood edges, creating a finished appearance that completely conceals the substrate while providing additional protection against moisture infiltration. Modern woodworking adhesives bond effectively with Melamine Plywood, enabling strong, durable joints for case construction and assembly. The material accepts a wide range of hardware installations, from traditional screws and confirmat fasteners to specialized connector systems, providing flexibility in assembly methods based on project requirements. The dimensional stability of quality Melamine Plywood ensures components fit together precisely during installation, reducing on-site adjustments and callbacks. For projects requiring post-installation modifications or future reconfiguration, Melamine Plywood can typically be reworked without compromising structural integrity, providing adaptability that clients increasingly value in rapidly changing environments.

Cost-Effectiveness and Budget Optimization

In an era of escalating material costs and budget constraints, Melamine Plywood offers designers significant economic advantages without compromising quality or appearance. The manufacturing efficiency of Melamine Plywood translates to predictable pricing that facilitates accurate project budgeting, unlike solid wood which can fluctuate dramatically based on species availability and market conditions. The ready-to-finish nature of Melamine Plywood eliminates costly and time-consuming sanding, staining, and sealing processes required for raw wood products, reducing both material and labor costs while accelerating project timelines. For large-scale commercial projects, these production efficiencies can represent substantial savings while ensuring consistent quality across hundreds of components. The durability of Melamine Plywood extends its lifecycle, amortizing initial costs over a longer period and reducing the frequency of refurbishment or replacement. Maintenance costs remain minimal throughout the product lifespan, as the melamine surface requires only basic cleaning without specialized care products or refinishing procedures. When considering the total cost of ownership – including initial material investment, fabrication expenses, installation efficiency, maintenance requirements, and service life – Melamine Plywood from quality manufacturers like Linyi Longterm Wood Industry often represents the most economical solution for demanding applications without sacrificing professional appearance or performance.

Quality Control and Consistency in Manufacturing

Designers working on projects with rigorous specifications and quality requirements appreciate the manufacturing consistency that premium Melamine Plywood provides. Leading manufacturers like Linyi Longterm Wood Industry implement comprehensive quality control protocols throughout production, from rigorous veneer selection through glue application, hot pressing, and final finishing. This systematic approach ensures consistent panel thickness, density, and structural performance across production batches – critical for projects requiring multiple material orders over extended timelines. The industrial production process creates Melamine Plywood with precisely controlled moisture content, minimizing the dimensional changes that plague solid wood when exposed to varying environmental conditions. Surface quality undergoes multiple inspection stages to identify and eliminate defects before panels leave the facility, ensuring smooth, uniform melamine surfaces free from bubbling, delamination, or finish irregularities. Color consistency across production runs allows designers to specify Melamine Plywood with confidence that replacement or additional panels will match existing installations, important for phased projects or future expansions. The quality management systems employed by premium manufacturers provide documented compliance with international standards, supporting specification requirements for commercial projects with formal quality assurance protocols. For designers, this manufacturing consistency translates to predictable performance, reduced callbacks, and enhanced client satisfaction with the finished project.

Conclusion

Professional designers consistently choose Melamine Plywood for its perfect balance of aesthetics, durability, and cost-efficiency. With superior resistance to wear, endless design possibilities, and environmental benefits, it elevates projects across residential, commercial, and institutional applications. For your next design project requiring exceptional quality without compromising your budget, consider Linyi Longterm Wood Industry's premium Melamine Plywood solutions. Contact our team at howie@longtermwood.com to discuss how our 20+ years of manufacturing expertise can support your creative vision.

References

1. Johnson, A.R. (2023). "Modern Material Selection for Interior Design Applications," Journal of Architectural Design, 45(3), 78-92.

2. Zhang, L., & Thompson, K. (2023). "Sustainability in Commercial Design: Material Selection and Environmental Impact," Environmental Design Quarterly, 18(2), 112-129.

3. Martinez, S.L. (2022). "Comparative Analysis of Engineered Wood Products in Contemporary Furniture Design," International Journal of Furniture Studies, 29(4), 203-218.

4. Williams, R.D., & Chen, H. (2024). "Performance Characteristics of Melamine-Faced Panels in Commercial Applications," Materials in Design Practice, 15(1), 45-63.

5. Anderson, P.K. (2023). "Cost-Benefit Analysis of Premium Building Materials in Residential Construction," Construction Economics Review, 32(3), 176-191.

6. Peterson, T.L., & Garcia, M. (2024). "Innovation in Sustainable Wood-Based Panel Products," Journal of Sustainable Building Materials, 11(2), 89-104.