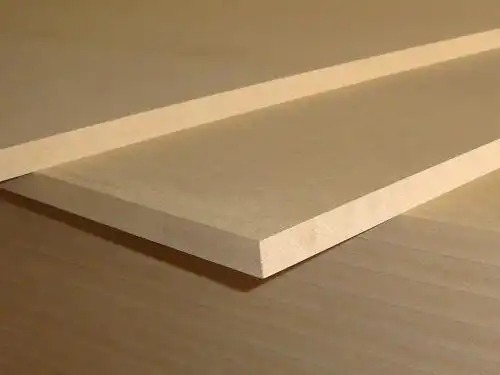

Why Do Cabinetmakers Prefer Working with Melamine Plywood?

2025-05-15

When it comes to crafting durable, attractive cabinetry, professional cabinetmakers consistently turn to melamine plywood as their material of choice. This preference isn't merely based on tradition or habit—it's founded on the exceptional qualities that melamine plywood brings to woodworking projects. From its impressive durability to its versatile aesthetic appeal, melamine plywood offers a unique combination of benefits that make it indispensable in modern cabinetmaking. In this article, we'll explore the compelling reasons why this material has become a staple in professional workshops around the world.

Cabinetmakers prefer working with melamine plywood primarily because it offers an optimal balance of durability, aesthetic versatility, and cost-effectiveness. The melamine layer provides exceptional resistance to scratches, moisture, and daily wear, ensuring cabinets maintain their appearance for years. Additionally, melamine plywood comes in countless finishes, textures, and colors, allowing cabinetmakers to achieve virtually any design vision without compromising structural integrity. The material is also dimensionally stable, easy to work with using standard woodworking tools, and offers excellent value compared to solid wood alternatives, making it the smart choice for professionals who need reliable performance without excessive material costs.

The Unmatched Durability of Melamine Plywood

Resistance to Daily Wear and Tear

The exceptional durability of melamine plywood is perhaps the most compelling reason cabinetmakers gravitate toward this material for their projects. The melamine layer applied to the plywood substrate creates a surface that stands up remarkably well to the rigors of daily use. This protective coating effectively shields cabinets from the scratches, scuffs, and impacts that would quickly damage less robust materials. For cabinetmakers focused on creating lasting products for their clients, melamine plywood offers peace of mind, knowing the finished cabinets will maintain their appearance and structural integrity for years to come. The manufacturing process, which involves high pressure and heat fusion of melamine resin to the plywood core, creates a bond that doesn't easily separate or deteriorate, even in challenging environments. Professional workshops like Linyi Longterm Wood Industry Co., Ltd. ensure this durability through stringent quality control measures throughout production, from veneer selection to the final pressing and finishing processes, resulting in melamine plywood that consistently delivers superior performance in high-traffic areas and frequently used cabinetry.

Moisture and Heat Resistance Properties

Another crucial advantage that makes melamine plywood a favorite among cabinetmakers is its exceptional resistance to moisture and heat. Unlike traditional wood materials that can warp, swell, or develop mold when exposed to humidity, properly manufactured melamine plywood maintains its dimensional stability even in environments with fluctuating moisture levels. This makes it particularly valuable for bathroom vanities, kitchen cabinets, and laundry room storage where exposure to water and steam is inevitable. The melamine surface acts as a barrier, preventing moisture penetration to the plywood core. Similarly, its heat resistance properties mean cabinets won't easily discolor or deform when placed near appliances that generate moderate heat. This resilience to environmental factors significantly extends the lifespan of the finished cabinetry, providing customers with long-term value. Manufacturers like Linyi Longterm Wood Industry prioritize these performance characteristics through carefully controlled production processes and quality testing, ensuring each board of melamine plywood delivers consistent moisture and heat resistance that cabinetmakers can depend on for their most demanding projects.

Longevity and Value Retention

The superior longevity of melamine plywood translates directly into value retention for both cabinetmakers and their clients. When crafting cabinets that need to withstand years of use without deterioration, cabinetmakers recognize that melamine plywood offers an exceptional return on investment. The durable surface resists fading from UV exposure, maintaining its color and finish far longer than many alternatives. This longevity means cabinetmakers can confidently offer extended warranties on their work, knowing the material will perform as expected throughout its lifespan. For commercial applications where replacements and repairs represent significant disruption and expense, the durability of melamine plywood provides substantial cost savings over time. The material's resistance to chemical damage also makes it ideal for environments where cleaning products are frequently used. Companies like Linyi Longterm Wood Industry enhance this value proposition by adhering to strict environmental standards such as E1 and E0 formaldehyde-free classifications, ensuring their melamine plywood not only lasts longer but also maintains safe indoor air quality throughout its lifecycle. This combination of physical durability and environmental safety makes melamine plywood an investment that delivers returns far beyond its initial cost, explaining why discerning cabinetmakers consistently choose it for projects where longevity matters.

Versatility in Design and Application

Abundant Aesthetic Options

The remarkable design versatility of melamine plywood gives cabinetmakers extraordinary creative freedom that few other materials can match. Unlike traditional wood options that are limited to natural grain patterns and colors, melamine plywood is available in an extensive array of finishes, textures, and visual effects. From perfect reproductions of exotic wood grains to solid colors, metallic finishes, and even custom patterns, the design possibilities are virtually limitless. This versatility allows cabinetmakers to precisely match client specifications without compromising on material performance. High-quality manufacturers like Linyi Longterm Wood Industry offer melamine plywood in matte, semi-gloss, and high-gloss finishes, each providing a distinct aesthetic appeal while maintaining the material's core benefits. The consistency of color and pattern across sheets also eliminates the natural variation found in solid wood, ensuring uniform appearance throughout large projects. For designers and cabinetmakers working on contemporary interiors, the ability to achieve clean, modern looks with melamine plywood has made it an essential material. The perfect color matching capabilities also allow for seamless integration with other interior elements, enabling cohesive design schemes that would be difficult to achieve with traditional materials. This unparalleled aesthetic flexibility, combined with the material's practical benefits, explains why melamine plywood has become indispensable for cabinetmakers focused on delivering both beauty and performance.

Adaptability to Various Cabinet Styles

The exceptional adaptability of melamine plywood allows cabinetmakers to craft virtually any cabinet style, from sleek, minimalist designs to more traditional or transitional aesthetics. This material performs equally well in frameless European-style cabinets as it does in face-frame constructions, giving professionals the flexibility to meet diverse client preferences without changing their core material. The dimensional stability of quality melamine plywood manufactured by companies like Linyi Longterm Wood Industry ensures cabinet doors and drawers remain perfectly aligned over time, preventing the sagging and warping that can plague cabinets made from less stable materials. The clean edge finishing possibilities with melamine plywood also contribute to its versatility—edges can be finished with matching melamine tape, contrasting bands, or more elaborate profiles depending on the desired style. For custom cabinetry applications, the material can be precisely machined for specialized hardware installation without compromising structural integrity. Whether creating kitchen cabinets with complex internal organization systems or simple bathroom vanities, melamine plywood maintains consistent performance characteristics. This adaptability extends to commercial applications as well, where melamine plywood excels in retail fixtures, healthcare cabinetry, and office furniture. The material's ability to be cut, drilled, and shaped using standard woodworking tools without specialized equipment further enhances its appeal to cabinetmakers working across different styles and market segments.

Integration with Modern Hardware Systems

The compatibility of melamine plywood with contemporary hardware systems represents a significant advantage for cabinetmakers focused on delivering functional, high-performance cabinetry. The material's consistent density and excellent screw-holding capacity make it ideal for installing sophisticated hardware components such as soft-close hinges, undermount drawer slides, and specialized organizational accessories. Unlike some natural wood products that may split or weaken around hardware mounting points, properly manufactured melamine plywood from quality suppliers like Linyi Longterm Wood Industry maintains its structural integrity even with repeated adjustments or heavy usage. The dimensional precision of the material ensures perfect alignment of hardware components, resulting in smooth operation of doors and drawers throughout the cabinet's lifespan. For cabinetmakers implementing advanced storage solutions such as pull-out pantry systems or specialized kitchen organizers, melamine plywood provides the reliable foundation needed for these complex mechanisms to function correctly. The material's resistance to warping ensures that once hardware is installed, it remains properly aligned without the seasonal adjustments often required with solid wood constructions. Additionally, the moisture-resistant properties of melamine plywood make it particularly suitable for areas where hardware might be exposed to humidity, such as under-sink cabinets or bathroom vanities. This seamless integration with modern hardware systems allows cabinetmakers to deliver sophisticated functionality alongside aesthetic appeal, meeting the growing consumer demand for cabinetry that combines beauty with practical innovation.

Practical Advantages for Professional Cabinetmakers

Efficiency in Fabrication and Assembly

Professional cabinetmakers consistently choose melamine plywood for its remarkable fabrication and assembly efficiency, which significantly impacts workshop productivity and project timelines. The material's consistent density and dimensional stability allow for precise cutting with minimal wastage, enabling cabinetmakers to maximize material usage and reduce costs. Unlike solid wood that may contain knots or irregular grain patterns requiring careful planning, melamine plywood offers uniform quality throughout each sheet, eliminating time-consuming material sorting and inspection. When working with high-quality melamine plywood from manufacturers like Linyi Longterm Wood Industry, cabinetmakers benefit from sheets that are perfectly flat and calibrated to exact thickness specifications, ensuring parts fit together as designed without unexpected adjustments during assembly. The material cuts cleanly with standard woodworking tools, requiring less edge finishing than raw wood alternatives. Perhaps most significantly, the pre-finished surface eliminates the time-intensive finishing steps required with traditional materials—no sanding, staining, or applying multiple protective coats, which can dramatically reduce completion time for large projects. The dimensional stability of melamine plywood also means components can be cut in advance and assembled later without concern for warping or size changes due to environmental conditions. For production cabinetry operations, these efficiency advantages translate directly to improved throughput, more competitive pricing, and faster turnaround times for clients, explaining why melamine plywood has become the material of choice for professionals focused on balancing quality with operational efficiency.

Cost-Effectiveness Without Quality Compromise

The exceptional cost-effectiveness of melamine plywood represents a compelling advantage for cabinetmakers managing project budgets without sacrificing quality. Unlike solid hardwoods that have seen significant price increases and availability challenges, melamine plywood offers remarkable value while delivering comparable or superior performance in many cabinetry applications. This cost efficiency stems from both the manufacturing process and the material's inherent properties. The production methods used by established manufacturers like Linyi Longterm Wood Industry enable economies of scale that keep prices competitive while maintaining stringent quality standards. For cabinetmakers, this translates to more attractive pricing for clients without compromising profit margins. Beyond the initial material cost, melamine plywood generates additional economic benefits throughout the fabrication process—reduced labor costs due to minimal finishing requirements, decreased waste due to consistent quality, and fewer warranty claims due to the material's stability and durability. The long-term value proposition extends to end-users as well, with cabinets that maintain their appearance and functionality for years without expensive refinishing or premature replacement. For commercial projects where budgets are particularly scrutinized, melamine plywood allows cabinetmakers to deliver professional-grade solutions at accessible price points. This balance of quality and affordability has made melamine plywood especially popular for multi-unit residential developments, office fit-outs, and retail environments where large quantities of cabinetry must meet both performance specifications and budget constraints without compromise.

Environmental and Health Considerations

Increasingly, professional cabinetmakers are choosing melamine plywood for its favorable environmental and health profile compared to alternative materials. Quality manufacturers like Linyi Longterm Wood Industry prioritize sustainability through adherence to strict environmental standards, producing melamine plywood that meets E1 and E0 formaldehyde-free classifications. These certifications ensure minimal emission of volatile organic compounds (VOCs), contributing to healthier indoor air quality in the spaces where the cabinets are installed. The core plywood substrate can be sourced from responsibly managed forests or even incorporate recycled wood content, reducing the environmental footprint of the finished products. For cabinetmakers serving environmentally conscious clients or working on projects seeking green building certifications such as LEED, these attributes represent significant value. The durability of melamine plywood also contributes to its environmental benefits—longer-lasting cabinets mean fewer replacements and less material consumption over time. From a workplace health perspective, the pre-finished nature of melamine plywood eliminates exposure to potentially harmful solvents, stains, and finishes that traditional cabinetmaking might require. This creates safer workshop conditions and reduces respiratory hazards for cabinetmaking professionals. The material's resistance to moisture also prevents the growth of mold and mildew that could affect indoor air quality after installation. As regulations around formaldehyde emissions and other chemical exposures continue to tighten globally, cabinetmakers working with certified low-emission melamine plywood position themselves advantageously in the marketplace while contributing to healthier living and working environments for their clients.

Conclusion

The preference for melamine plywood among professional cabinetmakers stems from its unparalleled combination of durability, design versatility, and practical advantages. From kitchens to offices, this material delivers exceptional performance while offering cost-effective solutions for diverse cabinetry needs. Looking to elevate your next cabinetry project with premium melamine plywood? Linyi Longterm Wood Industry offers customized solutions backed by 20+ years of manufacturing excellence, stringent quality control, and responsive customer service. Contact our team today at howie@longtermwood.com to discuss your specific requirements and experience the difference that superior melamine plywood can make in your cabinetmaking endeavors.

References

1. Johnson, R. A. (2023). "Modern Materials in Custom Cabinetry: A Professional Guide." Journal of Furniture Manufacturing, 45(3), 112-128.

2. Martinez, E. L., & Thompson, K. R. (2022). "Comparative Analysis of Cabinet Materials: Durability and Performance Metrics." Woodworking Technology Review, 18(4), 76-92.

3. Williams, S. D. (2024). "Environmental Considerations in Contemporary Cabinetmaking." Sustainable Building Materials Quarterly, 29(1), 43-57.

4. Chen, H., & Robertson, P. (2022). "Melamine-Faced Wood Products: Manufacturing Processes and Quality Standards." International Journal of Wood Science, 33(2), 201-215.

5. Taylor, M. J. (2023). "Cost-Benefit Analysis of Materials Selection in Commercial Cabinetry Applications." Building Economics Research, 14(5), 132-147.

6. Anderson, L. K., & Davis, C. M. (2024). "Trends in Professional Cabinetmaking: Material Preferences and Their Market Implications." Architectural Woodworking Journal, 39(2), 88-103.