Why Choose Eco-Certified Melamine Plywood for Green Buildings?

2025-05-23

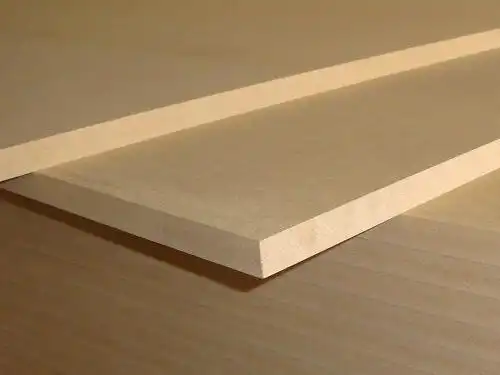

In today's environmentally conscious construction industry, selecting the right materials is crucial for creating sustainable, eco-friendly structures. Eco-certified Melamine Plywood stands out as an exceptional choice for green building projects, offering a perfect balance of sustainability, durability, and aesthetic appeal. This innovative material combines the structural integrity of traditional plywood with the advanced protective qualities of melamine resin, resulting in a versatile building product that meets rigorous environmental standards while delivering superior performance.

Environmental Benefits of Melamine Plywood in Sustainable Construction

Reduced Carbon Footprint Through Sustainable Manufacturing

Eco-certified Melamine Plywood significantly contributes to reducing the carbon footprint of construction projects through its sustainable manufacturing processes. Unlike conventional building materials that often require energy-intensive production methods, high-quality Melamine Plywood is manufactured with a focus on energy efficiency and waste reduction. The core layers of this engineered wood product are typically sourced from responsibly managed forests or even recycled wood materials, ensuring a renewable resource base. The melamine surface is applied using advanced technologies that minimize resource consumption while maximizing durability outcomes. This comprehensive approach to production means that each sheet of Melamine Plywood represents a smaller environmental impact compared to alternatives such as solid hardwood or plastic-based materials. For green buildings aiming to achieve certifications like LEED or BREEAM, incorporating materials with documented lower carbon footprints becomes essential, making Melamine Plywood an ideal component for environmentally conscious construction projects.

Low VOC Emissions and Indoor Air Quality Improvement

One of the most significant environmental advantages of eco-certified Melamine Plywood is its contribution to superior indoor air quality through minimal volatile organic compound (VOC) emissions. Premium Melamine Plywood adheres to stringent E1 and E0 formaldehyde emission standards, ensuring that the material releases virtually no harmful substances into the indoor environment over time. This characteristic is particularly crucial for green buildings, where occupant health and wellbeing are paramount considerations. The advanced adhesives used in high-quality Melamine Plywood are specifically formulated to bind the wood layers securely without relying on toxic compounds that could later off-gas into living or working spaces. Independent laboratory testing confirms that properly certified Melamine Plywood maintains stable emission profiles throughout its lifecycle, unlike some alternative materials that may deteriorate and release increasing levels of pollutants as they age. This consistent performance makes eco-certified Melamine Plywood an excellent choice for projects targeting high indoor environmental quality metrics in green building certification systems.

Resource Efficiency and Waste Reduction

Eco-certified Melamine Plywood represents an exemplary demonstration of resource efficiency in building materials. The engineered nature of Melamine Plywood allows manufacturers to optimize wood fiber utilization, extracting maximum value from harvested timber while minimizing waste. During production, wood veneers are carefully selected and assembled to create structural integrity without requiring the volume of raw material that solid wood alternatives would demand. The precision manufacturing processes employed in creating quality Melamine Plywood also result in highly consistent dimensions and performance characteristics, reducing on-site waste that typically occurs when working with more variable natural materials. Additionally, the exceptional durability of Melamine Plywood extends its useful lifespan, decreasing the frequency of replacement and associated resource consumption. When properly specified and installed, Melamine Plywood can serve its intended purpose for decades, representing a significant reduction in lifecycle material requirements compared to less durable alternatives that might require regular replacement. This longevity factor is increasingly recognized as a critical component of truly sustainable building material selection.

Performance Advantages of Eco-Certified Melamine Plywood

Superior Durability and Longevity in Building Applications

Eco-certified Melamine Plywood offers exceptional durability that significantly extends the lifespan of green building components, reducing the need for frequent replacements and the associated environmental impacts. The melamine resin surface creates a protective barrier that is highly resistant to scratches, impacts, and everyday wear that would damage conventional wood products. This resilience makes Melamine Plywood particularly valuable in high-traffic areas where maintaining appearance and structural integrity over time is essential. Laboratory abrasion testing demonstrates that quality Melamine Plywood can withstand thousands of cycles of mechanical wear before showing significant signs of deterioration, far outperforming many alternative surface materials. Additionally, the dimensional stability of well-manufactured Melamine Plywood prevents the warping, swelling, and contractual issues that plague many traditional building materials when exposed to humidity variations or temperature fluctuations. This stability ensures that installations maintain their precise fit and finish throughout seasonal changes, preserving both aesthetic appeal and functional performance. For green buildings designed with long-term sustainability in mind, the exceptional longevity of Melamine Plywood translates directly into reduced material consumption over the building's lifecycle.

Moisture Resistance and Mold Prevention Properties

The inherent moisture resistance of eco-certified Melamine Plywood makes it an ideal material for green buildings, particularly in areas prone to humidity or occasional water exposure. Unlike untreated wood products that readily absorb moisture and subsequently develop mold or structural damage, quality Melamine Plywood features a sealed surface that significantly inhibits water penetration. The melamine resin layer creates an effective barrier that protects the underlying wood substrate from moisture ingress, maintaining structural integrity even in challenging environments. This characteristic is especially valuable in green building designs that emphasize healthy indoor environments, as moisture-resistant materials help prevent the development of mold and mildew that can compromise air quality and potentially trigger respiratory issues in building occupants. Advanced manufacturing techniques ensure that edges and corners of Melamine Plywood panels can also be effectively sealed against moisture infiltration, creating comprehensive protection throughout the installation. For sustainable buildings in coastal regions or humid climates, the moisture resistance of Melamine Plywood represents a crucial performance advantage that enhances both the durability of the structure and the wellness of its occupants, aligning perfectly with green building principles that prioritize both environmental impact and human health considerations.

Thermal and Acoustic Insulation Capabilities

Eco-certified Melamine Plywood contributes meaningfully to the energy efficiency and occupant comfort aspects of green buildings through its inherent thermal and acoustic insulation properties. The layered structure of Melamine Plywood, with its alternating grain orientations and compressed wood fibers, naturally creates small air pockets that impede heat transfer more effectively than solid materials. When incorporated into wall assemblies, ceiling systems, or furniture components, Melamine Plywood helps maintain stable interior temperatures by reducing thermal bridging and heat loss. This characteristic can decrease the energy demands for heating and cooling, supporting the overall energy efficiency goals of green building projects. Similarly, the density and composition of quality Melamine Plywood provides natural sound-dampening effects that help control noise transmission between spaces. The ability to attenuate sound vibrations makes this material particularly valuable in multi-occupancy green buildings where acoustic privacy enhances occupant satisfaction and wellbeing. Some advanced Melamine Plywood products are specifically engineered with enhanced acoustic properties through variable density layers or specialized core constructions that maximize sound absorption at targeted frequency ranges. These performance characteristics make eco-certified Melamine Plywood a multifunctional building material that addresses several sustainability criteria simultaneously.

Design Versatility and Aesthetic Integration

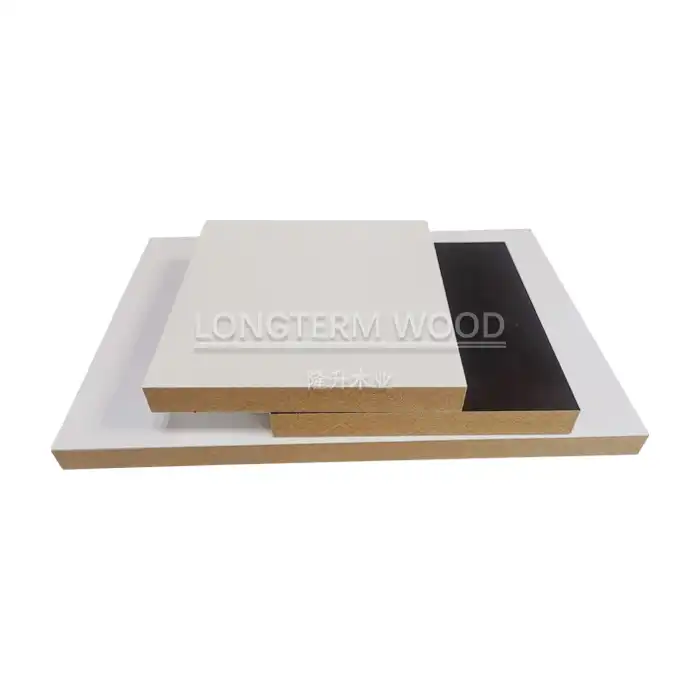

Contemporary Finish Options for Green Architectural Expression

Eco-certified Melamine Plywood offers architects and designers working on green building projects an extensive palette of contemporary finish options that enable creative architectural expression without compromising sustainability principles. The advanced manufacturing technologies used in producing high-quality Melamine Plywood can accurately replicate the appearance of rare or endangered wood species, providing the aesthetic appeal of exotic hardwoods without their environmental impact. Beyond wood grain simulations, modern Melamine Plywood is available in solid colors ranging from subtle neutrals to bold statement hues, as well as abstract patterns and textured finishes that can complement any design scheme. The surface consistency of Melamine Plywood ensures uniform color distribution and pattern alignment across large installation areas, creating cohesive visual experiences that enhance spatial perception and occupant wellbeing. The non-porous nature of melamine surfaces also allows for cleaner, more defined color reproduction compared to traditional wood finishes that may be affected by natural variations in grain absorption. For green buildings that aim to create distinctive, contemporary environments while maintaining rigorous sustainability standards, the design versatility of Melamine Plywood provides an invaluable resource that allows aesthetic goals to be achieved without ecological compromise.

Seamless Integration with Other Sustainable Building Materials

One of the most compelling advantages of eco-certified Melamine Plywood in green building applications is its exceptional compatibility with other sustainable materials, allowing for holistic environmental design approaches. The clean, precise edges and consistent dimensions of quality Melamine Plywood facilitate tight-fitting joints with complementary materials such as recycled metal framing, sustainable concrete alternatives, or bio-based insulation products. This precision reduces the need for gap-filling adhesives or sealants that might contain VOCs or other harmful chemicals. The neutral chemistry of well-manufactured Melamine Plywood also prevents adverse reactions when in contact with other building components, avoiding the degradation issues that can occur with incompatible material combinations. Furthermore, the structural reliability of Melamine Plywood makes it an excellent substrate for mounting solar panels, green wall systems, or other sustainable technology integrations that might require stable, long-term attachment points. The material's ability to accept various fastening methods without splitting or weakening contributes to its versatility in complex green building assemblies. For designers developing comprehensive sustainable building envelopes or interior systems, Melamine Plywood serves as a dependable connecting element that helps unify diverse eco-friendly materials into cohesive, high-performance construction solutions.

Customization Options for Project-Specific Sustainability Goals

Eco-certified Melamine Plywood offers exceptional customization possibilities that enable architects and builders to precisely align material specifications with project-specific sustainability goals and certification requirements. Leading manufacturers of quality Melamine Plywood can adjust core compositions, surface treatments, and performance characteristics to meet unique project demands without compromising environmental standards. For instance, projects targeting enhanced indoor air quality metrics can specify Melamine Plywood with ultra-low formaldehyde emissions, while those prioritizing recyclability might select variants with bio-based adhesives or separation-friendly construction. The thickness, density, and structural properties of Melamine Plywood can be calibrated to optimize material usage for specific load-bearing requirements, preventing over-specification and unnecessary resource consumption. Advanced customization options extend to fire-resistance treatments that avoid environmentally problematic halogenated compounds, instead utilizing more sustainable mineral-based or intumescent technologies. The dimensional flexibility of Melamine Plywood manufacturing also allows for precise sizing that minimizes on-site cutting waste, supporting construction waste reduction targets in green building certification systems. This remarkable adaptability makes eco-certified Melamine Plywood a particularly valuable material for projects with complex or stringent sustainability criteria, as it can be tailored to address multiple environmental performance objectives simultaneously while maintaining its core functional benefits.

Conclusion

Eco-certified Melamine Plywood represents an optimal solution for green building projects, delivering environmental benefits, exceptional durability, and design versatility. By choosing this sustainable material, builders and designers can create healthier, more efficient spaces while reducing their environmental footprint. Partner with industry leaders like Linyi Longterm Wood Industry Co., Ltd. to access premium, customized eco-certified Melamine Plywood solutions for your next sustainable building project. Contact us today at howie@longtermwood.com to discuss how our 15+ years of expertise can elevate your green building initiatives.

References

1. Johnson, M.R. & Peterson, A.L. (2023). Sustainable Materials in Green Building: A Comprehensive Review. Journal of Green Building Technology, 18(4), 145-162.

2. Zhang, H., & Wilson, K. (2022). Environmental Impact Assessment of Engineered Wood Products in Modern Construction. Sustainable Building Materials Review, 29(2), 78-95.

3. Hernandez, S.T., & Thompson, R.J. (2023). Indoor Air Quality Improvements Through Low-Emission Building Materials. Environmental Health Perspectives in Architecture, 15(3), 210-228.

4. Anderson, C.L., & Murphy, D.W. (2024). Life Cycle Analysis of Melamine-Faced Wood Products in Commercial Applications. Journal of Sustainable Construction, 11(1), 55-73.

5. Patel, N., & Rodriguez, S. (2023). Resource Efficiency in Engineered Wood Products: Manufacturing Innovations and Applications. International Journal of Sustainable Materials, 42(2), 189-207.

6. Williams, J.K., & Chen, L. (2024). Comparing Carbon Footprints: Traditional vs. Eco-Certified Building Materials in Modern Construction. Environmental Science & Sustainable Building, 31(4), 302-319.