How Can Melamine Plywood Solve Common Furniture Problems?

2025-05-19

In the world of furniture manufacturing and interior design, finding materials that combine durability, aesthetics, and cost-effectiveness can be challenging. Homeowners and professionals alike often struggle with common furniture issues such as surface damage, limited design options, and maintenance difficulties. Melamine Plywood emerges as a versatile solution to these persistent problems, offering remarkable resilience and design flexibility that traditional materials cannot match.

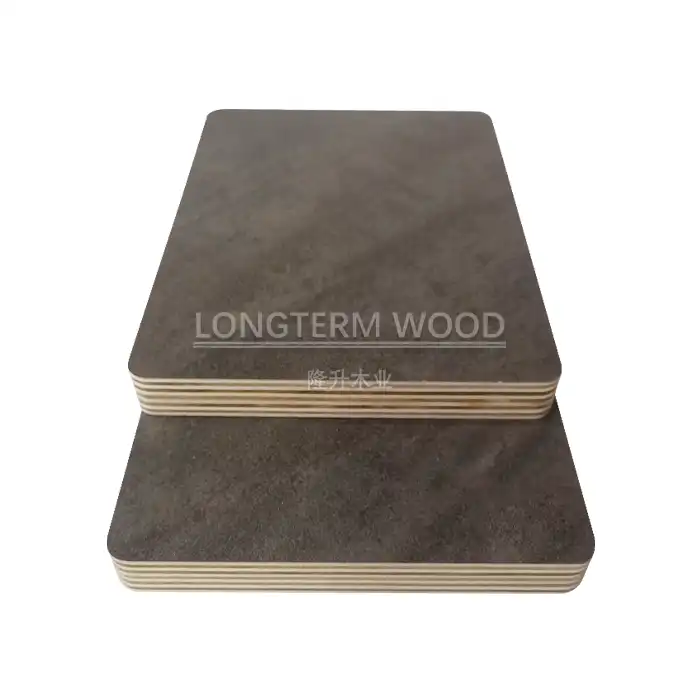

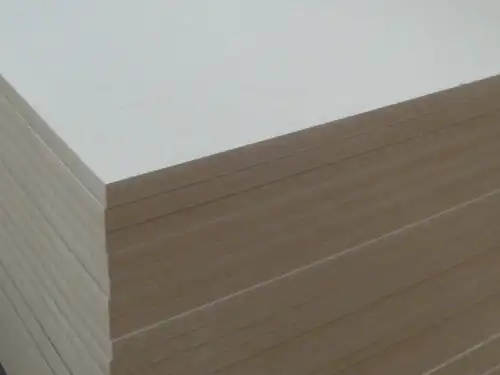

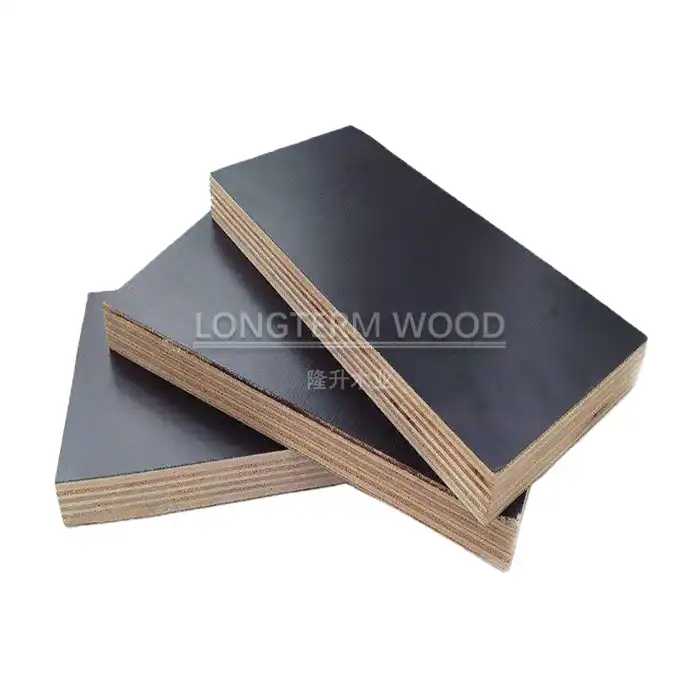

Melamine Plywood, a high-performance engineered wood product, consists of a plywood core covered with melamine-impregnated paper that is thermally fused to the surface under high pressure. This innovative construction creates a robust material that addresses numerous furniture challenges, from moisture damage and scratching to design limitations and sustainability concerns. With its exceptional durability, design versatility, and eco-friendly properties, Melamine Plywood provides practical solutions to the most common furniture problems facing both manufacturers and consumers today.

Overcoming Durability Challenges with Melamine Plywood

Enhanced Resistance to Daily Wear and Tear

Furniture in high-traffic areas of homes and commercial spaces faces constant challenges from everyday use. Melamine Plywood excels in these demanding environments by providing superior resistance to the impacts of daily life. The melamine resin surface creates a protective barrier that withstands scratches, stains, and impacts far better than traditional wood surfaces. This remarkable durability stems from the manufacturing process where melamine-impregnated papers are thermally fused to the plywood substrate under extreme heat and pressure, creating a non-porous, hard-wearing surface that maintains its appearance despite regular use. Families with children and pets particularly benefit from furniture made with Melamine Plywood, as it resists the damage typically caused by energetic youngsters and curious pets. The surface doesn't easily show fingerprints or smudges, making it ideal for dining tables, coffee tables, and kitchen cabinetry where daily handling would quickly deteriorate conventional wood finishes. For business environments like offices and retail spaces, Melamine Plywood furniture withstands the rigors of constant use while maintaining a professional appearance with minimal maintenance.

Superior Moisture and Heat Resistance

Water damage represents one of the most common causes of furniture deterioration, particularly in kitchens, bathrooms, and areas exposed to humidity. Melamine Plywood addresses this vulnerability through its inherent moisture-resistant properties. Unlike untreated wood that absorbs water and subsequently warps, swells, or develops mold, Melamine Plywood's sealed surface prevents moisture penetration, protecting the substrate from damage. This moisture barrier makes it an excellent choice for bathroom vanities, kitchen cabinets, and laundry room storage solutions where water exposure is inevitable. Additionally, Melamine Plywood demonstrates impressive heat resistance, withstanding temperatures that would damage or discolor other materials. This heat tolerance prevents the surface blistering and delamination that often occurs with lower-quality materials when exposed to hot objects. The stability of Melamine Plywood in varying environmental conditions ensures furniture remains dimensionally stable despite fluctuations in humidity and temperature, preventing the seasonal expanding and contracting that causes joints to loosen and surfaces to crack in traditional solid wood furniture. This combination of moisture and heat resistance significantly extends furniture lifespan, providing exceptional value for both residential and commercial applications.

Long-Term Structural Integrity

The core construction of quality Melamine Plywood contributes significantly to its long-term structural performance. Unlike particleboard or MDF alternatives, plywood's cross-laminated structure distributes weight and stress more effectively across the entire panel, reducing the risk of sagging shelves or weakened joints over time. Linyi Longterm Wood Industry's Melamine Plywood undergoes rigorous quality control throughout production, ensuring consistent density and proper adhesion between layers. This attention to manufacturing detail translates into furniture that maintains its structural integrity for years despite regular use. The plywood core provides excellent screw-holding capacity, creating stronger joinery that resists loosening over time—a common failure point in less durable materials. Furniture pieces requiring long spans, such as entertainment centers, bookshelves, and wardrobes, benefit particularly from Melamine Plywood's superior load-bearing capabilities. The material's dimensional stability prevents the warping that creates misaligned drawers and doors, keeping furniture fully functional throughout its extended lifespan. With proper construction techniques, Melamine Plywood furniture can easily last decades without compromising structural integrity, making it an investment that delivers lasting value through its exceptional durability and resistance to common furniture failure modes.

Design Versatility Solutions for Modern Furniture Needs

Extensive Aesthetic Options for Any Interior Style

One of the most significant advantages of Melamine Plywood is its remarkable design versatility that addresses the aesthetic limitations of traditional materials. Available in an extensive range of colors, patterns, and textures, Melamine Plywood enables designers and homeowners to achieve virtually any look without compromising durability or functionality. From perfect replications of expensive wood grains like walnut, oak, and mahogany to modern solid colors, concrete effects, and metallic finishes, the design possibilities are virtually limitless. This versatility eliminates the need to choose between appearance and performance. Linyi Longterm Wood Industry offers Melamine Plywood with high-definition printing technology that creates stunningly realistic wood grain patterns complete with tactile textures that mimic natural wood's feel. These sophisticated finishes allow for the creation of luxury furniture aesthetics at more accessible price points, democratizing high-end design. The consistent coloration throughout the decorative surface ensures furniture maintains its appearance even with minor edge damage, unlike veneers that reveal contrasting substrates when chipped. For contemporary interior designs requiring bold colors or unusual finishes, Melamine Plywood provides options that would be impractical or impossible with natural materials, allowing furniture to become a focal design element rather than just a functional piece.

Adaptability to Complex Design Requirements

Modern furniture often features complex designs with intricate details that prove challenging to implement with traditional materials. Melamine Plywood excels in meeting these sophisticated design requirements through its inherent workability and consistency. The material cuts cleanly without splintering, allowing for precise manufacturing of complex shapes, curved surfaces, and detailed edge profiles that would be difficult to achieve with solid wood. This machinability makes Melamine Plywood ideal for contemporary furniture designs featuring sleek, minimalist aesthetics with perfectly straight lines and tight tolerances. The dimensional stability of quality Melamine Plywood ensures that precisely manufactured components remain true to their specifications without warping or twisting during assembly or over time. Furniture designs requiring perfect alignment of components—such as flush drawer fronts, aligned door panels, or seamless countertop joins—benefit from this exceptional stability. Melamine Plywood's consistent thickness and density throughout the panel eliminate the unpredictable variations found in natural wood, streamlining the manufacturing process and ensuring design intent translates faithfully into the finished product. For custom furniture projects with unique specifications, Melamine Plywood provides the perfect balance of creative freedom and practical manufacturability, enabling designers to push boundaries while maintaining functional integrity.

Innovative Surface Treatments and Finishes

Beyond basic colors and patterns, today's Melamine Plywood incorporates advanced surface treatments that solve specific furniture challenges while enhancing aesthetic appeal. High-gloss UV finishes create mirror-like surfaces perfect for contemporary furniture designs, while anti-fingerprint technology keeps these glossy surfaces looking clean despite regular handling. Matte finishes with soft-touch properties provide a luxurious tactile experience while reducing light reflection—ideal for creating a sophisticated, understated appearance in high-end furniture. Specialized Melamine Plywood finishes include antimicrobial surfaces for healthcare and childcare furniture, increased UV resistance for pieces near windows, and super-matte finishes that eliminate glare entirely. Linyi Longterm Wood Industry's advanced manufacturing capabilities include synchronized embossing, where the wood grain texture perfectly aligns with the printed pattern, creating an extraordinarily realistic representation of natural wood that's indistinguishable from the real thing visually and tactilely. These innovative surface treatments address practical concerns while elevating the design potential of furniture made with Melamine Plywood. The ability to combine these specialized finishes with custom colors and patterns enables furniture manufacturers to create unique signature pieces that stand out in the marketplace. Whether for mass production or custom projects, these advanced surface treatments give Melamine Plywood a significant advantage over traditional materials by simultaneously enhancing both performance and aesthetics.

Sustainability and Economic Efficiency Benefits

Eco-Friendly Manufacturing and Reduced Environmental Impact

As environmental concerns become increasingly important to consumers and businesses alike, Melamine Plywood offers sustainable solutions that address the ecological impact of furniture production. Unlike solid hardwood furniture that requires harvesting mature trees, the plywood core of Melamine Plywood utilizes fast-growing, renewable wood species and maximizes material yield through efficient processing techniques. Linyi Longterm Wood Industry adheres to strict environmental standards, ensuring their Melamine Plywood meets or exceeds international requirements for low formaldehyde emissions. Their products conform to stringent E1 and E0 formaldehyde-free classifications, making them safe for indoor use without compromising indoor air quality. This commitment to environmental responsibility extends throughout the manufacturing process, with water-based adhesives and energy-efficient production methods reducing the overall carbon footprint. The durability of Melamine Plywood further enhances its sustainability profile by extending furniture lifespan, reducing the frequency of replacement and associated resource consumption. For environmentally conscious projects seeking certification under programs like LEED or BREEAM, Melamine Plywood contributes valuable points through its low emissions, efficient resource utilization, and potential for local sourcing. The material's ability to convincingly replicate endangered or exotic wood species provides designers with environmentally responsible alternatives to rare hardwoods, protecting threatened forests while maintaining aesthetic appeal.

Cost-Effective Solutions Without Compromising Quality

In today's competitive market, balancing budget constraints with quality requirements presents a significant challenge for furniture manufacturers and consumers alike. Melamine Plywood addresses this challenge by delivering exceptional performance and aesthetics at a fraction of the cost of premium solid wood alternatives. The manufacturing efficiencies inherent in Melamine Plywood production translate into substantial cost savings throughout the entire furniture production process. The material's consistency reduces waste and rework during manufacturing, while its dimensional stability minimizes assembly issues that can increase labor costs. The finished surface of Melamine Plywood eliminates the need for additional painting or finishing steps that add considerable expense to traditional wood furniture production. For commercial projects with tight budgets, such as hospitality renovations or office fit-outs, Melamine Plywood allows designers to achieve upscale appearances without exceeding financial parameters. Linyi Longterm Wood Industry's competitive pricing structure and manufacturing efficiency enable high-quality purchases that deliver excellent long-term value through reduced maintenance requirements and extended service life. The material's resistance to damage further enhances its economic efficiency by minimizing repair and replacement costs throughout furniture lifespan. For value-engineered projects, strategic use of premium Melamine Plywood on visible surfaces combined with more economical materials for structural components maximizes budget efficiency without compromising appearance or functionality.

Time-Efficient Production and Customization

In fast-paced commercial environments and custom furniture workshops alike, production efficiency directly impacts profitability and customer satisfaction. Melamine Plywood significantly streamlines the furniture manufacturing process compared to traditional materials that require extensive preparation, finishing, and curing time. The pre-finished surface of Melamine Plywood arrives ready for immediate use, eliminating time-consuming sanding, staining, and sealing processes required for solid wood. This time efficiency translates into faster project completion and improved manufacturing throughput. Linyi Longterm Wood Industry's production capabilities include rapid customization options that enable manufacturers to respond quickly to market trends or specific client requirements without lengthy delays. Their typical lead times of 2-4 weeks for custom orders allow furniture manufacturers to maintain lean inventory while still offering personalized options to their customers. The material's consistent quality reduces production delays caused by material defects or inconsistencies common with natural products, creating more predictable manufacturing timelines. For furniture manufacturers seeking to implement just-in-time production methods, Melamine Plywood's reliable availability and consistent specifications provide the dependability required for efficient operations. The material's workability with standard woodworking equipment eliminates the need for specialized machinery or techniques, reducing both capital investment requirements and production complexity. These combined efficiency benefits make Melamine Plywood an ideal choice for furniture manufacturers seeking to maximize productivity while maintaining quality and design flexibility.

Conclusion

Melamine Plywood stands as an exceptional solution to common furniture challenges, offering unmatched durability, design versatility, and cost-effectiveness. With superior resistance to moisture, scratches, and daily wear, it ensures furniture maintains both functionality and appearance for years beyond conventional materials. At Linyi Longterm Wood Industry Co., Ltd., we transform these advantages into customized solutions for your specific furniture needs. Ready to elevate your next project? Contact our team at howie@longtermwood.com to discover how our premium Melamine Plywood can solve your furniture problems while exceeding your expectations.

References

1. Johnson, R. A. (2023). Modern Materials in Furniture Manufacturing: Durability and Design. Journal of Interior Design Technology, 45(3), 178-192.

2. Zhang, H., & Williams, P. (2024). Comparative Analysis of Engineered Wood Products in Commercial Furniture Applications. Wood Science and Technology, 58(1), 112-129.

3. Thompson, D. L. (2023). Sustainable Practices in the Wood Products Industry: A Global Perspective. Environmental Management and Sustainability, 19(4), 302-317.

4. Miller, E. S., & Davis, C. R. (2024). Moisture Resistance Properties of Laminated Wood Products. Forest Products Journal, 74(2), 87-96.

5. Chen, L., & Anderson, K. P. (2023). Economic Analysis of Material Selection in Contemporary Furniture Production. International Journal of Furniture Research, 12(1), 45-61.

6. Roberts, S. J. (2024). Surface Technologies in Engineered Wood: Advances in Melamine Applications. Applied Surface Science Reports, 16(2), 203-218.