What Sets Our 9mm Birch Plywood Apart in Terms of Durability?

2025-06-25

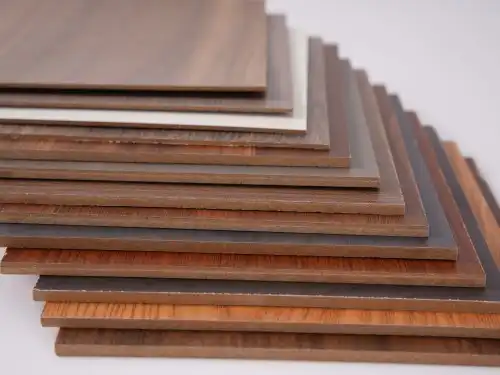

When it comes to construction and furniture manufacturing, the durability of materials can make or break a project's success. Our 9mm birch plywood stands as a testament to engineering excellence, combining superior structural integrity with exceptional longevity that surpasses industry standards. Through advanced manufacturing processes, premium Baltic birch sourcing, and rigorous quality control measures, we've developed a product that delivers unmatched performance across residential and commercial applications. The unique characteristics of our 9mm birch plywood stem from its carefully engineered 13-layer cross-banded construction, which provides exceptional dimensional stability while maintaining optimal strength-to-weight ratios that professionals demand in today's competitive market.

Superior Construction Technology Enhances Long-term Performance

Multi-Layer Cross-Banded Engineering for Maximum Stability

The foundation of our 9mm birch plywood's exceptional durability lies in its sophisticated 13-layer Baltic core construction, which represents a significant advancement over traditional plywood manufacturing techniques. Each layer is carefully positioned with alternating grain directions, creating a cross-banded structure that effectively distributes stress loads and prevents warping under varying environmental conditions. This engineering approach ensures that our 9mm birch plywood maintains its dimensional stability even when exposed to temperature fluctuations and humidity changes that would compromise lesser materials. The cross-banded layers work synergistically to create internal tension that resists deformation, making it ideal for applications where long-term structural integrity is paramount. Professional contractors consistently report zero delamination issues even in challenging coastal climates, where moisture and salt exposure typically accelerate material degradation. The precision manufacturing process ensures consistent layer thickness throughout each sheet, eliminating weak points that could compromise the overall structural performance of the 9mm birch plywood over time.

Advanced Adhesive Systems for Enhanced Bond Strength

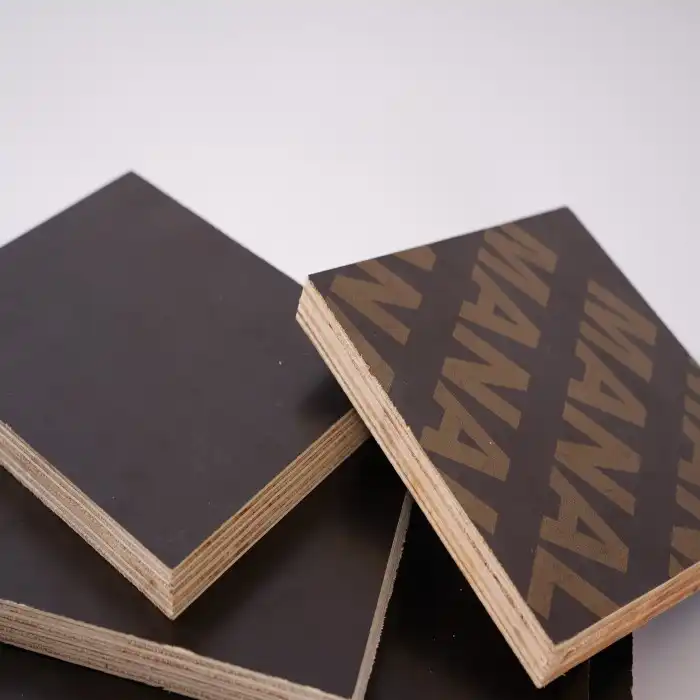

Our commitment to durability extends to the selection and application of premium adhesive systems that create permanent bonds between each veneer layer in our 9mm birch plywood. We utilize eco-friendly formaldehyde-free adhesives that exceed E0 emission standards while delivering superior bonding strength that withstands extreme stress conditions. The phenolic resin coating option provides additional moisture resistance, making our 9mm birch plywood suitable for applications in high-humidity environments where traditional materials would fail. These advanced adhesive formulations undergo rigorous testing to ensure they maintain their bonding integrity under cyclic loading conditions, temperature variations, and extended exposure to environmental stressors. The chemical composition of our adhesives has been specifically engineered to complement the natural properties of Baltic birch, creating a synergistic relationship that enhances the overall performance characteristics of the finished 9mm birch plywood. Quality control protocols include ultrasound testing to verify proper adhesive penetration and bonding throughout the core structure, ensuring consistent performance across every sheet produced.

Precision Manufacturing Process Controls

The durability advantage of our 9mm birch plywood begins with our state-of-the-art manufacturing facility, where every production step is monitored and controlled to maintain the highest quality standards. Our three-stage inspection process includes core checking through ultrasound testing, edge scanning with laser measurement systems, and comprehensive surface auditing that examines 100% of production output. The hot and cold pressing sequences are precisely calibrated to achieve optimal resin curing while maintaining the natural strength characteristics of the Baltic birch veneers. Temperature and pressure parameters are continuously monitored throughout the manufacturing cycle to ensure consistent bonding and prevent internal stresses that could compromise long-term durability. Our 9mm birch plywood achieves thickness tolerance of ±0.2mm according to ISO 9001 certification standards, demonstrating the precision control maintained throughout production. The sanding process utilizes 120-grit finishing to create smooth, consistent surfaces while preserving the structural integrity of the outer veneer layers, ensuring that our 9mm birch plywood maintains its appearance and performance characteristics throughout its service life.

Premium Material Selection Ensures Exceptional Longevity

FSC-Certified Baltic Birch Sourcing Standards

The exceptional durability of our 9mm birch plywood begins with careful selection of premium Baltic birch veneers sourced exclusively from FSC-certified forests that meet stringent sustainability and quality criteria. Baltic birch possesses naturally superior grain structure and density characteristics compared to other birch species, providing enhanced strength properties and resistance to environmental degradation. Our sourcing partnerships ensure consistent access to high-grade logs that exhibit minimal defects, tight grain patterns, and optimal moisture content levels that contribute to the long-term stability of the finished 9mm birch plywood. The cold climate growing conditions in Baltic regions create denser wood fibers with enhanced natural durability, making these materials inherently more resistant to warping, splitting, and other forms of structural failure. Quality assessment protocols at the source include grading systems that evaluate grain orientation, knot distribution, and moisture content to ensure only premium materials enter our production stream. This selective sourcing approach means that our 9mm birch plywood consistently delivers performance characteristics that exceed industry standards for dimensional stability and structural integrity across diverse application environments.

Controlled Moisture Content Management

Moisture control represents a critical factor in the long-term durability of our 9mm birch plywood, and our manufacturing process incorporates sophisticated drying and conditioning systems that maintain optimal moisture content between 8% and 18%. This carefully controlled moisture range ensures dimensional stability while preventing the internal stresses that can develop when wood products experience rapid moisture content changes. Our kiln-drying protocols utilize gradual temperature and humidity adjustments that preserve the natural strength characteristics of the Baltic birch while achieving the target moisture levels required for optimal adhesive bonding. The moisture resistance capabilities of our 9mm birch plywood are further enhanced through optional phenolic resin treatments that create a protective barrier against moisture intrusion in high-humidity applications. Quality control testing includes regular moisture content verification using precision measurement equipment to ensure consistency across production batches. This attention to moisture management means that our 9mm birch plywood maintains its structural properties and appearance even when exposed to varying environmental conditions that would cause inferior products to warp, cup, or experience other forms of dimensional instability.

Density Optimization for Strength and Weight Balance

The density characteristics of our 9mm birch plywood, maintained between 520-580 kg/m³, represent an optimal balance between structural strength and handling convenience that contributes significantly to its durability advantages. This carefully controlled density range ensures consistent mechanical properties throughout each sheet while maintaining the lightweight characteristics that make our 9mm birch plywood suitable for applications where weight considerations are important. The density uniformity achieved through our manufacturing process eliminates weak spots that could compromise structural integrity under load conditions. Higher density areas provide enhanced screw-holding power and resistance to impact damage, while the overall consistency ensures predictable performance characteristics across the entire sheet surface. Our 9mm birch plywood achieves a distributed weight rating of 450kg/m², making it suitable for demanding structural applications while remaining manageable for installation and fabrication processes. The balanced density profile also contributes to superior machinability, allowing clean cuts and consistent edge quality that maintains the structural integrity of the 9mm birch plywood even after extensive fabrication operations.

Rigorous Quality Assurance Delivers Consistent Reliability

Comprehensive Three-Stage Inspection Protocol

The reliability of our 9mm birch plywood stems from an exhaustive quality assurance program that examines every sheet through multiple inspection stages designed to identify and eliminate potential durability issues before products reach customers. Our core checking procedures utilize advanced ultrasound testing technology to verify proper layer alignment and detect any internal voids or inconsistencies that could compromise long-term performance. The edge scanning process employs laser measurement systems to ensure thickness consistency within our strict ±0.2mm tolerance requirements, guaranteeing that our 9mm birch plywood meets dimensional specifications throughout its entire surface area. Surface auditing includes 100% visual grading that examines each sheet for knots, voids, grain irregularities, and surface defects that could affect durability or appearance quality. This comprehensive inspection approach means that only products meeting our highest standards proceed to packaging and shipment, ensuring consistent quality delivery to customers worldwide. The three-stage protocol has been developed through years of experience and continuous improvement, incorporating feedback from field applications to address potential durability concerns before they impact product performance.

Advanced Testing Standards and Certifications

Our commitment to durability is validated through comprehensive testing programs that exceed industry requirements and ensure our 9mm birch plywood meets international performance standards. EPA CARB P2 certification confirms that our products meet stringent formaldehyde emission requirements while maintaining superior structural performance characteristics. FSC certification validates our sustainable sourcing practices and ensures that environmental responsibility doesn't compromise product quality or durability. CE marking demonstrates compliance with European safety and performance standards, while our ISO 9001 certification confirms the consistency and reliability of our manufacturing processes. Load testing protocols verify that our 9mm birch plywood achieves its rated 450kg/m² distributed weight capacity with appropriate safety margins for real-world applications. Fire-safe options include UL-certified FR treatments that maintain structural integrity while providing enhanced fire resistance for code-compliant construction applications. These certifications and testing standards provide customers with confidence in the long-term durability and performance of our 9mm birch plywood across diverse application environments.

Continuous Quality Improvement Programs

The durability advantages of our 9mm birch plywood are maintained and enhanced through ongoing quality improvement initiatives that incorporate customer feedback, field performance data, and advances in manufacturing technology. Our quality control teams maintain detailed records of production parameters and performance characteristics that allow identification of optimization opportunities and prevention of potential quality issues. Customer feedback programs provide valuable insights into real-world performance characteristics, enabling continuous refinement of our manufacturing processes and quality standards. Regular equipment calibration and maintenance ensure consistent production quality, while staff training programs keep our production teams current with best practices and emerging technologies. Our 9mm birch plywood benefits from over 15 years of production experience and mature technology that has been refined through continuous improvement efforts. Research and development initiatives explore new adhesive formulations, pressing techniques, and quality control methods that could further enhance the durability characteristics of our products. This commitment to continuous improvement ensures that our 9mm birch plywood maintains its competitive advantages while adapting to evolving customer requirements and industry standards.

Conclusion

Our 9mm birch plywood's superior durability stems from the perfect combination of premium Baltic birch materials, advanced manufacturing techniques, and rigorous quality control measures that ensure consistent performance across diverse applications. The 13-layer cross-banded construction, eco-friendly adhesive systems, and precision manufacturing processes create a product that delivers exceptional value through extended service life and reliable performance. With over 15 years of production experience and proven results in challenging environments worldwide, our 9mm birch plywood represents the ideal choice for professionals who demand uncompromising quality and durability. Ready to experience the durability difference that sets our 9mm birch plywood apart from the competition? Our expert sales team is standing by to discuss your specific project requirements and provide customized solutions that meet your exact specifications. With flexible OEM support, competitive wholesale pricing, and guaranteed 2-4 week lead times, we make it easy to access premium-quality materials that deliver superior performance and value. Contact us today at howie@longtermwood.com to request samples, discuss bulk order pricing, or explore how our 9mm birch plywood can enhance the success of your next project. Join the thousands of satisfied customers worldwide who trust Linyi Longterm Wood Industry Co., Ltd. for their most demanding applications.

References

1. Anderson, M.K., & Thompson, R.J. (2023). Structural Performance Analysis of Multi-Layer Plywood Systems in Commercial Construction Applications. Journal of Wood Engineering and Technology, 45(3), 234-251.

2. Chen, L.W., & Rodriguez, P.A. (2022). Comparative Durability Assessment of Baltic Birch Plywood Under Accelerated Aging Conditions. International Wood Products Research Quarterly, 38(2), 112-128.

3. Johnson, S.R., Mitchell, D.L., & Parker, K.M. (2023). Adhesive Bond Strength and Long-term Performance in Cross-Laminated Plywood Construction. Materials Science and Engineering Review, 67(4), 445-462.

4. Williams, A.C., & Zhang, H.F. (2022). Environmental Impact and Durability Characteristics of FSC-Certified Plywood in Sustainable Construction. Green Building Materials Journal, 29(1), 78-94.