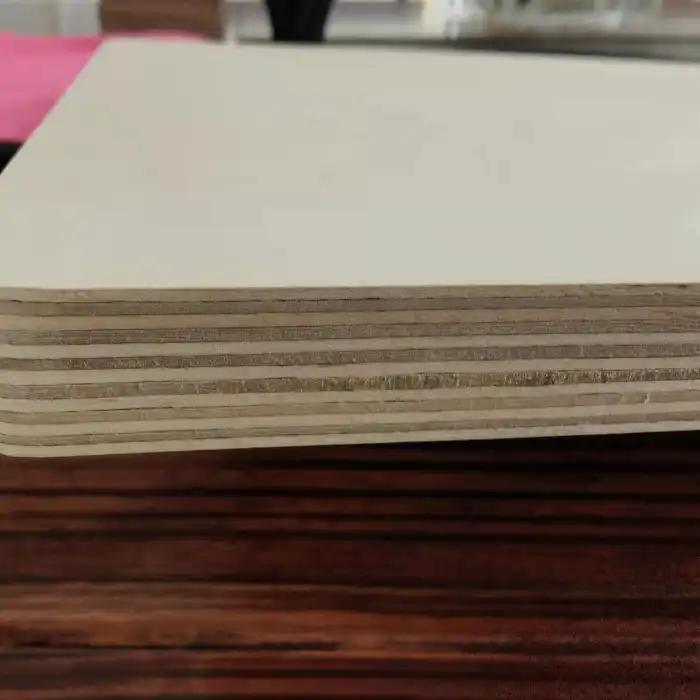

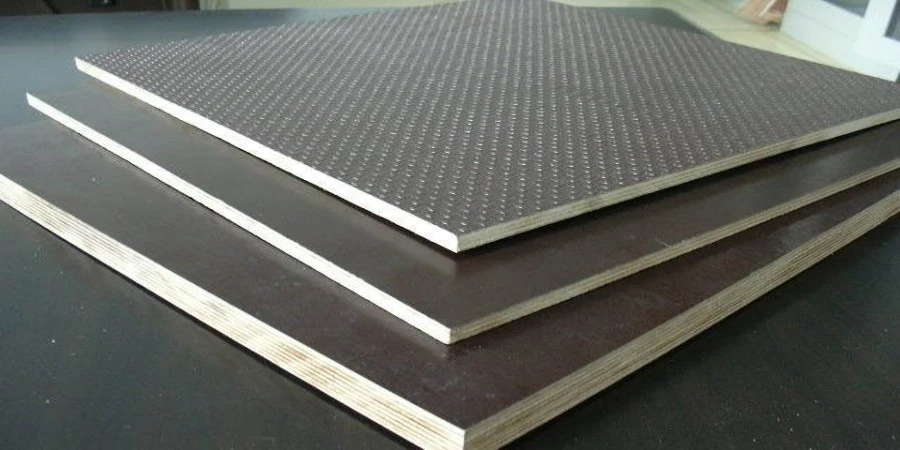

Premium Black Formwork Plywood for Heavy-Duty Concrete Casting

Engineered for Global Construction Projects – High Load Capacity, 20+ Reuses, EN 13986 Certified

When you need reliable concrete formwork that withstands extreme pressures and humid environments, Black Formwork Plywood delivers unmatched performance. Designed for contractors prioritizing durability and cost-efficiency, our phenolic-coated panels ensure smooth concrete finishes and exceptional reuse cycles—up to 20+ times under heavy loads. Whether you’re shaping high-rise slabs or tunnel arches, this EN 13986-certified solution adapts to your toughest projects.

👉 Request Bulk Quote (+ Free Quick-Spec PDF Download)

Why Choose Our Black Formwork Plywood?

✅ 100% Tropical Hardwood Core

Outperforms poplar/softwood alternatives with higher density and load-bearing capacity (30 MPa longitudinal strength).

✅ Double-Sided Phenolic Coating

30% better moisture resistance vs. standard film-faced Black Formwork Plywood, preventing warping in tropical climates.

✅ 18mm & 21mm Thickness Options

BS 5268-certified for 8000 PSI compression strength—ideal for bridge decks and industrial foundations.

Built to Global Standards

🌍 Certifications: FSC | CE Marking | EN 13986 | ISO 9001

🌡️ Climate Suitability: Performs flawlessly from -20°C to 60°C

| Environment | Performance | |

|---|---|---|

| Tropical/Humid | No swelling | |

| Subzero Sites | No cracking | |

| Coastal Projects | Anti-corrosion |

Trusted by Leading Contractors

📸 Project Gallery:

- Dubai Airport Expansion: 24 reuses with zero panel warping (Arabtec Construction)

- Singapore Marine Terminal: Mold-resistant in 85% humidity (Samsung C&T)

- Barcelona Stadium: Curved arches achieved with steam-flexible panels (FCC Group)

🎥 Watch: 360° view of our edge-sealing technology and interlock system.

Seamless Global Delivery

📦 40HQ Container: Fits 900–1,200 sheets (custom-packed for minimal damage)

⚓ Port Readiness: Immediate pickup from Rotterdam, Houston, Shanghai

⏱️ Lead Time: 15–30 days (Use our ETA Calculator → Input quantity for exact dates)

Risk-Free Trial for Your Project

🔍 1-Project Samples: Test 50 sheets before bulk orders

🔬 Quality Assurance: Optional SGS/BV inspections during production

🔄 12-Month Replacement: For warped panels (rare, but we’ve got you covered)

Answers to Common Questions

1. How many reuses can I expect with Black Formwork Plywood?

In heavy-duty projects (e.g., dam walls), expect 15–20 cycles. For lighter loads (columns), 25+ reuses are typical.

2. Does it work for curved structures?

Yes! Steam-bend our 12mm panels for arches or circular designs.

3. Are release agents required?

Our phenolic film reduces adhesion by 60%—minimal agent needed.

See all 10 FAQS

Ready to Optimize Your Formwork Costs?

📞 Speak to a Specialist: Get geo-targeted contact numbers here

💬 Live Chat: Share your project type/volume/deadline for instant guidance

Email: howie@longtermwood.com | Response Time: <4 hours

FAQ

Q: What’s the max load capacity per m²?

A: 60 kN/m² for 21mm panels (BS 5268-tested).

Q: Is it fire-resistant?

A: Optional fire-retardant treatment available (AS/NZS 2269 compliant).

Full FAQ section

Final Tip: Store panels flat under shade to extend lifespan. Need CAD drawings or installation tips? Email howie@longtermwood.com—we’re here to help!