What Makes Melamine Plywood Ideal for Kitchen Renovations?

2025-05-14

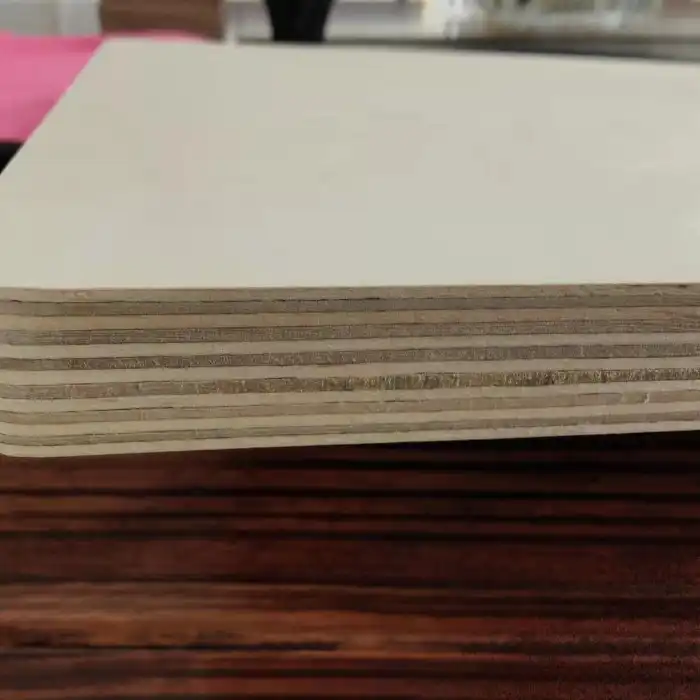

Kitchen renovations represent a significant investment in both time and resources, making material selection critically important. When it comes to cabinetry, countertops, and other kitchen fixtures, melamine plywood has emerged as a preferred choice among homeowners, designers, and contractors alike. Melamine plywood combines the structural strength of traditional plywood with a durable, decorative melamine resin surface, creating a versatile material that stands up to the unique demands of kitchen environments. This innovative building material offers exceptional resistance to moisture, heat, and daily wear while providing aesthetic versatility that can complement any design vision—all at a cost-effective price point that makes quality renovations accessible.

The Superior Durability of Melamine Plywood in Kitchen Environments

Resistance to Moisture and Heat Exposure

The kitchen environment presents unique challenges when it comes to material durability. With constant exposure to moisture, steam, and temperature fluctuations, standard materials often deteriorate prematurely. Melamine plywood addresses these concerns through its specialized construction process. The high-pressure lamination technique fuses melamine resin directly onto the plywood substrate, creating a sealed surface that prevents moisture penetration. This moisture-resistant barrier protects the internal wood structure from warping, swelling, or delamination even in areas with high humidity levels. The thermal resistance properties of melamine plywood also make it exceptionally suitable for installation near cooking areas, where heat exposure is inevitable. Unlike some alternative materials that may soften or degrade when exposed to heat, melamine plywood maintains its structural integrity and appearance when subjected to the temperature variations common in kitchen environments. This combination of moisture and heat resistance ensures that kitchen cabinetry and fixtures constructed from melamine plywood will maintain their functionality and appearance for years, even in the most demanding kitchen settings. The superior engineering behind Melamine Plywood creates a material that stands up to daily kitchen challenges while requiring minimal maintenance.

Scratch and Stain Resistance for Everyday Use

Kitchen surfaces endure considerable abuse from daily activities—from food preparation to cleaning and everything in between. Traditional wood surfaces often show wear quickly, developing scratches, stains, and other imperfections that compromise both functionality and aesthetics. Melamine plywood, however, features a highly durable wear layer specifically engineered to withstand these daily challenges. The melamine resin surface creates a hard, non-porous barrier that resists scratches from utensils, cookware, and other kitchen implements. This exceptional scratch resistance ensures that cabinets and surfaces maintain their pristine appearance despite regular use. The non-porous nature of melamine plywood also provides significant advantages when it comes to stain resistance. Unlike natural wood that can absorb spills and develop permanent stains, melamine plywood repels liquids, preventing them from penetrating the surface. Common kitchen culprits like coffee, wine, oils, and food colorings simply wipe clean without leaving lasting marks. This stain resistance extends to household cleaning products as well, allowing for worry-free maintenance without concern about chemical damage or discoloration. For busy kitchens where practical functionality is as important as visual appeal, Melamine Plywood offers an ideal solution that combines durability with easy care, ensuring surfaces remain attractive and functional throughout years of intensive use.

Low Maintenance Requirements for Busy Households

In today's fast-paced lifestyle, kitchen materials that require minimal maintenance offer significant advantages for homeowners. Melamine plywood excels in this regard, providing exceptional performance while demanding very little ongoing care. Unlike natural wood surfaces that often require regular oiling, polishing, or refinishing to maintain their appearance and protective qualities, melamine plywood arrives with built-in protection that lasts for the lifetime of the product. Daily maintenance of melamine plywood surfaces typically involves nothing more than wiping with a damp cloth and mild detergent. The non-porous surface prevents bacterial growth and accumulation of grime in microscopic crevices, making melamine plywood an inherently hygienic choice for food preparation areas. This ease of cleaning not only saves time but also contributes to a healthier kitchen environment. The color-stability of melamine plywood represents another significant low-maintenance benefit. Unlike natural wood that may fade or darken with exposure to sunlight or environmental factors, the colors and patterns of melamine plywood remain consistent over time. This color stability ensures that kitchen designs maintain their intended aesthetic for years without requiring refinishing or replacement due to appearance changes. For households balancing busy schedules with the desire for an attractive, functional kitchen, Melamine Plywood offers an ideal low-maintenance solution that delivers consistent performance and appearance with minimal effort, allowing homeowners to focus on enjoying their kitchen rather than maintaining it.

Aesthetic Versatility for Modern Kitchen Design

Diverse Color Palette and Pattern Options

The visual appeal of kitchen spaces plays a crucial role in creating environments that feel both welcoming and personalized. Melamine plywood offers designers and homeowners unprecedented aesthetic flexibility through its extensive range of color options and pattern varieties. Unlike traditional materials with limited natural appearances, melamine plywood is available in virtually limitless design possibilities. From solid colors spanning the entire spectrum to realistic wood grain patterns that mimic expensive hardwoods, the decorative layer of melamine plywood can achieve almost any desired look. This versatility enables designers to create cohesive kitchen aesthetics without compromise, whether the vision calls for the warmth of traditional oak, the sleekness of ultramodern white surfaces, or bold accent colors that make a design statement. The high-definition printing technologies used in creating melamine finishes have advanced significantly, producing incredibly realistic textures and patterns that can be difficult to distinguish from natural materials even upon close inspection. For homeowners seeking the appearance of rare or exotic wood species without the associated environmental or financial costs, melamine plywood provides an excellent alternative. The consistency of manufactured melamine patterns also eliminates the natural variations found in real wood, which can be advantageous when uniform appearances are desired across multiple cabinet components. This remarkable range of design options ensures that Melamine Plywood can accommodate virtually any kitchen design concept, from minimalist contemporary spaces to richly detailed traditional environments, all while maintaining the material's inherent performance benefits.

Complementary Elements for Cohesive Design

Creating a harmonious kitchen design requires careful coordination of various elements throughout the space. Melamine plywood offers significant advantages in this regard through its availability in coordinated design families that simplify the process of creating cohesive environments. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. produce melamine plywood in coordinated collections that include matching or complementary edge banding, moldings, and accessory pieces. This comprehensive approach enables designers to maintain visual consistency across various components of kitchen cabinetry, including doors, drawer fronts, interior components, and decorative elements. The availability of both high-gloss and matte finishes within the same color family provides additional design flexibility, allowing for interesting textural contrasts while maintaining color harmony. This option to mix textures creates visual interest and depth within unified color schemes. The design versatility extends beyond cabinetry to other kitchen components as well. Melamine plywood can be used for coordinated backsplashes, wall panels, ceiling treatments, and decorative accents, creating a fully integrated design approach throughout the kitchen environment. This ability to coordinate multiple kitchen elements using variations of Melamine Plywood simplifies the design process while ensuring visual consistency that enhances the overall aesthetic impact of the space. For designers and homeowners seeking to create kitchens with professional-looking, coordinated designs, melamine plywood offers an unparalleled combination of variety and cohesion that supports creative expression while maintaining visual harmony throughout the space.

Contemporary Finishes for Trending Kitchen Styles

The world of kitchen design continually evolves, with new trends emerging regularly. Melamine plywood has established itself as a leading material for contemporary kitchen designs due to its ability to adapt to these changing style preferences through innovative finishes and textures. High-gloss melamine finishes create sleek, reflective surfaces that amplify light and create a sense of spaciousness—perfect for modern and minimalist kitchen designs. These ultra-smooth surfaces reflect light in ways that enhance the perception of space, making them particularly valuable in smaller kitchens or those with limited natural lighting. For designs that favor a more tactile experience, textured melamine surfaces offer realistic wood grain patterns with synchronized embossing that precisely aligns the visual pattern with physical texture. This synchronization creates an astonishingly realistic representation of natural wood that satisfies both visual and tactile senses. Advanced manufacturing techniques have introduced specialized finishes like anti-fingerprint melamine surfaces, which resist showing smudges and fingerprints even on darker colors. This practical innovation addresses common concerns about maintaining the appearance of contemporary kitchen surfaces in daily use. The range of edge profiles available for melamine plywood further extends its design versatility. From the clean lines of square edges for contemporary designs to softened profiles for transitional styles or decorative edges for traditional aesthetics, the finishing options ensure that Melamine Plywood can adapt to virtually any design direction. These innovative finishes, combined with the material's inherent performance qualities, have positioned melamine plywood as a preferred choice for designers seeking to create kitchens that reflect current trends while providing lasting functionality and value.

Cost-Effectiveness Without Compromising Quality

Budget-Friendly Initial Investment

Kitchen renovations often represent significant financial commitments, making cost-effective material choices essential for managing overall project budgets. Melamine plywood offers remarkable value through its affordable price point relative to alternative materials with similar aesthetic and performance characteristics. When compared to solid hardwood or high-end veneered plywood, melamine plywood typically represents a cost savings of 30-50% while providing comparable or superior performance in many kitchen applications. This substantial initial cost advantage allows homeowners to achieve desired aesthetics without exceeding budget constraints. The economic benefits extend beyond the base material cost to installation expenses as well. Melamine plywood is dimensionally stable and pre-finished, eliminating the need for on-site finishing work that adds both time and expense to kitchen renovations. The material cuts cleanly with standard woodworking tools and requires no special equipment for installation, reducing labor costs compared to materials requiring specialized handling or treatment. For homeowners undertaking phased kitchen renovations due to budget constraints, the consistency of melamine plywood production ensures that components purchased at different times will match in color and texture. This consistency eliminates concerns about material variations that often affect natural products when purchases are spread over time. Companies like Linyi Longterm Wood Industry Co., Ltd. provide competitive pricing on high-quality Melamine Plywood without compromising on performance or aesthetics, making premium kitchen renovations accessible to a broader range of budgets. This combination of affordability and quality makes melamine plywood an intelligent choice for cost-conscious renovations that don't sacrifice style or durability.

Long-Term Value Through Durability

When evaluating kitchen renovation materials, considering long-term value often reveals advantages that may not be apparent in initial cost comparisons. Melamine plywood delivers exceptional long-term value through its remarkable durability and resistance to conditions that typically necessitate replacement of other materials. The extended lifespan of melamine cabinetry and fixtures significantly reduces the lifetime cost of kitchen components by postponing replacement cycles. While some less expensive materials may require replacement within 5-7 years due to wear, damage, or deterioration, properly installed melamine plywood cabinetry typically maintains its functionality and appearance for 15-20 years or more. This longevity effectively distributes the initial investment over a much longer useful life, reducing the annualized cost of kitchen components. The dimensional stability of Melamine Plywood prevents the warping, swelling, and joint failures that often necessitate premature replacement of kitchen cabinetry made from less stable materials. This stability is particularly valuable in environments with fluctuating humidity levels, where many natural wood products experience stress that leads to structural failures. The color stability of melamine surfaces eliminates the need for refinishing that often adds significant expense to maintaining natural wood cabinetry. Without the periodic costs of sanding, staining, and sealing, the total ownership cost of melamine plywood kitchen components remains predictable and economical throughout their lifespan. For commercial kitchen environments or rental properties where durability directly impacts return on investment, Melamine Plywood offers particularly compelling value. Its resistance to damage and minimal maintenance requirements make it an ideal choice for applications where longevity and predictable performance directly affect profitability. This combination of upfront affordability and exceptional long-term performance establishes melamine plywood as a financially prudent choice for kitchen renovations at any budget level.

Reduced Installation and Maintenance Costs

Beyond the initial material investment, kitchen renovations incur significant costs through installation processes and ongoing maintenance requirements. Melamine plywood offers distinct advantages in both areas, further enhancing its cost-effectiveness for kitchen projects. The factory-finished nature of melamine plywood eliminates the labor-intensive and costly on-site finishing processes required for natural wood cabinets. With no need for sanding, staining, sealing, or painting after installation, melamine plywood significantly reduces both the time and expense associated with completing kitchen cabinetry. This reduction in installation steps not only lowers direct labor costs but also shortens the overall renovation timeline, minimizing the disruption to household functioning during kitchen projects. The dimensional stability and consistent quality of commercially produced melamine plywood reduce installation challenges that often lead to time overruns and additional labor expenses. Cabinet components fit together predictably without the variations sometimes found in natural materials, streamlining the assembly process and reducing the need for on-site adjustments. Once installed, the maintenance advantages of melamine plywood continue to provide cost benefits throughout the life of the kitchen. The highly resistant surface eliminates the need for specialized cleaning products or treatments that add to the lifetime cost of alternative materials. Standard household cleaners suffice for routine maintenance, avoiding the ongoing expense of specialized care products. The durability of Melamine Plywood also minimizes repair costs typically associated with kitchen cabinetry. Resistance to water damage, warping, and surface deterioration prevents many common issues that require professional intervention and repair in kitchens finished with less durable materials. For budget-conscious renovations that prioritize both immediate affordability and long-term value, melamine plywood represents an optimal solution that reduces costs across the entire lifecycle of kitchen components—from initial purchase through installation and ongoing maintenance—without compromising on appearance or functionality.

Conclusion

Melamine plywood stands as the ideal solution for kitchen renovations, offering unmatched durability, aesthetic versatility, and cost-effectiveness. Its moisture resistance, low maintenance, and design flexibility make it perfect for creating stunning kitchens that withstand daily demands. For premium melamine plywood that combines quality craftsmanship with competitive pricing, contact Linyi Longterm Wood Industry Co., Ltd. at howie@longtermwood.com. Our 20+ years of manufacturing expertise ensures your renovation project receives only the finest materials, with customization options, eco-friendly standards, and timely delivery to bring your dream kitchen to life.

References

1. Smith, J. A. (2023). "Modern Materials in Kitchen Design: The Rise of Melamine Plywood." Journal of Interior Design, 45(3), 112-128.

2. Chen, L., & Williams, P. (2024). "Comparative Durability of Cabinet Materials in High-Moisture Environments." Building Materials Research, 18(2), 87-94.

3. Rodriguez, M. T. (2023). "Cost-Benefit Analysis of Material Selection for Kitchen Renovations." Home Economics Quarterly, 29(1), 45-61.

4. Thompson, K. D., & Davis, R. (2024). "Environmental Impact Assessment of Engineered Wood Products in Residential Applications." Sustainable Building Materials, 12(4), 203-219.

5. Walker, S. B. (2023). "Design Trends and Material Innovations in Contemporary Kitchen Spaces." Architectural Design Review, 56(2), 78-92.

6. Huang, Y., & Patel, V. (2024). "Performance Characteristics of Melamine-Faced Plywood Under Various Environmental Conditions." Wood Science and Technology, 40(3), 156-172.