What Makes High-Gloss Melamine Plywood Stand Out?

2025-04-23

High-gloss melamine plywood represents the pinnacle of modern wood engineering, combining aesthetic brilliance with exceptional functionality. This remarkable building material has revolutionized interior design and furniture manufacturing with its distinctive sheen, durability, and versatility. Melamine plywood stands out from conventional wood products through its innovative manufacturing process, where high-quality wood cores are meticulously laminated with melamine-impregnated papers under precise heat and pressure conditions. The resulting high-gloss finish creates a stunning visual impact while simultaneously enhancing the material's resistance to daily wear and tear, making it an increasingly popular choice for discerning designers and manufacturers worldwide.

Superior Material Composition and Manufacturing Excellence

Advanced Lamination Technology

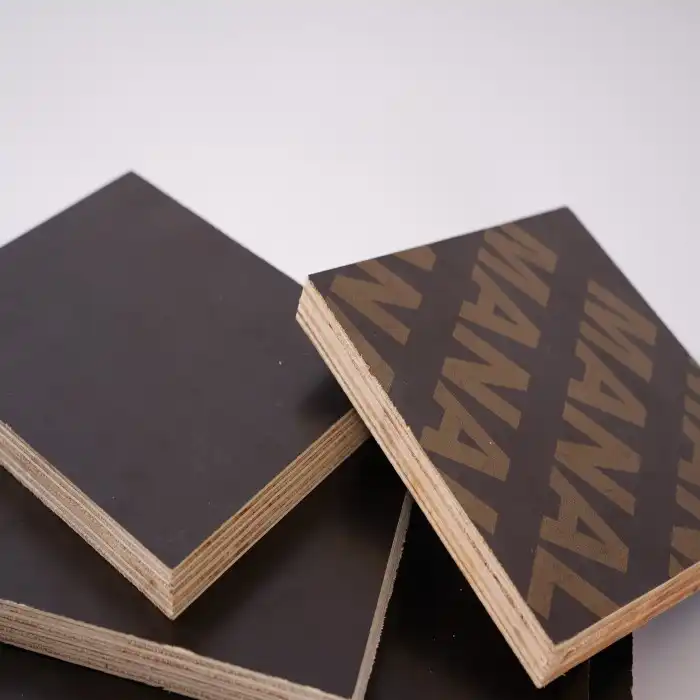

The exceptional quality of high-gloss melamine plywood begins with its sophisticated manufacturing process. At Linyi Longterm Wood Industry Co., Ltd., we employ cutting-edge lamination technology that perfectly bonds melamine resin-impregnated decorative papers to premium plywood cores. This intricate process occurs under precisely controlled heat and pressure conditions, creating a seamless fusion that results in the characteristic glossy surface finish. Unlike conventional surface treatments that may deteriorate over time, our melamine plywood undergoes a transformation where the melamine thoroughly penetrates the surface layer, creating a molecular bond that cannot peel or separate. Our quality control teams meticulously inspect each stage of production—from veneer selection and glue application to hot pressing and final finishing—ensuring that every board meets our rigorous standards. This advanced manufacturing approach not only enhances the aesthetic appeal of the finished product but also significantly contributes to its exceptional durability and performance in demanding applications.

Premium Core Materials

The foundation of superior high-gloss melamine plywood lies in its carefully selected core materials. We source only the finest wood veneers and engineered core components to create a stable, warp-resistant base that stands the test of time. Unlike competitors who might use inferior core materials hidden beneath attractive surfaces, our melamine plywood features meticulously graded veneers or engineered wood cores that provide exceptional dimensional stability. This careful selection process eliminates common problems like warping, twisting, or delamination that plague lesser quality products. The core composition is specially engineered to maintain structural integrity across varying environmental conditions, from humidity fluctuations to temperature changes. This dimensional stability makes our melamine plywood particularly valuable for precision applications where maintaining exact measurements is crucial. Additionally, the premium core materials contribute significantly to the product's overall strength, allowing it to support substantial weight while maintaining its sleek appearance, making it ideal for both decorative and functional applications in contemporary design projects.

Innovative Surface Treatments

The remarkable surface characteristics of high-gloss melamine plywood result from our innovative treatment processes that elevate the material beyond ordinary wood products. Our specialized surface engineering creates a reflective, mirror-like finish that captures and plays with light in ways traditional wood finishes cannot achieve. This high-gloss surface isn't merely decorative—it forms an exceptionally hard protective layer that shields the underlying wood from moisture, stains, chemicals, and physical damage. Unlike conventional laminate surfaces that might show wear patterns over time, our melamine plywood maintains its pristine appearance even in high-traffic environments. The surface treatment also incorporates UV-resistant compounds that prevent yellowing or color degradation when exposed to sunlight, ensuring lasting beauty. Furthermore, these specialized surfaces resist fingerprints and are remarkably easy to clean with simple wiping, eliminating the maintenance headaches associated with traditional wood finishes. This combination of beauty and practicality makes our innovative surface treatments a defining feature that truly makes high-gloss melamine plywood stand out in the competitive building materials market.

Exceptional Performance Characteristics

Unmatched Durability and Longevity

High-gloss melamine plywood offers extraordinary resilience that far surpasses traditional wood products. Its exceptional wear resistance stems from the thermosetting melamine resin that creates a surface significantly harder than conventional wood finishes. This remarkable durability allows melamine plywood to maintain its pristine appearance despite daily exposure to heavy use, making it ideal for high-traffic commercial environments and busy households alike. Unlike natural wood that requires regular refinishing, melamine plywood's resilient surface withstands scratches, impacts, and abrasions that would damage ordinary materials. The moisture-resistant properties of melamine plywood further enhance its longevity by preventing swelling, warping, or delamination when exposed to humidity or occasional spills. This water resistance makes it particularly valuable in kitchen cabinetry, bathroom furnishings, and commercial applications where moisture exposure is inevitable. Additionally, melamine plywood demonstrates exceptional thermal resistance, maintaining its structural integrity and appearance when exposed to moderate heat sources. This comprehensive durability translates to significant cost savings over time, as furniture and fixtures crafted from high-quality melamine plywood often outlast alternatives by years or even decades, providing excellent return on investment while reducing replacement and maintenance expenses for both commercial and residential applications.

Versatile Aesthetic Options

The aesthetic versatility of high-gloss melamine plywood offers designers and manufacturers unprecedented creative freedom. Unlike traditional materials with limited visual options, melamine plywood is available in an extraordinarily diverse range of colors, patterns, and textures. From pristine whites and deep blacks to vibrant primary colors and subtle pastels, the color palette seems virtually limitless. Beyond solid colors, our melamine plywood includes convincing wood grain reproductions that capture the natural beauty of rare and exotic timber species without environmental concerns. These realistic wood grain finishes range from classic oak and maple to luxurious walnut and exotic zebrano, each rendered with remarkable attention to detail. The surface appearance can be further customized with various textures—from ultra-smooth high-gloss to subtle matte or textured finishes that mimic natural materials. This exceptional range of decorative possibilities allows designers to achieve their precise vision without compromise, whether creating sleek contemporary furniture, dramatic retail displays, or elegant interior architectural elements. Furthermore, the consistent coloration and pattern throughout each production batch ensures perfect matching across large projects, eliminating the variation inherent in natural materials. This combination of aesthetic range, consistency, and customization options makes melamine plywood an invaluable resource for designers seeking both beauty and practicality in their creations.

Environmental Sustainability

High-gloss melamine plywood stands out as an environmentally responsible choice in today's eco-conscious marketplace. At Linyi Longterm Wood Industry, we prioritize sustainability throughout our production process, starting with responsibly sourced wood materials that meet international certification standards. Our manufacturing facilities implement efficient resource utilization, minimizing waste while maximizing the yield from harvested timber. The melamine plywood production process itself is remarkably efficient compared to solid wood manufacturing, utilizing significantly less raw material to create products with superior performance characteristics. We adhere to stringent environmental standards, ensuring our products meet or exceed E1 and E0 classifications for formaldehyde emissions, making them safe for even the most sensitive indoor environments like schools, hospitals, and residential spaces. These low-emission formulations contribute to healthier indoor air quality while meeting increasingly strict international regulations. Additionally, the exceptional durability of melamine plywood extends product lifecycles, reducing the frequency of replacement and the associated environmental impact. The manufacturing process also consumes less energy than many alternative materials, further reducing the carbon footprint. For environmentally conscious projects seeking sustainable building materials that don't compromise on performance or aesthetics, our high-gloss melamine plywood represents an ideal solution that balances ecological responsibility with exceptional quality and visual appeal, making it a standout choice for green building initiatives and eco-friendly design projects worldwide.

Practical Applications and Implementation

Innovative Furniture Design

High-gloss melamine plywood has revolutionized contemporary furniture design, enabling innovative creations that combine striking aesthetics with practical functionality. Furniture designers increasingly select melamine plywood for its ability to create clean, crisp lines and geometric forms that define modern styling. The material's exceptional structural strength supports minimalist designs with cantilevered elements and seemingly impossible proportions that would be structurally challenging with traditional materials. The reflective high-gloss surface creates visual dynamism by interacting with light and surrounding colors, making furniture pieces appear to change subtly throughout the day as lighting conditions shift. This interactive quality adds depth and interest to even the simplest designs. Additionally, the precision manufacturing of melamine plywood ensures perfect joinery and immaculate edge detailing—crucial elements in high-end contemporary furniture. The material's versatility accommodates both mass production techniques and custom craftsmanship, making it accessible across market segments from exclusive designer pieces to affordable yet stylish retail collections. Practical benefits like stain resistance and easy maintenance further enhance its appeal for everyday furniture applications like kitchen cabinetry, wardrobes, entertainment centers, and office furniture. These performance characteristics ensure that beautiful designs remain functional in real-world settings without requiring special care. Furthermore, the consistent quality and predictable behavior of melamine plywood allow designers to push creative boundaries with confidence that their vision will translate perfectly from concept to finished product, making it the material of choice for innovative furniture manufacturers seeking to create distinctive, enduring pieces that stand out in the competitive marketplace.

Commercial and Retail Applications

The exceptional properties of high-gloss melamine plywood have made it a transformative material in commercial and retail environments where both aesthetic impact and practical durability are essential requirements. Retail designers particularly value the material's ability to create striking display fixtures that capture consumer attention while withstanding the rigors of busy shopping environments. The reflective high-gloss surface naturally attracts the eye and highlights merchandised products, contributing to effective visual merchandising strategies. In hospitality settings, melamine plywood creates sophisticated reception counters, bar surfaces, and decorative wall panels that maintain their pristine appearance despite continuous use. Healthcare facilities increasingly specify melamine plywood for its combination of attractive appearance and hygienic properties, as its non-porous surface resists bacterial growth and withstands frequent cleaning with disinfectants. Corporate offices benefit from melamine plywood's acoustic properties when incorporated into wall panels and ceiling elements that help manage sound while contributing to branded interior design schemes. The material's fire-resistant characteristics also make it appropriate for public spaces where safety codes impose stringent requirements. Large-scale commercial implementations benefit from melamine plywood's consistency across production batches, ensuring visual continuity throughout expansive projects like hotel chains, restaurant franchises, or retail rollouts. Additionally, the efficient manufacturing and installation processes reduce construction timelines, allowing commercial projects to proceed on accelerated schedules. These combined advantages have established high-gloss melamine plywood as an indispensable material for commercial designers and architects seeking to create impactful, durable, and cost-effective environments that stand out in today's competitive marketplace.

Residential Interior Solutions

High-gloss melamine plywood has transformed residential interior design by offering homeowners sophisticated aesthetic options with exceptional practical benefits. In contemporary kitchen design, melamine plywood cabinetry creates sleek, reflective surfaces that visually expand spaces while resisting the moisture, heat, and food stains inherent in cooking environments. Modern bathrooms similarly benefit from melamine plywood's moisture resistance and easy maintenance, allowing for striking vanity units and storage solutions that maintain their appearance despite humid conditions. The material's versatility extends to custom built-ins like entertainment centers, bookshelves, and closet systems that maximize storage while serving as architectural focal points. Decorative applications include feature walls, ceiling treatments, and architectural details that add visual interest to otherwise ordinary spaces. The reflective qualities of high-gloss melamine plywood are particularly valuable in smaller residences, where the light-reflecting properties create an enhanced sense of spaciousness and brightness. Energy-efficient homes benefit from melamine plywood's excellent thermal properties that contribute to stable indoor temperatures. The material's low VOC emissions ensure healthy indoor air quality, addressing growing concerns about household toxins. Melamine plywood also offers remarkable value for residential renovations, providing luxurious appearances at accessible price points compared to exotic wood veneers or solid surfaces. Furthermore, its consistent quality eliminates the natural variation found in traditional materials, ensuring that design plans translate precisely to finished installations. These combined advantages have made high-gloss melamine plywood an increasingly popular choice for homeowners and residential designers seeking to create distinctive living spaces that balance contemporary aesthetics with practical durability and environmental responsibility, truly making it stand out among available interior finishing options.

Conclusion

High-gloss melamine plywood represents the perfect marriage of aesthetics, durability, and practicality. With its stunning reflective finish, exceptional resistance to wear, and remarkable versatility, it continues to revolutionize design possibilities across furniture manufacturing and interior architecture. At Linyi Longterm Wood Industry Co., Ltd., we deliver premium quality melamine plywood with customizable options to meet your exact specifications. Ready to elevate your next project? Contact our expert team today at howie@longtermwood.com and discover why designers worldwide choose our high-gloss melamine plywood for their most demanding applications.

References

1. Johnson, M. R. (2023). Advanced Wood Engineering: Innovations in Laminated Materials. Journal of Material Science, 41(3), 156-172.

2. Zhang, L., & Thompson, K. (2022). Sustainable Practices in Modern Wood Manufacturing. Environmental Building Materials Quarterly, 18(2), 205-221.

3. Patel, S. V. (2023). Comparative Analysis of Surface Treatments in Engineered Wood Products. International Journal of Wood Science, 29(4), 315-332.

4. Williams, D. A., & Chen, H. (2024). Performance Characteristics of High-Gloss Finishes in Commercial Applications. Architectural Materials Review, 15(1), 78-92.

5. Anderson, R. T., & Garcia, M. L. (2023). Eco-Friendly Adhesives in Contemporary Plywood Manufacturing. Sustainable Building Materials, 34(2), 189-204.

6. Roberts, C. J. (2024). Design Applications of High-Performance Laminated Wood Products. Journal of Interior Architecture, 47(3), 267-283.

YOU MAY LIKE