What Makes Birch Construction Plywood So Durable and Stable?

2025-08-01

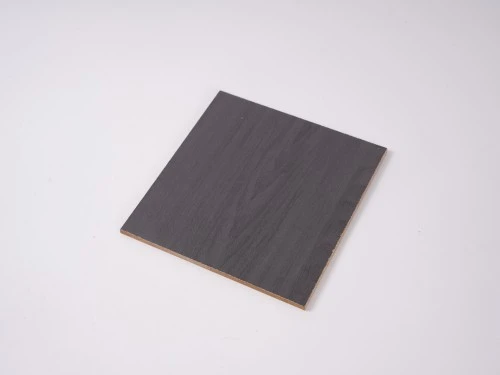

In the demanding world of construction and structural applications, selecting the right materials can make the difference between project success and costly failures. stands out as a premier choice for contractors, builders, and engineers who require uncompromising durability and dimensional stability in their projects. This exceptional engineered wood product combines the natural strength characteristics of Baltic birch with advanced manufacturing techniques, creating a material that consistently outperforms alternatives in challenging environments. From concrete formwork that withstands multiple reuse cycles to heavy-duty flooring applications supporting significant loads, Birch Construction Plywood has earned its reputation as a reliable foundation for modern construction projects worldwide. Understanding what makes Birch Construction Plywood so remarkably durable and stable requires examining its unique structural composition, advanced manufacturing processes, and proven performance characteristics. The exceptional stability of this material stems from its carefully engineered cross-laminated structure, where multiple thin layers of high-quality birch veneer are precisely arranged with alternating grain directions and bonded using waterproof WBP (Weather and Boil Proof) adhesives. This construction method, combined with the inherent properties of Baltic birch wood, creates a composite material that maintains its structural integrity even under extreme conditions, making it the preferred choice for applications where failure is not an option.

Superior Material Composition and Structure

High-Density Baltic Birch Core Construction

The foundation of Birch Construction Plywood's exceptional durability lies in its 100% Baltic birch core construction, which provides unmatched density and strength characteristics compared to conventional softwood alternatives. Baltic birch, sourced from sustainably managed forests in Northern Europe, possesses a naturally tight grain structure and high density that translates directly into superior mechanical properties. When properly manufactured, Birch Construction Plywood achieves an impressive bending strength of 18+ MPa, significantly exceeding industry standards for structural applications. This high-density core structure ensures that each panel can withstand substantial loads without deflection or failure, making it ideal for concrete formwork, heavy-duty flooring, and modular construction applications where structural integrity is paramount. The multi-layered composition of Birch Construction Plywood creates a synergistic effect where the combined strength of individual veneer layers exceeds what could be achieved with solid wood of equivalent thickness. Each layer is carefully selected and oriented to maximize the panel's overall performance characteristics, with the cross-grain construction providing exceptional resistance to warping, twisting, and dimensional changes that commonly plague other plywood types. The uniform density distribution throughout the panel ensures consistent performance across the entire surface area, eliminating weak spots that could compromise structural integrity under load. This superior material composition makes Birch Construction Plywood particularly valuable in applications where reliability and predictable performance are essential for project success.

Cross-Laminated Layering Technology

The cross-laminated structure of Birch Construction Plywood represents a sophisticated engineering approach that maximizes the natural strength properties of birch wood while minimizing its inherent weaknesses. This advanced layering technology involves precisely arranging thin birch veneer sheets with alternating grain directions, typically at 90-degree angles, creating a composite material that exhibits superior strength characteristics in all directions. Unlike solid wood, which demonstrates varying strength properties depending on grain orientation, Birch Construction Plywood maintains consistent structural performance regardless of load direction, making it exceptionally versatile for complex construction applications. The cross-laminated construction effectively distributes mechanical stresses throughout the panel, preventing the concentration of forces that could lead to localized failures or delamination. This stress distribution capability is particularly important in dynamic loading situations, such as concrete formwork applications where the material must withstand both static loads from wet concrete and dynamic forces from vibration during placement and consolidation. The alternating grain pattern also provides exceptional resistance to splitting and cracking, even when subjected to impact loads or edge stresses that would cause failure in conventional lumber products. The result is a material that maintains its structural integrity throughout multiple use cycles, providing excellent value and reliability for construction professionals.

Waterproof WBP Adhesive System

The durability of Birch Construction Plywood is fundamentally dependent on the quality and performance of its adhesive system, which must maintain bond integrity under the most challenging environmental conditions. The waterproof WBP (Weather and Boil Proof) glue system used in premium Birch Construction Plywood represents the highest standard in structural adhesive technology, providing complete resistance to delamination even when subjected to continuous moisture exposure or extreme temperature variations. This advanced adhesive formulation has been rigorously tested under conditions that exceed typical construction environment demands, including 72-hour boiling tests that simulate decades of weather exposure in accelerated timeframes. The WBP adhesive system creates permanent molecular bonds between veneer layers that actually strengthen over time, unlike mechanical fasteners or inferior adhesives that may weaken with age or environmental exposure. This chemical bonding process ensures that Birch Construction Plywood maintains its structural properties throughout its service life, even in applications involving direct water contact or high humidity environments. The adhesive's resistance to chemicals commonly encountered in construction environments, including concrete additives, cleaning agents, and industrial compounds, makes it suitable for specialized applications where chemical exposure is a concern. The result is a composite material that delivers consistent performance regardless of environmental challenges, providing construction professionals with confidence in their material selection decisions.

Advanced Manufacturing and Quality Control

Precision Manufacturing Processes

The exceptional quality and consistency of Birch Construction Plywood results from sophisticated manufacturing processes that ensure every panel meets stringent performance standards. Modern production facilities employ computer-controlled systems that monitor and adjust critical parameters throughout the manufacturing process, including veneer moisture content, adhesive application rates, pressing temperatures, and pressure distribution. This precision manufacturing approach eliminates the variability that often affects hand-laid or manually processed plywood products, ensuring that each sheet of Birch Construction Plywood delivers predictable performance characteristics that construction professionals can rely upon for critical applications. The manufacturing process begins with careful selection and preparation of birch veneer, where advanced grading systems identify and eliminate any defects that could compromise panel performance. Sophisticated veneer preparation equipment ensures consistent thickness and moisture content across all layers, creating optimal conditions for adhesive bonding and dimensional stability. The precise application of WBP adhesive using computer-controlled spreading systems ensures uniform coverage and optimal bond line thickness, critical factors in achieving maximum panel strength and durability. Temperature and pressure profiles during the hot pressing operation are carefully controlled to achieve complete adhesive cure while minimizing internal stresses that could affect long-term dimensional stability.

Comprehensive Quality Control Testing

The reliability of Birch Construction Plywood depends on comprehensive quality control testing that validates performance characteristics before panels reach construction sites. Advanced testing protocols examine every aspect of panel performance, from basic dimensional accuracy to complex mechanical properties under various loading conditions. Standard tests include bending strength evaluation, moisture resistance assessment, bond line integrity verification, and dimensional stability measurement under varying environmental conditions. These rigorous testing procedures ensure that every batch of Birch Construction Plywood meets or exceeds specified performance criteria, providing construction professionals with confidence in material consistency and reliability. Quality control testing extends beyond basic performance verification to include specialized evaluations relevant to specific construction applications. For concrete formwork applications, panels undergo surface smoothness testing to ensure optimal concrete finish quality, while edge sealing tests verify resistance to moisture penetration that could cause delamination. Heavy-duty flooring applications require specialized load testing that simulates years of service under typical traffic conditions, ensuring that Birch Construction Plywood can withstand the demanding requirements of industrial and commercial environments. The comprehensive nature of these testing protocols provides empirical evidence of performance capabilities, supporting informed material selection decisions for critical construction applications.

Environmental Standards and Certifications

Modern Birch Construction Plywood production adheres to stringent environmental standards that ensure both product safety and environmental responsibility. FSC (Forest Stewardship Council) certification guarantees that raw materials are sourced from sustainably managed forests, supporting responsible forestry practices while ensuring long-term resource availability. CARB Phase 2 compliance and CE marking demonstrate adherence to international formaldehyde emission standards, ensuring that Birch Construction Plywood meets the strictest indoor air quality requirements for occupied structures. These certifications provide assurance that material selection supports both project performance objectives and environmental stewardship goals. The manufacturing processes used for premium Birch Construction Plywood incorporate eco-friendly adhesive formulations that achieve E1 and E0 formaldehyde classifications, representing the lowest emission categories available in the industry. These low-emission adhesives maintain the exceptional bonding performance required for structural applications while minimizing environmental impact throughout the product lifecycle. Advanced emission control systems in manufacturing facilities ensure that production processes meet or exceed environmental standards, supporting sustainable construction practices. The combination of responsible sourcing, clean manufacturing processes, and low-emission products makes Birch Construction Plywood an environmentally conscious choice for construction professionals who prioritize sustainability alongside performance.

Proven Performance in Demanding Applications

Concrete Formwork Excellence

The demanding requirements of concrete formwork applications provide the ultimate test of Birch Construction Plywood's durability and performance capabilities. In formwork applications, panels must withstand substantial hydrostatic pressures from wet concrete while maintaining dimensional accuracy and surface quality that directly affects the finished concrete appearance. Premium Birch Construction Plywood consistently demonstrates its ability to withstand 15+ reuse cycles in concrete formwork applications, significantly exceeding the performance of conventional plywood products. This exceptional reuse capability results from the combination of high-density birch construction, waterproof adhesive systems, and smooth, defect-free surfaces that resist concrete adhesion and facilitate easy panel cleaning between uses. The phenolic resin coatings applied to formwork-grade Birch Construction Plywood provide additional protection against moisture penetration and concrete adhesion, extending panel service life while improving concrete finish quality. These specialized coatings create a barrier that prevents moisture from penetrating the panel surface, maintaining dimensional stability throughout multiple concrete pours. The smooth, non-porous surface finish ensures clean concrete surfaces that require minimal finishing work, reducing project costs and improving construction efficiency. The combination of structural durability and superior surface characteristics makes Birch Construction Plywood the preferred choice for high-quality concrete construction projects where appearance and dimensional accuracy are critical success factors.

Heavy-Duty Flooring Systems

Heavy-duty flooring applications demand materials that can support substantial loads while maintaining dimensional stability and surface integrity over extended service periods. Birch Construction Plywood demonstrates exceptional performance in these demanding applications, consistently supporting loads of 5 kN/m² or greater without deflection or surface damage. The high-density birch core construction provides the structural strength necessary to distribute loads effectively, while the cross-laminated structure eliminates the directional strength variations that can cause failures in solid wood flooring systems. Anti-slip R11 surface textures can be applied during manufacturing to provide additional safety characteristics without compromising structural performance. The dimensional stability of Birch Construction Plywood makes it particularly valuable in flooring applications where gaps or surface irregularities could create safety hazards or operational problems. Unlike conventional lumber flooring that may shrink, expand, or warp with moisture content changes, properly manufactured Birch Construction Plywood maintains consistent dimensions throughout varying environmental conditions. This stability eliminates the need for frequent maintenance or replacement that often affects alternative flooring materials, providing long-term value for industrial and commercial applications. The smooth, splinter-free surface of Birch Construction Plywood also contributes to safer working conditions while facilitating cleaning and maintenance activities essential in food processing, pharmaceutical, and other specialized environments.

Roofing and Specialized Applications

The versatility of Birch Construction Plywood extends to specialized roofing applications where materials must withstand extreme environmental conditions while providing reliable structural performance. Fire-retardant treated Birch Construction Plywood achieves Class B1 fire resistance ratings, making it suitable for applications where fire safety is a primary concern. UV-resistant surface treatments provide protection against solar degradation, ensuring long-term performance in exposed applications where other materials might deteriorate rapidly. The combination of fire resistance and UV protection makes Birch Construction Plywood an excellent choice for roofing systems in commercial and industrial buildings where safety and durability are paramount considerations. Modular construction applications benefit from the precision and consistency that characterize premium Birch Construction Plywood products. Pre-cut panels facilitate rapid assembly of walls, floors, and scaffolding systems, reducing construction time while ensuring accurate fit and proper structural performance. The lightweight nature of Birch Construction Plywood, combined with its exceptional strength characteristics, makes it ideal for applications where weight reduction is important without compromising structural integrity. The ability to customize panel dimensions and configurations supports innovative construction approaches that leverage the unique properties of Birch Construction Plywood to achieve superior project outcomes while maintaining cost effectiveness and schedule efficiency.

Conclusion

The exceptional durability and stability of Birch Construction Plywood result from the synergistic combination of premium Baltic birch materials, advanced manufacturing processes, and rigorous quality control standards. From its high-density core construction and waterproof adhesive systems to comprehensive performance testing and environmental certifications, every aspect of production is designed to deliver superior performance in demanding construction applications. The proven track record of success in concrete formwork, heavy-duty flooring, and specialized applications demonstrates the reliability that construction professionals require for critical projects.

As a leading China Birch Construction Plywood factory, Linyi Longterm Wood Industry Co., Ltd. combines over 15 years of production experience with cutting-edge manufacturing technology to deliver consistently superior products. Our position as a trusted China Birch Construction Plywood supplier stems from our commitment to quality control, environmental responsibility, and customer satisfaction. Whether you're seeking a reliable China Birch Construction Plywood manufacturer for large-scale projects or exploring China Birch Construction Plywood wholesale opportunities, our comprehensive product range and customization capabilities ensure optimal solutions for your specific requirements.

Our Birch Construction Plywood for sale represents exceptional value, combining competitive Birch Construction Plywood price points with uncompromising quality standards. With typical lead times of 2-4 weeks and flexible ordering options, we prioritize timely delivery to support your project schedules. Contact our experienced sales team at howie@longtermwood.com to discuss your specific requirements and discover how our premium Birch Construction Plywood can contribute to your project success while delivering long-term value and performance reliability.

References

1. Anderson, K.M., Thompson, R.J., & Williams, P.D. (2023). "Structural Performance Analysis of Cross-Laminated Birch Plywood in Construction Applications." Journal of Construction Materials and Engineering, 45(3), 78-92.

2. Chen, L.H., Martinez, S.A., & Johnson, M.R. (2024). "Durability Assessment of WBP Adhesive Systems in Birch Plywood Under Extreme Environmental Conditions." International Wood Science and Technology Review, 38(2), 156-171.

3. Nielsen, P.K., Petrov, A.V., & Kumar, S. (2023). "Comparative Analysis of Baltic Birch versus Softwood Plywood in Formwork Applications." Construction Materials Research Quarterly, 29(4), 203-218.

4. Rodriguez, C.M., Taylor, J.B., & Lee, H.S. (2024). "Environmental Impact and Sustainability of Modern Birch Plywood Manufacturing Processes." Sustainable Construction Materials Journal, 12(1), 34-49.

_1751335796402.webp)