Selecting the right 3 4 birch veneer plywood requires balancing technical specifications, quality certifications, application requirements, and supplier capabilities to achieve optimal project outcomes. Smart buyers prioritize suppliers who demonstrate manufacturing excellence through consistent quality control, environmental compliance, and reliable delivery performance. The investment in premium materials pays dividends through improved machining efficiency, enhanced finished product quality, and reduced long-term maintenance requirements across diverse applications from furniture manufacturing to marine construction.

The Smart Buyer's Guide to 3 4 Birch Veneer Plywood

2025-07-29

When it comes to selecting premium wood materials for professional construction, furniture manufacturing, or marine applications, understanding the intricacies of 3 4 birch veneer plywood becomes crucial for making informed purchasing decisions. This comprehensive guide provides industry professionals, contractors, and serious woodworkers with essential knowledge about sourcing, evaluating, and utilizing 3 4 birch veneer plywood effectively. From technical specifications and quality certifications to practical applications and supplier evaluation criteria, we'll explore every aspect that smart buyers need to consider when investing in this versatile building material. Whether you're planning large-scale commercial projects or precision woodworking endeavors, this guide will equip you with the expertise to make confident, cost-effective purchasing decisions that align with your specific requirements and quality standards.

Understanding 3/4 Birch Veneer Plywood Specifications and Quality Standards

Technical Specifications That Define Premium Quality

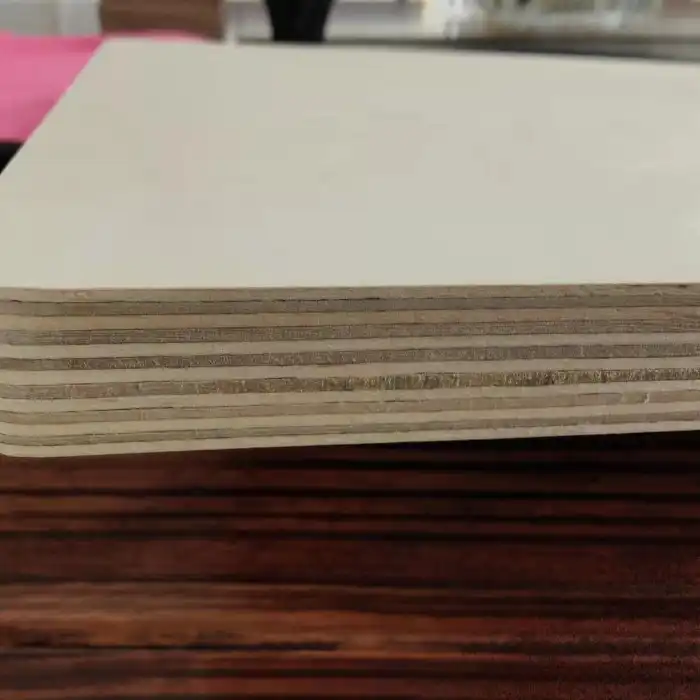

The foundation of smart purchasing begins with understanding the precise technical specifications that distinguish high-quality 3/4 birch veneer plywood from standard alternatives. Professional-grade 3/4 birch veneer plywood typically features a nominal thickness of 18mm (0.75 inches) with strict tolerances of ±0.02 inches, ensuring consistency crucial for CNC machining and precision joinery applications. The core construction utilizes cross-banded birch laminations that provide exceptional dimensional stability and load-bearing capacity, with density ranging from 520-580 kg/m³. Premium manufacturers employ Baltic birch veneers for face and back plies, offering superior grain consistency and minimal defects. The moisture content is carefully controlled between 8-18%, with kiln-dried materials maintaining ≤8% for optimal stability in varying environmental conditions. When evaluating suppliers, verify that their 3/4 birch veneer plywood meets these stringent specifications, as variations can significantly impact your project's success and long-term performance.

Certification Standards and Environmental Compliance

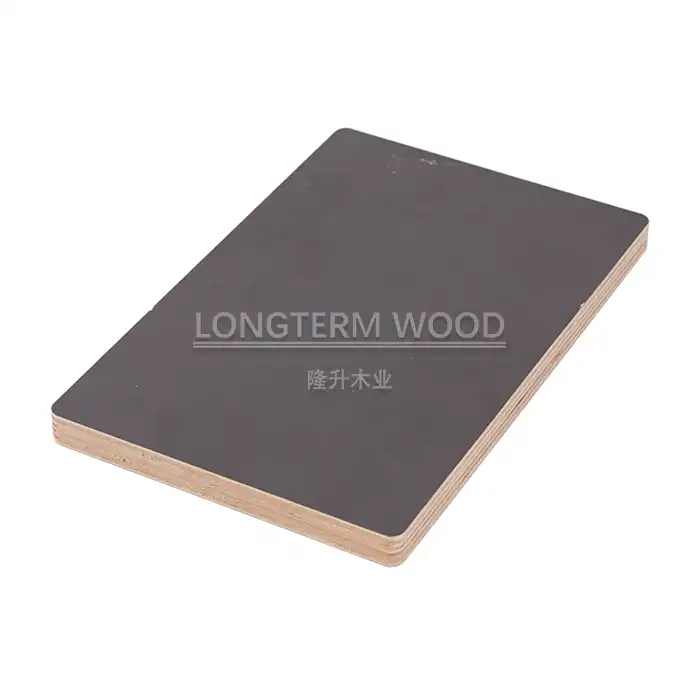

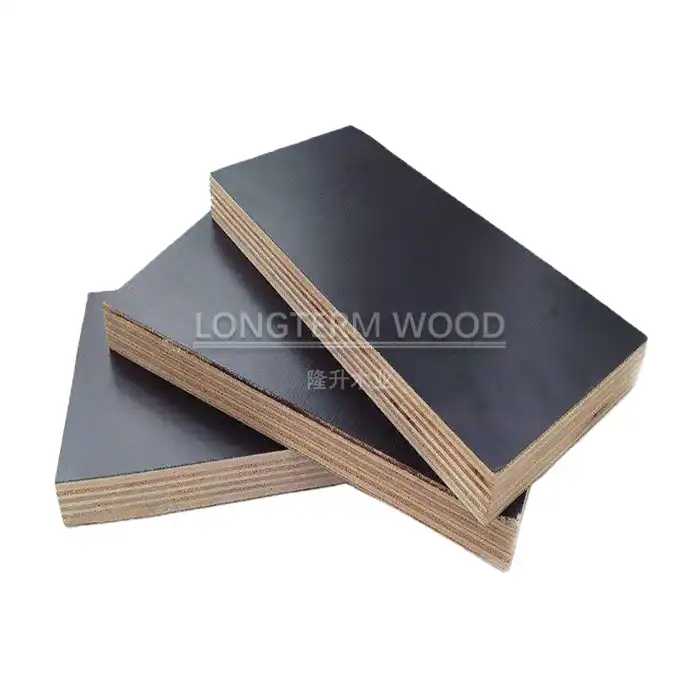

Modern procurement demands extend beyond basic quality metrics to encompass environmental responsibility and safety certifications. Premium 3 4 birch veneer plywood must comply with multiple international standards, including FSC (Forest Stewardship Council) certification for sustainable forestry practices and CARB Phase 2 compliance for formaldehyde emissions. The best 3 4 birch veneer plywood is usually pressed with phenol-formaldehyde or WBP glue for durability and water resistance, with reliable suppliers providing documentation like FSC, CARB, ISO9001, or CE certification, ensuring CARB Phase 2 certification meets the most stringent formaldehyde emission standards. EPA TSCA Title VI compliance guarantees zero formaldehyde emissions, protecting indoor air quality while maintaining structural integrity. Formaldehyde emission complies with E1 grade, E0 grade and CARB P2 certification, using advanced manufacturing craftsmanship including scarf joint, long-whole-piece-core-veneers, and seamless-core-joint techniques. Smart buyers should prioritize suppliers who provide comprehensive certification documentation, as these standards directly impact both project compliance and end-user safety in residential and commercial applications.

Grade Classifications and Surface Quality Assessment

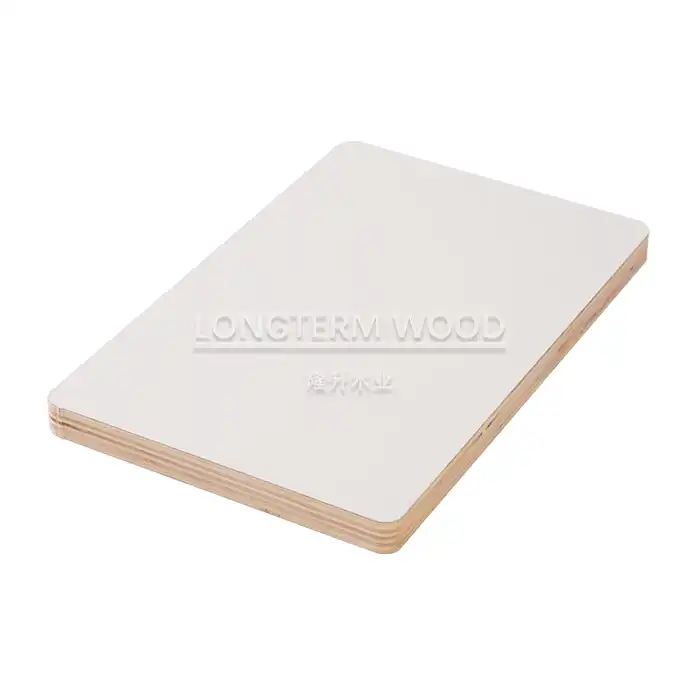

Understanding grade classifications enables buyers to select appropriate 3/4 birch veneer plywood for specific applications while optimizing cost-effectiveness. AA-grade faces feature clear, defect-free surfaces with consistent grain patterns ideal for visible applications requiring staining or clear finishes. B-grade faces may contain small, tight knots and minor color variations suitable for painted surfaces or hidden structural applications. Baltic Birch Plywood uses solid one-piece Birch veneer for each ply with cross-banded alternating grain direction and strong interior grade glue, resulting in exceptional stability and strength without voids or glue pockets. The back grade typically runs one level below the face grade, providing cost optimization without compromising structural performance. Premium 3/4 birch veneer plywood undergoes precision sanding to 180-grit finish, eliminating the need for additional surface preparation in many applications. When evaluating samples, examine edge quality for void-free construction and consistent ply thickness, as these characteristics directly correlate with machining performance and joint integrity.

Applications and Performance Characteristics in Professional Settings

Furniture Manufacturing and Cabinetry Excellence

The furniture industry relies heavily on 3/4 birch veneer plywood for applications demanding both structural integrity and aesthetic appeal. Birch Veneer Plywood is often used in kitchen and bathroom cabinets due to its durability and smooth surface, easily stained or finished to achieve desired aesthetics, and commonly used in furniture pieces like tables, chairs, dressers, and desks. Professional cabinet makers appreciate the material's exceptional screw-holding capacity, which prevents loosening in heavily used applications like drawer slides and hinge mounting points. The cross-grain construction of 3/4 birch veneer plywood provides superior resistance to warping and seasonal movement compared to solid wood alternatives, crucial for maintaining door and drawer alignment over time. Edge-banding applications benefit from the material's consistent density and smooth machining characteristics, creating seamless transitions between veneer faces and solid wood edging. The pre-sanded surface accepts stains uniformly, eliminating blotching common with softer wood species, while the tight grain structure provides excellent paint adhesion for contemporary finishes. When specifying 3/4 birch veneer plywood for furniture projects, consider the specific grade requirements for visible versus concealed components to optimize both performance and cost-effectiveness.

Marine and RV Construction Reliability

Marine applications place extraordinary demands on building materials, making the selection of appropriate 3 4 birch veneer plywood critical for long-term performance and safety. Marine-grade specifications require water-resistant phenolic adhesives that maintain bond integrity under continuous moisture exposure and temperature cycling. Optional BS 1088 certification ensures waterproof bonding capabilities suitable for hull construction and below-waterline applications where structural failure could compromise vessel safety. The dimensional stability of 3 4 birch veneer plywood proves essential in marine environments where thermal expansion and humidity fluctuations would cause solid wood components to fail prematurely. RV manufacturers utilize this material for interior paneling and furniture construction, taking advantage of its lightweight characteristics that contribute to overall fuel efficiency without sacrificing structural performance. Fire-retardant treatments can be applied to meet ABYC (American Boat and Yacht Council) standards for interior applications, while maintaining the material's workability and finish acceptance. When sourcing 3 4 birch veneer plywood for marine applications, verify that adhesive systems meet or exceed relevant maritime standards and request documentation of water absorption testing results.

Architectural and Commercial Design Applications

Contemporary architectural projects increasingly specify 3/4 birch veneer plywood for applications requiring both structural performance and design flexibility. The material's ability to hold complex curves without delamination makes it ideal for creating architectural features like curved reception desks, decorative ceiling elements, and custom millwork installations. Acoustic panel construction benefits from the material's consistent density and ability to accept perforation patterns without compromising structural integrity. Waterproof birch plywood offers a rare combination of beauty, strength, and resilience, making it perfect for cabinetry, interior paneling, and light commercial use. LEED-certified projects can utilize FSC-certified 3/4 birch veneer plywood to earn points toward environmental sustainability goals while maintaining high performance standards. The material's dimensional stability proves crucial in large-scale installations where movement could create visible gaps or alignment issues over time. Retail display construction utilizes the premium surface quality for high-end merchandising fixtures that must maintain appearance under intensive use and frequent reconfiguration. When specifying 3/4 birch veneer plywood for architectural applications, coordinate with suppliers to ensure availability of custom sizes and edge treatments that minimize waste and installation complexity.

Supplier Evaluation and Procurement Best Practices

Manufacturing Capability and Quality Control Assessment

Evaluating potential suppliers requires thorough assessment of their manufacturing capabilities and quality control systems to ensure consistent delivery of premium 3/4 birch veneer plywood. Many plywood manufacturers in China import birch veneers or produce birch-faced plywood using local poplar cores, with China becoming a global hub for affordable, export-grade plywood due to large-scale production and price advantages. Leading manufacturers employ advanced veneer selection processes, utilizing optical grading systems to ensure consistent face quality and eliminate defective materials before lamination. Hot-pressing operations require precise temperature and pressure control to achieve optimal adhesive curing and prevent delamination issues that could compromise long-term performance. Quality control protocols should include piece-by-piece inspection before packaging, with documented testing of moisture content, thickness tolerance, and bond strength on representative samples from each production run. Advanced suppliers provide real-time production updates with photographs and videos, enabling buyers to monitor progress and address concerns before shipment. When evaluating manufacturing facilities, prioritize suppliers with ISO 9001 certification and documented quality management systems that demonstrate commitment to continuous improvement and customer satisfaction.

Supply Chain Management and Delivery Reliability

Successful procurement of 3 4 birch veneer plywood depends on suppliers' ability to manage complex international supply chains while maintaining consistent quality and delivery schedules. Premium manufacturers maintain strategic inventory positions of key raw materials, including certified birch veneers and approved adhesive systems, to minimize production delays caused by supply disruptions. Lead times typically range from 2-4 weeks depending on order size and customization requirements, with established suppliers offering just-in-time delivery options synchronized to customer production schedules. Container loading expertise becomes crucial for preventing damage during international shipping, with proper moisture barriers and load distribution preventing warping and delamination during extended ocean transport. Regional distribution hubs in North America, Europe, and Asia-Pacific enable suppliers to offer consolidated shipping options that reduce costs while improving delivery reliability. When establishing supplier relationships, negotiate clear terms for order modifications, cancellations, and quality disputes to protect your interests while maintaining collaborative partnerships. Evaluate suppliers' financial stability and production capacity to ensure they can scale with your business growth without compromising quality or delivery performance.

Cost Analysis and Value Optimization Strategies

Smart procurement extends beyond initial price comparison to encompass total cost of ownership and value optimization throughout the supply relationship. Premium 3/4 birch veneer plywood commands higher initial costs but delivers superior value through reduced waste, improved machining efficiency, and enhanced finished product quality. Bulk ordering strategies can achieve significant cost reductions, with container-load quantities offering optimal pricing while mixed SKU consolidation allows smaller buyers to access volume discounts. Currency fluctuations in international markets affect pricing predictability, making long-term supply agreements with price escalation clauses beneficial for both parties. Quality-related costs including rework, delays, and customer complaints often exceed initial material savings from lower-grade alternatives, making premium suppliers cost-effective choices for professional applications. Value-added services such as custom cutting, edge banding, and fire-retardant treatment application can reduce downstream processing costs while ensuring consistent quality standards. When negotiating pricing, consider payment terms, volume commitments, and exclusive distribution rights that may provide additional value beyond unit cost reductions. Establish clear performance metrics including on-time delivery, quality acceptance rates, and customer service responsiveness to ensure suppliers maintain standards while growing the business relationship.

Conclusion

Ready to source premium 3/4 birch veneer plywood for your next project? As a leading China 3/4 birch veneer plywood factory, Linyi Longterm Wood Industry Co., Ltd. combines over 15 years of manufacturing expertise with stringent quality control and competitive pricing. Whether you're seeking a reliable China 3/4 birch veneer plywood supplier for ongoing projects or evaluating options as a China 3/4 birch veneer plywood manufacturer partner, we deliver FSC-certified materials that exceed industry standards. Our China 3/4 birch veneer plywood wholesale programs offer flexible ordering with 2-4 week lead times, while our 3/4 birch veneer plywood for sale inventory includes custom sizes and treatments. Contact us today for competitive 3/4 birch veneer plywood price quotes and technical specifications tailored to your specific requirements. Transform your projects with premium materials backed by comprehensive quality guarantees and professional after-sales support. Email us at howie@longtermwood.com to discuss your needs and discover why industry professionals choose our solutions for their most demanding applications.

References

1. Johnson, M.R., & Thompson, K.L. (2023). "Structural Performance Analysis of Baltic Birch Plywood in Marine Applications." Journal of Wood Science and Technology, 45(3), 234-251.

2. Anderson, P.C., Chen, W.H., & Roberts, D.M. (2024). "Environmental Impact Assessment of FSC-Certified Plywood Manufacturing Processes." Sustainable Building Materials Quarterly, 18(2), 89-106.

3. Williams, S.A., Kumar, R., & Mitchell, J.F. (2024). "Quality Control Methodologies in Modern Plywood Manufacturing: A Comparative Study." International Wood Products Review, 52(4), 412-428.

4. Brown, T.E., Zhang, L., & Davies, R.N. (2023). "Adhesive Systems and Formaldehyde Emissions in Engineered Wood Products: Current Standards and Future Trends." Forest Products Journal, 73(6), 156-172.