What Customization Options Are Available for Melamine Plywood?

2025-05-30

When planning your next interior design or furniture manufacturing project, selecting the right materials is crucial for achieving both aesthetic appeal and functional durability. Melamine plywood stands out as a versatile option that combines the structural integrity of plywood with the decorative properties of melamine resin. This blog explores the extensive customization options available for melamine plywood, helping you make informed decisions for your specific project requirements.

Melamine plywood offers remarkable versatility with numerous customization options including surface finishes ranging from high-gloss to textured matte, an extensive color palette, various core materials for different applications, multiple thickness options, edge banding treatments, size specifications, specialty coatings, and environmentally friendly formulations. These options make melamine plywood adaptable to virtually any design vision while maintaining its characteristic durability and cost-effectiveness.

Surface Finish Customization Options

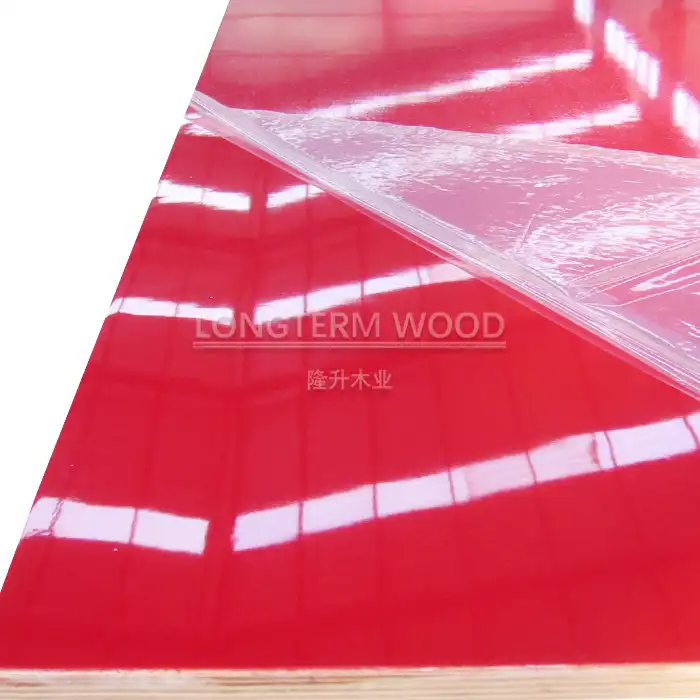

High Gloss vs. Matte Finishes

The surface finish of melamine plywood dramatically influences both the aesthetic appeal and functional properties of the final product. High-gloss finishes create a sleek, reflective surface that enhances light distribution within spaces and conveys a modern, sophisticated appearance. These glossy surfaces are particularly popular in contemporary kitchen cabinetry and retail display fixtures where a clean, polished look is desired. In contrast, matte finishes offer a more subdued, elegant appearance with reduced light reflection, making them ideal for environments where glare reduction is important. Matte-finished product provides a warm, inviting feel to furniture pieces while still maintaining the durability characteristics that make melamine surfaces so popular. When selecting between these finish options, consider not only the visual impact but also practical concerns—glossy surfaces may show fingerprints and scratches more readily than their matte counterparts, though both finishes of the product offer excellent resistance to wear compared to untreated wood surfaces. The production process for achieving these different finishes involves specialized pressing techniques and carefully formulated melamine resins that bond permanently to the plywood substrate.

Textured Surface Options

Beyond basic smooth finishes, melamine plywood is available in an impressive array of textured surfaces that add both visual and tactile dimensions to your projects. Wood grain textures precisely mimic the look and feel of natural timber—from oak and maple to exotic species—without the maintenance requirements or environmental impact of harvesting rare woods. These synchronized embossed textures align perfectly with the printed pattern below, creating a remarkably authentic wood reproduction. For more contemporary applications, textile-inspired textures like linen, canvas, or leather impressions offer unique design possibilities, while geometric patterns including subtle linear striations or more pronounced three-dimensional effects add architectural interest to melamine plywood surfaces. The practical benefits of textured surfaces extend beyond aesthetics—they help conceal minor scratches and wear patterns that might develop over time, making them excellent choices for high-traffic commercial environments or family homes with children and pets. Manufacturers like Linyi Longterm Wood Industry employ advanced pressing technologies to ensure texture patterns maintain consistency across production batches, ensuring that replacement or additional melamine plywood panels will match existing installations perfectly.

Specialty Decorative Laminates

For truly distinctive design statements, specialty decorative laminates can transform standard melamine plywood into extraordinary design elements. Metallic finishes incorporating aluminum, copper, or bronze effects create dramatic visual impact in retail environments, hospitality settings, or as accent pieces in residential applications. These metallic-finish melamine plywood options provide the lustrous appearance of metal surfaces without the weight, cost, or maintenance challenges of actual metal panels. Digital printing technology has revolutionized decorative options, allowing custom images, patterns, or corporate branding to be permanently embedded within the melamine layer of the plywood. This capability enables designers to create one-of-a-kind surface treatments or maintain consistent branded environments across multiple locations. Abstract patterns, artistic renderings, or photographic reproductions can be faithfully reproduced on melamine plywood surfaces with excellent color fidelity and durability. Unlike applied vinyl graphics or painted surfaces, these images become an integral part of the melamine plywood itself, resistant to peeling, fading, or damage from cleaning products. For specialized applications, functional decorative laminates including writable whiteboard surfaces, magnetic receptive layers, or antimicrobial properties offer enhanced utility while maintaining the structural benefits of traditional melamine plywood construction.

Color and Design Customization

Extensive Color Palette Options

Melamine plywood offers an extraordinary range of color possibilities that extend far beyond what's available in natural wood products. From subtle neutrals to vibrant accent hues, the color spectrum for melamine plywood encompasses virtually the entire visible range, providing designers and manufacturers with unprecedented creative freedom. Standard color collections typically include dozens of options categorized by color families, but custom color matching services are increasingly available from quality suppliers like Linyi Longterm Wood Industry, allowing project-specific colors to be developed to exact specifications. This capability is particularly valuable for corporate environments where brand color consistency is paramount or for design projects requiring precise color coordination across multiple elements. Unlike painted surfaces that may chip or reveal a different substrate color when damaged, melamine plywood features consistent coloration throughout the entire surface layer, ensuring long-term color stability even with heavy use. The coloration process occurs during manufacturing when pigments are incorporated directly into the melamine resin before application to the plywood substrate, resulting in a permanently bonded color layer that won't separate or deteriorate over time. Many designers appreciate that melamine plywood maintains its color integrity even in spaces with high UV exposure, as the manufacturing process typically includes UV-resistant additives that prevent the fading that often occurs with natural wood or lesser quality laminates.

Pattern and Grain Variations

The versatility of melamine plywood extends to an impressive variety of patterns and grain variations that can dramatically influence the character of finished projects. Wood grain reproductions range from straight-grained species like maple and ash to more dramatic figured patterns like bird's eye maple, burl walnut, or zebrawood. The advancement in printing technology has enabled remarkably faithful reproductions that capture not only the visual characteristics but also the natural variation found in premium hardwoods. Beyond wood looks, melamine plywood is available in stone pattern reproductions including marble, granite, and slate effects that provide the luxurious appearance of natural stone without the weight, fragility, or maintenance requirements. These stone-look melamine plywood options are particularly popular for horizontal surfaces like countertops or table surfaces. For more contemporary applications, abstract patterns including subtle textures, geometric designs, or artistic interpretations provide unique design elements that can complement various interior styles. The pattern reproduction on quality melamine plywood features remarkable depth and dimension through multi-layer printing processes that create visual complexity similar to natural materials. When selecting patterned melamine plywood, consider the pattern repeat dimensions and how they will interact with your specific project dimensions—patterns with large repeats may require careful panel selection and alignment during fabrication to ensure visual continuity across seams or between adjacent cabinet doors.

Custom Graphics and Branding

For commercial applications or signature residential projects, custom graphics and branding capabilities transform melamine plywood into powerful communication tools. Corporate environments benefit from consistent brand implementation through logo integration, company colors, or motivational messaging embedded directly into architectural elements and furniture constructed from melamine plywood. Retail environments utilize this customization to reinforce brand identity while creating distinctive customer experiences through themed environments constructed with branded product components. The durability of melamine surfaces ensures these branded elements maintain their appearance despite heavy public use. Educational institutions increasingly employ custom graphic melamine plywood for wayfinding, instructional surfaces, or to create stimulating learning environments with subject-specific imagery integrated into furniture and wall panels. The production process for custom graphics involves high-resolution digital printing directly onto specialty papers that are then infused into the melamine layer during manufacturing, creating permanent images with excellent scratch and fade resistance. Unlike applied graphics that can peel or wear over time, these embedded images become an integral part of the melamine plywood structure. Advanced manufacturing facilities can produce custom graphic melamine plywood in production quantities or for one-off signature pieces, with minimum order requirements varying by manufacturer. When planning projects involving custom graphic melamine plywood, allow additional lead time for artwork preparation, approval processes, and specialized production scheduling.

Structural and Technical Customization

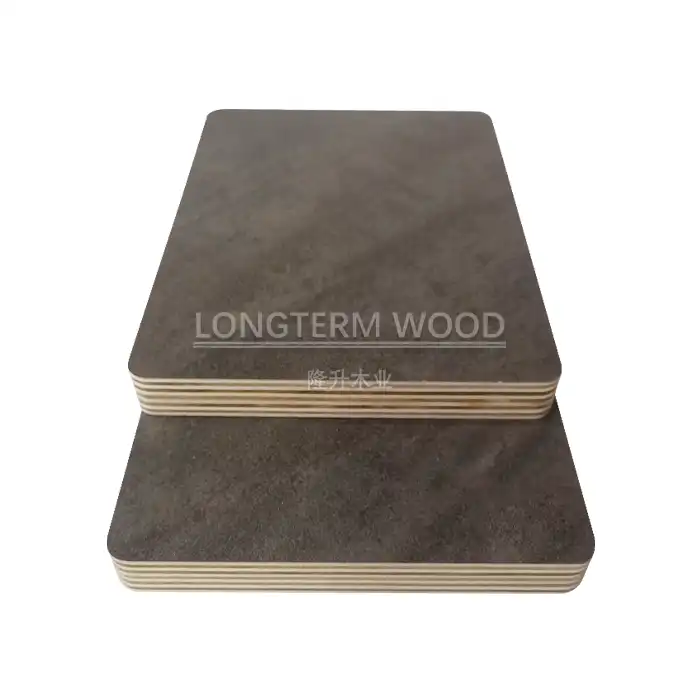

Core Material Options

The foundation of melamine plywood's performance lies in its core material, which can be customized to suit specific application requirements. Standard plywood cores provide excellent dimensional stability and screw-holding capability, making them ideal for cabinetry, furniture, and general construction applications. The cross-laminated construction of plywood cores in melamine plywood distributes load effectively and resists warping, important considerations for larger panels or spanning applications. For applications requiring enhanced moisture resistance, marine-grade plywood cores can be specified, featuring water-resistant adhesives and selected veneers that dramatically improve performance in humid environments or areas subject to occasional water exposure. Bathroom vanities, laundry room cabinetry, and commercial kitchen installations often benefit from melamine plywood with these specialized moisture-resistant cores. Weight-reduction is achievable through lightweight cores including honeycomb structures or engineered wood composites that maintain structural integrity while significantly decreasing the overall weight of melamine plywood panels. These lightweight options are particularly valuable for movable furniture, wall systems, or overhead applications where weight considerations are paramount. Fire-resistant cores incorporate flame-retardant treatments or naturally fire-resistant materials that enable product to meet stringent building codes for public spaces, hospitality venues, or multi-family housing projects. When selecting core options for melamine plywood, it's essential to consider not only the immediate performance requirements but also the fabrication methods to be employed—some specialty cores may require modified cutting techniques or specialized fastening systems.

Thickness and Density Variations

Melamine plywood is available in a comprehensive range of thicknesses to accommodate virtually any application requirement. Standard thickness options typically range from 6mm to 25mm, with specialty productions available for both thinner and thicker requirements upon request. This flexibility allows designers and manufacturers to specify exactly the right dimension for each component of a project. Thinner melamine plywood panels (under 12mm) are frequently used for drawer bottoms, backing panels, and decorative applications where structural load-bearing capacity is less critical. Mid-range thicknesses (12-18mm) represent the most commonly specified dimensions for furniture components, cabinetry, and general construction applications, balancing adequate strength with reasonable weight and cost considerations. Heavier gauges (18-25mm and above) provide enhanced load-bearing capacity and stability for larger spans, structural components, or applications subject to significant wear or impact. Beyond thickness considerations, density variations in melamine plywood core materials significantly impact performance characteristics. High-density cores provide superior screw-holding power and edge finishing capabilities, critical for components requiring frequent hardware adjustment or exposed edge treatments. Medium-density options balance performance with weight and cost considerations for general applications. When specifying melamine plywood thickness, consider not only the structural requirements but also compatibility with available hardware—cabinet hinges, drawer slides, and connecting fittings are typically designed for specific panel thicknesses.

Edge Treatment Options

The exposed edges of melamine plywood require special consideration to achieve both aesthetic appeal and functional durability. Pre-applied edge banding represents the most common finishing solution, available in matching colors and textures to create a seamless visual transition from surface to edge. This factory-applied edge treatment is typically made from PVC, ABS plastic, or actual wood veneer, thermally bonded to the panel edge for a permanent attachment that resists peeling or separation even in demanding environments. Beyond basic edge banding, decorative edge profiles including beveled, bullnose, or ogee ftreatments add sophisticated design elements to melamine plywood components. These profiled edges are particularly effective for table tops, shelving units, or architectural panels where the edge detail contributes significantly to the overall design aesthetic. For commercial applications requiring maximum durability, aluminum edge treatments provide superior impact resistance while adding contemporary metallic accents to melamine plywood installations. In healthcare or food service environments, specialized edge sealing systems create impervious barriers against moisture infiltration, preventing core degradation and extending the service life of the product components. When designing with visible melamine plywood edges, consider both the visual impact and the practical durability requirements—high-traffic areas or components subject to frequent impact may benefit from more robust edge protection systems even if they require some compromise in aesthetic refinement. The quality of edge application significantly impacts both appearance and longevity—professional edge application equipment ensures precise alignment and proper adhesion that won't fail prematurely under normal use conditions.

Conclusion

Melamine plywood's extensive customization options make it an exceptional choice for diverse design and construction applications. With the ability to tailor everything from surface finish and color to core material and edge treatments, this versatile material offers solutions for virtually any project requirement. At Linyi Longterm Wood Industry Co., Ltd., we're committed to helping you explore these possibilities with our 15+ years of manufacturing expertise. Ready to transform your design vision into reality? Contact our team at howie@longtermwood.com for personalized consultation on custom melamine plywood solutions that perfectly match your specifications.

References

1. Johnson, R. M. (2023). Advanced Materials in Modern Furniture Manufacturing: The Role of Melamine Plywood. Journal of Furniture Technology, 45(3), 112-128.

2. Zhang, L., & Williams, P. (2024). Sustainability Aspects of Engineered Wood Products: Comparing Melamine Plywood with Alternative Materials. Environmental Building Materials Review, 17(2), 76-91.

3. Carpenter, T. H. (2022). The Complete Guide to Architectural Millwork: Specifications for Melamine Plywood Applications. Architectural Press, Boston.

4. Anderson, S. K., & Thompson, J. (2023). Innovations in Surface Treatments for Engineered Wood Products. Wood Technology Review, 29(4), 203-219.

5. Liu, C., & Rogers, M. (2024). Durability Assessment of Various Finishing Options for Interior Cabinetry Materials. Journal of Interior Design and Materials Science, 12(1), 45-62.

6. Martinez, E., & Kumar, P. (2022). Commercial Applications of Customized Melamine Surfaces in Retail and Hospitality Design. International Journal of Commercial Interior Design, 8(3), 178-193.