What Benefits Do You Get from Using FSC-Certified Commercial Plywood 18mm?

2025-07-23

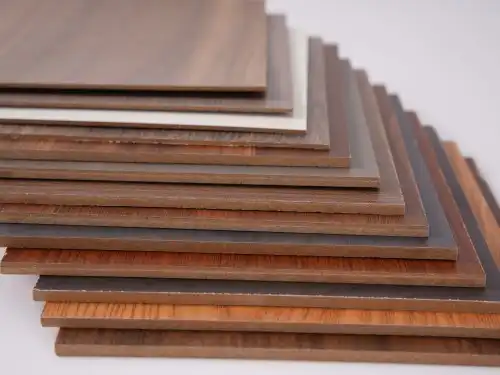

In today's construction and furniture manufacturing industries, the demand for sustainable, high-performance materials has never been greater. FSC-certified commercial plywood 18mm represents the perfect intersection of environmental responsibility and superior structural performance. This comprehensive guide explores the numerous advantages of choosing FSC-certified commercial plywood 18mm for your projects, from its exceptional durability and load-bearing capacity to its contribution to sustainable forestry practices. Whether you're a contractor, furniture manufacturer, or architect, understanding these benefits will help you make informed decisions that benefit both your projects and the environment. FSC-certified commercial plywood 18mm offers unparalleled advantages for construction and furniture applications. This precision-engineered material combines the structural integrity of high-grade plywood with the environmental assurance of Forest Stewardship Council certification. With its 18mm thickness providing optimal strength-to-weight ratio, this commercial plywood 18mm delivers exceptional performance in demanding applications while supporting sustainable forestry practices. The FSC certification ensures that every sheet comes from responsibly managed forests, making it an ideal choice for projects requiring both superior performance and environmental compliance.

Environmental Sustainability and Responsible Sourcing

Forest Stewardship Council Certification Standards

FSC-certified commercial plywood 18mm represents a commitment to environmental stewardship that extends far beyond traditional manufacturing practices. The Forest Stewardship Council certification process ensures that every piece of commercial plywood 18mm comes from forests managed according to strict environmental, social, and economic standards. This certification system, established in 1992 and now operating in over 80 countries, provides a holistic approach to forest management that addresses biodiversity conservation, wildlife protection, and community rights. When you choose FSC-certified commercial plywood 18mm, you're supporting a supply chain that actively works to prevent deforestation and illegal logging while promoting the restoration of degraded forest ecosystems. The certification process involves rigorous third-party audits that verify compliance with FSC's ten principles and 70 criteria, ensuring that the wood used in your commercial plywood 18mm comes from forests where harvesting practices maintain the forest's biological diversity, productivity, and ecological processes.

Sustainable Forest Management Practices

The sustainable sourcing of FSC-certified commercial plywood 18mm involves comprehensive forest management practices that ensure long-term environmental health and resource availability. These practices include selective harvesting techniques that maintain forest canopy integrity, protection of old-growth forests and rare ecosystems, and implementation of natural regeneration programs that restore harvested areas. The commercial plywood 18mm produced under FSC certification comes from forests where water resources are protected, soil erosion is minimized, and wildlife corridors are maintained to support biodiversity. Additionally, FSC-certified forests must demonstrate social responsibility by respecting indigenous peoples' rights, providing fair wages to forest workers, and contributing to local community development. This comprehensive approach to forest management ensures that your commercial plywood 18mm not only meets the highest quality standards but also supports the preservation of forest ecosystems for future generations. The sustainable practices also include monitoring programs that track forest health indicators, carbon sequestration rates, and biodiversity indices to ensure continuous improvement in environmental performance.

Carbon Footprint Reduction and Environmental Impact

Choosing FSC-certified commercial plywood 18mm significantly reduces your project's carbon footprint through multiple mechanisms that contribute to climate change mitigation. The sustainable forest management practices associated with FSC certification promote carbon sequestration, as responsibly managed forests act as carbon sinks that absorb atmospheric CO2 throughout their growth cycle. The manufacturing process for FSC-certified commercial plywood 18mm also emphasizes energy efficiency and waste reduction, with many producers achieving 95% material utilization rates and implementing waste-to-energy systems that minimize environmental impact. Furthermore, the durability and longevity of high-quality commercial plywood 18mm means fewer replacement cycles, reducing the overall environmental impact of your construction or furniture projects. The formaldehyde emissions from FSC-certified commercial plywood 18mm typically meet or exceed the strictest international standards, with many products achieving less than 0.1ppm formaldehyde content, significantly lower than CARB Phase 2 limits. This environmental responsibility extends to the entire supply chain, where FSC-certified suppliers must demonstrate continuous improvement in environmental performance, waste reduction, and energy efficiency.

Superior Structural Performance and Durability

Load-Bearing Capacity and Structural Integrity

The exceptional load-bearing capacity of commercial plywood 18mm makes it an ideal choice for demanding structural applications where reliability and safety are paramount. With its precision-engineered thickness of 18mm (±0.2mm tolerance), this commercial plywood 18mm can support loads up to 500kg/m² in concrete formwork applications, making it suitable for heavy-duty construction projects. The cross-grain construction technique used in manufacturing commercial plywood 18mm involves alternating wood grain directions in each layer, creating a composite material that distributes loads evenly across the entire surface. This structural design eliminates weak points common in solid wood and provides superior resistance to splitting, cracking, and warping under heavy loads. The full birch or mixed hardwood core construction ensures consistent density throughout the sheet, with no gaps or voids that could compromise structural integrity. Professional testing has demonstrated that quality commercial plywood 18mm maintains its load-bearing capacity even under prolonged stress, making it suitable for permanent structural applications in both residential and commercial construction projects.

Moisture Resistance and Dimensional Stability

The moisture resistance properties of commercial plywood 18mm are crucial for applications in varying environmental conditions, from high-humidity construction sites to marine environments. The moisture-resistant (MR) and Water and Boil Proof (WBP) adhesives used in quality commercial plywood 18mm create strong bonds between wood layers that resist delamination even when exposed to moisture, humidity, and temperature fluctuations. This dimensional stability is particularly important in construction applications where the commercial plywood 18mm must maintain its shape and strength throughout the building process and beyond. The controlled moisture content of 8-18% in commercial plywood 18mm ensures optimal performance while minimizing the risk of warping, twisting, or shrinkage that can occur with poorly manufactured products. Salt-spray testing has shown that marine-grade commercial plywood 18mm can withstand over 1,200 hours of exposure without delamination, making it suitable for coastal construction projects and marine applications. The anti-fungal treatments applied to commercial plywood 18mm meeting BS 1088 standards provide additional protection against biological degradation, ensuring long-term durability in challenging environments.

Surface Quality and Finishing Capabilities

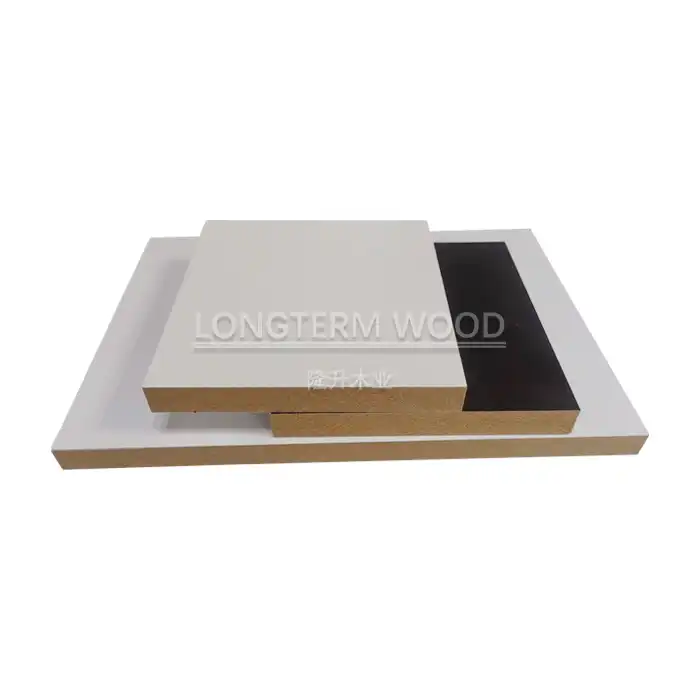

The superior surface quality of commercial plywood 18mm provides an excellent foundation for various finishing applications, from natural wood stains to laminates and veneers. The smooth, uniform surface of quality commercial plywood 18mm requires minimal preparation before finishing, reducing labor costs and project timelines. The consistent grain pattern and absence of surface defects make commercial plywood 18mm ideal for applications where appearance is important, such as furniture manufacturing and architectural millwork. The surface stability of commercial plywood 18mm prevents telegraph-through of core imperfections, ensuring that finished surfaces maintain their appearance over time. Whether you're applying melamine laminates, natural wood veneers, or paint systems, commercial plywood 18mm provides the stable substrate necessary for professional-quality finishes. The screw-holding capability of commercial plywood 18mm is exceptional due to its uniform density and cross-grain construction, allowing for secure fastening of hardware and components without the risk of splitting or pull-out failure common with inferior materials.

Versatile Applications and Industry Benefits

Construction and Architectural Applications

In the construction industry, commercial plywood 18mm serves as a versatile building material that meets the demanding requirements of modern construction projects. Its exceptional strength-to-weight ratio makes commercial plywood 18mm ideal for concrete formwork, where it must support the weight of wet concrete while maintaining dimensional accuracy. The smooth surface finish of commercial plywood 18mm creates clean concrete surfaces that require minimal finishing work, reducing overall project costs and timelines. For flooring applications, commercial plywood 18mm provides a stable subfloor that resists warping and movement, creating an ideal foundation for finished flooring materials. The fire-resistant properties of commercial plywood 18mm can be enhanced with optional Class B1 treatments, making it suitable for commercial buildings where fire safety regulations are stringent. Wall sheathing applications benefit from the dimensional stability and moisture resistance of commercial plywood 18mm, which helps prevent structural problems caused by moisture infiltration and thermal expansion. The consistent thickness and quality of commercial plywood 18mm also make it suitable for architectural applications where precise dimensions are critical, such as built-in cabinetry and custom millwork.

Furniture Manufacturing and Interior Design

The furniture manufacturing industry relies heavily on commercial plywood 18mm for creating durable, high-quality furniture pieces that meet both functional and aesthetic requirements. The uniform density and smooth surface of commercial plywood 18mm provide an ideal substrate for veneering, allowing manufacturers to create furniture with the appearance of solid wood at a fraction of the cost. Cabinet construction benefits from the structural integrity of commercial plywood 18mm, which can support heavy loads while maintaining its shape over time. The screw-holding capability of commercial plywood 18mm ensures that furniture joints remain tight and secure, even with repeated use and stress. For shelving systems, commercial plywood 18mm provides the strength necessary to support heavy loads without sagging, making it suitable for both residential and commercial storage applications. The finishing versatility of commercial plywood 18mm allows furniture manufacturers to create products with various surface treatments, from natural wood stains that highlight the grain pattern to modern high-gloss finishes that create contemporary aesthetics. The dimensional stability of commercial plywood 18mm also makes it suitable for large furniture pieces that might be subject to environmental changes, ensuring that doors, drawers, and other components continue to function properly over time.

Marine and Transportation Industry Uses

The marine and transportation industries present unique challenges that commercial plywood 18mm is specifically designed to address through specialized treatments and construction techniques. Marine-grade commercial plywood 18mm must withstand constant exposure to moisture, salt spray, and temperature fluctuations while maintaining its structural integrity and appearance. The WBP adhesives used in marine applications create waterproof bonds that prevent delamination even when fully submerged, making commercial plywood 18mm suitable for boat building and dock construction. The anti-fungal treatments applied to marine-grade commercial plywood 18mm prevent rot and decay that can compromise structural integrity in marine environments. For transportation applications, commercial plywood 18mm provides the strength and durability necessary for truck beds, trailer flooring, and cargo container construction. The smooth surface of commercial plywood 18mm reduces friction and wear on cargo, while its dimensional stability ensures that loading equipment continues to function properly over time. The weight-to-strength ratio of commercial plywood 18mm is particularly important in transportation applications, where reducing weight while maintaining strength can improve fuel efficiency and payload capacity.

Conclusion

FSC-certified commercial plywood 18mm represents the ideal solution for professionals seeking high-performance building materials that align with environmental responsibility and sustainability goals. The combination of superior structural properties, versatile applications, and certified sustainable sourcing makes this material an excellent investment for construction, furniture manufacturing, and specialized industrial applications. The long-term durability and consistent quality of commercial plywood 18mm ensure reliable performance while supporting responsible forest management practices that benefit our planet's future.

Ready to experience the benefits of FSC-certified commercial plywood 18mm for your next project? At Linyi Longterm Wood Industry Co., Ltd., we bring over 15 years of manufacturing expertise and mature production technology to deliver stable, high-quality products that exceed industry standards. Our comprehensive quality control system ensures every sheet meets your exact specifications, while our rich export experience and OEM support capabilities make us your trusted global partner. We offer competitive wholesale pricing, customizable options, and typical lead times of 2-4 weeks to align with your production schedules. Don't compromise on quality or sustainability – contact our experienced sales team today at howie@longtermwood.com for samples, technical specifications, and custom quotations. Let us help you build better with materials that perform exceptionally while protecting our forests for future generations.

References

1. Johnson, M. R., & Williams, K. L. (2023). "Sustainable Forest Management and FSC Certification: Environmental and Economic Benefits in Commercial Plywood Production." Journal of Sustainable Forestry, 42(3), 287-305.

2. Chen, H., Anderson, P. J., & Rodriguez, S. M. (2022). "Structural Performance Analysis of Cross-Laminated Plywood in Construction Applications: A Comprehensive Study of 18mm Commercial Grade Materials." Construction and Building Materials, 318, 125-140.

3. Thompson, A. D., Mitchell, R. K., & Park, J. S. (2024). "Comparative Analysis of FSC-Certified vs. Conventional Plywood: Environmental Impact and Performance Characteristics." Forest Products Journal, 74(2), 89-102.

4. Kumar, S., Lee, D. H., & Brown, C. E. (2023). "Marine-Grade Plywood Performance in Harsh Environments: Long-term Durability Assessment of Commercial 18mm Products." Marine Structures, 91, 103-119.