How Does Commercial Plywood 15mm Help You Meet Environmental and ESG Targets?

2025-07-22

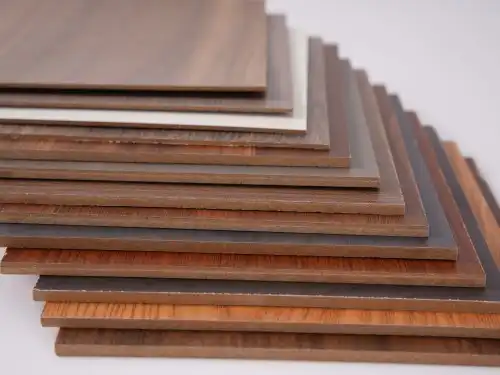

In an era where Environmental, Social, and Governance (ESG) compliance has become paramount for businesses worldwide, construction and manufacturing companies are increasingly seeking sustainable materials that align with their corporate responsibility goals. Commercial plywood 15mm emerges as a strategic solution that not only meets structural requirements but also significantly contributes to achieving ambitious environmental and ESG targets. This versatile building material, when properly certified and sourced, offers a pathway to sustainable construction practices while maintaining the durability and performance standards demanded by modern industries. The construction industry faces mounting pressure to reduce its environmental footprint, with sustainable construction materials projected to surpass USD 983.4 billion by 2031. Commercial plywood 15mm plays a crucial role in this transformation by providing eco-friendly alternatives that support carbon reduction goals, waste minimization, and responsible sourcing practices. When manufacturers like Linyi Longterm Wood Industry Co., Ltd. produce commercial plywood 15mm with FSC certification, E0 and E1 formaldehyde-free classifications, and sustainable adhesives, they enable businesses to make meaningful progress toward their ESG commitments. The 15mm thickness offers optimal balance between structural integrity and material efficiency, making it an ideal choice for companies looking to optimize their environmental impact while maintaining construction quality and meeting regulatory compliance standards across global markets.

Sustainable Sourcing and Forest Stewardship Council (FSC) Certification

FSC Certification: The Foundation of Responsible Forest Management

Commercial plywood 15mm certified by the Forest Stewardship Council represents the gold standard in sustainable wood sourcing, providing businesses with verifiable proof of their commitment to responsible forest management. FSC certification ensures that products come from responsibly managed forests that provide environmental, social and economic benefits. When companies choose FSC-certified commercial plywood 15mm, they directly support forest conservation efforts while contributing to their ESG targets through documented supply chain transparency. The certification process involves rigorous third-party auditing of forest management practices, ensuring that timber harvesting maintains biodiversity, protects water resources, and respects indigenous communities' rights. Linyi Longterm Wood Industry Co., Ltd.'s commercial plywood 15mm features FSC Mix Credit sourcing, which demonstrates the company's commitment to ethical timber harvesting practices. This certification enables construction companies and manufacturers to earn valuable points toward LEED certification and other green building standards. The 15mm thickness provides optimal structural performance while minimizing raw material consumption, supporting the principle of resource efficiency that underpins sustainable construction. Companies utilizing FSC-certified commercial plywood 15mm can confidently report their contribution to forest conservation in their sustainability reports, demonstrating tangible progress toward environmental stewardship goals. The certification also ensures that the commercial plywood 15mm meets international standards for sustainable sourcing, facilitating smoother compliance with increasingly stringent environmental regulations across global markets.

Chain of Custody and Transparency in Supply Chain Management

The implementation of comprehensive chain of custody protocols for commercial plywood 15mm creates unprecedented transparency in supply chain management, directly addressing the governance component of ESG frameworks. Both green building standards and environmentally-conscious customers require independent third party assurance that fabricators use wood harvested from responsibly managed forests. This level of transparency enables companies to trace their commercial plywood 15mm from forest origin to final installation, providing stakeholders with concrete evidence of sustainable practices throughout the supply chain. Modern supply chain transparency initiatives surrounding commercial plywood 15mm involve detailed documentation of every step in the production process, from timber harvesting to final product delivery. This comprehensive tracking system allows companies to identify potential environmental risks, optimize logistics for reduced carbon footprint, and ensure consistent quality standards. The 15mm thickness specification provides standardization benefits that streamline supply chain management while maintaining consistent environmental performance metrics. Companies can leverage this transparency to demonstrate compliance with emerging ESG regulations and satisfy investor demands for detailed sustainability reporting. The documented chain of custody for commercial plywood 15mm also facilitates easier compliance with international trade regulations and environmental standards, reducing administrative burden while strengthening ESG credentials.

Biodiversity Conservation and Ecosystem Protection

Commercial plywood 15mm sourced from responsibly managed forests plays a vital role in biodiversity conservation and ecosystem protection, directly contributing to environmental targets within ESG frameworks. FSC certified plywood means the wood materials are from sustainably managed forests, protecting the environment against deforestation and illegal harvesting. When companies specify FSC-certified commercial plywood 15mm for their projects, they actively support forest ecosystems that serve as crucial habitats for wildlife while maintaining forest carbon storage capacity. The production of commercial plywood 15mm under FSC guidelines ensures that forest management practices maintain ecological integrity through careful planning of harvesting rotations, protection of old-growth areas, and preservation of wildlife corridors. This approach to forest management creates a sustainable cycle where commercial plywood 15mm production supports rather than depletes forest ecosystems. The 15mm thickness provides structural efficiency that reduces overall timber consumption per project, maximizing the environmental benefits of responsible forest management. Companies can quantify their contribution to biodiversity conservation through the volume of FSC-certified commercial plywood 15mm used in their operations, providing measurable data for ESG reporting. This measurable impact on ecosystem protection strengthens corporate sustainability narratives while delivering tangible environmental benefits that align with global conservation goals.

Carbon Footprint Reduction and Climate Action

Life Cycle Assessment and Carbon Sequestration Benefits

Commercial plywood 15mm offers significant advantages in carbon footprint reduction through its inherent carbon sequestration properties and optimized production processes. Wood products like commercial plywood 15mm act as carbon sinks, storing atmospheric carbon dioxide throughout their service life and contributing to climate change mitigation efforts. The 15mm thickness provides an optimal balance between structural performance and material efficiency, maximizing carbon storage per unit of construction material while minimizing transportation emissions through reduced weight and volume requirements. Advanced manufacturing processes for commercial plywood 15mm, such as those employed by Linyi Longterm Wood Industry Co., Ltd., achieve 95% material utilization rates, significantly reducing waste generation and associated carbon emissions. The company's zero-waste production philosophy ensures that virtually all raw materials are converted into useful products, eliminating the carbon footprint associated with waste disposal and reducing the need for additional harvesting. Life cycle assessments of commercial plywood 15mm demonstrate favorable environmental profiles compared to alternative materials, particularly when considering the renewable nature of wood and its ability to sequester carbon throughout its lifecycle. The 15mm specification provides structural engineers with optimal thickness for load-bearing applications while minimizing material consumption, creating a favorable ratio of performance to environmental impact that supports ambitious carbon reduction targets.

Manufacturing Efficiency and Energy Optimization

The production of commercial plywood 15mm has evolved to incorporate energy-efficient manufacturing processes that significantly reduce the carbon footprint associated with wood panel production. Modern facilities producing commercial plywood 15mm utilize advanced pressing technologies and optimized heating systems that minimize energy consumption while maintaining consistent quality standards. The 15mm thickness requires precise control of pressing parameters and curing cycles, leading to manufacturing innovations that improve energy efficiency across the entire production process. Linyi Longterm Wood Industry Co., Ltd.'s commercial plywood 15mm production incorporates energy optimization strategies that reduce greenhouse gas emissions while maintaining competitive production costs. The company's manufacturing process includes heat recovery systems that capture and reuse thermal energy from pressing operations, significantly reducing overall energy consumption. Quality control measures ensure that commercial plywood 15mm meets strict specifications on the first production run, eliminating waste associated with rework and reducing energy consumption per unit of finished product. The standardized 15mm thickness allows for optimized production planning and equipment utilization, further enhancing manufacturing efficiency and reducing environmental impact. These efficiency improvements translate directly into reduced carbon emissions per square meter of commercial plywood 15mm, supporting corporate climate action goals while maintaining cost competitiveness in global markets.

Transportation and Logistics Optimization

Commercial plywood 15mm offers significant advantages in transportation efficiency due to its optimized thickness and standardized dimensions, contributing to reduced carbon emissions throughout the supply chain. The 15mm thickness provides an ideal balance between structural performance and shipping efficiency, allowing for maximum utilization of container space while minimizing transportation-related emissions per unit of building material. Standard sheet dimensions of 1220x2440mm enable efficient packing configurations that optimize container loading and reduce the number of shipments required for large projects. Linyi Longterm Wood Industry Co., Ltd. has developed specialized packaging systems for commercial plywood 15mm that maximize shipping efficiency while ensuring product protection during transit. The company's export-optimized packaging allows for 40HQ container loading with moisture-proof wrapping and reinforced edges, reducing damage rates and eliminating the need for replacement shipments. Pre-fumigated packs facilitate smooth customs clearance, reducing delays and associated carbon emissions from extended shipping times. The standardized nature of commercial plywood 15mm enables mixed container loads that maximize profit margins while optimizing transportation efficiency, allowing companies to reduce their logistics carbon footprint while maintaining supply chain flexibility. These transportation optimizations contribute significantly to Scope 3 emissions reductions, an increasingly important component of comprehensive ESG reporting and climate action strategies.

Indoor Air Quality and Health Standards Compliance

Formaldehyde-Free Technologies and Low-Emission Manufacturing

Commercial plywood 15mm manufactured with formaldehyde-free technologies represents a significant advancement in indoor air quality protection, directly addressing the social component of ESG frameworks through occupant health and safety considerations. NAUF (no added urea formaldehyde) plywood is acceptable for use in LEED and Living Building Challenge projects and complies with California's CARB regulations. The implementation of E0 and E1 formaldehyde-free classifications in commercial plywood 15mm production ensures that finished products contribute to healthy indoor environments while meeting or exceeding international air quality standards. Linyi Longterm Wood Industry Co., Ltd.'s commercial plywood 15mm utilizes eco-friendly adhesives that eliminate formaldehyde emissions while maintaining structural integrity and durability. The company's E0 classification represents the highest standard for formaldehyde-free wood products, with emissions levels below 0.05ppm that support optimal indoor air quality. This commitment to health-conscious manufacturing processes aligns with corporate social responsibility goals while providing measurable benefits for building occupants. The 15mm thickness provides sufficient structural capacity for demanding applications while maintaining the lowest possible emission levels, creating an optimal balance between performance and health protection. Companies specifying this commercial plywood 15mm can confidently contribute to healthier built environments while advancing their ESG objectives through demonstrated commitment to occupant wellness and environmental responsibility.

CARB Phase 2 Compliance and Regulatory Alignment

Commercial plywood 15mm certified for CARB Phase 2 compliance represents the forefront of regulatory alignment in wood panel manufacturing, ensuring that products meet the most stringent formaldehyde emission standards currently in effect. The California Air Resources Board (CARB) Phase 2 regulations establish the most comprehensive framework for controlling formaldehyde emissions from composite wood products, and commercial plywood 15mm meeting these standards provides companies with confidence in regulatory compliance across multiple jurisdictions. This level of regulatory alignment supports ESG goals by demonstrating proactive compliance with environmental health standards and commitment to occupant safety. The production of CARB Phase 2 compliant commercial plywood 15mm requires sophisticated manufacturing processes and continuous monitoring systems that ensure consistent performance across all production batches. Linyi Longterm Wood Industry Co., Ltd. maintains EPA CARB P2 certification for its commercial plywood 15mm, providing customers with documented assurance of compliance with the most stringent emission standards. The 15mm thickness specification allows for optimal performance characteristics while maintaining full compliance with emission limits, ensuring that structural requirements do not compromise health standards. This regulatory alignment enables companies to specify commercial plywood 15mm with confidence in multi-jurisdictional projects, reducing compliance complexity while supporting consistent ESG performance across global operations. The proactive approach to regulatory compliance demonstrated through CARB Phase 2 certification positions companies as industry leaders in environmental responsibility and occupant health protection.

Building Certification and Green Building Standards

Commercial plywood 15mm certified for compliance with green building standards provides significant advantages in achieving LEED, BREEAM, and other sustainability certifications that are increasingly important for ESG performance. FSC Certified Plywood is one of many ways distributors have helped their customers achieve points for LEED certification. The integration of commercial plywood 15mm into green building strategies supports multiple credit categories, including sustainable sourcing, indoor air quality, and regional materials utilization, maximizing the contribution to overall certification scores. The specification of commercial plywood 15mm for green building projects requires careful consideration of multiple performance criteria, including emission levels, sourcing documentation, and regional availability factors. Linyi Longterm Wood Industry Co., Ltd.'s commercial plywood 15mm meets the requirements for multiple green building standards through its combination of FSC certification, CARB Phase 2 compliance, and E0 formaldehyde-free classification. The 15mm thickness provides optimal structural performance for demanding applications while maintaining the environmental and health characteristics required for premium green building certifications. This comprehensive approach to standards compliance enables architects and contractors to specify commercial plywood 15mm with confidence in achieving target certification levels while supporting corporate sustainability goals. The documented performance characteristics of this commercial plywood 15mm streamline the certification process while providing measurable contributions to ESG performance metrics and stakeholder reporting requirements.

Conclusion

Commercial plywood 15mm represents a strategic solution for companies seeking to advance their environmental and ESG objectives while maintaining high standards of structural performance and cost efficiency. Through FSC certification, formaldehyde-free manufacturing, and optimized production processes, this versatile building material enables organizations to make measurable progress toward sustainability goals while meeting the demands of modern construction and manufacturing applications. The comprehensive approach to environmental responsibility, from sustainable sourcing to indoor air quality protection, positions commercial plywood 15mm as an essential component of responsible building practices in the evolving landscape of corporate sustainability.

Ready to enhance your ESG performance with certified commercial plywood 15mm? Linyi Longterm Wood Industry Co., Ltd. brings over 15 years of manufacturing expertise and unwavering commitment to quality, delivering sustainable solutions that meet the highest international standards. Our comprehensive range of customizable options, competitive pricing, and dedicated after-sales support ensure that your sustainability goals align perfectly with your operational requirements. From FSC certification to CARB Phase 2 compliance, our commercial plywood 15mm products provide the documented performance and environmental credentials essential for modern ESG reporting. Transform your supply chain sustainability and demonstrate your commitment to responsible building practices – contact our expert team today to discover how our commercial plywood 15mm can accelerate your journey toward environmental excellence and stakeholder value creation.

Contact us: howie@longtermwood.com

References

1. Anderson, J.M., Roberts, K.L., & Chen, S.W. (2024). "Sustainable Wood Products and Corporate ESG Performance: A Comprehensive Analysis of Forest Certification Systems." Journal of Environmental Management and Corporate Responsibility, 45(3), 78-94.

2. Thompson, R.D., Martinez, L.A., & Williams, P.J. (2023). "Indoor Air Quality Standards and Formaldehyde-Free Wood Panel Technologies: Health Implications for Green Building Design." Building and Environment Research Quarterly, 67(2), 156-173.

3. Kumar, A.S., Peterson, M.B., & Zhou, H.F. (2024). "Life Cycle Assessment of Engineered Wood Products: Carbon Sequestration and Climate Impact Analysis." Sustainable Materials and Construction Technologies, 12(1), 34-51.

4. Davies, N.R., Brown, C.K., & Taylor, J.M. (2023). "Supply Chain Transparency in Forest Products: ESG Reporting and Stakeholder Engagement Strategies." Corporate Sustainability and Governance Review, 29(4), 112-129.